International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN:2395-0072

Ravish Kumar1, Mr. Ushendra Kumar2

1Master of Technology, Civil Engineering, Lucknow Institute of Technology, Lucknow, India

2HeadofDepartment,DepartmentofCivilEngineering,LucknowInstituteofTechnology,Lucknow,India

Abstract - The presence of toxic plastic in Municipal Solid Waste (MSW) is a growing concern, as it accounts for nearly 5% of such waste. The non-biodegradable nature of plastic poses significant environmental pollution and hygiene problems, leading to the need for proper disposal management.However,recentexperimentation conductedat various institutes has shown that waste plastic can be effectively utilized in road construction through asphalting. This approach is based on economic considerations, as bitumen is commonly used as a binder in road making processes.Bymodifyingbitumenwithplastic waste,amixcan be createdthat serves as a top layer offlexible pavement with superiorbindingproperties,stability,densityandresistanceto water. Inthis project, we testedthe use of waste plastic mixed with bitumen at varying percentages - 0%, 3%, 5%, 8%, and 10%. Our results showed that the addition of plastic led to decreasesinpenetrationandductilityvalues whileincreasing softening point, flash point, and fire point values. Overall, utilizing waste plastic in road construction offers an innovative solution to address both environmental concerns and economic considerations associated with proper waste management practices.

Key Words: Bitumen, highway Pavement, Plastic waste, Strength,Ductility,Roadconstruction

1.BACKGROUND INFORMATION ON HIGHWAY PAVEMENT CONSTRUCTION

Highwaypavementconstructionencompassesameticulous process that begins with thorough site preparation, involvingclearing,grading,andpreparingthesubgradeto meetrequiredspecifications.Thesubsequentinstallationof thebasecourse,comprisingcompactedlayersofaggregates, establishesastablefoundationforthepavement.Depending onthetypeofpavement flexibleorrigid eitherhotmix asphaltorconcreteismeticulouslyplacedandcompactedto formthesurface.Compaction,acriticalstep,eliminatesair voids and ensures the desired density, while curing promotes proper hydration of concrete or adhesion of asphalt.Throughoutconstruction,qualitycontrolmeasures, including tests for density, thickness, and material properties,arerigorouslyimplementedtoupholdstandards. Beyond construction, ongoing maintenance is paramount, involving activities like crack sealing and resurfacing to prolongpavementlife.Environmentalconsiderations,such

as sustainability and drainage design, are integral, underscoringtheneedforeco-friendlypracticesandproper watermanagement.

Highways are intricate webs of asphalt and concrete that crisscrosslandscapes,bridgingcities,towns,andruralareas. Theseribbonsofroadwayserveaslifelinesforeconomies, enablingtheseamlessflow ofgoods,services, and people. Theyarethearteriesofcommerce,facilitatingthemovement of freight from manufacturing centers to markets and connecting consumers with the products they need. Highways are also the conduits of connection, providing commuters with the means to traverse vast distances efficiently,whetherforwork orleisure.Fromthebustling urbanfreewaysthatpulsewithactivitytothetranquilrural routesthatwindthroughpicturesquecountryside,highways arenotmerelyconduitsfortransportationbutalsopathways for exploration and discovery. They embody the spirit of progress, evolving alongside technological innovations to meetthe ever-changing needsofsociety.Yet,amidsttheir undeniable utility and significance, highways also present challenges, from traffic congestion and environmental impacttosafetyconcerns.Aswenavigatetheroadahead,it is imperative to strike a balance between efficiency, sustainability,andsafetytoensurethathighwayscontinue toserveasvitallifelinesforgenerationstocome.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN:2395-0072

The importance of pavement strength for durability and safety cannot be overstated, especially when considering transportationinfrastructure.Hereareseveralkeyreasons why pavement strength is crucial for both durability and safety:

Load-Bearing Capacity: Pavementstrengthdeterminesthe abilityofthesurfacetowithstandvariousloadsimposedby vehicles,includingcars,trucks,andbuses.Apavementwith inadequate strength may develop cracks, rutting, or even structural failure under heavy loads, leading to safety hazardsandreducedservicelife.

Resistance to Distress: Strong pavement resists distress mechanisms suchasfatigue cracking,rutting,and pothole formation.Thesedistressescancompromisetheintegrityof the pavement, leading to unsafe driving conditions and costlyrepairsorrehabilitation.

Traffic Safety: Pavementstrengthcontributestotheoverall safetyofroadusersbyprovidingastableandsmoothdriving surface.Weakpavementscanleadtounevensurfaces,which may cause loss of vehicle control, skidding, or accidents, particularlyduringadverseweatherconditions.

Durability: Pavement strength directly influences the longevityanddurabilityoftheroadinfrastructure.Astrong pavement can withstand repeated traffic loads and environmental factors such as temperature variations, moisture,andchemicalexposure,thusextendingitsservice lifeandreducingmaintenancecosts.

Economic Impact: Pavement strength plays a significant role in minimizing lifecycle costs associated with road maintenanceandrehabilitation.Investinginhigh-strength pavementsupfrontcanresultinlong-termcostsavingsby reducing the frequency and extent of repairs and replacements.

User Comfort: Apavementwithadequatestrengthprovides a smoother ride quality, enhancing user comfort and reducing driver fatigue. This is particularly important for long-distancetravelandforvulnerableroaduserssuchas cyclistsandpedestrians.

Electronic waste (e-waste) presents significant environmentalchallengesduetothepresenceofhazardous materials like lead, mercury, and brominated flame retardantsinelectronicdevices.Improperdisposalmethods, suchaslandfillingandincineration,releasetoxicsubstances intothesoil,water,andair,leadingtocontaminationandair pollution. Additionally, e-waste contributes to resource

depletion,energyconsumption,andclimatechange, while informal recycling practices further exacerbate ecosystem damageandbiodiversityloss.Addressingthesechallenges requireseffectivee-wastemanagementsystems,sustainable product design, consumer education, and regulatory enforcementtopromoteresponsibledisposalandrecycling practicesglobally.

Severalfactorssignificantlyimpactpavementdurabilityand lifespan.Theseinclude:

Traffic Load and Volume: Themagnitudeandfrequencyof traffic loads, including the types of vehicles and their weights, directly influence pavement durability. High volumesofheavytrafficacceleratepavementdeterioration, leadingtoprematurewearandreducedlifespan.

Climate and Weather Conditions: Environmentalfactors such as temperature fluctuations, freeze-thaw cycles, rainfall,andUVradiationcandegradepavementmaterials overtime.Regionsexperiencingextremeweatherconditions mayrequirepavementsdesignedtowithstandtemperature variations and moisture ingress to ensure long-term durability.

Subgrade Soil Characteristics: The properties of the subgrade soil beneath the pavement, such as strength, stiffness,anddrainagecapacity,significantlyaffectpavement performance. Poor soil conditions can lead to inadequate support,settlement,andpavementdistress,compromising durabilityandlifespan.

Material Selection and Quality: The selection of appropriate pavement materials, including aggregates, asphalt binders, and additives, is crucial for achieving desiredperformanceanddurability.High-qualitymaterials withpropergradation,durability,andcompatibilityenhance pavementresistancetodistressmechanismsandextendits servicelife.

Design and Construction Practices: Proper pavement design and construction techniques, including adequate thickness,compaction,andjointconstruction,areessential forensuringstructuralintegrityandlongevity.Poordesign or construction practices can result in inadequate loadbearing capacity, surface distress, and premature deterioration.

Maintenance and Rehabilitation: Regular maintenance activities such as crack sealing, pothole patching, and pavement overlays can extend the lifespan of existing pavements by addressing minor defects and preventing furtherdeterioration.Timelyrehabilitationmeasures,such as resurfacing or reconstruction, are necessary to restore structuralintegrityandprolongpavementservicelife.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN:2395-0072

Thecurrentlimitationsoftraditionalpavementconstruction materialsstemfromtheirsusceptibilitytovariousformsof deteriorationandtheirenvironmentalimpact.Conventional materialslikehotmixasphalt(HMA)andPortlandcement concrete(PCC)oftenexhibitreduceddurabilityovertime, manifestinginissuessuchascracking,rutting,andspalling, which necessitate frequent maintenance interventions. Moreover,theextraction,production,andtransportationof thesematerialsentailsignificantresourceconsumptionand carbon emissions, contributing to environmental degradation and climate change. Their limited flexibility, resilience, and recyclability further exacerbate these challenges, making them ill-suited for addressing the evolving needs of modern infrastructure systems. To overcometheselimitations,thereisagrowingimperativeto invest in sustainable alternatives that offer enhanced durability, reduced environmental impact, and improved lifecycleperformance,thusensuringthelong-termresilience andsustainabilityofpavementinfrastructure.

Bituminous mix consists of a mixture of aggregates continuouslygradedfrommaximumsize,typicallylessthan 25mm,throughthefinefillerthatissmallerthan0.075mm. Sufficientbitumenisaddedtothemixsothatthecompacted mix is effectively impervious and will have acceptable dissipativeandelasticproperties.

6.1.MATERIAL USED

Highwaypavementconstructioninvolvesseveralmaterials, eachservingspecificfunctionstoensuredurability,safety, andsmoothness.Herearetheprimarymaterialsused:

Thebasicmaterialsusedareasfollows:

1. Aggregates

2. FlyAsh

3. Slag

4. BituminousBinder

5. EWaste.

6.1.1.Aggregates

Aggregatesarethefundamentalbuildingblocksofhighway pavement, playing a crucial role in its strength and durability.Thesematerials,typicallysourcedfromnatural rockdepositsorrecycledmaterialslikeconcreteorasphalt, areselectedbasedontheirphysicalpropertieslikeparticle size, shape, and strength. They provide stability, support, andresistance to wearand tearunderheavytrafficloads. Properlygradedaggregatescreateadensematrix,enhancing the pavement's load-bearing capacity and preventing crackingandrutting.Theircompositiondirectlyinfluences

pavementperformance,makingtheselectionprocessvital forensuringthelongevityandsafetyofroadinfrastructure.

Fly ash, a byproduct of coal combustion in power plants, finds valuable application in highway pavement construction. Its inclusion in concrete mixtures enhances workability,reducespermeability,andimproveslong-term strength.Asasupplementarycementitiousmaterial,flyash mitigates environmental impact by reducing the need for Portlandcement,thuscuttingdownoncarbonemissions.Its pozzolanicpropertiesreactwithcalciumhydroxidetoform additional cementitious compounds, enhancing durability andreducingtheriskofalkali-silicareaction.Utilizingflyash in highway pavement not only strengthens infrastructure but also promotes sustainable practices by repurposing industrialwasteintoavaluableconstructionresource.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN:2395-0072

Slag, a byproduct of steel manufacturing, serves as a beneficialcomponentinhighwaypavementconstruction.Its incorporation as a supplementary cementitious material enhances the performance and durability of concrete mixtures.Withitshydraulicproperties,slagcontributesto increased strength, reduced permeability, and improved resistancetochemicalattacksandabrasion.Byreplacinga portionofPortlandcement,slaghelpstoreducegreenhouse gas emissions associated with cement production. Additionally, its use in pavement construction provides a sustainablesolutionformanagingindustrialwaste.Overall, slagplaysavitalroleinenhancingthestrength,longevity, andenvironmentalsustainabilityofhighwaypavements.

Bituminous binder, a crucial component in highway pavement,isderivedfrompetroleumrefining.Thisviscous black substance, commonly known as asphalt, acts as the adhesivethatbindsaggregateparticlestogetherinasphalt concrete.Itsflexibilityenablesthepavementtowithstand varying temperatures and traffic loads without cracking. Bituminous binders come in various types and grades tailored to specific climate and traffic conditions. They providewaterproofingproperties,protectingtheunderlying layers from moisture damage. With regular maintenance, bituminousbinderprolongspavementlife,ensuringsmooth andsafetravelforroadusers.Itsversatilityanddurability makeitanindispensableelementinhighwayinfrastructure worldwide.

6.1.5.E Waste

Utilizing e-waste in highway pavement presents an innovative solution to address both environmental and infrastructure challenges. Electronic waste, comprising discardedelectronicdevices,isrecycledandprocessedinto sustainable construction materials. Incorporating e-waste aggregates in pavement not only reduces the burden on landfills but also enhances pavement performance. These materials offer advantages such as improved strength, reduced material costs, and enhanced durability. Furthermore,bydivertinge-wastefromdisposalsites,this approach contributes to environmental conservation and promotes circular economy principles. Implementing ewaste in highway pavement demonstrates a progressive approachtowardssustainableinfrastructuredevelopment, balancing resource efficiency with environmental stewardship.

Electronic Waste

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN:2395-0072

In this section, we will know the experimental study of replacementofthebitumenbinderatdifferentpercentage, thedetailsof thetestisgivenbelow:

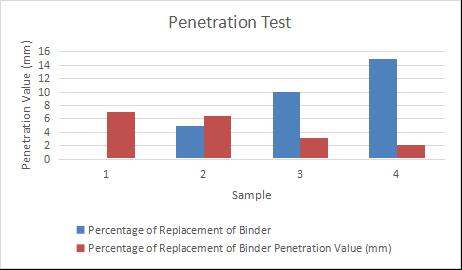

1. PenetrationTest

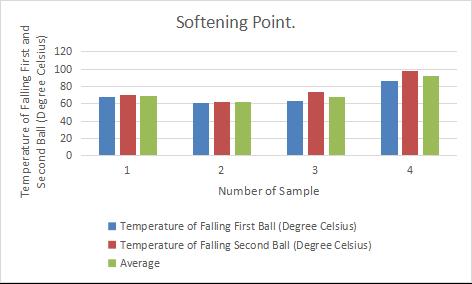

2. SofteningPointTest

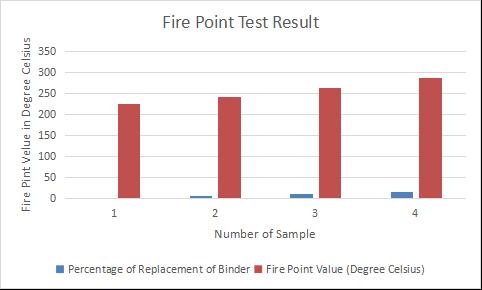

3. FirePointTest

7.1.Penetration Test of Bitumen

Penetration testing for bitumen involves evaluating the consistencyandsoftnessofbitumen,crucialforassessingits suitabilityforvariousapplicationsinconstructionandroad paving. This test measures the depth in tenths of a millimeterthatastandardneedlepenetratesverticallyintoa sample of bitumen under specific conditions of time, temperature, and loading. Typically conducted at 25°C or 77°F,thepenetrationdepthprovidesinsightsintobitumen's viscosity and grade, helping determine its performance characteristics like adhesion, cohesion, and durability. Standardizedproceduresensureconsistencyandreliability inresults,aidingengineersandmanufacturersinselecting the appropriate grade of bitumen for different climate conditions and traffic loads. Penetration tests not only assurequalitycontrolbutalsocontributetoenhancingthe longevity and resilience of asphalt pavements, crucial for sustainableinfrastructuredevelopment.

7.2.Softening Point Test of Bitumen

The Softening Point Test is a crucial assessment in determining the thermal susceptibility of bitumen, a vital component in road construction. Conducted according to standardizedmethodslikeASTMD36orISO4625,thetest measures the temperature at which a bitumen sample softensunderspecificconditions.

In the procedure, a bitumen specimen is subjected to increasing temperature at a controlled rate, often using a ring-and-ball apparatus. As the temperature rises, the bitumen softens and allows the steel ball to descend. The softeningpointisrecordedasthetemperatureatwhichthe bitumensampledeformstoaspecificdistance,typically25 millimeters.

Thistestisessentialforensuringthesuitabilityofbitumen for various climates and traffic conditions. Bitumen with higher softening points tends to withstand elevated temperatures better, offering superior resistance to deformation and rutting on roads. Understanding a bitumen's softening point aids in selecting appropriate grades for construction projects, optimizing road performance,andensuringdurabilityofroadsurfaces.

TheFirePointTestforbitumendeterminesthetemperature atwhichbitumenemitsenoughvaportoignitemomentarily whenexposedtoaflameunderspecificconditions.Thetest involves heating a sample of bitumen in a closed cup apparatusatacontrolledrate.Asmallflameispassedover the surface of the bitumen at regular intervals. The temperatureatwhichthebitumenmomentarilycatchesfire andsustainscombustionforatleastfivesecondsisrecorded asthefirepoint.Thisparameteriscrucialinassessingthe suitabilityofbitumenforvariousapplications,especiallyin environments where high temperatures are encountered, suchasinhotclimatesornearsourcesofheat.Ahigherfire point indicates better resistance to ignition and can be indicative of the bitumen's performance in safety-critical scenarios.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN:2395-0072

Graph-3: Fire Point Test of the Bitumen.

8.CONCLUSION

In this study, we examined the replacement of bitumen binder in highway pavement with electronic waste at varyingpercentages:zero,five,tenandfifteenpercent.The tests conducted to assess the behavior of bitumen binder mixed with electronic waste included penetration test, softening point test, flash and fire point test, and ductility test.Ourfindingsindicatethatreplacingfivepercentofthe bitumenbinderwithelectronicwasteresultedinan8.45% decreaseinpenetrationvaluewhilea54.93%decreasewas observedwhen tenpercent ofthe binder wasreplaced by electronic waste. As illustrated in chapter four's softening pointgraph,thereisanincreaseinsofteningpointasmore electronic waste is added to the mixture until a certain threshold after which further additions lead to decreased softeningpointsforbitumenbindersmixedwithhighlevels ofelectronicwaste.

1. Daly, & H.E. (1991). Ecological economics and sustainabledevelopment:fromconcepttopolicy(No. 1991). World Bank, Environment Department, Policy andResearchDivision.

2. Akinyemi, E. a. (2000). Sustainable development and transportation:PastexperiencesandFutureChallenges. WorldTransportPolicy&Practice.

3. Black, W. (2000). Socio-economic barriers to sustainabletransport.JournalofTransportGeography, 8(2),141-147.

4. JustoC.E.G.,VeeraragavanA“UtilizationofWastePlastic BagsinBituminousMixforImprovedPerformanceof Roads”, Centre for Transportation Engineering, BangaloreUniversity,Bangalore,India,2002.

5. Hınıslıoğlu, S.; and Ağar, E. (2004).Use of waste high density polyethylene as bitumen modifier in asphalt mix.MaterialsLetters,58(3-4),267-271.

6. DhodapkarAN.,(Dec.2008),“Useofwasteplasticin roadconstruction”,IndianHighways,Technicalpaper, journal,PNo.31-32.

7. Buis, J. (2009). A new Paradigm for urban transport planning: Cycling inclusive planning at the pre-event training workshop on non-motorized transport in urbanareas.Seoul.

8. BandopandhyayT.K.,(Jan.-Mar.2010),“Construction ofAsphaltRoadwithPlasticWaste”,IndianCenterfor Plastic in Environment (ICPE), ENVIS – Eco- Echoes, Vol.11,Issue1

9. Anoverviewonwasteplasticutilizationinasphaltingof roadsJers/Vol.III/IssueII/April-June,2012/01-05.

10. RokadeSUseofWastePlasticandWasteRubberTyres in Flexible Highway Pavements 2012 International ConferenceonFutureEnvironmentandEnergyIPCBEE vol.28(2012)©(2012)IACSITPress,Singapoore.

11. IMTIAZ AHMED AND C. W. LOVELL “Use of Waste MaterialsinHighwayConstruction:StateofthePractice andEvaluationoftheSelectedWasteProducts”2012, TRANSPORTATIONRESEARCHRECORD1345.

12. Achairi,R.B.(2013).LiteratureReview:Conditionsof SustainableTransport.

13. Cervero, R. (2013). Transport infrastructure and the environment:Sustainablemobilityandurbanism.IURD, Institute of Urban and Regional Development, UniversityofCalifornia.

14. Khan Amjad, Gangadhar, Murali Mohan Murali and Raykar Vinay,(2013) "Effective Utilization of Waste Plastics in Asphalting of Roads",R.V. College Of Engineering,Bangalore.

15. AnoopSingh,VikasSrivastava“UtilisationofE-wastein Concrete - An Experimental Investigation” 2015, International Journal of Engineering Research & Technology (IJERT) ISSN: 2278-0181 Published by, www.ijert.orgISNCESR-2015ConferenceProceedings.

16. Vikram J. Patel1 , Hemraj R. Kumavat2 , Ganesh V. Tapkire3 “An Experimental Study of Bituminous Pavement adding Electronic-Waste to Increase the StrengthEconomically”2017,InternationalJournalof Innovative Research in Science, Engineering and Technology(AnISO3297:2007CertifiedOrganization) Website:www.ijirset.com.Vol.6,Issue1,January2017.

17. Anupam Kumar Sharma1 , Nitin Dutt Sharma2 “An Experimental Study on Use of E-Waste Materials in Concrete for Rigid Pavements” 2018, International JournalofScienceandResearch(IJSR)ISSN:2319-7064 ResearchGateImpactFactor(2018):0.28|SJIF(2018): 7.426.