International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

Aniket P. Dhawale 1 , Pranav S. Pathrabe 2 , Rohan I. Thawkar 3 Tejas R. Wasnik 4 , Pankaj I. Chavhan 5 , Abhay A. Kathane 6

Guide: Professor, Sanjay Bhadke Department of civil engineering TGPCET [RTMNU], Nagpur, India

1 Student, Aniket P. Dhawale, Department of civil engineering TGPCET [RTMNU], Nagpur, India

2 Student, Pranav S. Pathrabe, Department of civil engineering TGPCET [RTMNU], Nagpur, India

3 Student, Rohan I. Thawkar, Department of civil engineering TGPCET [RTMNU], Nagpur, India

4 Student, Tejas R. Wasnik, Department of civil engineering TGPCET [RTMNU], Nagpur, India

5 Student, Pankaj I. Chavhan, Department of civil engineering TGPCET [RTMNU], Nagpur, India

6 Student, Abhay A. Kathane, Department of civil engineering TGPCET [RTMNU], Nagpur, India

Abstract - Pervious concrete is one of the type of concrete it’s have a property to allow a water flow through concrete. Pervious concrete is a lightweight concrete which mainly comprised by cement, water, coarse aggregate and glass fiber threads. Size of aggregate near about 9mm < 12.5mm ≤ or minimum 9.6mm. Size of glass fibre threads 70-80mm andthe size of sample cube of testingis 150*150*150mm. The pervious concrete has a ratio of mix proportion 1:2.25:0.45, 1 part of cement, 2.25 part of coarse aggregate and 0.45 part of water. The problem that society going to face unwanted surface water or storm water collected on road so the pervious concrete have the ability to pass directly through the drainage system.

Key Words: Pervious concrete, glass fibre threads, porosity,drainagesystem,cost.

Pervious concrete is also called as “porous concrete”, “permeableconcrete”,“nofinesconcrete”andit’smadeup by using the cement, coarse aggregate and water, with addition of glass fibre threads. Pervious concrete is traditionallyusedinparkingareas,areaswithlighttraffic, residentialstreet,pedestrianwalkway,andgreenhouses.

Itisanimportantapplicationforsustainable construction propertyapplicationforsustainableconstruction.Property of the pervious concrete is to allow water thought itself becauseit’saporousconcreteandaddingadrainagesystem andcollectingtankbelowthepreviouspavement.Collecting the storm water for domestic usage. Pervious concrete functionslikeastormwaterandcanreducepollutantload entering into stream, pond and rivers. The ratio of mix proportion1:2.25:0.45and theratioofglassfibrethreads 0.50% of concrete. Increase strength of pervious concrete pavementbyusingaglassfibrethreads

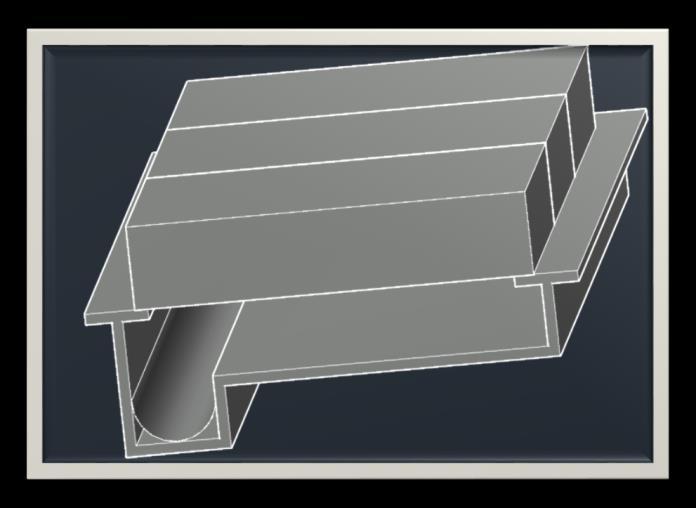

Perviouspavementblock.

Plybase.

Drainagepipe.

2. LITERATURE REVIEW

B.RadhaKiranmaye,D.Tarangini,K.V.RamanaReddy

LengthofGlassFibreusedis12mm.

CompressiveStrengthofM20gradeofconcretefor28 days – 25-30MPa

MeghaNBelagal,RamyaBV

Pervious Concrete Specimens with 0.50% Glass fibreallowthewatertopassquicklyascompared to that of specimens of mix containing 2% glass fibres.

PaulDTennis,MichaelLLeming,DavidJAkers

Pervious Concrete as a paving material has seen renewedinterestduetoitsabilitytoallowwaterto

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

flow through itself to recharge groundwater and minimizestormwaterrunoff.

JingYang,GuoliangJiang

In this paper, a Pervious Concrete Pavement materialusedforroadwayisintroduced.

Using the common material and method, the strengthoftheperviousconcreteislow.

AshokKumar,AghilaB,MSamuleThanaraj

Use0.50feetdepthofperviousconcretelayer thatmeans15.24cm(0.1524m)

It will give higher amount of porosity that allowswatertopercolateintogroundwater.

AndrewDawson,NickThom,XuanxuanChu

Onlyfreewatercanberemovedbydrainingunder gravity.

ZeinabYazdanfar,AshokSharma

Extrawaterstorage.

Futurestickwaterharvesting.

3. CONCLUSION

Fromliteraturereviewwecansaythatwewantthe compressivestrengthofM20gradeofconcretefor 28daysits25-30Mpa.

Fromliteraturereviewwecansaythattheprojectis eco-friendlyandreducesthecostofconstruction.

Weareprovide0.50feetdepthofperviousconcrete layerthatmeans15.24cm(0.1524m).

Weuseglassfibresheetforbetterobservationand strength.

4. PROJECT WORK

Conductedtestonaggregatesareasfollows:

Sieve analysis of coarse aggregate:

Fineness modulus = ∑ cumulative weight retained in %/100

Weightofsampletaken=3000g =2430/100 =24.3

This test is used to collect accurate size of aggregate for concretemixture(9<12.5mm≤).

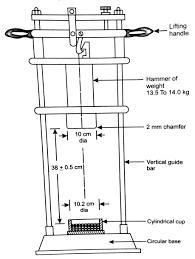

Sudden impact test on coarse aggregate:

A.I.V(AggregateImpactValue)

= W2/W1*100 =11.36+11.25+12.26/3

= 11.62%

[Exceptionallystrong]

Table -1

Wt.ofsurfacedrysample passthrough12.5mmsieve, retainedon10mmsieve(W1)

Wt. of fraction pass 2.36mm sieveaftertest(W2)

Wt. of fraction retained on 2.36mmsieve aftertest(W3)

AIV=W2/W1X100

Specific gravity test on coarse aggregate:

Weightofemptypycnometerofglass

W1=650g

Weightofpycnometer+Aggregateofmass

W2=650g+600g =1250g

Weightofpycnometer+Aggregatemass+Waterofmass

W3=650g+600g+270g Description

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

=1520g

Weightofpycnometer+Watermass

W4=650g+525g =1175g

Specificgravitytest

=______W2–W1_____ (W2–W1)–(W3–W4) = 1250-650________ (1250–650)–(1520–1175) = 2.35 = 2.4

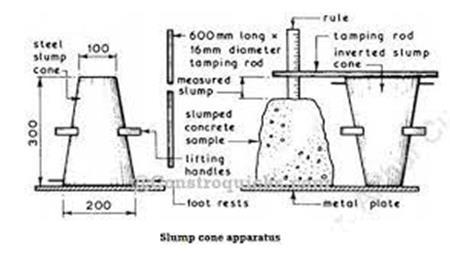

Slump cone test on pervious concrete:

Collapseconcreteheight=210mm

Slumpconeheight=300mm

SlumpValue=300–210 =90mm =0.9cm

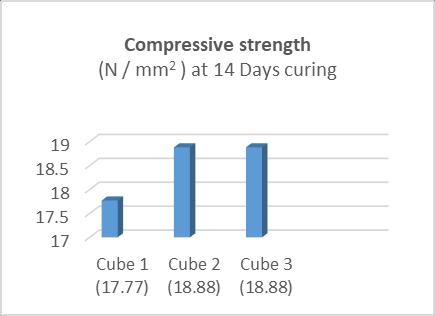

Compressive strength testing for a 14 days and 28 days.

Weuse(CTM)CompressiveTestMachineforcompressive testingforperviousconcretecubes.GradeofconcreteM20, mixratioofperviousconcrete1:2.25:0.45,usedofglassfibre 0.50%ofconcrete.

Cross section area of one cube = 150 x 150 mm2 = 22500 mm2

Stress(MPa)= forceN Areamm2

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072 © 2024, IRJET | Impact Factor value: 8.226 | ISO 9001:2008

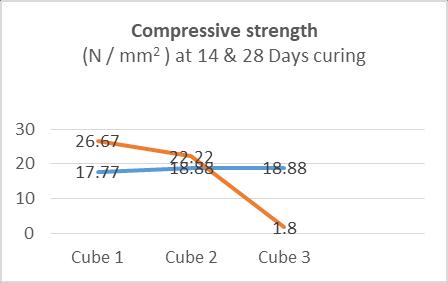

Table -2 Compressive strength for 14 days

Chart -1 Compressive strength 14 days

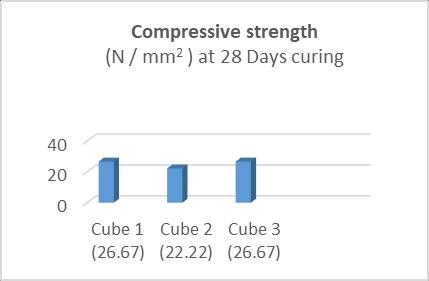

Table -2 Compressive strength for 28 days Sr.no Ageofcube Compressive

Chart -2 Compressive strength 28

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

Meancompressivestrength(14days)=18.51N/mm2

Meancompressivestrength(28days)=25.18N/mm2

Chart -3 Compressive strength 14& 28 days

5. DESIGN

Pervious concrete pavement

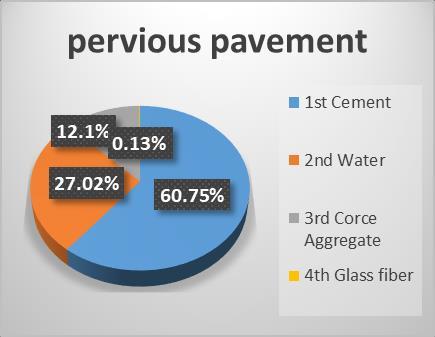

Size of Pervious concrete pavement (488mm* 304mm* 122mm) l*b*h weight of aggregate 74.850kg, weight of cement 33.26 kg, weight of water 14.96 kg for three (3) perviousconcretepavementblocks.

Chart -4 Pervious Pavement materials Quantity

Permeability test

Drypavementweight=29.890kg

Water=1000g

Waterpass=840g

Pavementabsorbwater=160g

6. CONCLUSION

It’s reduce a storm water and collect a rain water for domesticuse.

Doapermeabilitytest,theweightofthedrypavementis 29,890kg,1000gofwaterspreadsonthesurface,840g of water passes through the pavement and 160 g of waterisabsorbedintothepavement.

(Onadryconditionitspercolate82to85%of water)

(Onawetconditionitspercolateabove90%ofwater)

Asweuse,werecommendthismodeltocollectwater.

Itsreducecostofconstructionandmaintenance.

Itstimesavingbecauseweuseprecastblocksandithas lessmaintenancerequireditreducetherainwaterfast.

Weusestoragewaterforamultipledomesticuseslike wateringlawnsandgarden,firewaterextinguisheretc.

[1]AndrewDawson,NickThom,XuanXuanChu“Sustainable Pavementdrainagesystem:Sub-grademoisture,subsurface drainagemethodsanddrainageeffectiveness”Jan2023

[2]Musa Adamu “Durability performance of Pervious ConcretecontainingRiceHuskashandCalciumCarbon”June 2021

[3]Ashok Kumar,Aghila B, MSamuleThanaraj“Design of Improved Drainage System using Pervious Concrete” Aug 2020

[4]MeghaNBelagal,RamyaBV“ExperimentalInvestigation onGlassFibreReinforcementPerviousConcretebyPartial ReplacementofcementbyGlassPowder”August2020

[5] Jing Yang, Guoliang Jiang “Experimental study on properties of pervious concrete pavement materials” Dec 2019

[6] S. Ramesh, K.Selvi “Experimental Study on Pervious ConcretewithadditionofFlyash”July–Sept2019

[7]PaulDTennis,MichaelLLeming,DavidJAkers“Pervious ConcretePavements”2019

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

[8] B. Radha Kiranmaye, D.Tarangini , K.V.Ramana Reddy “Effects of Glass fibre on properties of Pervious Concrete” 2018-19

[9]ZeinabYazdanfar,AshokSharma“Urbandrainagesystem planning and design - challenges with climate change and urbanization:areview“Jun2018

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072 © 2024, IRJET | Impact Factor value: 8.226 | ISO 9001:2008