International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

Mrs. Suchetha1,2 , Dr. Asha Saraswathi B2

1Department of Mathematics, Sahyadri College of Engineering and Management, Adyar, 574007, India

2Department of Mathematics, Srinivas University, College of Engineering and Technology, Mukka, 574146, India

Abstract - Faultdiagnosisincomplexengineeringsystemsis asignificantactivitythataffectsoperationalefficiency,safety, andmaintenancecosts.This paperprovidesacomprehensive review of innovative methodology and techniques for a fault diagnosis, with a focus on the application of graph-based representations and sophisticated machine learning algorithms. The assessment emphasizes the difficulties associated with standard data-driven methodologies for properly leveraging the correlation and geometric structure present in vast amounts of unlabeled industrial data. To address these problems, the review investigates novel technologiessuchashypergraphsforrepresentingequipment structure,deephypergraphautoencoderembedding(DHAEE) for defect detection, and multiresolution hypergraph neural networks for discovering higher-order correlations in data. Furthermore,thestudyinvestigatesthecombinationofmodelbased and data-driven approaches, as demonstrated by the series configuration approach, which combines Bayesian Networks with adaptive gas path analysis. While these approaches present intriguing opportunities for enhancing fault detectionaccuracyand efficacy,issueslikeasalgorithm complexity, data availability, and result interpretability remainrelevant.Thesurveyresultshighlighttheneedofusing integrated and creative approaches to problem diagnosis, which have the potential to improve operational reliability, minimizedowntime,andoptimizemaintenanceproceduresin complex engineering systems.

Key Words: GraphConvolutionNeuralnetwork,Knowledge graph,faultdiagnosis,hypergraphs,industry4.0

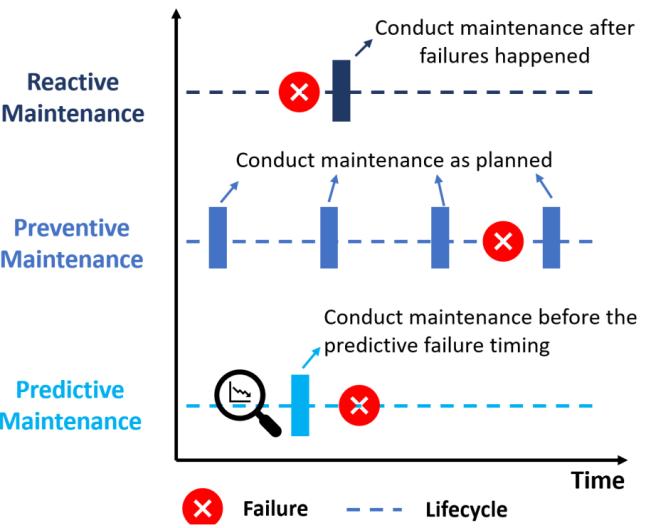

In the landscape of industrial operations, the concept of maintenance has undergone a profound evolution. Historically, maintenance methods have predominantly followed a reactive strategy, responding to equipment failuresormalfunctionswithrepairsorreplacements.The reactive paradigm, which has been widespread for many years, has notable disadvantages, including unforeseen periodsofinactivity,decreasedproduction, andincreased expenses for upkeep [1,2]. Furthermore, it frequently neglects to tackle fundamental problems that cause recurringfailures,leadingtosubparassetperformanceanda shortened lifespan. Acknowledging these constraints, the industrial sector has shifted towards more proactive maintenance practices, with predictive maintenance

emerging as a promising model. Predictive maintenance seeks to anticipate equipment malfunctions in advance, allowingfortimelyinterventionsandpreventiveactionsto minimizepotentialhazards.Predictivemaintenancesystems utilize data analytics, sensor technology, and machine learningalgorithmstoanalysepreviousperformancedata. This analysis helps detect patterns and anomalies that indicatepotentialbreakdownsinthefuture.Thisproactive strategynotonlyreducestheamountoftimethatsystems are not functioning, and the expenses associated with maintenance, but also improves the effectiveness of operations and the dependability of assets [3]. Figure 1 illustratesthedistinctapproachesofreactivemaintenance, preventivemaintenance,andpredictivemaintenancewithin thecontextofindustrialoperations

However,therelianceonpre-establishedrulesorstatistical models,whichmayoverlookintricateinterconnectionsand dynamicinteractionswithinindustrialsystems,oftenlimits the effectiveness of conventional predictive maintenance methods. Furthermore, as industrial infrastructures grow moreinterconnectedandreliantonlargeamountsofdata, traditionalapproacheshavechallengesdealingwiththesize and intricacy of modern operational settings. In order to tacklethesedifficultiesandcapitalizeonfreshpossibilities for predictive maintenance, there has been a rising fascination with incorporating cognitive technologies like artificial intelligence (AI), machine learning (ML), and

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

sophisticatedanalytics[4].Cognitivepredictivemaintenance signifies a fundamental change towards maintenance systemsthataremoreintelligent,adaptable,andrelianton data. Through the utilization of cognitive computing, predictive maintenance systems may acquire knowledge frompreviousoccurrences,adjusttoevolvingcircumstances, and make proactive determinations instantaneously [5]. Graph-basedtechniqueshavebecomeapotentialfoundation formodellingandanalyzingcomplicatedrelationshipsinside industrial systems in the field of cognitive predictive maintenance[6].Graphtheoryisamathematicaldiscipline thatfocusesonstudyingthecharacteristicsanddynamicsof networks,orgraphs.Itoffersarobustsetoftechniquesfor encoding, visualizing, and analyzing interconnected data structures. Graphs are used in predictive maintenance to representdifferentelementsofindustrialsystems,suchas equipmentinterconnections,operationalprocesses,andthe spreadoffaults.

Themotivationforinvestigatinggraph-basedmethodsfor predictivemaintenanceistheirintrinsicabilitytorepresent thecomplexcharacteristicsofindustrialsystems,including both physical and logical interconnections. Graph-based methodologies allow for comprehensive modelling of interconnected assets, subsystems, and processes, in contrast to traditional methods that typically consider equipment as separate entities. Graph-based models can effectively capture intricate interconnections, cascading impacts,andemergent phenomena thatmay not be easily discernibleusingconventionalanalyticalapproaches[7].We achievethisbydescribingtheserelationshipsasanetwork of nodes and edges. Graph-based approaches provide a flexibleframeworkforcombiningdiversedatasources,such as sensor data, maintenance records, environmental conditions, and operating parameters. Predictive maintenance systems may effectively identify important failuremodes,prioritizemaintenancetasks,andfindhidden trends by creating a unified graph representation of the underlyingsystemandutilizingtherichdataenvironment.

Graph-based techniques have a wide range of possible applicationsinpredictivemaintenance,whichcanbeutilized in diverse industries such as manufacturing, energy, transportation, healthcare, and utilities [8]. Graph-based models in manufacturing environments can enhance production workflows, efficiently schedule maintenance tasks, and effectively prevent expensive equipment breakdowns[9].Withintheenergyindustry,thesestrategies canimprovethedependabilityofthepowergrid,optimize the performance of assets, and reduce the likelihood of powerfailures.Graph-basedstrategiescanenhancesafety, efficiency,andpassengerpleasureintransportationsystems likerailnetworksoraviationfleets[10].Thisisachievedby identifying possible failure areas and optimizing maintenance schedules. Although graph-based techniques promisebenefits,thereareseveralobstaclesandresearch gaps that require attention. These obstacles encompass

scalability problems in managing extensive industrial networks, difficulties in ensuring data quality and integration,theabilitytointerpretgraph-basedmodels,and the necessity for collaboration between humans and machines in decision-making processes. To tackle these issues,itisnecessarytodointerdisciplinaryresearchthat integratesknowledgefromseveralfields,suchascomputer science, engineering, operations research, and industrial management.

Thispaperseekstoofferanextensiveexaminationofgraphbased methodologies within the framework of cognitive predictive maintenance. Using innovative computational methods, this survey enhances the ongoing discussion on improving asset management and industrial reliability. It achieves this by analyzing existing literature, exploring practicalapplications,andidentifyingfutureresearchareas.

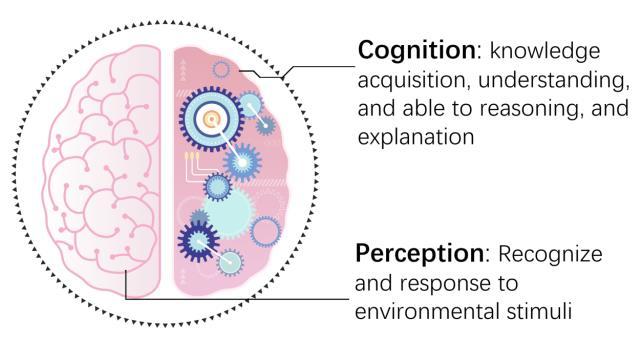

Numerousfieldshaveshownsignificantinterestincognitive intelligence,alsoknownascognitivecomputation,duetoits exceptional abilities in perception, prediction, and explanation[11].Cognitiveintelligence,whichisbased on neuroscience, is motivated by the organization and operationsofthehumanbrain.Thistheorypositsthatthe humanbraincomprisestwofundamentalcomponents.The initialcomponentisresponsibleforperception,discernment, anddecision-making,whilethesubsequentcomponentlinks to more complex cognitive processes such as explanation and reasoning (see Figure 2). Cognitive intelligence is fundamentally characterized by its capacity to grasp intricateinformation,differentiatesubtlecontextualdetails, andextractvaluableinsightsviatheprocessesofcorrelation analysisandcausalinference.Cognitivecomputingsystems strivetorecreatethecognitivecapacitiesofthehumanbrain intheinterpretationandprocessingofenormousquantities ofdatabyimitatingcognitiveprocessesthatarediscernible inhumancognition[12].CognitivePredictiveMaintenance (PdM) is an innovative approach that integrates conventional predictive maintenance methodologies with cognitive intelligence. By utilizing cognitive computing methods, predictive maintenance strategies are improved through the ability of systems to comprehend the information provided, deduce meaning from context, and form conclusions through advanced analysis [13]. Traditional predictive maintenance methods only use historicaldataandstatisticalmodels.CognitivePdM,onthe other hand, uses cognitive intelligence to find hidden patterns,predictwhatwillhappennext,andgivereasonsfor maintenancesuggestions

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

2.1. Graph-based Methods for cognitive Predictive Maintenance

Graph-basedmethods(GbM)offerapromisingapproachto attainingcognitiveintelligencebyleveragingthesemantic associations that establish connections between events, features, samples, and equipment components. Unlike traditional methods that treat data points as separate entities, GbM models consider the complex interdependenciesthatexistwithincomplexsystems.This makes it easier to understand the underlying data environmentonadeeperlevel[14].Oneofthekeybenefits ofGbMisitscapacitytovisualizeandanalyseinformationin theformofnetworksorgraphs.Throughtheutilizationof nodes (which symbolize entities or variables) and edges (whichsymbolizerelationshipsorconnections),GbMoffers a flexible framework that effectively captures complex interdependenciesandinteractionspresentinthedata[15].

The utilization of this graph-based depiction enables the investigationofintricateconnections,enablingtheretrieval ofsignificantobservationsthatmightnotbeevidentusing traditional methodologies. GbM demonstrates exceptional capability in aggregating information from various data sourcesthroughtheutilizationofsemanticassociations.By encoding the meanings of relationships between entities, GbM makes it possible to combine different types of data, suchasstructuredandunstructureddata,sensorreadings, maintenance records, and operational parameters. By integrating all relevant data, this system becomes more holistic, facilitating the generation of more precise predictionsandpracticalinsights.

Furthermore, GbM enables the implementation of sophisticatedmachinelearningandanalyticsfunctionalities, facilitating the construction of predictive models and algorithmsfordetectinganomalies.Theutilizationofgraphbased algorithms, including random walk algorithms and graphneuralnetworks(GNNs),enablesGbMtoaccurately forecastfutureoutcomes,detectcriticalfailuremodes,and unveil latent patterns [16]. The ability to foresee future events facilitates proactive decision-making and preventativemaintenancemeasures,ultimatelyimproving thedependabilityofassetsandtheefficiencyofoperations.

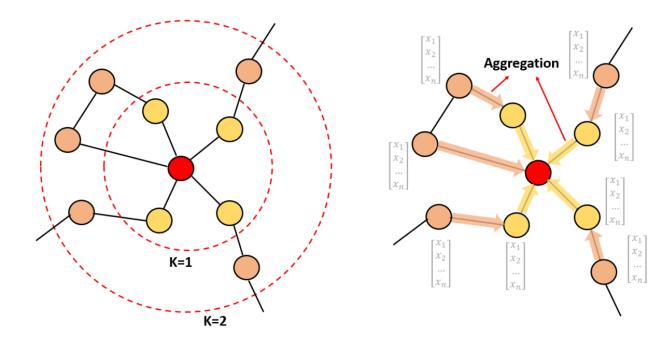

GNNsareasubsetofdeeplearningarchitecturesdesignedto process data in the form of graphs. They have garnered considerableattentionduetotheirabilitytogeneratehighlevel representations by aggregating information from adjacentnodesinagraph(asdepictedinFigure3).GNNscan captureintricateinterdependenciesandinteractionswithin the graph using this aggregation procedure. This enriches the representations to include both local and global information. One can implement the highly adaptable embeddings,whicharerepresentationsderivedfromGNNs, in a variety of subsequent tasks with varying degrees of specificity. At the node level, GNN embeddings encode information about specific entities within the graph. This enables tasks such as node classification, node clustering, andnode-levelpredictiontobeexecuted.GNNembeddings offercomprehensivefeaturerepresentationsthatarehighly suitablefornode-centrictasksduetotheirabilitytocapture thespatialneighbourhoodstructuresurroundingeachnode. GNNs facilitate efficient information aggregation and representationlearningbycapitalizingonthetenetsofdeep learning and graph theory. This has far-reaching implications for various domains, including scientific researchandindustrialapplications[17,18].

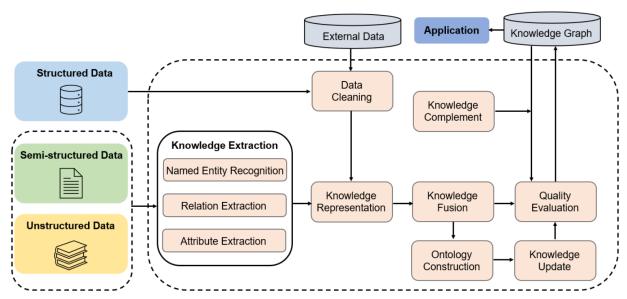

A knowledge graph is a robust framework that uses a graphical structure to integrate and manage data, information, and knowledge in a seamless manner [19]. Fundamentally, a knowledge graph serves as a semantic representationofinterrelatedentities,includingconcepts, events, and objects, encapsulating their complex interrelationshipsandinterdependencies.Asillustratedin Figure 4, the formation of a knowledge graph generally commenceswiththeacquisitionofknowledgefromvarious disparatedata sources.Databases,documents,web pages, sensor data, and other repositories containing structured andunstructuredinformationmaybeamongthesesources. By employing methodologies such as data mining, information retrieval, natural language processing, and informationretrieval,pertinentknowledgeisretrievedfrom theseheterogeneoussourcesandorganizedinastructured fashion that is appropriate for incorporation into the knowledgegraph[20].

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

The establishment of a standardized knowledge representation is critical to guarantee consistency and interoperability across the knowledge graph. Ontology schemas, which establish the formal semantics and interconnectionsamongvariousconceptsandentitieswithin the domain of knowledge, accomplish this [21]. The knowledge graph facilitates efficient data integration, querying, and reasoning by establishing a shared comprehension of the underlying domain and an agreedupon vocabulary through the utilization of an ontology schema. With a graphical framework and semantic depictions, knowledge graphs empower institutions to exploit the abundance of data dispersed among diverse sources(Fig-4).Thisfacilitatesthediscoveryofinvaluable insights and promotes well-informed decision-making acrossawiderangeofdomainsandapplications[22].

After identifying an anomaly in a system, it is critical to conducta comprehensive diagnosis in orderto determine whetherithasthecapabilitytoprogressintofurtherdamage or a complete malfunction in the future. The primary function of diagnosis is to determine the existence of a genuinedefectand,subsequently,identifyitsprecisenature and fundamental origin. A systematic examination of the anomalous behaviour detected in the system constitutes diagnosis. Generally, this procedure commences with a comprehensiveexaminationofthesymptomsdisplayedby the system. These symptoms may consist of anomalous sensor readings, deviations from anticipated performance metrics,oratypicalpatternsinoperationaldata.Througha combination of contextual information regarding the system'soperationalconditionsandhistoricaldata,analysts endeavourtoidentifytheunderlyingcauseoftheanomaly byanalyzingthesesymptoms.

One type of neural network architecture that excels at processinggraph-structureddataistheGraphConvolutional Network, or GCN. The capacity to do convolutional operationsdirectlyinsidethegraphstructureisadefining characteristic of GCNs, allowing them to take use of the intrinsicsimilarityoffeaturesrecordedinthenetwork[23]. By using integrated objective functions, semi-supervised GCNs can use both labelled and unlabeled data for a fault diagnosis.Thisintegrationimprovesthemodel'scapacityto learn from both labelled and unlabeled instances [24].

Labelled instances give unambiguous fault labels, while unlabeled cases provide vital information about the distribution and structure of the underlying data. Considering the weight of distinct samples is vital for effectively representing relationships within the data. To capture the dynamic features and interdependencies between samples, weighted horizontal visibility graphs (WHVG)provideawaytoconverttemporalsignaldataintoa graph format [25]. A WHVG plot shows the horizontal visibility betweensamples, where the weightoftheedges indicates the importance or strength of the association between the samples. To extract discriminative characteristicsforfaultdiagnosis,theauthorsofreference [26] investigated deep learning models that integrated embeddedgraphregularization.Thegoalofthismethodwas toimprovefaultdetectionperformancebymakinguseofthe graph's inherent structure and linkages. By using feature engineeringapproachestoreducethedimensionalityofthe featurespace,thedefectdiagnosticprocedurewasfurther optimized. To extract meaningful features, the suggested discriminantgraphembeddingmethodcombinedthedata's geometricstructurewithlabelinformation,asmentionedin reference[27].Researchersaimedtofindfeaturesthatwere both representative of the data distribution and highly discriminativefordifferentfaultclassesbyinsertingthedata into a discriminant graph space, which takes into considerationboththestructuralpropertiesofthedataand theclasslabels.

Analternativetodata-drivenGNN,KnowledgeGraphs(KG) usecorrelationanalysistofindsystemicflaws.Inaddition, KGscanexplainthecauseoferrorsinawaythatnoother typeofdatacan.WhenKGsarestandardizedconnectedwith real-time heterogeneous industrial data, diagnosis procedures can be applied more effectively in practical manufacturing settings. They also work in tandem with SWRL,orSemanticWebRuleLanguage,toallowfortheearly identification of errors [28]. The process of correlation analysisinKGsentailsscrutinizingtheinterconnectionsand associations between various entities and events that are inscribedwithinthegraph.KGscandetectpotentialdefects ordeviationsfromnormaloperatingconditionsthroughthe identificationofpatterns,trends,andanomaliesthroughthe analysis of correlations among multiple data points. Researchersestablishedarulelibraryinreference[29]with the purpose of associating temporal signal patterns with rules that can be queried within the context of a KG. The operational principle of this mechanism is that dynamic temporal data can be translated or connected to nodes within the KG structure in an efficient manner. The rule library functions as a collection of pre-established regulations that enable the conversion of temporal signal patterns into KG framework-compatible queries. Hidden Markov Models (HMM) were initially proposed as a technique to identify signal patterns for use as querying elementsinaKG,asdescribedinreference[30].Commonly used to model sequential data, HMMs are probabilistic

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

modelsinwhichitispresumedthattheunderlyingsystemis aMarkovprocessinwhichobservedsignalsareinfluenced byhiddenstates.Asaframeworkforgeneratingsimulation results, a KG-based qualitative mechanics theory was introduced in reference [31]. By utilizing the structured knowledgerepresentationofferedbyknowledgegraphs,this methodology simulates, and models intricate mechanical systems. The generation of virtual data that closely resemblesreal-worldobservationsismadepossiblebythe KG-based mechanics theory through the encoding of qualitativerelationshipsamongvarioussystemcomponents, behaviours, and interactions. An important benefit of this methodologyisitscapacitytoquantifythedisparitybetween empirical data obtained from tangible systems and simulated data. The authors of reference [32] utilized a Knowledge Graph (KG) to depict the hierarchical connectionsbetweenapparatuscomponents.ThisKGwas intentionally developed to encompass a wider array of domains and integrate operational factors, in contrast to previousmethodologies.Consequently,itfurnishedanallencompassing depiction of the equipment ecosystem, encompassing operational dependencies as well as structuralrelationships.

Thediagnosticprocedureisenhancedbytheavailabilityofa considerable amount of data, which enables the implementationofeffectiveperformancebyarangeofGNN models,includingGraphAttentionNetworksandFastGCN. TheKGprovidesaccesstoextensivedata,whichenablesthe implementationofsophisticatedalgorithmsthatgobeyond thescopeofsemanticsearchingalone.Bycapitalizingonan abundance of data, GNN models are capable of accurately representing the complex interconnections and reliances thatexistwithinthesystembeingdiagnosed.Forexample, GraphAttentionNetworkshavethecapabilitytoconcentrate on pertinent nodes and edges within the graph, utilizing attentionmechanismstogiveprioritytocriticalinformation whileperformingthediagnosisprocedure.Inthesameway, Fast GCN algorithms have the capability to propagate information across the graph in an efficient manner, enablingthepromptandprecisedeductionofmalfunction conditions or anomalies. In addition, the extensive knowledge base generated from copious amounts of data servesasavaluableresourceforinformingandenhancing diagnosticmodels.Throughtheintegrationofvariousforms ofdata suchasstructureddata,unstructuredtext,sensor readings,andhistoricalrecords diagnosticalgorithmscan acquire resilient representations that intimately comprehend the intricate dynamics of the system. This permits the identification of prospective root causes and contributing factors, in addition to more precise and nuancedfaultdiagnosis.

Withintherealmofhybridmodes,theseriesconfiguration denotesasituationinwhichtwodiscretemethodologiesare implemented consecutively, with one methodology influencingandbeinginfluencedbytheother.Aneffective justification for utilizing the series configuration is the complementary nature of model-based and data-driven approaches, which capitalize on one another's respective advantages. An exemplary instance of this series configurationoccurswhenadata-drivenapproach,suchas BayesianNetworks(BN),isintegratedwithamodel-based approach, specifically adaptive gas path analysis [33]. Furthermore,model-basedresidualsareutilizedasinputs foraRandomForestalgorithm,augmentingthecapabilityto identify defects that were previously unknown [34], in additiontoconventionalmethods.Thismethodologytakes advantageoftheresidualerrorsorinconsistenciesthatarise from model-based techniques when comparing observed and predicted values. By inputting these residuals into a Random Forest model, an algorithm known for its robust ensemble learning capabilities, the system can efficiently detectanomaliesordeviationsfromanticipatedpatternsof operation that could potentially signify the existence of unidentified defects. Furthermore, information already possessedregardingtheapparatuscanbeutilizedtoanalyse the results of black-box models generated by data-driven methodologies[35].Althoughblack-boxmodels,including support vector machines and neural networks, frequently generateprecisepredictions,theyaredifficulttointerpret. AneffectivelytrainedBayesianclassifierthatisdata-driven utilizes a model-based methodology to compute the posterior probability of distinct classes or categories, utilizingthedatathathasbeenobserved.Followingthis,the classifier model is revised through the integration of distinguishing samples, thereby enhancing its capacity to generate precise predictions [36]. Furthermore, a hybrid methodologyintegratescomponentsfromdata-drivenand model-based approaches, where the initial model configuration is regarded as a theoretical deduction supported by empirical evidence. Subsequently, this configurationisrevisediterativelythroughtheincorporation ofnewdata-drivenobservationsintotheclassifier[37].

The utilization of a graph structure to depict the arrangement of equipment is influenced by the idea of representinginterrelatedcomponentsandmechanisms in intricate engineering systems. Each node in the graph corresponds to a specific equipment component, and the edgesreflecttherelationshipsorinteractionsbetweenthese components.Nevertheless,itiscrucialtoacknowledgethat intricateengineeringequipmenttypicallyentailssystemsor reactionsthatfrequentlyencompassmorethanamerepair ofcomponents.Modellingcomplexinteractionseffectivelyin a limited setting can be difficult, unlike in standard graph architectures where edges usually connect two nodes. To tackle this difficulty, it may be necessary to utilize more

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

advancedgraphrepresentations.Hypergraphs,whichenable edges to connect several nodes simultaneously, provide a more expressive framework for representing intricate relationshipsinsideengineeringsystems[38].Hypergraphs provideamorecomprehensiveandpreciserepresentation oftheconnectionsandrelationshipsbetweencomponentsin theequipmentstructurebyincorporatinghyperedgesthat canlinkmultiplenodes.Traditionaldata-drivenintelligent faultdiagnosismethodsfrequentlyencounterconstraintsin their ability to completely exploit the correlation and geometricstructure information thatare intrinsicin large volumesofunlabeledindustrialdata.Consequently,itmay be difficult for these methods to produce adequate fault diagnosisresults.Inresponsetothisdifficulty,scholarshave suggestedastreamlinedmethodfordefectdiagnosiscalled deephypergraphautoencoderembedding(DHAEE),whichis elaborated upon in reference [39]. By capitalizing on the capabilities of deep learning and hypergraph embedding methods, this approach surpasses the constraints of conventionalmethodologiesandattainssuperiorprecision in defect diagnosis outcomes. A novel algorithm called a multiresolutionhypergraphneuralnetworkispresentedin reference [40]. Its objective is to extract latent structures from data and reveal higher-order complex relationships between samples. By establishing and integrating hypergraphstructuresatmultipleresolutions,thisalgorithm enablesanexhaustiveinvestigationoftheunderlyingdata topology.Table1givestheanalysisofthisliteraturesurvey.

Refer ence Contribu tion Techniqu e used

[23] GCNsfor fault diagnosis

Graph Convolutio nal Networks (GCNs), semisupervised learning.

[24] Integrati onof objective functions

[25] WHVG for capturing dynamic features

Advantages

Abilityto leverage bothlabelled and unlabeled data. Improved learning capacity.

Semisupervised GCNs -Enhanced learning fromboth labelledand unlabeled instances

Weighted Horizontal Visibility Graphs (WHVGs) Effective representati onof temporal signaldata asgraphs

[26] Deep learning with embedde dgraph regulariz ation Graph regularizat ion, feature engineerin g

Improved fault detection performance

Challenges

Relianceon availabilityof labelleddata. Complexityof GCN architecture.

Potentialbiasin labelleddata. Complexityof integrated objective functions

Interpretability ofWHVGplots. Sensitivityto noiseinsignal data

Complexityof deeplearning models.Needfor extensivetuning andoptimization

[27] Discrimi nant graph embeddi ngfor feature extractio n

[28] Utilizatio nof Knowled ge Graphs forfault diagnosis

[29] Establish mentof rule library for temporal signal patterns

[30] Applicati onof Hidden Markov Models (HMM) forsignal pattern identifica tion

[31] Introduct ionof KG-based qualitativ e mechanic stheory

Discrimina ntgraph embedding

[33] Integrati onof Bayesian Network swith adaptive gaspath analysis

[36] Training of Bayesian classifier using modelbased methodol

Extractionof meaningful features representati veofdata distribution

Correlatio nanalysis, Semantic WebRule Language (SWRL)

Rule-based association , Knowledge Graphs

Hidden Markov Models (HMM), probabilist ic modeling

Qualitative mechanics theory, Knowledge Graphs

Abilityto explain errors effectively. Effective integration withrealtime industrial data

Efficient translation ofdynamic temporal datatoKG queries

Effective modelingof sequential data. Captureof hidden states influencing observed signals

Simulation and modelingof intricate mechanical systems. Generation ofvirtual data resembling real-world observations

Bayesian Networks (BN), adaptive gaspath analysis

Complement arynatureof model-based anddatadriven approaches. Augmented defect identificatio n capabilities

Potential overfitting. Sensitivityto chooseofgraph embedding method

ComplexityofKG constructionand standardization. Limited scalabilitywith largedatasets

Dependencyon pre-established rules.Limited flexibilityin querying dynamicdata

Complexityof HMMtraining andinference. Sensitivityto model assumptionsand parameter settings

Complexityof qualitative mechanics theory. Challengesin quantifying disparity between empiricaland simulateddata

Complexityof integrating disparate methodologies. Potential challengesin model calibrationand validation

Bayesian classifier, modelbased methodolo gy

Utilizationof model-based methodology for computing posterior probabilities .Revisionof

Dependencyon accuratemodelbased information. Potential overfittingor underfittingof classifier.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

ogy classifier modelfor improved precision

[38] Introduct ionof hypergra phsfor equipme nt structure represen tation

[40] Introduct ionof multireso lution hypergra phneural network

Hypergrap hs More expressive framework for representing complex interactions. Comprehens ive representati onof connections between components

Multiresol ution analysis, Hypergrap hs

Extractionof latent structures andhigherorder relationships .Exhaustive investigation ofdata topology

Complexityof hypergraph construction. Limited familiarityand adoptionin engineering applications

Complexityof algorithm implementation. Potential scalabilityissues withlarge datasets

Table1:Analysisofliteraturesurvey.

5. Conclusion

Evidently,faultdiagnosisincomplexengineeringsystemsis a multifaceted challenge requiring novel approaches to effectively leverage available data and reveal concealed patternsandrelationships,asdemonstratedbytheliterature review that was presented. By employing graph-based representations,suchashypergraphs,itispossibletomodel with precision the complex interconnections and configurations of equipment components within these systems.Byincorporatingsophisticatedmethodologieslike deep learning and hypergraph embedding, it becomes possible to extract latent structures and higher-order relationships from data. This enhancement significantly improves the accuracy and efficiency of defect diagnosis. Methods such as multiresolution hypergraph neural networks and deep hypergraph autoencoder embedding (DHAEE)illustratethepotentialofintegratingdeeplearning techniques with hypergraph-based representations to surpass the drawbacks of conventional data-driven approaches and attain enhanced fault diagnosis results. Furthermore,byleveragingthecomplementaryqualitiesof model-basedanddata-drivenapproaches,theinvestigation of hybrid methodologies that combine the two improves diagnosticcapabilitiesevenfurther.Theseriesconfiguration, which integrates adaptive gas path analysis and Bayesian Networks, serves as an illustration of the synergistic advantages that can be obtained by combining various methodologiestoimprovethereliabilityoffaultdiagnosis. Recognizing the difficulties linked to these methods is crucial, such as the intricate process of implementing

algorithms,therequirementforabundanttrainingdata,and the possibility of encountering scalability problems when dealingwithhugedatasets.Furthermore,theunderstanding and incorporation of outcomes from black-box models producedbydata-drivenapproachespresentdifficultiesin termsofcomprehensibilityanddependability.

[1] B.Xu,Z.Wang,W.Luo,T.Ma,andH.Huang,“AResearch ontheCombinedMaintenanceStrategyforProduction Line Equipment Based on Mixed Failure Rate,” Mathematical Problems in Engineering,vol.2021,pp.1–15,Feb.2021,doi:10.1155/2021/8856279.

[2] [1] M. M. Hamasha et al., “Strategical selection of maintenancetypeunderdifferentconditions,” Scientific Reports,vol.13,no.1,Sep.2023,doi:10.1038/s41598023-42751-5.

[3] D.E.Ighravwe,“AssessmentofSustainableMaintenance StrategyforManufacturingIndustry,” Sustainability,vol. 14, no. 21, p. 13850, Oct. 2022, doi: 10.3390/su142113850.

[4] T. P. Carvalho, F. A. A. M. N. Soares, R. Vita, R. da P. Francisco, J. P. Basto, and S. G. S. Alcalá, “A systematic literaturereviewofmachinelearningmethodsappliedto predictive maintenance,” Computers & Industrial Engineering, vol. 137, p. 106024, Nov. 2019, doi: 10.1016/j.cie.2019.106024.

[5] V.Poosapati,V.Katneni,V.K.Manda,andT.L.V.Ramesh, “Enabling Cognitive Predictive Maintenance Using Machine Learning: Approaches and Design Methodologies,” Advances in Intelligent Systems and Computing,pp.37–45,2019,doi:10.1007/978-981-133393-4_5.

[6] G.Fenza,M.Gallo, V.Loia,D. Marino,andF. Orciuoli,“A CognitiveApproachbasedontheActionableKnowledge Graph for supporting Maintenance Operations,” 2020 IEEE Conference on Evolving and Adaptive Intelligent Systems (EAIS), May 2020, Published, doi: 10.1109/eais48028.2020.9122759.

[7] E. W. Zegura, K. L. Calvert, and M. J. Donahoo, “A quantitative comparison of graph-based models for Internet topology,” IEEE/ACM Transactions on Networking, vol. 5, no. 6, pp. 770–783, 1997, doi: 10.1109/90.650138.

[8] Y.Jiang,P.Dai,P.Fang,R.Y.Zhong,andX.Cao,“ElectricalSTGCN: An Electrical Spatio-Temporal Graph Convolutional Network for Intelligent Predictive Maintenance,” IEEE Transactions on Industrial Informatics, vol.18, no.12, pp.8509–8518,Dec.2022, doi:10.1109/tii.2022.3143148.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

[9] J.Weise,S.Benkhardt,andS.Mostaghim,“ASurveyon Graph-basedSystemsinManufacturingProcesses,” 2018 IEEE Symposium Series on Computational Intelligence (SSCI), Nov. 2018, Published, doi: 10.1109/ssci.2018.8628683.

[10] L. Wenhui, C. Fengtian, W. Chuna, and M. Xingkai, “Bayesian Network-Based Knowledge Graph Inference for Highway Transportation Safety Risks,” Advances in Civil Engineering, vol. 2021, pp. 1–11, Mar. 2021, doi: 10.1155/2021/6624579.

[11] M. Chen, F. Herrera, and K. Hwang, “Cognitive Computing: Architecture, Technologies and Intelligent Applications,” IEEE Access, vol. 6, pp. 19774–19783, 2018,doi:10.1109/access.2018.2791469.

[12] I. Otero, J. F. Salgado, and S. Moscoso, “Cognitive reflection,cognitiveintelligence,andcognitiveabilities:A meta-analysis,” Intelligence,vol.90,p.101614,Jan.2022, doi:10.1016/j.intell.2021.101614.

[13] V.Rousopoulou,A.Nizamis,T.Vafeiadis,D.Ioannidis, andD.Tzovaras,“Predictive MaintenanceforInjection Molding Machines Enabled by Cognitive Analytics for Industry 4.0,” Frontiers in Artificial Intelligence, vol. 3, Nov.2020,doi:10.3389/frai.2020.578152.

[14] F. Farbiz, Y. Miaolong, and Z. Yu, “A Cognitive Analytics based Approach for Machine Health Monitoring, Anomaly Detection, and Predictive Maintenance,” 2020 15th IEEE Conference on Industrial Electronics and Applications (ICIEA), Nov. 2020, Published,doi:10.1109/iciea48937.2020.9248409.

[15] M. Liu, X. Li, J. Li, Y. Liu, B. Zhou, and J. Bao, “A knowledgegraph-baseddatarepresentationapproachfor IIoT-enabled cognitive manufacturing,” Advanced Engineering Informatics, vol. 51, p. 101515, Jan. 2022, doi:10.1016/j.aei.2021.101515.

[16] Y. Dong, J. Kang, H. Tong, and J. Li, “Individual FairnessforGraphNeuralNetworks,” Proceedingsofthe 27th ACM SIGKDD Conference on Knowledge Discovery & Data Mining, Aug. 2021, Published, doi: 10.1145/3447548.3467266.

[17] C. W. Coley et al., “A graph-convolutional neural networkmodelforthepredictionofchemicalreactivity,” Chemical Science,vol.10,no.2,pp.370–377,2019,doi: 10.1039/c8sc04228d.

[18] D.Wang et al.,“ASemi-SupervisedGraphAttentive Network for Financial Fraud Detection,” 2019 IEEE International Conference on Data Mining (ICDM), Nov. 2019, Published,doi:10.1109/icdm.2019.00070.

[19] X. Chen, S. Jia, and Y. Xiang, “A review: Knowledge reasoning over knowledge graph,” Expert Systems with

Applications, vol. 141, p. 112948, Mar. 2020, doi: 10.1016/j.eswa.2019.112948.

[20] D.Fensel et al.,“Introduction:WhatIsaKnowledge Graph?” Knowledge Graphs, pp. 1–10, 2020, doi: 10.1007/978-3-030-37439-6_1.

[21] K.Wiharja,J.Z.Pan,M.J.Kollingbaum,andY.Deng, “SchemaawareiterativeKnowledgeGraphcompletion,” Journal of Web Semantics,vol.65,p.100616,Dec.2020, doi:10.1016/j.websem.2020.100616.

[22] T. Shen, F. Zhang, and J. Cheng, “A comprehensive overview of knowledge graph completion,” KnowledgeBased Systems, vol. 255, p. 109597, Nov. 2022, doi: 10.1016/j.knosys.2022.109597.

[23] T. Li, Z. Zhao, C. Sun, R. Yan, and X. Chen, “MultireceptiveFieldGraphConvolutionalNetworksfor MachineFaultDiagnosis,” IEEETransactionsonIndustrial Electronics,vol.68,no.12,pp.12739–12749,Dec.2021, doi:10.1109/tie.2020.3040669.

[24] X. Zhao, M. Jia, and Z. Liu, “Semisupervised Graph ConvolutionDeepBeliefNetworkforFaultDiagnosisof Electormechanical System with Limited Labeled Data,” IEEETransactionsonIndustrialInformatics,vol.17,no.8, pp. 5450–5460, Aug. 2021, doi: 10.1109/tii.2020.3034189.

[25] C.Li,L.Mo,andR.Yan,“FaultDiagnosis ofRolling BearingBasedonWHVGandGCN,” IEEETransactionson Instrumentation and Measurement, vol. 70, pp. 1–11, 2021,doi:10.1109/tim.2021.3087834.

[26] C. Yang, J. Liu, K. Zhou, X. Jiang, and X. Zeng, “An improved multi-channel graph convolutional network and its applications for rotating machinery diagnosis,” Measurement, vol. 190, p. 110720, Feb. 2022, doi: 10.1016/j.measurement.2022.110720.

[27] Z. Hu, J. Peng, and H. Zhao, “Uncorrelated discriminant graph embedding for fault classification,” The Canadian Journal of Chemical Engineering, vol.99, no.S1,Mar.2021,doi:10.1002/cjce.24045.

[28] Q.Cao etal.,“KSPMI:AKnowledge-basedSystemfor Predictive Maintenance in Industry 4.0,” Robotics and Computer-IntegratedManufacturing,vol.74,p.102281, Apr.2022,doi:10.1016/j.rcim.2021.102281.

[29] S. Wang, J. Wan, D. Li, and C. Liu, “Knowledge Reasoning with Semantic Data for Real-Time Data Processing in Smart Factory,” Sensors, vol. 18, no. 2, p. 471,Feb.2018,doi:10.3390/s18020471.

[30] Q. Zhou, P. Yan, H. Liu, and Y. Xin, “A hybrid fault diagnosismethodformechanicalcomponentsbasedon ontology and signal analysis,” Journal of Intelligent

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN: 2395-0072

Manufacturing,vol.30,no.4,pp.1693–1715,Aug.2017, doi:10.1007/s10845-017-1351-1.

[31] L. Wang, J. Hodges, D. Yu, and R. S. Fearing, “Automatic modeling and fault diagnosis of car production lines based on first-principle qualitative mechanics and semantic web technology,” Advanced Engineering Informatics,vol.49,p.101248,Aug.2021, doi:10.1016/j.aei.2021.101248.

[32] J. Qiu, Q. Du, K. Yin, S.-L. Zhang, and C. Qian, “A CausalityMiningandKnowledgeGraphBasedMethodof RootCauseDiagnosisforPerformanceAnomalyinCloud Applications,” Applied Sciences, vol. 10, no. 6, p. 2166, Mar.2020,doi:10.3390/app10062166.

[33] A.Fentaye,V.Zaccaria,M.Rahman,M.Stenfelt,andK. Kyprianidis, “Hybrid Model-Based and Data-Driven DiagnosticAlgorithmforGasTurbineEngines,” Volume5: Controls, Diagnostics, and Instrumentation; Cycle Innovations; Cycle Innovations: Energy Storage, Sep 2020, Published,doi:10.1115/gt2020-14481.

[34] D.Jung,“EngineFaultDiagnosisCombiningModelbased Residuals and Data-Driven Classifiers,” IFACPapersOnLine, vol. 52, no. 5, pp. 285–290, 2019, doi: 10.1016/j.ifacol.2019.09.046.

[35] J.Grezmak,J.Zhang,P.Wang,K.A.Loparo,andR.X. Gao, “Interpretable Convolutional Neural Network ThroughLayer-wiseRelevancePropagationforMachine FaultDiagnosis,” IEEE Sensors Journal,vol.20,no.6,pp. 3172–3181, Mar. 2020, doi: 10.1109/jsen.2019.2958787.

[36] M.A.AtouiandA.Cohen,“Couplingdata-drivenand model-based methods to improve fault diagnosis,” ComputersinIndustry,vol.128,p.103401,Jun.2021,doi: 10.1016/j.compind.2021.103401.

[37] W.Luo,T.Hu,Y.Ye,C.Zhang,andY.Wei,“Ahybrid predictivemaintenanceapproachforCNCmachinetool driven by Digital Twin,” Robotics and ComputerIntegratedManufacturing,vol.65,p.101974,Oct.2020, doi:10.1016/j.rcim.2020.101974.

[38] L. Xia, Y. Liang, P. Zheng, and X. Huang, “ResidualHypergraph Convolution Network: A Model-Based and Data-DrivenIntegratedApproachforFaultDiagnosisin Complex Equipment,” IEEE Transactions on Instrumentation and Measurement, vol. 72, pp. 1–11, 2023,doi:10.1109/tim.2022.3227609.

[39] M. Shi et al., “Deep hypergraph autoencoder embedding:Anefficientintelligentapproachforrotating machineryfaultdiagnosis,” Knowledge-BasedSystems,vol. 260, p. 110172, Jan. 2023, doi: 10.1016/j.knosys.2022.110172.

2024, IRJET | Impact Factor value: 8.226 |

[40] X. Yan, Y. Liu, and C.-A. Zhang, “Multiresolution Hypergraph Neural Network for Intelligent Fault Diagnosis,” IEEE Transactions on Instrumentation and Measurement, vol. 71, pp. 1–10, 2022, doi: 10.1109/tim.2022.3212532.