International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net

p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net

p-ISSN:2395-0072

Satwika Samal & Sanat Kumar Sahoo*

Textile Engineering Department, Odisha University of Technology and Research, Bhubaneswar, Odisha, India -751029

Abstract:

Intherecentyearsoftechnicaladvancesinthefieldoftextiles,naturalfibre-reinforcedcompositeshavebecomeremarkably popularfortheirwide rangeof applicationsandsubstratebehavioural enhancement.Theseexhibit benefitsof natural fibres as per the improvements in the core material's attributes in terms of tribological qualities, impact strength, flexural rigidity, specificstrength,andsoon.Theseincreasesdependonafewvariables,suchasthefibre'skind,length,andvolumepercent. The entire characterization of such materials consists of a range of advanced techniques starting from tensile testing for strength monitoring, FTIR for functional group presence, X-ray diffraction, TGA, DSC, SEM and FRF-Frequency Response Function. Each of these fibres comes from various common plants, such as Prosopis juliflora, and long staple fibres like jute, coir, kenaf, hemp, bamboo mesh, etc. Due to their superior behaviour in the resulting composite materials, high biodegradability,andaffordability,naturalfibreshavesupplantedallregeneratedsources.

Keywords:Materials,mechanisms,textilefibres,matrix

1. Introduction

Acompositematerialischaracterizedasablendofamatrixandreinforcingmaterial.Whenconventionalmaterialslikemetals, ceramics,andpolymersfailedtomeettheprecisespecificationsneededforacertainapplication,thesematerialsbecamemore and more common. Textile-reinforced composites (TRC) were first developed in the 1980s [1]. The Sächsisches Textiforschungs-institute(STFI),aGermaninstitutionspecializingintextiletechnology,iscreditedwithdevelopingtheideaof textile-reinforced composites. The first patent for textile-reinforced composite was issued in 1982 [1] for a concrete design pertainingtosafetyobjectsfortransportation.Sincemanyyearsago,compositematerialshavebeenusedwithgreatsuccess in a many of the industries, from consumer products, mobiltech based, infrastructure, and aircraft. The incorporation of the technology of composite materials facilitated upon the development of structural components with high damage tolerance, toughness,handlingofthereinforcedmaterial,andtheabilitytobearmultidirectionalmechanicalandthermalstress.

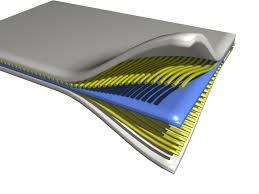

The primary load-bearing element in the composite material, reinforcement, which comes in the shapes of fibres, particles, andflakes,iswhatgivesititsstrengthandstiffness.Incontrast,thereinforcementisheldinplaceandshieldedfromphysical andchemical harm bythe matrix. Theuniform distributionofanappliedloadamongthereinforcingcomponentsislikewise theresultofthematrices.Whentextile-reinforcedcompositeswerefirstdeveloped,theyweremadeexclusivelyofartificialor high-performance fibres, but this resulted in expensive raw materials and processing costs, which hampered their development significantly. Therefore, natural fibres were added. The primary justification for including natural fibres was their abundance in the natural world, which improved their thresholds of the flexural properties in terms of splitting, durability, ductility, and break resistance are enhanced when compared to matrices that are not reinforced.Furthermore, natural fibers have outperformed synthetic fibers in numerous applications as reinforcements, whether in cement matrix or polymer matrix formby taking advantage of their lower density, comfortable wear, and affordability. Additionally, natural fibres are simple to discard by incinerating or composting due to their regenerative and biodegradable qualities. Technical textile composite materials are essentially made of polymer matrix embedded in better tensilestrengthfibreslikeflax,kenaf,sisal,palm,juteandcoir.Polymersareoftenclassifiedasthermosetsorthermoplastics. This structure gives thermoset polymers excellent strength, modulus, and tremendous flexibility for customising desired qualities. Polyethylene, polypropylene, and poly vinyl chloride are the thermoplastics utilised in composite matrices. This reviewprimarilyfocusesuponthemechanicalpropertiesoftextilereinforcedcompositematerials,whicharedevelopedbased onvariousnaturalfiber-reinforcedmatricesandproducedthroughwovenformsfabricatedwithepoxyresin.Italsodiscusses themechanismsandmaterialbehaviourofthesematerials,aswellastheirapplicationsinthefieldoftechnicaltextiles.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN:2395-0072

Compositesarethematerialsengineeredbyintroducingtwoormorethantwo materialsradicallydiversepropertiesthatcan be either physical or chemical based such that the resultant is a material with qualities entirely distinct from those of the individual components. Composites are distinguished from mixes and solid solutions by the various individual components thatremaininsidethecompletedstructure[2].Generallyspeaking,thefollowingreasonscallforcomposites: Thesematerials exhibitextremelylowthermalexpansion,exceptionallyhighdirectionalthermalconductivity,versatilestrengthandstiffness customization, strong resistance to fatigue damage, chemical and corrosion resistance, ease of creating complex geometries, andthecapabilitytointroducesubstantialmaterialdamping,highlightingitssuperiority.

Constituent materials are the discrete components that make up a composite. Constituent materials fall into two categories: reinforcement and matrix. The matrix provides the composite component its net structure, transmits loads between fibres, bindsthefibrereinforcementwiththeaidofresin,andcontrolsthesurfacequalityofthecomponent.Carbon,metal,ceramic, orpolymersmayall befoundina compositematrix[3]. Compositematerialsmaybedividedintotwogroups:thermoplastic andthermo-setcomposites, depending on the kind of resinutilised.The reinforcing material might be made of thermoset or thermoplasticresins.Thermosetcompositesfrequentlyincorporateresinslikepolyesters,vinylesters,epoxies,bismaleimides, cyanate esters, polyimides, and others. [4]. While thermoplastics harden when cooled while maintaining their flexibility, thermosets have a cure reaction that cannot be undone. Thus, by heating them over their processing temperature, the thermoplasticsmayberemeltedandreformed.

Reinforcements might be thick woven fabric or laminates that are combined to achieve a certain thickness throughout the productionprocess.Reinforcementcompositesmaythusbedividedintotwogroups:laminatedcompositesand3-Dwoven composites,dependingonthelaminatesthatareutilised.Laminarcompositesaremadeoflayersofreinforcementarranged in a certain way to give the final composite component the necessary qualities. We refer to these layers as laminates or plies. Reinforcement material for laminates may be non-woven, braided, fiber-reinforced, matte, two-dimensional woven, orunidirectionalfibres[4].

Incomposite materials,the 'direction-specific'feature ismostlydeterminedby the orientationofthefibres. Withthe bulk of thefibrespositionedalongthedirectionofthemainloadroutes,the"anisotropic"propertyofcompositesmaybeemployedto excellent advantage in designs. By doing this, the quantity of parasitic material introduced into orientations with little to no loadisreduced[5].Becausetheirmechanicalqualitiesarenotasgoodasthoseofmostmetals,resinssuchaspolyestersand epoxieshaverestrictedapplications[6].

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN:2395-0072

3. Resources as raw materials

3.1.Primaryclassification

Textilenaturalfiberreinforcedcompositematerialsutilizethreedifferenttypesofrawmaterials,whichincludefibers,yarns, orfabricsatvariousstagesofproduction [6].Thesekindswhichserveasthebasisforthefinalproduct,arealsoinchargeof thefinal material'scharacteristics.They are essentiallychosen based on thespecificationsor the raw material'sperformance atthatparticularstage.

3.1.1.Fibreform:

Natural,synthetic,orinorganicfibresarethespecifiedbasicrawmaterialsutilisedinthefibreform.Examplesofnaturalfibres include flax, jute, hemp, coir, sisal, and ramie. Inorganic materials including carbon, glass, ceramics, and basalt, as well as syntheticmaterialslikearamid,polyesters,andpolypropylene,maybeincludedintocomposites.

3.1.1.1.NaturalFibres

These days, matrices made of natural fibre are becoming more popular. Materials reinforced with textile fibres are mostly made from long staple natural fibres. Natural fibers offer numerous advantages over synthetic fibers, including their lower weight, cost-effectiveness, reduced damage to processing equipment, favorable mechanical properties such as specific and flexuralmodulus,enhancedsurfacefinishofcompositemoldedparts,accesstorenewableresourcesduetotheirabundancein nature, flexibility during processing, and biodegradability. These factors collectively contribute to the preference for fiberreinforced polymer matrix materials[8]. A variety of fibrous materials such as wood, sisal, hemp, coconut, cotton, kenaf, flax, jute, abaca, bananas, wheat straw, and otherscanserveasthenaturalfibercomponent,pairedwithapolymericsubstanceasthematrix[9].

3.1.1.SyntheticFibres

Bothbiologicalandinorganicman-madefibresmaybeusedinthefibreformofthecompositematrix.Thesefindwidespread use in a variety of technological applications in addition to textiles and clothing of all kinds. Despite all of their admirable traits,theyarenotaspopularastheyoncewere.Theirlongermanufacturingcycleandhighcostarethereasonsbehindthis. Theirnon-biodegradabilityisoneofthefactorscontributingtotheirobscurity[10].

3.1.2.Yarnbased

Basically,hybridyarnsareusedinthisform.Engineeredyarnswithascalablestructureareknownashybridyarns[11]. This form'sextensiveuseinthetextilecompositesindustryhasnotbeensuccessfulforitsneedsformuchextensiveprocessing

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN:2395-0072

Reinforced composite materials can be in fabric forms that include knitting, braiding, non-woven, or weaving Due to their inherent benefits, non-woven fabric matrices are becoming more and more popular among all these conceivable forms in advanced structural applications [12]. In particular, the matrices of nonwoven fabric made by needle punching method are employed.Itsoverallstructure,whichpermitsenoughresincirculationandaidsinuniformlydispersingthepressureapplied toitthroughoutthemanufacturingsteps,accountsforitsfavour.Theyarealsomoreappropriatethantheotherkindsdueto theirexceptionalimpactstrength[13].

Themainpurposeoftheresinsistotransmitstressfromthereinforcementtothematrix.Inessence,resinfunctionsasaglue tokeepfibrestogetherandshieldthemfromabrasionfromtheenvironmentandmechanicalforces.Resiniscomposedoftwo ingredients:hardenerandresin.Whentheyarecombined,achemicalreactionistriggeredinthecombination,whichsolidifies it from a liquid condition [14]. The hardener or accelerator is a specialized combination used for curing and can act as a reactantorcatalystduringmixing.Theresincomponentistheactive,potentiallytoxicpart. Thestrengthandcureperiods of thefinalresinmixturearedependentonthehardenercontent.

4.1.MatrixClassification

4.1.1.Thermosetting

Currently, thermoset (TS) resin is the most commonly processed matrix type, increasingly favored by composite manufacturers. Unsaturated polyester,vinyl ester, epoxy,phenolics,cyanate esters, benzoxazines,andpolyimidesare typical examples of thermoset resins. Because of their affordability, simplicity of handling, and well-balanced mechanical, electrical, andchemical characteristics,epoxyand polyester resins(unsaturated)areamongst themost widelyused forthe applications incommercialormassbasis[15].

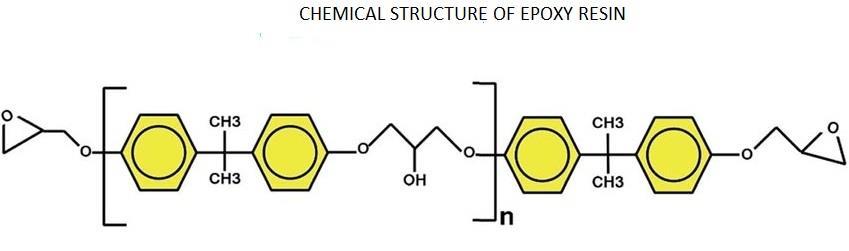

Epoxies are available in liquid, solid, and semisolid states. They usually heal by reacting with anhydrides or amines. Epoxies are cured using hardener rather than a catalyst like polyester resin. Due to the presence of oxirane groups, epoxy resin functionalities exhibit high reactivity and readily participate in ring-opening reactions with nucleophiles such as hydroxyl groups.Epoxyresinscanexistaslow-viscosityliquidsorsolids,dependingontheirchemicalcomposition.Achievingadequate wettingoffibersbylow-viscosityresinispossiblewithoutrequiringhighpressureortemperature[15].Buthighpressureand temperatureareoftenusedtoimpregnatefibreswithhigh-viscosityresins.

4.1.2.Thermoplastic

However, unlike crosslinking thermosets, thermoplastic resins are unable to undo the curing process. When cooled, thermoplastics solidify yet maintain their pliability. Polycarbonate (PC), polyesters, polyethylene (PE), polyethylene terephthalate (PET), polybutylene terephthalate (PBT), acrylonitrile butadiene styrene (ABS), polyamide (PA or nylon), and polypropylene(PP)areexamplesofplasticcomponents.Hightoughnessandmoistureresistanceareproducedbytheseresins [16].

4.2.Propertiesensemble

4.2.1.Chemistryandsynthesisofepoxy

Amoleculeisclassifiedasepoxyifitcontainsoneormoreepoxidegroups,alsoknownasoxiraneorethoxylinegroups,which are considered representative units of epoxy polymers. Currently, the widely used epoxy resins are oligomers derived from diglycidyletherofbisphenolA(DGEBA).Theseoligomersundergocuringwithahardenertoformtheepoxypolymer.Epoxies are categorized into two main groups: glycidyl (ethers) epoxies and non-glycidyl (aliphatic) epoxies [15]. Compared to polyesterorvinylesterresins,epoxyresinsoftenneedalargerquantityofcuringagentintheresintohardenerratio(1:1or 2:1)[15].Certainmanufacturingprocesses,suchascompressionmouldingandhandlayup,maybeusedtostrengthennatural fibresinepoxycomposites[17].

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN:2395-0072

Fig3:Structureofepoxyresin[18].

These components contribute to increasing the specific moduli and flexural strength of composite materials, along with enhancing their damping coefficient, which experiences a 10–13% increase. [18]. It offers outstanding performance at elevatedtemperatures,withhot/wetservicetemperaturesreachingupto121°C.[16].

4.3.ImprovementofEpoxyResin

Epoxy thermosets have structural disadvantages that restrict their potential usage in many high-performance applications [19]. Most epoxy resins are modified with various additives and fillers, including reactive oligomers, low molecular weight polymers,plasticizers,nanoparticles,nanofillers,andcarbonnanotubes,toaddresstheseweaknesses[20].

4.4.CertainCommercialUseCasesofEpoxy

Because of its inextensible nature, epoxy resin is widely employed as a dielectric substance and as an essential insulating medium un heavy machinery [21]. Epoxy resins find extensive applications in various areas, including general adhesives, binders in cements and mortars, production of rigid foams, non-skid coatings, solidifying sand surfaces in oil drilling, industrialpaintsandcoatings,pottingandencapsulatingmaterials,andfiber-reinforcedplastics[22].

5. Composite Preparation Process

5.1.TraditionalMethod

Prepregsaremadeofuncured resinandfibresthathavebeenpre-impregnatedwiththermoplasticorthermosetresinsthat need just a certain temperature to activate. The quickly impregnated layers are cut and deposited into the open mould to createtheseprepregs,whichareready-to-usematerials[23].

Dow Automotive Systems introduced VORAFUSE, a prepreg process combining epoxy resin and carbon fiber, aiming to improvematerialhandlingandreducecycletimeinthecompressionmoldingofcompositestructures.Theyhavesuccessfully reduced weight via partnership with many automotive firms, leading to the efficient production of Carbon Fibre Reinforced Polymer(CFRP)compositeconstructions[23].

5.2.OutOftheBoxProcedure

5.2.1.MercerizationorAlkaliTreatment

One of the most popular chemical techniques for altering the plant fiber's cellulose molecular structure is alkali treatment, whichisusedtoenhancethermosetsandthermoplastics. Thismethod,usuallyperformedusingawater-basedNaOHsolution, separates fiber clusters and forms amorphous cellulose, sacrificing the tightly packed crystalline cellulose. The disruption of hydrogen bonds within the network structure is the key change occurring during this process As a consequence, the fiber's surface roughness increases and the hydrophilic OH groups decrease. Additionally, it depolymerizes cellulose, exposing the

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN:2395-0072

short-lengthcrystallites,andeliminatesapartofthehemicellulose,lignin,waxes,andoilscoatingthefibrecellwall'sexterior [24].

5.2.2:TechnicalAssistance

The thermal processing involved in the mechanical treatment was conducted as outlined below. Jute fiber textile mats were alsopreparedforthetensilestrengthtesttoassessthetensilepropertiesofisotropicandorthotropicfiber-reinforcedplastic composites.Afterthat,thesematswerebakedfor48hoursat50°C[24].

5.3.TheReadyMethod

Thefibresarefirstinsertedintothematrixsheetaccordingtothespecificationstocreatethecompositematrix.Priorto being sprayed with hardener in a 1:2/1:1/1:3 ratios, these fibres are aligned [25]. Once the sheets have been dried and cured to a predetermined thickness, they undergo compression molding using a pressure and load ranging from 10 to 30 N, at a speed between 1 to 3 m/s, between the reinforcement and matrix, around 15 to 25 percent of resin is added [26]. By heating the composite to between 300 and 600 degrees Celsius, the binding substance is destroyed after the structure is correctly assembled[25].

5.5.2.

The amount of physico-chemical stresses that the fibres are subjected to during traditional procedures is reduced by the microwaveradiation(MWR)technology.ThequalitiesofnaturalfibrestransformedusingtheMWRprocessareonparwithor superior to those of fibres modified using the traditional method. Using the MWR process, graft copolymerized the polyacrylamideontoguargumandchitosan,andreportedthatmaximalgraftingwasobservedinarelativelyshortamountof time[33].

5.5.3.

One tool to assess damage processes in composites is the acoustic emission (AE) technique. This method has been used extensively to polymer-reinforced composites, glass/epoxy, hemp/epoxy, and carbon composites. When composites are exposed to mechanical stress, they may sustain several forms of damage, including matrix cracking, delamination, and fibre de-bonding,whichcanultimatelyresultinmaterialfailure.DifferentdamagemechanismsprovidedifferentAEsignals.Tensile testingonplainresinandunidirectionalcompositesmaybeusedtocharacterisedamageincross-plylaminates[27].

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN:2395-0072

6. Material Properties

The overall qualities of the resulting material, such as its high strength and structure, are further enhanced when composite material is reinforced. The orientation of the fibres, their strength, their physical characteristics, their interfacial adhesion property, and many other factors determine the material's activity and performance [33]. The crucial factors in determining themechanicalpropertiesofreinforcedcompositematerialsincludetheorientation,moistureabsorption,impurities,physical characteristics,andvolumefractionofnaturalfibers[27].

6.1.PhysicalProperties

VarioustypesofnaturalfibersinfluencethephysicalpropertiesofmatricessuchasPLA,epoxy,PP,andpolyester.Composites reinforced with these natural fibers demonstrate enhanced mechanical capabilities compared to matrices made entirely of syntheticmaterials.Forexample,thespecificstrengthofPLAincreasesby75.8%whenjutefibersareincorporated[28],and thespecificstrengthofcompositematerialsrisesby16%withtheadditionofflaxfibers[29].Notably,compositescontaining jute,hemp,orcoirshowthemostsignificantimprovement,withatotalincreaseof121%comparedtopurepolyester[29].

Tensile strength

Modulus of elasticity

Compressive strength

Flexural strength

Flexural modulus

6.1.1.Adaptability

The rubber phase in the gum compound imparts a broader flexibility range to these materials, reducing their stiffness and storage modulus. Studies conducted on these composites suggest that, unlike the gum's 415 MPa loss modulus, the loss modulusofcompositesisexpectedtoincreasewiththeadditionoffibers,reaching756MPaatafiberloadingof50partsper hundredrubber(partsperhundredrubber)[30].

6.1.2.

Because of the increased loading of fibre content, there is a noticeable improvement in hardness, specific modulus, and tear strength.Thespecificstrengthdecreasesasthefibrecontenthitstheupperlimit[35].Particularly,thestaplelengthsof10and 12mmforpalm,ramie,flax,andcoirexhibita35%increaseinspecificstrength,whereasthespecificstrengthofjutefibreis comparabletothatofpolyester[36].

6.1.3:

When the fibre content rises to 30 weight percent, an increase in impact strength is shown. When natural fibres such coir, sisal,jute,andhibiscuscannebinusareaddedasreinforcement,theresultingcompositematerial'simpactresistancerisesby 3–18 times [37]. Despite this encouraging trend, the total impact strength falls as the fibre content rises. Impact strength of polypropylene reinforced with flax and jute fibres rose from 20 to 40 weight percent and reduced from 40 to 50 weight percent. Comparativelyspeaking,theimpactstrengthofotherfibrereinforcingislower[31].

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN:2395-0072

6.1.4.ExplosivePower

The composite that exhibits the greatest fibre density has a stronger bursting point. The composite's ultimate bursting strength increases as the number of laminations in the composite increases. Nonwoven form natural fibre reinforced composites have a maximum bursting strength of 3370N [38]. The loop size for the knitted fabric form matrix controls the composite'sburstingstrength[39].

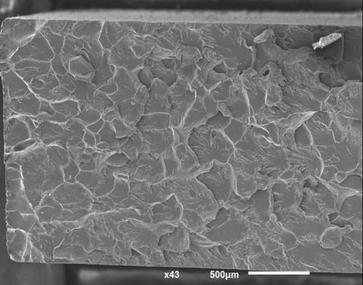

6.1.5.FractionalActions

The fracture behavior of composites is influenced by tensile-shear stresses due to the nonlinear mechanical behavior of naturalfibers[26].Thestrengthofthebondbetweenthefiberandthepolymermatrixiscrucialforachievingexcellentfiberreinforced composite properties. Chemical treatment of fibres is done to assist reduce their hydrophilic behaviour, which is necessarytogeneratecompositeswithacceptablemechanicalcharacteristics[40].

6.1.6TribologyPerformance

Variations in tribological loading circumstances cause around 90% of the failure, changing the materials' wear and friction characteristics [21]. Kenaf fibers reinforced with epoxy composite demonstrate an 85% enhancement in wear performance and normal orientation in composites [25]. When compared to plain PLA, produced composites exhibit an estimatedreductionincoefficientoffrictionof10–44%,withalargerreductionof70%[21].

6.1.7.CharacteristicsofWaterAbsorption

Composite materials with a high water intake often weigh more when wet, and their strength may potentially deteriorate. They also deflect, swell, and put strain on surrounding structures more frequently. These may result in buckling, wrapping, increased microbial inhabitation, and the breakdown of mechanical properties of composite materials via freezing and unfreezing[39].

6.1.8.PermeabilityToNoise

Because fibres have porous architectures, they are often utilised to reduce noise. A review is given of a variety of fibrous materials, such as metallic and inorganic fibres, natural and synthetic fibres, and fibrous membranes for noise reduction. Synthetic fibres with shaped cross-sections like triangular, hollow, and round help to enhance their sound absorption capabilities. Natural fibrous materials are renewable, biodegradable, and environmentally beneficial. Composite materials bondedwithnaturalfibresexhibitlowweightandpromisingpropertiesformitigatinglowfrequencynoise[41].

6.1.9 ViscoelasticBehaviour

Dynamicmechanical testsatdifferent temperaturesoffervaluableinformationregardingtheviscoelasticbehaviorof natural fiber composite materials, aiding in understanding their structure and interface properties. The mechanical damping coefficient,determinedbytheratioofthelossmodulustothestoragemodulus,reflectsthelevelofmolecularmobilityinthe polymericmaterial.Inturn,thelossmodulusislinkedtotheamountofenergydissipatedasheatbythesample[42].

6.1.10.MatrixDevelopment

Natural fiber reinforcement in polymers leads to high-strength composites with added or enhanced biodegradability, affordability, lightweight nature, and superior mechanical properties. Natural fibers start to degrade at temperatures up to 240°C,withcomponentslikehemicelluloses,cellulose,andlignindegradingatlowertemperatures[42].Thethermalstability offibersisinfluencedbystructuralcomponentslikeligninandhemicelluloses,andreducingtheirconcentrationoreliminating thementirelycanimprovefiberthermalstability,oftenachievedthroughchemicaltreatments[39].

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN:2395-0072

ChemicalProperties

6.2.1.ImpactofAlkaliMedication

Thealkalinetreatmenteliminatescertainchemicalconstituentsfromthefibersurface,includinguranic acid(foundin hemicellulose),aromaticgroups(extractives),andnonpolarmoleculesresultingfrompartiallignindepolymerization[44].

Hemicellulose(%)

Lignin(%)

Fig6:ChemicalattributesofNFRC[45].

The non-cellulosic fibers possess slightly higher crystallinity compared to cellulosic fibers. Consequently, alkaline treatment can substantially improve both the wettability and specific interaction of these fibers. Studies examining the impact of alkali (NaOH) treatments at varying concentrations, from 0.5% to 20%, on natural fiber reinforced composites have found that composites reinforced with 1% NaOH-treated fibers demonstrate enhanced properties compared to other treated and untreatedfibercomposites[46].Nevertheless,anincreaseinalkalineconcentrationcarriestheriskoffiberdamage[20].

6.2.2.ImpactonFlexualAttribute

When using jute or flax fibres, chemical treatments provide the greatest improvement in the reinforced epoxy composites'flexuralcharacteristics.Thelongitudinalpropertiesoftheunidirectionalcomposites(bothmodulusandstrength) improveby40%ormore,whilethetransversestrengthexperiencesamassive500%rise[47].

6.2.3.PropertiesofFlameRetardancy

Being organic materials, natural fibres and polymers are very susceptible to having any property altered by the presence of flame. Another factor that has been more important in order to meet safety requirements throughout the development of natural fibre composites is flame retardancy [34]. The fire resistance of polypropylene (PP) composite reinforced with jute fibers is enhanced by incorporating expandable graphite (EG) and ammonium polyphosphate (APP) into the composite polymerasflameretardant(FR)sources.Whenconsideringthedegradationofnaturalfibers,twoessentialfactorstoconsider aretheevolutionoffibersandmaterialsthatofferservices[48].

6.2.4.ImpactofMicrobialAndFungalDeterioration

Elevatedlevelsofrelativehumiditycanleadtothegrowthofbacteriaandfungionthesurfaceofnaturalfibercomposites. If exposedtothisenvironmentformorethan28days,themechanicalproperties(likeYoung'smodulus)andphysicalproperties (suchasmass)ofthematerialswillexperiencenotabledeterioration[45].

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN:2395-0072

7. Applications

Natural fibre reinforced composites are finding increasing use in a wide range of industries. The many natural fibre types, including oil-palm, bamboo, kenaf, hemp, and jute, have become more important in automotive applications for reinforced polymer composites. Applications for natural fire reinforced composites may be found in a variety of industries, including sports,leisureequipment,boats,offices,manufacturing,andtheelectricalandelectronicsectors[41].Thesearealsoemployed intheproductionofrope,baskets,clothesandgeotextile;theyarealsoutilisedinaircraft,automobile,maritimeandknickers vehicleconstruction,aswellasbulletproofing[49].

7.1.BusinessApplications

For use in social, commercial, and industrial contexts, coir fibre reinforced composites are produced for use in post boxes, mirrorcasings,storagetanks,projectorcovers,voltagestabilisercovers,packagingmaterials,helmets,ropeandfinishing nets, brushes, mattresses, automated interiors, panelling, and roofing [41]. Floor mats, roofing, carpets, cement reinforcement, slippers,andotheritemsaremadefromsisalfibres[49].

7.2.GeotechnicalField

In the realm of geotechnical engineering, natural fibre reinforced composites are being used as barriers, filtration, drainage, separation,anderosioncontrol[51].

7.3.FurnishingsatHome

Flaxfibresareusedasarawmaterialtomakepaper,ropes,andtoolsforwebbingcanvas.Theyarealsousedforornamental fabric, surgical thread, sewing thread, garments, and tableware, among other things. Hemp fibres are used in clothing production,interiordesign,andthecreationofUV-blockingsheets[49].Bamboofibresareusedinthetextilesectorasaraw materialandintheproductionofhygienegoods,décoritemsandotherthingsforthebathroom.

7.4MedicalArea

Compositesareusedinthemedicalfieldfororthopaedicapplications,namelyinbonefixationplates,hipreplacements,bone transplants, and bone cement. In clinical settings, composite materials are also used for anterior and posterior tooth restoration. Composite materials are used to repair damaged or missing teeth. In addition to being widely used in the productionofartificialhearts,pacemakers,vasculargrafts,intraocularlenses,biosensors,andartificialhearts,italsoservesto restorethefunctionalityofdamagedbodilytissuesandorgansandtoreplaceamalgamthathaswornout[41].

7.5.Sports

Sports equipment such as skis, surfboards, wind surfers, Composite materials are utilized in the production of items such as tennisrackets,badmintonrackets,slats,golfclubs,golfclubheads,climbingropes,andswords.Sportsequipmenthassuperior mechanicalqualities,suchasdegrees,modulus,andelasticmodulus,makingitmoreappropriateforusageinthisspecificarea [41].

7.6.TheChemicalSector

Composites are utilised in the chemical industry to make reactors, ducting, pipes, casings, drive shafts, stalks, fan blades, subterraneanstoragetanks,andcompositecontainers[49].

7.7.TheFieldOfElectricalAndElectronics

Composite materials are employed as conductors and insulators in the electrical industry. These may sometimes be used as switches, circuit boards, terminals, home plugs, connections, etc. Interconnections, fuel cell devices, electronic packaging, capacitors, thermistors, dielectrics, heat sinks, housing, and other components are among the electronics industry uses for compositematerials.49]

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN:2395-0072

7.8.

Composite materials have found numerous applications in construction, including tanks, industrial supports, longspan roof structures, lightweight doors, furniture, lightweight buildings, windows, and bridge components. Coir fiber is utilizedinmanufacturing roofing boards,falseceilingpartitions,and wall panels.Roofingsheetsand panel sets canbe made using PVC and jute, which are also employed in constructing construction templates, park benches, outdoor bed-boards, interiordecorativeboards,floorcoverings,roofcoverings,andvariousotheritems[41].

These days, yarns, wall decorations, carpet backing, rope, and packaging materials (bags) are made of reinforced composite materialsusingjuteandkenaffibres[49].Asaresult,everyareaisdrawingattentiontoitsfavourablecharacteristicsandease ofproductionviavariousmeans.yetstillfacecertainobstaclestoovercome[41].

Despiteall of the benefitsof using natural fibre reinforcedcomposite materials,thereare still certainobstaclesthatmust be solved in order to produce a particular product that retains all of its features. The specific forms of composite matrices, production techniques, temperature management, humidity levels, moisture uptake, damping coefficient, suitable raw materialcomposition,resinapplication,andotherfactorsarechallengesthatneedtobeaddressed[52].

It is clear from the whole research that natural fibres offer several benefits, including the ability to decompose naturally, be environmentallyfriendly,benontoxic,renewable,andnon-abrasive.Theyhavegreatthermalinsulatingqualities.Additionally, they are more resilient to fatigue, flexible, long-lasting, glossy, compressive strong, low in specific gravity, high in specific strength,highinparticularmodulus,andsoon[52].

Because of their strength, low heat conductivity, light weight, dimensional stability, resistance to corrosion, resistance to impact,andnonmagneticbehaviour,naturalfibrereinforcedcompositematerialsarefavoured.Notonlydonaturalfibresnot causeskindiscomfort,buttheyalsouselessenergy.itsaccessibilityisoneoftheprimaryfactorsinitsacceptability[52].

Inspiteofthesebenefits,compositematerialsalsohaveanumberofdrawbacks,suchashighvariability,poorfire,moisture, and moisture resistance, as well as a lack of fibre matrix adherence when utilised to create composite materials for certain uses. In terms of performance, natural fibres have certain limitations; when a polymer is introduced for the purpose of creatingandprocessingnewcomposites,theirbehaviouralters[52].Whenthematrixbearsthemajorityoftheload,itisalso moredifficultto repairsusceptibilityto impactdamage. Additionally,thereareseveral drawbacksto epoxyresin,suchasits high cost and caustic handling and mixing. The hardener is difficult to evaporate entirely [52]. This lessens strength and sometimes causes the composite to degrade more quickly due to heat, but only when the material is exposed to high temperaturesduringusage[34].

Naturalfibreswillbecomemorepopularinthefuturebecauseoftheirenvironmentallyfavourablequalities,sincethecurrent society is more concerned with sustainability and eco-friendly alternatives. Furthermore, some pertinent research indicates thatsomefibres,suchasroselle(hibiscussabdariffa),sugarcane(saccharumcilliare),pine,bagasse,henequen,andalfa,maybe abletofunctionasreinforcedoptionsinthenearfuture [52].Thecommercial qualitiesandincreasedregulation,namelythe establishment of manufacturing and post-treatment requirements, will determine the extent to which natural fibres may be used, particularly as composite reinforcement. As our understanding of natural fibres advances, developers will be able to standardisethetypesoffibresthatareavailableonthemarketandwillalsobeabletohavemoreconfidenceinthemechanical and chemical characteristics of composite materials. In order to enable a significant improvement in the foundational

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

knowledge of natural fibres, the scientific community will also play a critical role in the release of precise and well characterisedresearch[53].

After reading through a lot of research papers and publications on the subject, we have come to the conclusion that natural fibres provide superior replacements for the man-made fibres that are often utilised in the textile composites industry. The overall strength and improved ability to endure wear and tear of the natural fibre reinforced composite materials are advantages. Natural fibres are being used more often in composites creation because of their environmentally friendly qualities, which make them viable substitutes. Because of its superior mechanical qualities, natural fibre reinforced compositesaremorewidelyemployedinavarietyofsectors.Tosomedegree,theproductioncyclesinvolvedinthecreationof natural fibre reinforced composites are difficult. Natural fibre reinforced composites may be produced easily, which might resultintheirwidespreaduseinallindustriesworldwide.

References

1. History,textilereinforcedconcrete,Wikipedia.

2. Compositematerial,Wikipedia.

3. TheTextileInstitute,TextileTermsandDefinitions,TenthEdition,TextileInstitute,Manchester,1994.

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN:2395-0072 © 2024, IRJET | Impact Factor value: 8.226 | ISO 9001:2008 Certified Journal | Page2634

4. AmosAdeniyi,W.K.Kupolati, inDesign and Applications of Nanostructured Polymer Blends and Nanocomposite Systems,2016

5. Masters J E, et al: Mechanical Properties of Triaxially Braided Composites: Experimental and Analytical Results, JournalofCompositesTechnologyandResearch,1993.

6. RoePJandAnsellMP:Jute-reinforcedPolyesterComposites,JMaterSci1985.

7. Fibrereinforcedpolymercomposites;manufacturing,propertiesandapplications,2019.

8. AggarwalLK,ThapliyalPCandKaradeSR.Anticorrosivepropertiesoftheepoxy-cardanol resinbasedpaints,2007.

9. K.R.Rajisha,S.Thomas,inInterfaceEngineeringofNaturalFibreCompositesforMaximumPerformance,2011.

10. EuropeanAsianfortextilepoly-olefines,manmadefibre,2017.

11. Compositefabrics,KadolfandLangford,2002.

12. Mechanicalpropertiesofnonwovenreinforcedthermoplasticpolyurethanecomposites,2010.

13. Man-madefibressustainability,Europeanman-madefibreassociation,2017.

14. Resins,compositemanufacturingmagazine,2015.

15. MishraVandBiswasS.Physicalandmechanicalpropertiesofbi-directionaljutefibreepoxycomposites,2013.

16. Guadagno L, Vertuccio L, Sorrentino A, et al. Mechanical and barrier properties of epoxy resin filled with multiwalledcarbonnanotubes,2009.

17. Damagemechanismsinhempfibrewovenfabriccompositesstudiedbyacousticemission,2010.

18. MECHANICALPROPERTIESSTUDYOFPSEUDO-STEMBANANAFIBERREINFORCEDEPOXYCOMPOSITE,2006.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN:2395-0072

19. AReviewoftheImpactPerformanceofNaturalFiberThermoplasticComposites,2018.

20. Effect of Various Chemical Treatments of Prosopis juliflora Fibers as Composite Reinforcement: Physicochemical, Thermal,Mechanical,andMorphologicalProperties,2018.

21. P.K.Bajpai,I.Singh,andJ.Madaan,“TribologicalbehaviorofnaturalfiberreinforcedPLAcomposites,”2013.

22. ExperimentalandmicromechanicalinvestigationofT300/7901unidirectionalcompositestrength,2018.

23. Mechanical, morphological, and thermogravimetric analysis of alkali-treated Cordia-Dichotoma natural fiber compositesB.MadhusudhanReddy,Y.VenkataMohanaReddy,B.ChandraMohanReddy&R.MeenakshiReddy,2018.

24. StrengtheningofRCbeamsinflexureusingnaturaljutefibretextilereinforcedcompositesystemanditscomparative studywithCARBONFIBREREINFORCEDPOLYMER(CFRP)andGFRPstrengtheningsystems,2013.

25. Processforthepreparationoffibrereinforcedmetalmatrixcompositesandnovelpreforms,2011.

26. A.LakshumuNaidu,“Areviewonchemicalandphysicalpropertiesofnaturalfibrereinforcedcomposites”,2017.

27. A.R.Kakroodi,S.Cheng,M.Sain,andA.Asiri,“Mechanical,thermal,andmorphologicalpropertiesofnanocomposites basedonpolyvinylalcoholandcellulosenanofiberfrom Aloe vera rind,”2014.

28. E. Jayamani, S. Hamdan, M. R. Rahman, and M. K. B. Bakri, “Investigation of fiber surface treatment on mechanical, acousticalandthermalpropertiesofbetelnutfiberpolyestercomposites,”2014.

29. A.ShalwanandB.F.Yousif,“Instateofart:mechanicalandtribologicalbehaviourofpolymericcompositesbasedon naturalfibres,”2013.

30. S.Shinoj,R.Visvanathan,S.Panigrahi,andM.Kochubabu,“Oilpalmfiber(OPF)anditscomposites:areview,”2011.

31. B. Ren, T. Mizue, K. Goda, and J. Noda, “Effects of fluctuation of fibre orientation on tensile properties of flax sliverreinforcedgreencomposites,”2012.

32. Naturalfibretextilereinforcedbio-basedcomposites:Mechanicalproperties,creep,andenvironmentalimpacts,2018.

33. Thermalandmicrostructuralcharacterizationofepoxyinfiltratedhydroxyapatitecomposites,2009.

34. Naturalfiberreinforcedpolymercomposites:history,types,advantagesandapplicationsKamrunN.Keya1NasrinA. Kona1FarjanaA.Koly1KaziMadinaMaraz1Md.NaimulIslam1RuhulA.Khan1,2019.

35. A.May-Pat,A.Valadez-González,andP.J.Herrera-Franco,“Effectoffibersurfacetreatmentsontheessentialworkof fractureofHDPE-continuoushenequenfiber-reinforcedcomposites,”2013.

36. N. S. M. El-Tayeb, “A study on the potential of sugarcane fibers/polyester composite for tribological applications,” 2008.

37. Impact strength of a few natural fibre reinforced cement mortar slabs: a comparative study,G.RamakrishnaT.Sundararajan,2005.

38. Bioinspired foam composites resembling pomelo peel: Structural design and compressive, bursting and cushioning propertiesTing-TingLi,HongyangWang,Shih-YuHuang,Ching-WenLou,2020.

39. I.VandeWeyenberg,J.Ivens,A.DeCoster,B.Kino,E.Baetens,andI.Verpoest,“Influenceofprocessingandchemical treatmentofflaxfibresontheircomposites,”2003.

2024, IRJET | Impact Factor value: 8.226 | ISO 9001:2008

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN:2395-0072

40. ExperimentalandmicromechanicalinvestigationofT300/7901unidirectionalcompositestrength,2018.

41. Naturalfiberreinforcedpolymercomposites:history,types,advantagesandapplications,2019.

42. B. Schartel, U. Braun, U. Knoll et al., “Mechanical, thermal, and fire behavior of bisphenol a polycarbonate/multiwall carbonnanotubenanocomposites,”vol.48,2008.

43. Effect of Fungal Deterioration on Physical and Mechanical Properties of Hemp and Flax Natural Fiber Composites. 2017.

44. M.N.M.Ansari,“AReviewonNaturalFiberReinforcedPolymerCompositeandItsApplications”,2015.

45. UsingtextilereinforcedmortarmodifiedwithcarbonnanotubestoimproveflexuralperformanceofRCbeams,2018.

46. Effect of Various Chemical Treatments of Fibre Composite Reinforced materials: Physicochemical, Thermal, Mechanical,andMorphologicalProperties,2013.

47. M.Rokbi, H. Osmani, A.Imad,and N.Benseddiq, “Effect ofchemical treatment onflexure properties of natural fiberreinforcedpolyestercomposite,”vol.10,2011.

48. M. George, P. G. Mussone, Z. Abboud, and D. C. Bressler, “Characterization of chemically and enzymatically treated hempfibresusingatomicforcemicroscopyandspectroscopy,”2014.

49. NaturalFiberCompositesSelectioninViewofMechanical,LightWeight,andEconomicProperties,2015.

50. Naturalfibrereinforcedcompositesopportunitiesandchallenges,2010.

51. Reviewofapplicationandinnovationofgeotextilesingeotechnical engineering.Hao Wu,ChongkaiYao,ChenghanLi, MiaoMiao,YujianZhong,YuquanLuandTongLiu.2020

52. Bharath, K.N.; Basavarajappa, S. Applications of biocomposite materials based on natural fibers from renewable resources:Areview.Sci.Eng.Compos.Mater.2016.

53. NaturalFibreCompositesandTheirApplications:AReview.2018.