International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | APR 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | APR 2024 www.irjet.net p-ISSN: 2395-0072

Rahul Kapse

1

, Vaishnavi Mudkanna

2

, Jay Jadhav3 , Prachi Bhoinallu4 , Prerana Jogdand

5

, Mansi Jadhav6

1Assistant Professor Civil Engineering, RMD Sinhgad School of Engineering, Warje, Pune, Maharashtra, India

2Student Civil Engineering, RMD Sinhgad School of Engineering, Warje, Pune, Maharashtra, India

3Student Civil Engineering, RMD Sinhgad School of Engineering, Warje, Pune, Maharashtra, India

4Student Civil Engineering, RMD Sinhgad School of Engineering, Warje, Pune, Maharashtra, India

5Student Civil Engineering, RMD Sinhgad School of Engineering, Warje, Pune, Maharashtra, India

6Student Civil Engineering, RMD Sinhgad School of Engineering, Warje, Pune, Maharashtra, India

Abstract – Sisal fiber is a natural and sustainable material that has gained attention in recent years due to its various applications in different industries. This abstract focuses on the development of wall panels or sheets using sisal fiber as a primarycomponent. Thedevelopmentprocessinvolvesseveral steps, starting with the extraction of sisal fibers from the leaves of the Agave sisal an a plant. These fibers are then cleaned, dried, and processed to remove impurities and enhance their strength and durability. Various treatments, such as chemical or mechanical methods, can be employed to modify the properties of the fibers to suit specific requirements. Next, theprocessedsisalfibersaremixedwitha suitable binder, such as a polymer or cement-based material, to form a composite material. The fiber-to-binder ratio and other additives can be adjusted to achieve the desired mechanical properties, such as strength, flexibility, and fire resistance. The composite mixture is then molded into the desired shape and size using techniques like compression molding or extrusion. The panels or sheets can be further enhanced by incorporating additional materials, such as fillers, reinforcements, orpigments, toimprovetheiraesthetic appeal and functional characteristics. The developed sisal fiber-basedwallpanelsorsheetsofferseveraladvantagesover traditional materials. Firstly, sisal fiber is renewable and biodegradable, making it an environmentally friendly alternative to synthetic materials. Additionally, sisal fiber exhibits excellent thermal and acoustic insulation properties, contributing to energy efficiency and noise reduction in buildings. Thepanelsalsopossessgoodimpactresistanceand can withstand harsh weather conditions. Furthermore, sisal fiber-based wall panels or sheets can be easily installed and maintained. They can be customized to meet specific design requirements and can be painted or coated with different finishes to match various architectural styles.

Key Words: Sisal Fiber, Sustainable Material, Wall Panels, Composite Material, Biodegradable

The Sisal fiber has been widely used as a reinforcement material in various applications, including composite materialsandcementcomposites.Theuseofsisalfiberas reinforcementinconstructionmaterialsiswell-knowninthe somepriorart.Useofresinmatrixtobindsisalfibersina composite panel is a well-known technique in the field of fiber-reinforcedcomposites.Thecombinationofsisalfibers andresinmatrixisanobviouschoiceforcreatingastrong andlightweightpanel.

Sisalisthenaturalfibersextractedfromtheleavesofsisal plant.Sisalfiberisahighlypliablematerialwithhighaspect ratio.Currently, there isa bigattentionin maximizingthe utilizationofleaf-basedfibersforconventionalandtechnical applicationsbecauseoftheirsustainabilityFeatures.

Themainadvantagesofcompositematerialsaretheirhigh strength and stiffness, combined with low density, when compared with bulk materials, allowing for a weight reduction in the finished part. Natural fibers have special appeal in the fieldofcivil engineering. The costof natural fibersisexpectedtobepricecompetitive.Theadvantagesof natural fibers materials are strength, better durability, competitive cost, environmental compatibility and bio degradability.

By incorporating sisal fiber into wall panels/sheets, the mechanicalpropertiesofthesematerialscanbeenhanced. Sisalfiberhashightensilestrengthandstiffness,whichcan improve the overall strength and durability of the panels/sheet.Sisalfiberisrelativelylow-costcomparedto otherreinforcingmaterialslikeglassorcarbonfibers.This can potentially lower the production costs of wall panels/sheets,makingthemmoreaffordableandaccessible forconstructionprojects.

Overall,theuseofsisalfiberasareinforcingmaterialinwall panels/sheets represents an innovative step towards sustainableconstruction.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | APR 2024 www.irjet.net p-ISSN: 2395-0072

Rabi[1] Thepresentstudywascarriedoutasanattemptto produce durable fiber-cement roofing tiles (approximate dimensions: 500 mm long, 275 mm wide, 8 mm thick) by slurry dewatering technique and using sisal (Agave) Kraft pulpasreinforcement.Effectsofacceleratedcarbonationon physical and mechanical performances of vegetable fiber reinforcedcementationstileswereevaluatedalongwiththeir consequent behaviors after ageing. Cement raw materials mixture was prepared with approximately 40% of solids (comprising 4.7% sisal pulp, 78.8% cement, and 16.5% groundcarbonatematerial).

Ramakrishna et.al[2] Based on the comprehensive experimentalinvestigationscarriedoutandontherangeof various parameters considered in the this study, are summarizedbelow:Sisalfiberscorrugatedroofingsheetsof (mortar / composites) couldn’t match the high strength exhibitedbythecommercialtypecorrugatedroofingsheet considered in this study, with respect to the flexural and splittingloadsandwithintherangeofsisalfiberscontents(0 -2%)andflyashcontents(0-30%)considered.

Reddy[3]Inthestudyherein,theapplicabilityofjutetextile FRP as a strengthening material was investigated through variousexperimentalworksofmechanicalcharacterization oftheFRP,andstrengtheningeffectsprovidedbybondingof jutetextileFRPtobeamsoverbondingofcarbontextileFRP andglasstextileFRP.

Vijaychandrakanth[4]Thestudyofthisinvestigationwasfind outthebehaviorofsisalfiberinconcrete,therebyoptimum amountofsisalfiberthatcanbeusedinvariousapplication suchas pavements, industrial floors, etc. thus enhance the concretequality.

Kavin[5]Theyinventedtheinfluenceofsisalfibersonthe minimizingofplasticshrinkageinthepre-hardenedstate,on tensile,compressiveandbendingstrengthinthehardened stateofmortarmixesimproved.Developmentofproduction techniquesformanufacturekeepinginviewthatitmustbe cost-effective. Physical and mechanical properties, impact and abrasive resistance, water absorption, shrinkage, chemical resistance, acoustic requirements, thermal performance and durability of sisal fibers cement based productsshouldbethoroughlyevaluatedsoastoarriveata seriesofcompositestobeusedinruralandcivilconstruction. Design procedures must also be standardized. The results show that the composites reinforced with sisal fibers are reliablematerialstobeusedinpracticefortheproductionof structuralelementstobeusedinruralandcivilconstruction.

Josephet.al[6]Experimentalcharacterizationofsisalfibers reinforcedconcreteshowedthatincorporatingfibersintothe concretemixtureisbeneficial.Optimumperformancefora matrix having sisal fibers as reinforcement is at 3% fibers

volume fraction, with 70mm fibers length and at a water cementratioof0.6.

Augustineet.al[7]Thermalconditioningofwovensisalfibers wascarriedout,followedbythedevelopmentofwovensisal fibersreinforcedpolymercompositesystem,anditstensile andflexuralbehaviorwascharacterized.Itwasobservedthat thermalconditioningimprovedthetensilestrengthandthe flexuralstrengthofthewovensisalfiberscomposites,which were observed to bear superior values than those in the untreatedones.

Reddyet.al[8]Theyinventedthe,Concretereinforcedwith sisalfibersandusingIraqibauxiteexhibitedimprovementin flexuralstrengthandsplittingtensilestrengthwhileasmall reduction in compressive strength was reported. The addition of sisal fibers improved the flexural strength and splitting tensile strength ofplain concrete. The increasein flexural strength at age of 28 day represented by (7.7%, 13.6%and9.1%)forconcretereinforcedwithsisalfiberwith (0.5%,1.0%and1.5%)respectivelyandatageof90daythe improvement in flexural strength represented by (15.3%, 16% and 5.2%) for the same percentage of fibers respectively.

Rawi [9] He invented the study of sisal fibers as concrete reinforcementmaterialincementbasedcomposites.Abrief description on the use of the cement based composite materials as building products has been included. The influenceofsisalfibersontensile,compressiveandbending strength in the hardened state of mortar mixes was discussed.Thedurabilityofnaturalfibersincementbased matriceswasofparticularinterestandwasalsohighlighted. From the hysteresis stress-strain curves it was noticed no signsofdegradationformaximumstresslevel.Formaximum stresslevels;therewasanincreaseinthehysteresisareaand decreaseintheYoung´smodulus.

1. To develop a systematic approach forfabricating construction components from sisal fibers.

Tofabricatethesisalfiberscompositeepoxymatrixisused. This fabrication will be carried either by vacuum bagging techniqueorhandlayuptechniqueasbothgivesgoodresult.

2. To fabricate and test plate type structure panel. The panel of sisal fibers will be fabricated by using epoxy matrix. The fabricated panels will be tested for Impact strength,FlexuralstrengthandAxialstrength.Theproperties ofsisalpanelwillbecomparedwithplywoodpanelofsame sizei.e.30cmX30cm.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | APR 2024 www.irjet.net p-ISSN: 2395-0072

3. To fabricate and test plate type structure of box beam and rod.

The sisal fibers box beam and rod composite will be fabricated.ThecompositewillbetestedforFlexuralstrength andAxialstrength.

4. To develop process for various application for low cost housing, rapid housing, interior decoration etc.

Makingsisalfibersfabricationlikeboxes,rodsandpanelare developedbyusingEpoxychemical.Thepanelsaredirectly make from by vacuum bagging technique or hand layup technique different size of panels will be made depend on theirrequirementinparticularapplication.Forroofpanelby usingbambooframe,inthatframethatpanelisplacedand theyareusedasroofsheet.Alsoforboxandrodwecanuse emptyboxesorrodandabovethatsisalfibrecompositewill placedorpackedthatequipment.Afterthatweonlyremove thatboxorrodthenwewillgetthatparticularshapedboxor rod.Thatshapedboxorrodofsisalfiberscompositeisthen wecanusedfordecoratedpurposeasinterior.

4. Materials and Methodology

4.1Materials

1. Sisal fiber: Sisalisavegetablefiberthatcomesfromthe leavesoftheAgavesisalanaplant.Sisalisastrong,coarse, and inflexible fiber witha toughtexture.It'sknown for its highstrength,durability,andabilitytostretch.Sisalhasareal densityof1.45g/cm,anapparentdensityof1.20g/cm,anda porosityof17%.It'salsoknownforitsresistancetowear, acid,base,andcorrosion.

2. Epoxy resin:Epoxy resins are a class of thermosetting polymersthatcontainatleasttwoepoxidegroups.Theyare tough,chemicallyresistant,andhavestrongadhesion.Epoxy resins are used in a variety of consumer and industrial products.Epoxyresinsaremadebyreactingepichlorohydrin (ECH)andbisphenol-A(BPA).Otherrawmaterials,suchas aliphaticglycols,phenol,ando-cresolnovolacs,canbeused toproducespecialtyresins.Epoxyresinscanbeobtainedin eitherliquidorsolidstates.Epoxyresinsareusedinmany industries,includingmanufacturingandconstruction.

3.Hardener: Epoxyhardeners,alsoknownascuringagents orcatalysts,arechemicalcompoundsthathelpepoxyresins cross-link.Whenmixedwithliquidepoxyresins,hardeners start thecuring process,whichtransformsthe resinintoa durable, solid material. Epoxy hardeners are made from a polycarboxylicanhydridethatissyntheticallycompounded withrenewableresources.Somecommoncuringagentsfor epoxyresinsinclude:Polyamines,Polyamides,Organicacids, Anhydrides,Borontrifluoride,Tertiaryaminecatalysts.

1.MaterialSelection:Identifythetypeofsisalfibertobeused (natural or treated), determine the appropriate resin or binderforthecompositematerial,andselectanyadditional additivesforenhancingproperties.

2.FiberTreatment:Ifusingnaturalsisalfiber,itmayneedto be treated to improve its compatibility with the resin. Treatmentssuchasalkalitreatmentorsurfacemodification canbeconsidered.

3.Composite Formulation: Determine the optimal ratio of sisalfibertoresin/binder,aswellasanyadditives,fillers,or reinforcementstobeincludedinthecompositematerial.

4.Mixing Process: Mix the sisal fiber with the resin/binder and any other additives using appropriate equipment and techniquestoensureuniformdistributionandgoodbonding betweenthecomponents.

5.MoldingProcess:Chooseasuitablemoldingtechnique(e.g., compression molding, injection molding) to form the wall panels/sheets.Applypressureandheatasneededtoachieve properconsolidationandcuringofthecompositematerial.

6.Testing and Evaluation: Conduct tests to assess the mechanical properties (e.g., tensile strength, flexural strength),thermalandacousticinsulationproperties,impact resistance, and other relevant characteristics of the developedwallpanels/sheet.

5.1. Impact resistance test on surface of sisal fibre composite sheet

Thecapabilityofthematerialtowithstandsuddenlyapplied loadisitsimpactstrength.Thecompositesheetof30cmx 30cm and thickness 8mm was tested using a Impact test setup.Thissetupcontainssteelballanddialgauge.Thepanel is simply supported at four corners. The steel ball of 5cm diameterandweight450gm.isdroppedfrom100cmheight.

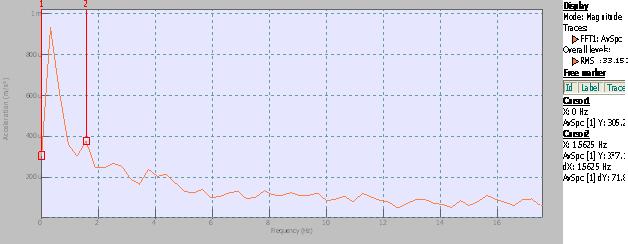

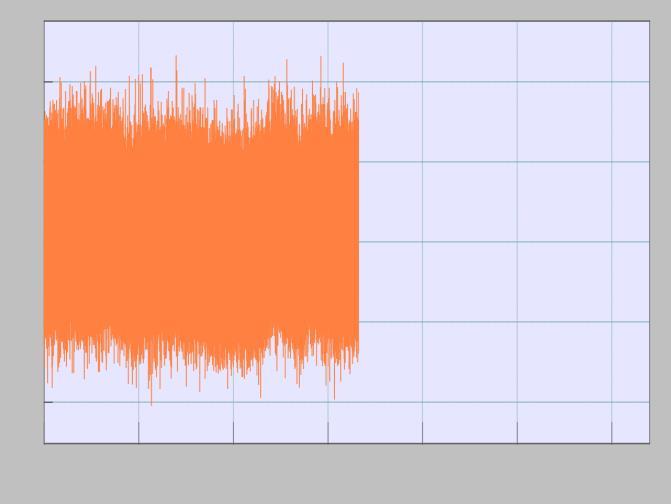

5.2. Sound Absorption test on Sisal fibre Composite panel

Sisal fibre composite and Plywood of size 30 X 30 cm and thickness8mmweretestedforsoundabsorptiontestusing FFTAnalyzer.FastFouriertransformequipmentisusedto measurethesoundfrequencypassingthroughtheSisalfibre composite.Thisequipmentishavingthemicrophoneatits tipwhichabsorbssoundwavesandgeneratesthegraphof AcousticspressurevsTimefortheabsorbedsoundSisalfibre compositeofsize30X30cmistakenfortheexperimentation on. On one side of Panel the circular pipe is kept through whichsoundistransmittedinproperchannel.Ontheother sidemicrophoneisplacedwhichisverysensitive.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | APR 2024 www.irjet.net p-ISSN: 2395-0072

5.3 Test for bending on Sisal fibre composite and plywood:

The Sisal fibre composite panels are prepared in size 20x 50cmandplywoodsheetsofsamesizeareprepared.These panels are tested under Flexural Testing Machine so as to calculate the bending strength and deflection of both the panels.ThedeflectionismeasuredbyusingtheDialGaugesof 0.01mmleastcount.Thepanelsfabricatedaretestedunder theFTMtomeasurethemaximumloaditcansustainunder the bending. Thus using the parameters such as Load and Deflection of the tested panel the Flexural rigidity is calculated.

1. Impact resistance test on surface of sisal fibre composite sheet

Deflectionsatfourdifferentpointsafterfreefallofsteelball onSisalFibreComposite:

4. Test for Determination of moisture content in Sisal Fibre Composite block

2. Sound Absorption test on Sisal fibre Composite panel: FFT analyzer

The fabrication and experimentation of Natural sisal fiber compositeiscarriedout.Theworkinthisthesisiscarriedout in two parts. first part is focused on fabrication of natural fiber composite material, whereas in second part, experimentation of fabricated composite is carried out, in which tensile and shear strength and flexural strength of compositeisdetermined,alsotensilestrengthofbeamsand stripsiscalculated.

Followingconclusionsaredrawnfromthework:

1.Fabricationprocessofnaturalfiberreinforcedcompositeis developedtofabricatethesisalfiberreinforcedcomposite. Thehandlay-uptechniqueisusedforfabrication.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | APR 2024 www.irjet.net p-ISSN: 2395-0072

2.Experimental work is carried out to find the Structural strengthofplate,beams,andstripsalsobondingstrengthof composite.TheStructuralpropertiessuchastensilestrength, flexuralstrengthandimpactstrengtharecalculated.These experimental results are compared with the result of plywoodforitsstrength.Theflexuralstrengthofsisalfibreis compositetakes351.56N/mm2loadsthatofplywoodpanel is117.18N/mm2.

3.ThepanelsfabricatedusingSisal fibreCompositeexhibit morestrength,Impactresistanceandflexibilityascompared to the plywood of same size and thickness. The deflection developed in the Sisal fibre Composite panel was more as compared to the plywood but there were no cracks developedatthepointofmaximumdeflection.

4.Thepanelsareverygoodinsoundabsorptionascompared totheplywood.WhensoundwaspassedthroughtheSisal fibre Composite panel and the plywood, the Sisal fibre Compositepanelshows30%moresoundabsorptioncapacity thanplywood.

5.ThematerialsusedinfabricationofSisalfibreComposite panelsareofmuchcheapercost.Thepanelscostalmost10% to15%lessthanplywoodofsamethickness.Thepersquare ft rate of Sisal fibre Composite panel is 310 Rs whereas Waterproof plywood of same thickness costs 420 Rs per squareft.

Currentstudyaboutfabricationanddevelopmentofnatural fibercompositematerialresultedinfollowingfuturework:

1. There is wide scope to study or compare the surface treatmenteffectonfibersurfacewithchemicalormechanical processoftreatment.

2. There is wide scope to study strength of single fiber as thereisvariationobservedfromliterature.

TheauthorswouldliketothankDr.P.M.AlandkarHeadofthe Civil Engineering Department RMD Sinhgad School of EngineeringWarjePune,fortheirkindsupportandproviding good infrastructure. The authors are also grateful for her encouragementandsupport.

[1] P. Parandaman and M. Jayaraman Department of Mechanical Engineering, Paavai Engineering College, Namakkal, Tamil Nadu, India and Department of MechanicalEngineering,VelalarCollegeofEngineering and Technology, Erode, Tamil Nadu, India (2015) “Experimental Investigation on the Mechanical

Properties of Jute/Sisal/Glass and Jute/Banana/Glass HybridCompositeMaterials”

[2] JoséA.Rabi,SérgioF.Santos,GustavoH.D.Tonoliand HolmerSavastanoJr.FacultyofAnimalScience&Food Engineering (FZEA), University of São Paulo (USP) Avenida Duque de Caxias Norte, 225, 13635-900, Pirassununga, SP, Brazil (2009). “AGRICULTURAL WASTES AS BUILDING MATERIALS: PROPERTIES, PERFORMANCEANDAPPLICATIONS”.

[3] ChristosBabu&KaleshKK,M.TechScholar,Department of Mechanical Engineering, Sree Buddha College of Engineering, University of Kerala, India (2015). “DevelopmentofaNaturalFibreReinforcedComposite forSafetyandConstructionApplications”

[4] Nilsson and Kavin G.(1975), ‘Study on flexural and toughness behavior of natural fibres in concrete’, JournalofCompositeStructures,Vol.23,pp.95-115.

[5] Kuruvilla Joseph., George Leslie and Khosrow Ghavami.(1999),‘TheuseofSisalFibreasreinforcement in cement based composites’, Revista Brasileira de EngenhariaAgrícolaeAmbiental,Vol.12,pp.245-256.

[6] AugustineUcheElinwaandStephenPinderEjeh.(2003), ‘Characterization of Sisal Fibre Reinforced Concrete’, JournalofAppliedSciences,Vol.3,pp.23-30.

[7] JagannathaReddyH.N.andTaraSen.(2007),‘Efficiency of Thermally Conditioned Sisal FRP Composite on the Shear Characteristics of Reinforced Concrete Beams’, Research Journal of Engineering Sciences, Vol. 5, pp. 230-245.

[8] KawkabHabeebAlRawi.(2009),‘Effectofaddingsisal fiberandiraqibauxiteonsomepropertiesofconcrete’, JournalofAppliedMechanics,Vol.9,pp.45-52.

[9] G.Ramakrishna,T.SundararajanandS.Kothandaraman Department of Civil Engineering, Pondicherry Engineering College, Pondicherry, India24 (2011)STRENGTHOFCORRUGATIONSOFAROOFING SHEETSREINFORCEDWITHSISALFIBRES

[10] TaraSen,H.N.JagannathaReddy(2013)“Strengthening of RC beams in flexure using natural jute fibre textile reinforcedcompositesystemanditscomparativestudy withCFRPandGFRPstrengtheningsystems”

[11] Athiappan., Vijaychandrakanth.(2014) Experimental StudyonFlexuralBehaviorofSisalFibreinReinforced ConcreteBeam

[12] Ms. Shweta A. Sajjanshetty, Ms. Rupali B. Kejkar, Ms. Supriya S. Choudhari , Mr. Vinayak B. Kale (2014) Flexural Behavior of Strengthened and Repaired R.C. BeamsbyusingSteelandCoirFiberConcreteJacket.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | APR 2024 www.irjet.net p-ISSN: 2395-0072

[13] KotreshSardar,Dr.T.Rangaswamy,Shivakumar(2014) FabricationandInvestigationofBendingTestonHybrid (Sisal and Banana) Fiber Reinforced Polyester CompositeMaterial

[14] M. R. Sanjay,G. R. Arpitha, L. Laxmana Naik, K. Gopalakrishna, B. Yogesha(2016) Applications of NaturalFibersandItsComposites:AnOverview.

[15] Arpitha G R, Sanjay M R, L Laxmana Naik, B Yogesha DepartmentofMechanicalEngineering,MalnadCollege ofEngineering,Hassan,Karnataka,India(2014).

[16] Thyavihalli Girijappa YG, Mavinkere Rangappa S, Parameswaranpillai, et al.J Front Mater (2019); 6(September):1–14:“Naturalfibersassustainableand renewable resource for development of eco-friendly composites:acomprehensivereview”.

[17] Müssig J.A John Wiley and Sons, Ltd., Publication, (2010):“Industrial Applications of natural fibres: structure”, properties and technical applications. In: Müssig J (ed) Industrial applications of natural fibres: structure,propertiesandtechnicalapplications.,p.538.

[18] Chand N, Verma S and Khazanchi AC,J Mater Sci Lett (1989):”SEMandstrengthcharacteristicsofacetylated sisalfibre”,8(11):1307–1309.

[19] BharathK,SanjayMM,JawaidM,etal.JIndText(2019): Effectofstackingsequenceonpropertiesofcoconutleaf sheath/jute/E-glass reinforced phenol formaldehyde hybridcomposites.;49(1):3–32.

[20] Khan JA, Khan MA and Islam R(2012):Effect of mercerizationonmechanical,thermalanddegradation characteristics of jute fabricreinforced polypropylene composites.FibersPolym;13(10):1300–1309.

[21] NaguibHM,KandilUF,HashemAI,etal.JRadiatResAppl Sci(2015):Effectoffiberloadingonthemechanicaland physical properties of “green” bagassepolyester composite.;8(4):544–548.

[22] Subramonian S, Ali A, Amran M,Adv Mech Eng,et al.(2016):Effect of fiber loading on the mechanical properties of bagasse fiber-reinforced polypropylene composites.;8(8):1–5.

[23] Taib MNAM and Julkapli NM,Elsevier Ltd, (2018): Dimensionalstabilityofnaturalfiber-basedandhybrid composites. Mechanical and physical testing of biocomposites,fibre-reinforcedcompositesandhybrid composites.,pp.61–79.

[24] Gudayu AD, Steuernagel L, Meiners D,et al.J Ind Text (2020):1–21.DOI:10.1177/1528083720924774.Effect ofsurfacetreatmentonmoistureabsorption,thermal, andmechanicalpropertiesofsisalfiber.

[25] Li M, Pu Y, Thomas VM,Compos B: Eng et al.(2020): Recent advancements of plant-based natural fiberreinforced composites and their applications; 200(February):108254.

[26] Bafekrpour E, Santulli C, Sarasini F, et al(2017): Injectionmouldingofplantfibrecomposites.Advanced CompositeMaterials;PropertiesandApplications:420–439.DOI:10.1515/9783110574432-008

[27] Faruk O, Kc B, Sobh A, et al(2017):Natural fiber reinforcedthermoplasticcomposites.Lightweightand sustainablematerialsforautomotiveapplications.CRC Press,:1–38.

[28] Nystrom B, Joffe R and L ¨ angstr ˚ om R,J Reinf Plast Compos(2007):Microstructureandstrengthofinjection moldednatural¨fibercomposites;26(6):579–599.

[29] VenkatachalamN,NavaneethakrishnanP,RajsekarR,et al(2016).Effectofpretreatmentmethodsonproperties of natural fiber composites: a review. Polym Polym Compos;24(7):555–566.

[30] Latif R, Wakeel S, Zaman Khan N, et al,J Reinf Plasti Compos(2019):Surfacetreatmentsofplantfibersand their effects on mechanical properties of fiberreinforcedcomposites:areview;38(1):15–30.

BIOGRAPHIES

Rahul Kapase AssistantProfessor RMDSSOEWarje,Pune

Vaishnavi Mudkanna StudentCivilEnggineeringDept. RMDSSOEWarje,Pune.

Prachi Bhoinallu StudentCivilEnggineeringDept. RMDSSOEWarje,Pune.

Prerana Jogdand StudentCivilEnggineeringDept. RMDSSOEWarje,Pune.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 04 | APR 2024 www.irjet.net p-ISSN: 2395-0072

Jay Jadhav

StudentCivilEnggineeringDept. RMDSSOEWarje,Pune.

Mansi Jadhav

StudentCivilEnggineeringDept. RMDSSOEWarje,Pune.

© 2024, IRJET | Impact Factor value: 8.226 | ISO 9001:2008 Certified Journal | Page969