International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

Akash. K. Anil1 , Sachin. T. M2 , Chethan Chandru3

1PG Student (M. Tech), Department of Civil Engineering, Bangalore Institute of Technology, Karnataka, India

2Assistant Professor, Department of Civil Engineering, Bangalore Institute of Technology, Karnataka, India

3Assistant Professor, Department of Civil Engineering, Bangalore Institute of Technology, Karnataka, India

Abstract - The goal of the current study is to investigate how adding synthetic macrofibres, or twisted monofilament ferro fiber, to concrete affects its mechanical properties. Numerous physical and mechanical propertiesofconcrete will be improved by the application of carefully tailored macrofiber. Throughout this inquiry, M30 grade concrete with a 0.4 water-to-cement ratio was used. Numerous strength attributes, including split tensile strength, flexural strength, and compressive strength, were investigatedanddocumented.

Key Words: Synthetic Macro Fiber-Twisted Monofilament Ferro Fiber (TMF Fiber), Concrete, Compressive strength, SplitTensilestrength,Flexuralstrength.

1.INTRODUCTION

Whileithaslessresistancetotensionandflexure,concrete hasastrongerresistancetocompression.Asaresult,some fracturesarevisible,butmostarehiddenbecausetheyhave developeddeepbelowthesurface,insidetheconcretemass. Cracksformwhentensilestrainsaretoohigh.Anyalteration intheweatherhasanimpactonthemechanismthatcauses cracking.Thereinforcementholdsthecracksintheconcrete together as they occur. Subsequently, the weight is transferredthroughbondactionandbaranchorage.Similar results are obtained by the use of Twisted Monofilament FerroFiber(TMFFiber)reinforcement:adecreaseincrack width and an increase in tensile strength. One important factor in stopping these cracks is TMF Fiber. TMF Fiber evenlyholdstheconcreteinplaceandpreventscracksfrom forming.

1.1 Applications

ThemainareaforTwistedMonofilamentFiber(TMFFiber) applicationsareasfollows:

1.Highway(PQC)

2.IndustrialFlooring

3.Tunnellining

4.AirportRunway

5.Parkingarea

6.Canallining

7.Nuclearpowerplant

8.Paverblocksandsolid/Haloblocks

9.Precastconcrete

Mydin M.A.O et al. (2023) [3]

By experimental study of concrete specimens PTBF was providedin0%,0.5%upto2.5%ratiosprovidingconcrete densities of 500,700 and 900kg/m^3 (as per British standards).Slumpflowfallsasitrises.inPTBF.Testresultsof compression,flexuralandsplittensilestrengthisfound-500 and700kg/m^3densitytheoptimumvalueis1.5%andfor 900kg/m^3densitytheoptimumvalueis2.0%.Thusbeyond 2.0% the diminished significantly. Thus, there will be reductioninairvoids,thermalinsulationandboostthelight weightfiberconcrete.

Buratti N et al. (2011) [4]

Byexperimentalstudyofconcretespecimenprisms/beams werecastedindifferentratiosofsamemixdesign(British standard).Todeterminethe effectoffiberdistribution on Flexuraltoughnessbyusing3-pointbendingtest.BothSteel fiberandmacrosyntheticfiberwerecastedseparatelyand combinationofbothinconcrete.Syntheticfiberhastensile strength greater than 575MPa. Steel fiber concrete shows highstrengthinflexuraltoughnessandmacrosyntheticfiber showslowstrengthinflexuraltoughnesshowever,synthetic fiber increases in reduction of crack opening due to shrinkage. Thus, macro synthetic fiber is proposed for alternativetosteelfiberinstructuralapplications.Synthetic fiberisstilllimited.

A. J. Babafemi (2016) [5]

Byexperimentalinvestigationfiberwasusedatavolumeof 1% throughout the conduction by considering one mix design.Diameteroffiberis0.8mm,tensilestrength-400MPa, length-40mm,elasticmodulus-4GPa,aspectratio-50.study examinesthecreepresponseofcrackedreinforcedconcrete that has been macro synthetic fibers and mechanism responsible for creep behavior. Stress of 30%, 40%,50%, 60% about 70% of average uniaxial tensile strength(2.90MPa) is accustomed to determine uniaxial tensilecreeptest.Resultshowedtensilecreepover8months even at stress level as low as 30% and creep fracture specimen occurred at 60 and 70% stress level. Its compressive strength is 40.19MPa. large-scale synthetic fiberisbecomingincreasinglypreferredtosteelfiber,dueto lightweight,resistancetocorrosionandcheapincost

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

Estela Oliari Garcez et al. (2019) [6]

Slumpflow,compressivestrengthandsplittensilestrength were compared for performance. and flexural strength. 3 different concrete mixtures with fiber dosage of 4, 6, and 8kg/m^3wereproduced.Mixturewith4and6kg/m^3fiber contenthasmostsatisfactoryflowabilityandslumpflowfor 6kg/m^3was670mmwithoutanybleedingandsegregation. Mixtureof6kg/m^3exhibitshighsplittensile,compressive, and8kg/m^3mixtureachievedmaximumflexuralstrength residual(indicatesgreatermomentofcarrycapacity).

1. By use of Synthetic macro fiber pores in concrete structures will be minimized, leads less corrosion to steel reinforcementplacedwithinconcrete.

2.Polypropylenetwistedbundlefiberhastensilestrength >575MPa. Thus, it is applicable as partial replacement to steel reinforcement or fully replaced for ground level touchedsurface.

3. Improves in bending Tensile power additionally also preventincrackinginhorizontalformedstructure.

4. Increase in strain or deformation of structural element under a constant or sustained loading (Creep) can be minimized.

2.2. GAP ANALYSIS

1.Afterstudyingthepreviousresearchpapers,cameacross those researchers had been performed on lower grade concreteandlowdensitiesandaddingfibers0.5%to2.5% weightofconcretemix.

2.Therefore,investigationbyexperimentofconcreteofM30 grade is used and Twisted Monofilament fibers are introducedtotheconcreteofthemassofthe,respectively, 0.1%,0.2%,and0.3%concretemixdesign.

1.FindingtheCompressiveStrength,Split-TensileStrength, andFlexuralStrengthofTwistedMonofilamentFerro(TMF) FiberinconcreteofgradeM30byadding0.1%,0.2%,and 0.3%percentageoffiber.

2.ToResearchtheImpactofStrengthdifferencesbetween TMFFiberinbothconcreteandconventionalconcrete strengthvalues.

Stepsinvolvedinmethodologyareasfollows:

1. Literature survey was made by collecting prior studies thataresimilartocurrentinvestigation

2.Researchgapandproperobjectivesoftheresearchwas documented

3.CollectionofMaterials

4.DesignofConcreteMix

5.Castingofcube,cylinderandprismsamples

6.Demoldingthesamplesafter24hours

7.Curingofthesamplesoveraspanof28days

8.Concretethathashardenedistested

9.Resultsandcomparison

10.Conclusions

5. EXPERIMENTAL PROGRAMME

5.1. Materials

Table-1: Materialproperties

Cement OPC-53grade

Fineaggregate Wellgraded(zoneII)

Coarseaggregate crushed(20mm–12mm)

Water

Potablewater(drinkingwater)

Admixture FosrocconplastSP430DIS

TMF Fiber (As per Kalyani polymers

Pvt.Ltd)

Material-Polypropylene

Color-cementgrey

Diameter/thickness-0.3mm

Tensilestrength>575MPa

Aspectratio>90

Availablelength-30mm

Fig-1: TMFFiberAvailablelength

5.2.

Inthisexperiment,TheM30concretegradewascreatedas perIndianStandard(IS)-1026-2009code.Thequantityof TMF fiber was added in 0.1%, 0.2% and 0.3% volume of concrete.Thequantityofmaterialsusedperm3

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

Table-2: MaterialQuantity

Slump 100mm

Ratioofwatertocement 0.40

Water 158kg/m3

Chemicaladmixture 7.9kg/m3

Cement 395kg/m3

CoarseAggregate 1223.78kg/m3

FineAggregate 660.54kg/m3

6.1. Test of Compressive Strength

150 x 150 x 150 mm size cube specimen was utilized to measure the strength under compression. The steps and techniques used were in line with IS 516-1959. Subsequently, the specimen sample was positioned in the CompressionTestingMachine(CTM)withtheforceapplied perpendicular to the casting side at a consistent 1000 kg/mmrate.

CompressiveStrength=failureLoadinN/Areainmm2

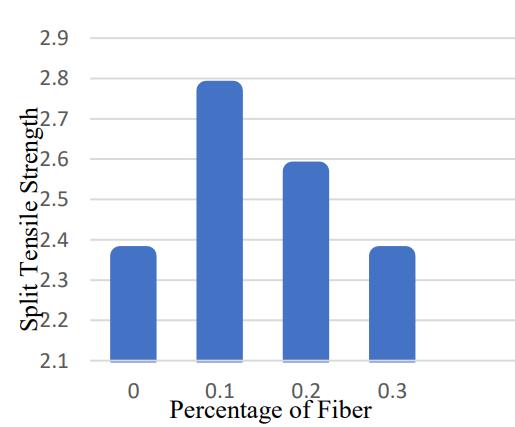

6.2. Test of Split Tensile Strength

ForSplitTensiletest,aspecimenwithadiameterof150mm anda height of300mm wasutilized. Theproceduresand methodsfollowedIS5816-1999.Theloadwasappliedinthe compressiontestingmachineatasteadyrateof250kg/mm.

TensileStrength=2P/����D

P=failureload

D,L=diameterandlengthofspecimenrespectively(mm)

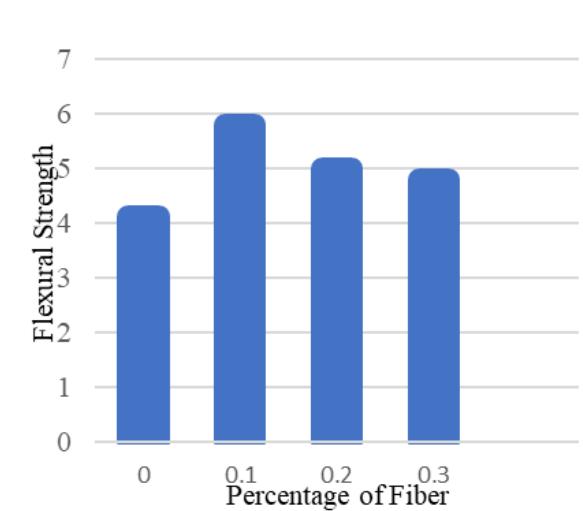

6.3. Test of Flexural Strength

The100X100X500mmbeamspecimenwasusedtotestthe concrete'sflexuralstrength.Aflexuraltestingapparatuswas employedtoconductathree-pointtestincompliancewithIS 516-1959.

Table-3: Flexuralstrengthformula

Cases strength

Ifa>13cm PL/bd2

Ifa<13cm 3Pa/bd2

P=Failureload

L=spanlength

a=lengthfromfailurepointtoreferenceline

b=widthofspecimen

d=depthofspecimen(mm)

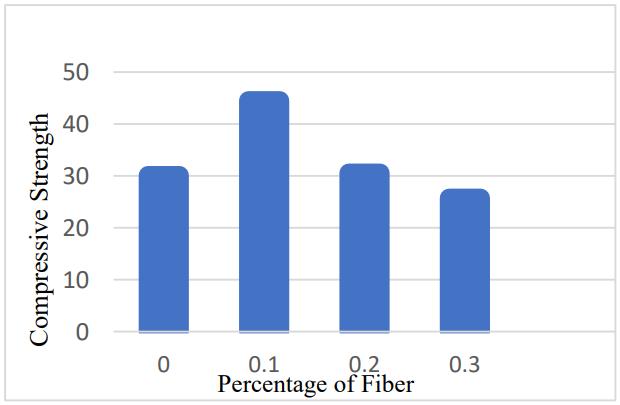

7.1. Test of Compressive Strength

Table-4: ValuesoftheTestforCompressiveStrength

Areaofspecimen(cube)=22500mm2

1: PercentageofFibervsCompressivestrength

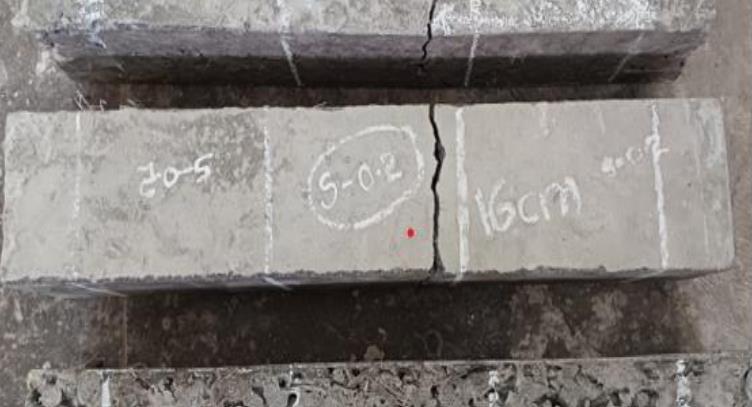

Figure-2: Cubeafterapplicationofload

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

Table-5: ValuesoftestforSplitTensileStrength

specimenincorporatedwithTMFfiber showingcomparativelylessporous

Table-6: ValuesoftestforFlexuralStrength

8. CONCLUSION

FromExperimentalTestreport,theAmountofStrengthis calculatedRegardingPercentage(shownbelowtable)

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

Table-7: AmountofStrengthcalculatedinpercentage

TMFfiberconcretestrengthincreased(%)iscompared withconventionalconcrete

Sl no Fiber in

1

2

3

1.It'sclearfromtheabovetestingthat0.1%ofTMFFiberin concreteisthehighestpossiblevaluetoincreaseconcrete strength.

2.0.1%offibercanachievegoodcohesion,workability,less pores,ductilityanddurabilitytoconcretestructures.

3.0.2%offiberhavestrengthgreaterthanregularconcrete, butlessthan0.1%offiberstrength.

4.0.3%offibersstrengthvaluesdecreasedincompressive strengthandsplittensilestrength,howeverthereisincrease inflexuralstrength.

5.Asthefibercontentincreasedinconcretetheworkability becomesverystiffandleadstobeingbrittleinnature.

[1] IS 10262-2009 for Concrete Mix ProportioningGuidelines.

[2] IS 456-2000 Plain and Reinforced Concrete - Code of Practice

[3] MydinM.A.O,AbdullahM.M.A.B,RazakR,NawiM.N.M, RisdanareniP,PuspitasariP,SanduA.V,(16thFeb2023) - Study on Polypropylene twisted bundle fiber reinforcedlightweightfoamedconcrete.

[4] BurattiN.;MazzottiC.;SavoiaM;(2011)–Postcracking behaviourofsteelandmacro-syntheticfiber–reinforced concretes

[5] A.J.BabafemiandW.P.Boshoff,(march2016)-Macro Synthetic fiber reinforced concrete: Creep and Creep Mechanisms.

[6] EstelaOliariGarcez,MuhammadIkramulKabir,Alastair MacLeod,MahbubeSubhaniandKazemGhabraie-Self CompactingConcreteReinforcedwithTwisted-Bundle Macro-Syntheticfiber

“AkashKAnil PGStudent(M.TechStructural Engineering) DepartmentofCivilEngineering BangaloreInstituteofTechnology” “Sachin.T.M AssistantProfessor DepartmentofCivilEngineering BangaloreInstituteofTechnology“ “ChethanChandru AssistantProfessor DepartmentofCivilEngineering BangaloreInstituteofTechnology“