International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

1Department of Electrical Engineering, Dr. CVRU Kota Bilaspur Chhattisgarh, India

2Asst. Professor, Dept. of Electrical Engineering, Dr. CVRU Kota, Bilaspur, Chhattisgarh, India

3 Asst. Professor, Dept. of Electrical Engineering, Dr. CVRU Kota, Bilaspur, Chhattisgarh, India

Abstract - Late Advancements in the field of seductive accoutrementsandforcewidgets,alongsidetheavailability ofmodestamazingprocessors,haveexpandedtheeventof (BLDC)machinesfordifferentoperations,forillustration,in home machines just as in bus, aeronautics, and clinical businesses.Thewideeventofthismachineisbecauseofits multitudinousbenefitsoverdifferentkindsofmachines,like higheffectiveness,highimportant response,long working life, relatively calm exertion, and advanced speed ranges. Becauseofexpandingtheapplicationofthebrushlessdirect current (BLDC) machine in multitudinous life operations ratherthantheconventionalmachines,listanddetermine the further for its controlling strategies. This paper introduces vibrant methods for controlling speed and current, including hysteresis band control, variable DCconnected transport voltage, and pulse width modulation (PWM) regulation for twinkle range adjustment. These control methods leverage essential proportional-integralderivative(PID)gains,whichareoptimizedthroughparticle swarm optimization (PSO) computation. Utilizing fast Fourier transform (FFT) analysis to assess controller performancefromreal-timesignalprocessingandcalculate totalharmonicdistortion(THD),itenablestheselectionof themosteffectivecontrolstrategy.

Key Words: Speed Control, BLDC Motor, Closed Loop, Review.

Rushabhkumar S. Patil etal. (2020) The proposed Lasting MagnetBrushlessDCmachine(PMBLDC)hasvariablehaste programs. There's the application of enhanced inordinate powerperpetualattractionsappliedandmaximumcurrent pressurewidgetsinventionproliferationappliedtotheBLDC machine.Becauseofthelowprotectionprice,highgift,and clevercontrollabilityoftheBLDCmachine,theapplication rateisincreased.Likewise,atthesametime,thismachine has a negotiation of encounter set as compared to the brushed DC machine. The boundary development of this BLDCmachinewasdoneusinganetherealcausecontroller, andthehastemanipulationofthemachinewascompleted with an ethereal motive controller. This proposed frame upgraded the multitudinous walls of the BLDC machine using MATLAB Simulink with outfit system prosecution,

makinguseoftheArduinocontroller.Thefirstthingofthis proposedfashionistoachievethedonationofhastecontrol ofaBLDCmachinebyexercisingaetherealmotivecontroller with applicable boundary advancement. This proposed approachhasbeen,usingconfiguration,triedanddelvedon a10000KV,30Ampperpetualattractionbrushlessmachine power.

BasimAlsayidetal.(2019)demonstratedadvanceddetector controlofthelastingattractionBLDCmachinespeedusing the MATLAB/ SIMULINK rainfall. near- circle speed operationwascreated,andmultitudinousassessmentswere made to assess the legality of the control computations. Results confirm the desirable exertion of the proposed manipulation computations. An interpretation of the motorized haste operation of the brushless dc Engine, in clockwise and counterclockwise headlines, is introduced. The delivered model was efficaciously evolved in Matlab/ Simulinkandtriedatdifferentfreights.Therecreationgoods affirmedthelegalityoftheproposedcontrollerasalongway from an exact pastime. The proposed configuration demonstratedanestimabledistinctprosecutionandhaste tenet.

HayderSalimHameedetal.(2018)TheDCmachineboasts numerous advantages, such as high torque at startup, efficiency, elevated power output, and minimal electrical noise, making it a preferred choice for contemporary applications.Thispaperintroducesavarietyofcontrollers employedfordrivingtheBrushlessdcmachine.Thepaper hastriedtoconcocta(PID)controlleranddiscrepancyitwith relative(P)andcorrespondingirreplaceable(PI)controllers to control speed of BLDC machine. The goods of BLDC reduplication with PID complete the briskly prosecution speed achieved when comparing PI and P controllers. Likewise, BLDC machine showing and reduplication controllers are carried out by using the outfit on top of it (HIL)systemthroughtheproductpackMATLAB/SIMULINK withSimulinkhelppackageforArduino.

Xu, Ling etal. (2016) proposed using the numerical interpretation of bldc machine, exercising MATLAB/ Simulink to construct unique, tone- sufficient salutary modules, and incorporate them into the reenactment interpretation ofthe brushlessDCmachinecontrol frame. The system employs a dual-loop control approach,

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

comprisinganinnercurrentloopandanouterspeedloop,to ensure optimal performance across high and low-speed ranges, providing rapid, adaptable control, stability, and otheradvantages.Throughconductingtwosimulationtests focusedonspeedtrackingandpowerregulation,weinitially evaluatetheeffectivenessandaccuracyofthesystemmodel and the feasibility of the control framework design. Duplicate and putting obstacles can likewise be made to ameliorate the real controller's operation and appoint reference.

Sarojini Devi etal. (2016) Some proposed brushless DC machines (BLDC) are considerably applied to some mechanicaloperationsgiventheirinordinateeffectiveness, inordinateforce,andlowvolume.Theaimofthispaperison the haste control of a BLDC machine using a sensitive processing fashion. The challenges associated with controlling materials include undesired overshoots, prolongedsettlingtimes,andvariationsencounteredwhen transitioningbetweendiverseenvironments.Toaddressthe issuesofexcessiveovershootandextendedsettlingtimes, bothPIDandtone-tuningvirtualPIDcontrolstrategieswere incorporated into the closed-loop controller design. MATLAB/SIMULINK was utilized to simulate the speed operation of the BLDC machine, and the results were analyzed. The findings indicate that the proposed tonetuning virtual PID controller outperforms a conventional controller. Additionally, the BLDC machine model is presented,anditsspeedresponseisvisuallyobservedvia theTV.

Maloth Purnalal etal. (2015) The proposed electronically commutatedbrushlessDCmachinefindswidespreadusein various modern applications, highlighting the need for an efficientoperationalapproachforthesesilentmachines.This paper focuses on closed-loop speed control of the BLDC machine,withitsperformancesimulated.APIcontrolleris employedtoregulatethedutycycleofthePWMpulsessent totheinverterswitches,ensuringthemachineoperatesatits desiredspeed.Theimplementationoftheproposedscheme iscarriedoutusingMATLABprogramming.

Narendra Kumar etal. (2014) delivered the Brushless DC(BLDC)machinepaceridingfabricsthathavegrown in differentconstrainedcompassandgreatcompassprograms like machine associations, homegrown machines, and so forth. This activates the advancement in the brushless DC machine(BLDCM).TheuseoftheBLDCmachineupgrades exceptional prosecution rudiments, transitioning from improvedefficiencyandenhancedlow-speedperformance to consistent high-pressure output, lower maintenance requirements,andreducednoisecomparedtoconventional machines. The BLDC machine can be allowed ofasanoptionforstandardmachineslikeinvestitureand changedhesitancemachines.Inthispaper,aPIDcontroller isachievedwithahastegrievancecircle,andit'sclearthat forceswellsarelimited.Reenactmentisfinishedexercising

MATLAB/Simulink. The results indicate that the performance of the BLDC Engine is highly suitable for variousmoldingscenarios.BrushlessDCmachinedrivesare utilizedinspeed-controlledapplications.

M.Sandeep,etal.(2014),inthispaperBLDCmachinewhere in a power conversion device is managed to use of Pulse width modulation ways and checked the donation of sinusoidal PWM and Space Vector PWM plans and reproduced to supply the precise dynamic and stationary pace-forceattributes.Thehasteeasycontrolinacloseloop hasteofthemachine.Themistakeisinsidethesetspeedand therealspeedisdetermined.Arelative,inadditiontovital, inadditiontoattachment(P.I.D)controllerscanbeapplied andregularlytradethePWMdutycycle.Thecreatedhaste controlconspireischeckedviaMatlab/Simulink

IntroducedbyMdMustafaKamaletal.(2014)TheBLDCM hasbeengenerallyappliedingamblesduetoitsadvantages like unwavering excellence, inordinate effectiveness, inordinatestartingpressure,muchlesselectricalclamor,and inordinateweighttopressproportion.Forthehastecontrol ofbrushless motor,colorful controllersareapplied.When comparedtoconventionalcontrollers,etherealcontrollers givefasterresponses;still,conventional controllersgive a better response with lower converting burden at the expenditureofalongersettlingtime.theterrainisappliedto completethebelowexamination.

V.M. Varatharaju et al. (2010) The proposed display and reenactment of electromechanical fabrics with machine drivesareabecedarianstridesintheplansectionofsimilar fabrics. This paper describes the system of figuring out a modelforthebrushlessDCmachinewitha120-parchment inverter frame and its blessing at the MATLAB/ Simulink position.ThereduplicationconsequencesforBLDCmachine drivefabricsaffirmthelegalityoftheproposedapproach.

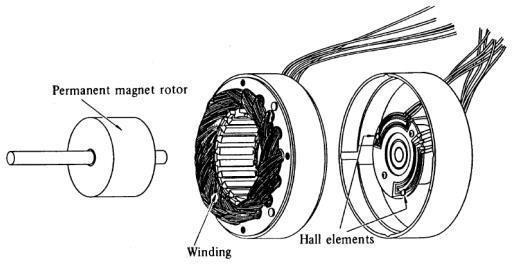

Thearchitectureofmodernbrushlessmotorsresembles thatofACmotors,oftenreferredtoaspermanentmagnet synchronousmotors(PMSM).Figure2depictsthestructure of a standard bldc motor. The stator windings closely resemble those found in polyphase AC motors, while the rotor consists of one or more permanent magnets. In discrepancytoaccoetaneousmotors,BLDCmotorshavea medium for detecting the rotor position (or glamorous poles) and using that information to induce signals that operate electronic switches.The mostcommon position/ poledetectoristheHallelement,butsomemotorsuseoptic detectors.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

Closed Loop Control Closed Loop control of BLDC motor: Oneoftheconventionalmethodslistedbelowcanbeutilized toregulateBLDCsinanopen-loopconfiguration:currentand speedfeedback,speedandcurrentfeedback,ornocurrent andspeedfeedback.

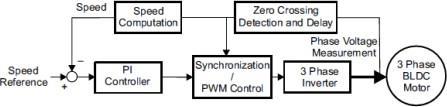

Speed feedback:

In the model above, speed is calculated using the VI measurement at the BLDC motor's terminals. While the speedestimatedfromthebrushlessdirectcurrentmotoris supplied back as negative feedback for computing the inaccuracy in the target speed, the hall sensor output is used for synchronization and PWM control. The PI controller receivesthe error and uses it once again to generate PWM. The aforementioned control method is beneficial since VI measurement is simple at the output terminals.

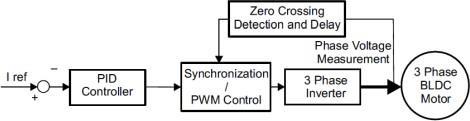

1. No speed/ current feedback:

According totheblock illustrationover,thealternate kindofcontrolstrategyusesasetupforthepresentcontrol circle. In this, the PID regulator is simply handed a reference current. At the BLDC motor's outstations, VI dimensionisformerlyagainperformed.Bycomparingthe currenttotheterminalaffair,thecurrentisemployedto producethegatebeatsfortheinverter.

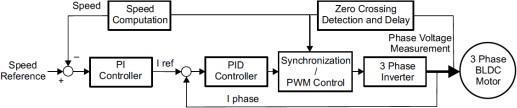

2. Speed and current feedback:

Analogous feedback is there in this approach to BLDC motor closed circle speed control as it's in the former fashion.still,colorfulcorridorofthecontrolroutegetsthe feedback. First, the speed is varied with the reference speed. A PI regulator processes the error, and source currentisreckonedasaresult.Thecurrentisalsovaried withthecurrentattheaffairoutstationbeforebeingrouted formerlyagainthroughaPIDregulatorforfreshadaptation. The plan needs two phases of tuning and redundant circuitry, making it by far the most complicated fashion. ThePWMcontrolunit,whichproducesthesensebeatsfor the PWMcontrol,receives the affair ofthe PID regulator next.

Intherealmofelectricvehicles(EVs),theefficientcontrolof BLDCmotorsstandsasa critical component forachieving optimal performance and energy utilization. This review delves into the realm of BLDC motor control, particularly focusing on the application of Proportional-IntegralDerivative(PID)controllersimplementedthroughMATLAB, aimedatenhancingtheefficacyofEVpropulsionsystems. The integration of Proportional Integral Derivative controllerswithBLDCmotorsoffersamyriadofadvantages. Firstly, PID control provides a robust framework for regulating motor speed and position, allowing for precise manipulationoftorqueandrotationalmotion.Thisprecision isparamountinEVs,wheretheseamlesstransitionbetween different speeds and driving conditions is essential for a smooth and responsive driving experience. By fine-tuning thePIDparameters,engineerscantailorthemotorcontrol systemtomeetspecificperformancerequirements,striking abalancebetweenspeed,torque,andenergyefficiency. Moreover,PIDcontrollendsitselftoadaptability,acrucial trait in the context of EVs operating in dynamic environments. Whether encountering changes in load, terrain, or external disturbances, PID controllers excel at maintaining stability and responsiveness, ensuring consistentperformanceacrossvarieddrivingscenarios.This adaptabilitynotonlyenhancesthesafetyandreliabilityof Electrical vehicle is but also contributes to their overall versatilityandusability.

Moreover, utilizing PID controllers in MATLAB provides a flexibleplatformforsimulating,designing,andoptimizing

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

systems. MATLAB's extensive suite of tools and libraries enables engineers to model complex motor dynamics, analyzecontrolalgorithms,anditerateondesignparameters withease.Thissimulation-drivenapproachacceleratesthe development cycle, allowing for rapid prototyping and testingofcontrolstrategiesbeforedeploymentinreal-world EV systems. Additionally, MATLAB's integration with hardware enables seamless transition from simulation to hardware-in-the-loop (HIL) testing, further validating the efficacy of Proportional Integral Derivative control in practicalapplications.

Intermsofperformancemetrics,PID-controlledBLDCmotor systems exhibit notable improvements in efficiency and responsiveness. By leveraging PID's feedback mechanism, motorcontrolloopscanquicklyadapttochangingdemands, minimizingenergywastageandmaximizingbatterylifein EVs.Furthermore,PIDcontrolmitigatesundesirableeffects such as overshoot and oscillations, ensuring smoother acceleration and deceleration profiles, thereby enhancing ridecomfortandvehiclestability.

However,despiteitsnumerousbenefits,PIDcontrolisnot withoutitschallenges.ThetuningofPIDparameterscanbea non-trivial task, requiring a deep understanding of motor dynamicsandcontroltheory.Moreover,PIDcontrollersmay exhibitlimitationsinhandlingnonlinearitiesand Tackling thesechallengesnecessitatesamultidisciplinaryapproach that includes advanced control techniques, system identification,androbustoptimizationmethods.

[1] Basim Alsayid, Wael A. Salah, Yazeed Alawneh, “ModellingofsensoredspeedcontrolofBLDCmotor using MATLAB/SIMULINK”, International Journal of ElectricalandComputerEngineering(IJECE)Volume 9,Number5,October2019.

[2] HayderSalimHameed,“BrushlessDCMotorController Design Using Matlab Applications”, 2018 1st International Scientific Conference of Engineering Sciences - 3rd Scientific Conference of Engineering Science(ISCES).

[3] K. Sarojini Devi, M. Dhanasekaran, S. Muthulakshmi, “ImprovementofSpeedControlPerformanceinBLDC MotorUsingFuzzyPIDController”,2016International ConferenceonAdvancedCommunicationControland ComputingTechnologies(ICACCCT).

[4] Ling Xu, Jian-Guo Song, Qiang-Qiang Lin, “Brushless DC Motor Speed Control System Simulink Simulation”, 2016 IEEE International Conference onPowerandRenewableEnergy.

[5] Md Mustafa kamal, Dr. (Mrs.) Lini Mathew, Dr. S. Chatterji,“SpeedControlofBrushlessDCMotorUsing Fuzzy Based Controllers”, 2014 IEEE Students’ Conference on Electrical, Electronics and Computer Science.

[6] MSandeep,BLachulal,“DesignofAClosedLoopSpeed Control for BLDC Motor”, International Refereed JournalofEngineeringandScience(IRJES),Volume3, Issue11(November2014).

[7] Maloth Purnalal, Sunil kumar T K, “Development of Mathematical Model and Speed Control of BLDC Motor”, International Journal of Electrical and ElectronicsEngineers,IJEEE,Volume07,Issue01,JanJune2015.

[8] Rushabhkumar S. Patil, Chetan M. Bobade, “Speed ControlofPermanentMagnetBrushlessDCMotorwith Parameter Optimization”, International Research Journal of Engineering and Technology (IRJET), Volume:07Issue:06|June2020.

[9] VMVaratharaju,BLMathur,KUdhyakumar,“Speed Control of PMBLDC Motor Using MATLAB/Simulink and Effects of Load and Inertia Changes”, 2010 InternationalConferenceonMechanicalandElectrical Technology(ICMET2010).

[10] Y.NarendraKumar,P.EswaraRao,P.VijayVarma,V.V. RamVikas,P.KasiNaidu,“SpeedControlofBldcMotor DriveByUsingPidControllers”,InternationalJournal of Engineering Research and Applications www.ijera.com ISSN : 2248-9622, Vol. 4, Issue 4( Version 4), April 2014.K. Elissa, “Title of paper if known,”unpublished