International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

Mr. Vishal J. Rana1 , Mr. Dharmang H. Patel2 , Mr. Jayesh D. Ramani3, Dr. Vineet Goel4

1M. Tech (Mechanical) Scholar, Bhagwan Mahavir College of Engineering & Technology, Surat, Gujarat, India

2Head of Mechanical Department, Bhagwan Mahavir College of Engineering & Technology, Surat, Gujarat, India

3Head of Mechanical Department, Tapi Diploma Engineering College, Surat, Gujarat, India

4Dean, Faculty of Engineering, Bhagwan Mahavir University, Surat, Gujarat, India

Abstract - Laser cutting has emerged as a versatile and efficient technology for various industries,offeringprecise and rapid material processing capabilities. This study going into the critical analysis of laser cutting parameters and their impact on the cutting process, aiming to optimize precision and efficiency. By considering variables such as changing in standoff distance, changing in gas pressure, changing in cutting speed etc. This analysis shows how these parameters put influence on surface roughness, kerf width, production time and power consumption. Through comprehensive experimentation and data analysis, this research aims to provide insights into the most effective parameter settings for Mild Steel material and thicknesses,ultimatelycontributingto the advancement of laser cutting technology. The findings presented in this analysis can guide manufacturers,engineers, and researchers in making informed decisions for improved cutting outcomes and enhanced productivity in laser cutting applications.

Key Words: LaserCutting,StandoffDistance,GasPressure, CuttingSpeed,SurfaceRoughness,KerfWidth,Production Time,PowerConsumption,MildSteel

Lasercuttingisbasicallya CNCcuttingprocessin whichahigh-poweredlaserisusedtocutthroughmaterials asperdesigndata.Inthisprocess,ahigh-densitylightbeam isgeneratedbystimulatinglasingmaterialwithanelectrical discharge, withinan enclosedcontainer.Lasercutting has becomeanincreasinglypopularmethodforcuttingmaterials such as metal, plastic, wood, and glass. A wide variety of industries, including automotive and medical device industriesuselasercuttingbecauseitoffersahighdegreeof accuracyandprecision.

Industryhaveusedthesetprocessparameterslike gas pressure, cutting speed, stand-off distance, etc. to manufacture a different job of different material in laser cuttingmachine.Inthisresearchwork,theanalysisofjobs were performed bychangingthe laser cuttingparameters and try to optimize it, which could help the industry to improve its operation and processes. Optimization in processparametersoflasercuttingmachinewillaffectthe

surface roughness, power consumption, kerf width and productiontimeofpreparedjob Byoptimizingtheprocess parameters,manufacturingplantscanreducetheincidence of errors in e.g., configuring processes, increase product quality, reduce equipment and plant downtime. All the experimentswereperformedatMausamEngineering,Surat inthisresearch.

Laser cutting is a non-conventional machining process that uses a laser beam to cut material. The laser beamisfocusedontothematerialandmeltsorvaporizesit, leavinga clean,precisecut. LaserBeamCutting(LBC)has becomethepredominantmethodforcuttingvarioustypesof sheetmaterialsinindustriestoday.Thisadvancedtechnique offerstheabilitytocutawiderangeofmaterials,including metals,composites,andceramics.

By delivering thermal energy through a focused laserbeam,thematerialisheatedandsubsequentlycut.This uniqueprocesseliminatestheneedformechanicalcutting force,toolwear,andvibration,makingLBCidealforcutting evenhardorbrittlematerials.Thelaserbeaminteractswith theelectronsofthematerial,causingsomeoftheenergyto beabsorbed.Thisabsorptionresultsinalocalizedincrease intemperature,whichcanleadtomelting,vaporization,ora changeinthechemicalstateofthematerial.

Incutting,apressurizedgasisusedtoremovethe moltenmaterialfromthegroove.Thetypeofauxiliarygas employeddependsonthematerialbeingcut.Inertgasesare usedtoprotectthesurfacefromoxidation,whileactivegases (usuallyoxygen)generateanintenseexothermalreaction, furtherincreasingthetemperatureinthecuttingarea.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

Amachineusedtopreparethedifferentjobsofmild steelcontainsfollowingspecifications.

PARAMETERS

RANGE

ModelNumber MT-3015

CuttingMaterial

M.S.,S.S,G.I,AL

Application MetalCutting Capacity 2KW

MachineType OpenBody

MachineDimension 5000*3300*2000mm

WorkingArea 3000*1500mm

Phase 3Phase

Screen 17-inchLCD

CNCSystem Cypcut

Transmissionmode RackandPinion

Weight 45ton

Worktablemax.weight capacity 1000kg

RatedVoltage 380V

Cuttingthicknessrange 14mm

X-Axistraveldistance 3030mm

Y-Axistraveldistance 1520mm

Z-Axistraveldistance 105mm

Max.cuttingspeed 100m/min

LasercuttingofaluminumalloyAlMg3,steelSt37-2, and stainless steel AISI 304 was successfully performed withinthetestedrangeofparameters.Overallcutqualitywas goodwithlimitedimperfections.Kerfgeometrywasmainly affected by material type, thickness, and gas pressure. Narrowerkerfswereobtainedatsmallerthicknesses.AlMg3 showedthewidestkerfsduetoitshighreflectivity.Surface roughnesswasprimarilyinfluencedbymaterialtypeandthe interactionofmaterialwithcuttingspeed.AlMg3exhibited the roughest cuts while AISI 304 had the smoothest. Increasingspeedimprovedroughnessforsteelbutworsened it for aluminum alloy. For AlMg3, low speed and high pressureispreferred.ForSt37-2,highspeedandpressure worked best. And for AISI 304, high speed with moderate pressuregavethehighestquality. [1]

Therecentupgradationofnewerandhighstrength materialshasmadethemachiningtaskinfiberlasercuttingis quite challenging. Thus, for the optimum use of all the resources it is essential to make the required mechanical properties, accuracy and quality. There are different operatingparameterswhichwillaffectdifferentmechanical properties ofthe material tobe cutandalso qualityof the cutting. These parameters are operating power, cutting speed, assist gas type, and assist gas pressure, focal point, stand-offdistanceandalsomaterialspecificproperties.[2]

Lasercuttingisanon-contact,thermalprocessused tocutmaterialswithhighprecisionandaccuracy.Itusesa focusedlaserbeamtomeltandvaporizematerialalongthe cut path. Common laser cutting machines use CO2 or Nd: YAG lasers. Process parameters like laser power, cutting speed, gas pressure and focus position affect cut quality. Importantqualitycharacteristicsaresurfaceroughness,heat affectedzone(HAZ)andkerfwidth.Lowerlaserpowerand highercuttingspeedreduceroughness.Highergaspressure increases HAZ width. Laser power and cutting speed have significant effects on quality. Increasing power and decreasing speed reduces roughness. Kerf width increases withpoweranddecreaseswithspeed.ForHAZ,resultsare mixed. Some studies show HAZ reduces with speed and increases with power. Others show opposite trends dependingonmaterial.[3]

Lasercuttingisathermal,non-contactprocessused forcuttingcomplexprofilesinmaterialswithhighprecision. CO2 lasers operate at 10.6 μm wavelength while Nd: YAG lasersoperateat1.06μm.Importantprocessparametersare laser power, cutting speed, and gas pressure and nozzle design. Key quality characteristics are surface roughness, heat affected zone (HAZ) and kerf width. Increasing laser power and decreasing cutting speed reduces surface roughness.HighergaspressureincreasesHAZwidth.Smaller nozzle diameter gives narrower kerf. Lower power and higherspeedincreasedroughness. [4]

One of the main problems with laser cutting equipment is related to the wrong setting of cutting parameters.Themismatchingoftheseparametersleadstoa lossofcutsurfacequality,whichishardlyre-established.This lossofqualityisusuallyrelatedtoaburrproblem.Thus,this studyisaimedtoimproveandoptimizethisprocessusinga fiber laser equipment. Three important laser cutting parameters were studied in order to investigate their importance in the cut surface quality: radiation power, cuttingspeedandgaspressure.So,thispaperprovidesthe workonthestainless-steelmaterial.Fromthispaper,itwas concluded that the values recommended by the machine’s manufacturer are not the optimum to get the best quality because,withlessradiationpowerandhighercuttingspeed values,thelasercuttingprocesswillbeoptimized,allowing aswellthereductionofpowerconsumptionandincreasein productivity.[5]

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

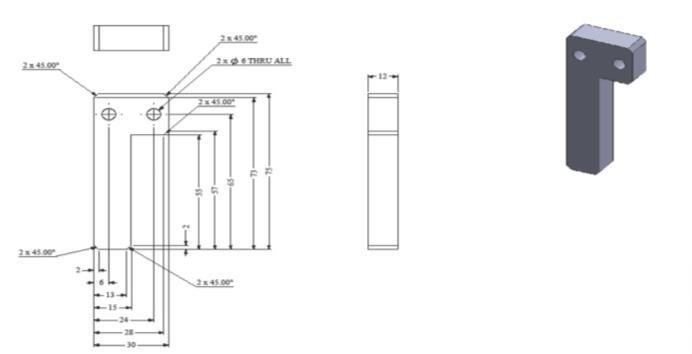

Fig -2:DesignofJob

Figure 2 represents the detailed drawing of selected job which can be used to manufacture different pieces by changingtheprocessparameterinlasercuttingprocess.

By varying the values of process parameters of LaserCuttingMachine,variationsareobtainedinthevalues ofsurfaceroughness,kerfwidth,productiontimeandpower consumption.So,optimumvaluescanbegainedbyvarying the values of parameters which can help the industry to increase its production rate, reduction in power consumption, more accurate production in terms of dimensionalstabilityandreductioninthesurfaceroughness.

Following parameters were considered in the research for variation to make different samples on laser cuttingmachine.

1. Standoffdistance 2.GasPressure 3.CuttingSpeed

Otherparametersareusedassameforalljobs.Tovary the above-mentioned parameters, 27 data sets were prepared before manufacturing of job by laser cutting machineinwhichtotal6datasetswerepreparedbyvarying thesingleprocessparameter,12datasetswerepreparedby varying any two process parameters, 8 data sets were preparedbyvaryingallthreeprocessparametersand1data set(SetNo.-27)wasdirectlytakenonwhichindustryworks.

Table -2: DataSet

Afterfinalizethementioneddatasetsintable2,jobs werepreparedonlasercuttingmachineaccordingtodesign withM.S.materialhavingthicknessofplateof10mm.Allthe parameterswereenteredaspertable2inCypcutsoftware oflasercuttingmachine.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

Different properties like production time, kerf width, power consumption and surface roughness were measuredtoidentifytheoptimumvalueofdataset.

6.1 Production Time:

Productiontimeformanufacturingofalljobswas measuredwiththehelpofstop-watchduringmanufacturing ofjobatindustry.

6.2 Power Consumption:

Power consumed during manufacturing of individual job is calculated with the help of power clamp meterinwhichvoltageandcurrentwasmeasured.Afterthat to calculate the power consumption, both are multiplied together.

P=VI

Where,P=PowerConsumption,W V=Voltage,V I=Current,A

6.3 Kerf Width:

Kerf width describes the amount of taper formed betweentopandbottomsurfaceofjobwhichwasmeasured withverniercaliper.

6.4 Surface Roughness:

The value of surface roughness was measured by surfaceroughnesstester.

Allthemeasuredpropertiesaccordingtodatasetnumberis mentionedbelow.

-3: MeasuredPropertiesofJobs

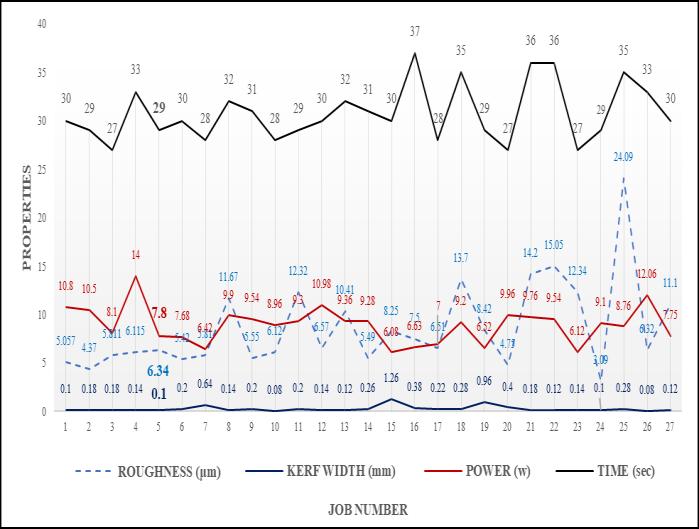

According to the variation in process parameters like cutting speed, stand-off distance and gas pressure, values of properties i.e. production time, power consumption, kerf width and surface roughness were recordedinthetable3 Aftermeasuringalltheproperties, comparative analysis was carried out to determine the optimum process parameters while making a job on laser cuttingmachine.Analysiswasperformedforfourdifferent measured properties by making a graph of all properties againstthejobnumber.

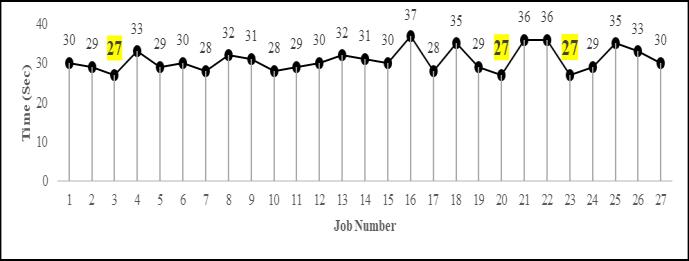

7.1 Production Time Analysis:

To improve the productivity on laser cutting machine,itisnecessarythatproductiontimeshouldbeas lessaspossible.Frommeasureddataofproductiontimeon 27jobs,minimumtimewasobtainedforjobnumberofdata set3,20and23

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

Chart -1:AnalysisofProductionTime

Optimumdata setsarementionedbelow whichconsumes minimumtimeof27secondtoprepareajobonlasercutting machine.

Table-4: OptimumDataSetforMinimumProductionTime

3

7.2 Power Consumption Analysis:

Ifconsumptionofpowerisreducedwhilemakinga jobonlasercuttingmachinethenitshouldbebeneficialfor anindustry.Frommeasureddataofpowerconsumptionon 27jobs,minimumpowerwasconsumedforjobnumber15.

Chart -2:AnalysisofPowerConsumption

Optimum data set is mentioned below which consumes minimumpowerof6.08Wtoprepareajobonlasercutting machine.

Table-5: OptimumDataSetforMinimumPower

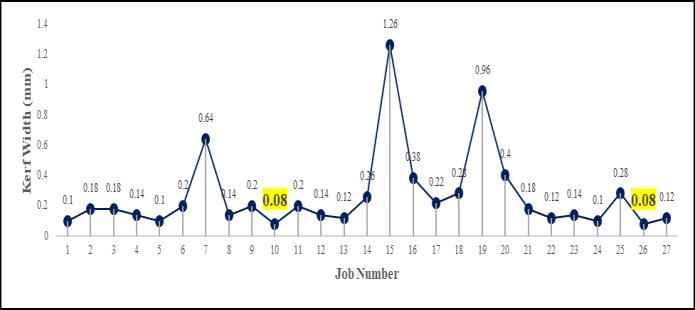

kerfwidthfor27jobs,minimumkerfwidthwasgenerated forjobnumber10and26havingvalueof0.08mm.

Chart -3:AnalysisofKerfWidth

Optimum data sets are mentioned below which generates minimumkerfwidthof0.08mm.

Table-7: OptimumDataSetforMinimumRoughness Job

7.3 Kerf Width Analysis:

It is necessary that after manufacturing of job on lasercuttingmachine,dimensionsofjobsshouldbematch with design. But generally slight taper is taking place between top and bottom surface of job due to cutting of piecewithhightemperaturelaser.Frommeasureddataof

Table-6: OptimumDataSetforMinimumKerfWidth

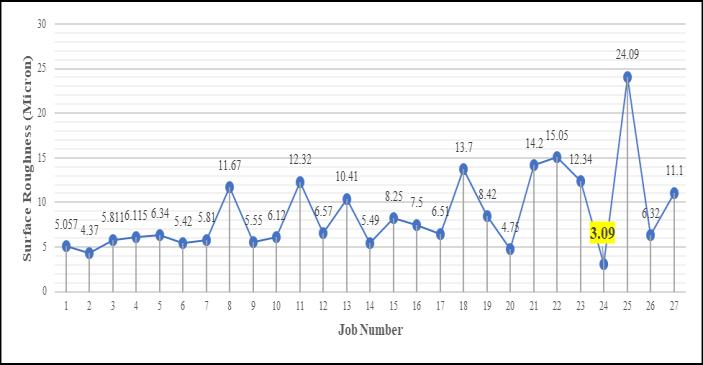

7.4 Surface Roughness Analysis:

After making a job on laser cutting machine, it is necessary that it provides the smoother surface i.e. jobs havinglowersurfaceroughnessvalueforbetterfinishingofa product. From measured data of surface roughness for 27 jobs,minimumroughnesswasobtainedforjobnumber24 with3.090micron.

Chart -4:AnalysisofSurfaceRoughness

Optimum data set is mentioned below which generates minimumvalueofsurfaceroughnessof3.09micron.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

Comparative

Chart -5:ComparativeAnalysisofAllProperties

Theresearchprovidestheoptimumdatasetofjobs madeupofmildsteelforwhichvalueofsurfaceroughness, production time, power consumption and kerf width will becomeminimum.Selectionofdatasetswillbedependedon industry according to its objective to reduce mentioned parameter.

Fromtable3;whenthecuttingspeedisincreased, thentimeformakingajobisdecreased.Fromtable4;power consumption isbecomeoptimumwhencuttingspeedand pressure of gas have their larger value. Consumption of powerisdecreasedbyincreasingthecuttingspeedandgas pressure.Fromtable5;kerfwidthhasminimumvaluewhen thestand-offdistanceisdecreasedinbothcases.Fromtable 6; if value of cutting speed increased, gas pressure and standoffdistancedecreasedthen,jobhavingtheminimum valueofsurface roughness whichultimatelyimprovesthe surfacefinishoftheproduct.

[1] Silvio Genna, Erica Menna, Gianluca Rubino, Vincenzo Tagliaferri, “Experimental Investigation of Industrial LaserCutting:Theeffectof theMaterial Selectionand the Process Parameters on the Kerf Quality”, Applied Science,Vol.10,2020.

[2] VikrantB.Mahajan,VidyaN.Nair,“ALiteratureReview on Fiber Laser Cutting on Stainless Steel-304”, International Journal for Scientific Research & Development,Vol.1,Issue09,2013,2002-2003

[3] V. Senthilkumar, “Laser cutting process – A Review”, International Journal of Darshan Institute on EngineeringResearch&EmergingTechnologies,Vol.3, No.1,2014,44-48.

[4] Suraj S Patel, Viraj H Patel, Ketul M Patel, Bhaumik A Patel, Aseem A Patel, Saumil C Patel, “Experimental AnalysisofLaserCuttingMachine”,InternationalJournal ofEngineeringResearch&Technology,Vol.10,Issue04, April-2021,129-135.

[5] I.Amaral,F.J.G.Silva,G.F.L.Pinto,R.D.S.G.Campilho, R. M. Gouveia, “Improving the Cut Surface Quality by Optimizing Parameters in the Fibre Laser Cutting Process”, 29th International Conference on Flexible AutomationandIntelligentManufacturing(FAIM2019), June24-27,2019,Limerick,Ireland.