International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN:2395-0072

1B.Tech Civil Engineering, Student, JCET, Palakkad, Kerala, India

2B.Tech Civil Engineering, Student, JCET, Palakkad, Kerala, India

3B.Tech Civil Engineering, Student, JCET, Palakkad, Kerala, India

4 Assistant Professor, Dept. of Civil Engineering, JCET, Palakkad, Kerala, India

Abstract - Thisprojectaimstoprovideanoverviewofthe role and potential of PCMs in enhancing the energy efficiency and comfort of buildings. Phase-changing materials (PCMs) have garnered considerable attention as thermal control materials in buildings due to their ability to store and release large amounts of energy during phase transitions. Paraffin and beeswax are two commonly used phase-changing materials (PCMs) that offer effective temperature control in buildings. Paraffin wax andbeeswax both exhibit phase transitions at temperatures suitable for building applications. The paraffin and beeswax integrated into building materials like gypsum mortar offer several advantages. Firstly, it reduces the reliance on mechanical heating and cooling systems, thereby lowering energy consumption and utility costs. Additionally, it enhances thermal comfort by stabilizing indoor temperatures and reducing temperature fluctuations. Furthermore, paraffin and beeswax PCMs contribute to environmental sustainability by reducing carbon emissions associated with conventional heating ventilation and air conditioning (HVAC) systems. Performing a thermal analysis of paraffin and beeswax integrated into the gypsum mortar using ANSYS software involves simulating the heat transfer behavior of these phase-changing materials. Steady-state thermal analysis is done, and compressive strength is identified by performing compression tests on gypsum and PCM-incorporated cubes. By comparing the results, it is foundthat the combinationof gypsum with paraffinis more effective in terms of thermal control than gypsum with beeswax. But compressive strength is greater for the combinationofgypsumandbeeswax.

Key Words: Phase changing materials, Paraffin, Beeswax, ANSYS,Steadystateanalysis,Explicitdynamicanalysis.

Energy consumption in buildings has become one of the mosturgentissuesinmostcountriesworldwide.Globally, the energy consumed for space heating and cooling is as high as 40% and 61% of the total energy demand in commercial and residential buildings, respectively. The incorporation of phase change materials (PCMs) into building envelopes has the desired impact of controlling

the thermal load, thereby resulting in remarkable energy savings. PCMs are implemented to minimize the cooling and heating loads through the building envelope due to their massive potential for energy storage during melting and solidification, thereby maintaining an acceptable thermal comfort. Paraffin and beeswax are the most commonly available PCMs that can be incorporated with gypsum mortar to make gypsum boards, which can be used as facades, partition walls, and also when incorporated into building components such as walls, ceilings,orfloors.

●CollectionofmaterialslikePCMs,gypsumetc.

●Selectingdimensionofcubesandboards.

●Thermal analysis using ANSYS and explicit dynamics analysisforstressv/sstraincurve.

●Plotting graph.

●Castingcubesandboardforcompressiontest.

●Comparingtheresults.

ANSYSisusedtoidentifyhowaproductwillfunctionwith different specifications, without building test products or conducting crash tests. It uses computer-based numerical techniques to solve complex problems. The range of problemsANSYScan solve is immense and could be anythingfromfluidflow,heattransfer,stressanalysisand manymore.

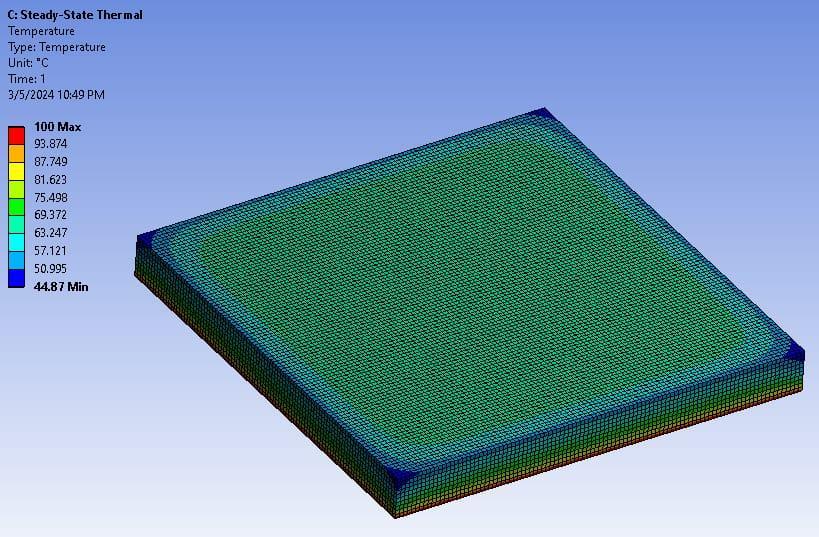

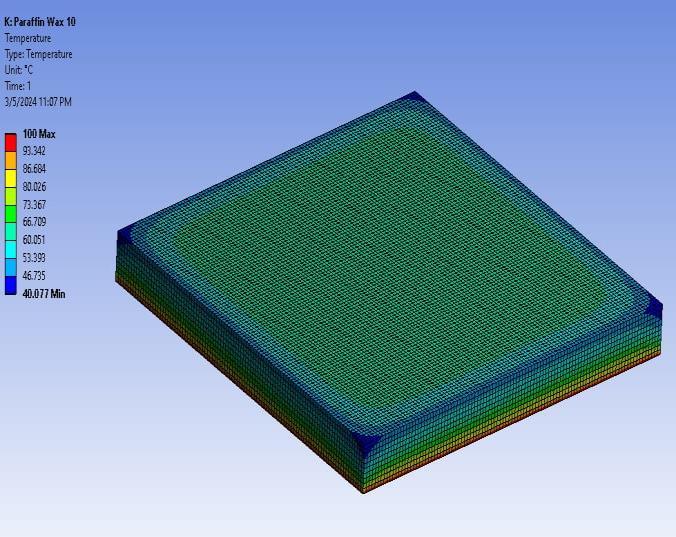

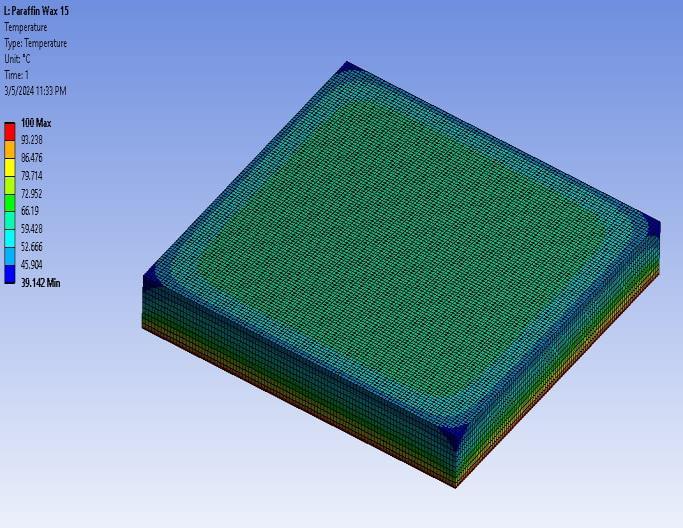

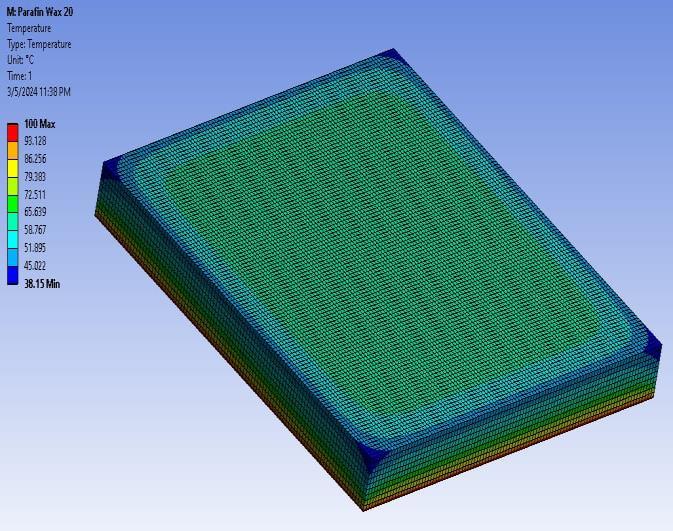

Steady-state thermal analysis using ANSYS involves analyzing the temperature distribution within a structure or system when the temperature does not change with time. Maximum of 100℃ is applied and the minimum temperature obtained for gypsum board, gypsum + Paraffin with 5 different percentage and gypsum + beeswax with 5 different percentages is shown in the followingfigures

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN:2395-0072

Thestepsfollowedforthermalanalysis:

To design the model in ANSYS workbench for thermal, open ANSYS and add steady state thermal analysis to workspace

1. Oncesteady-statethermalisadded,clickongeometry and open space claim. Space claim is the space where youcreate3Dmodels.

2. Once space claim is open, select the plane you want to create the geometry. Draw a rectangle of dimension 20cm by 20cm. exit sketch and use pull command to add height to the drawing. Height of 2cm is added to thedrawingmakingitintoa3Dmodel

3. Open engineering data to input the material data to createanewmaterial

4. Openmodelworkbenchtomakeameshofthedesign

5. Once mesh is created, open setup module to input the boundaryconditionoftheanalysis

6. Add boundary condition of required temperature to onefaceofthedesign

Solutiontabisopenedandvolumetricthermalisadded.

Result is run for a 1000 iteration set a minimum. Result willrununtilthetemperatureresultisreached

Maxtemperatureapplied-100℃

Mintemperatureobtained-44.87℃

Maxtemperatureapplied-100℃

Mintemperatureobtained-40.077℃

Maxtemperatureapplied-100℃

Mintemperatureobtained–39.142℃

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN:2395-0072

Maxtemperatureapplied-100℃

Mintemperatureobtained-38.15℃

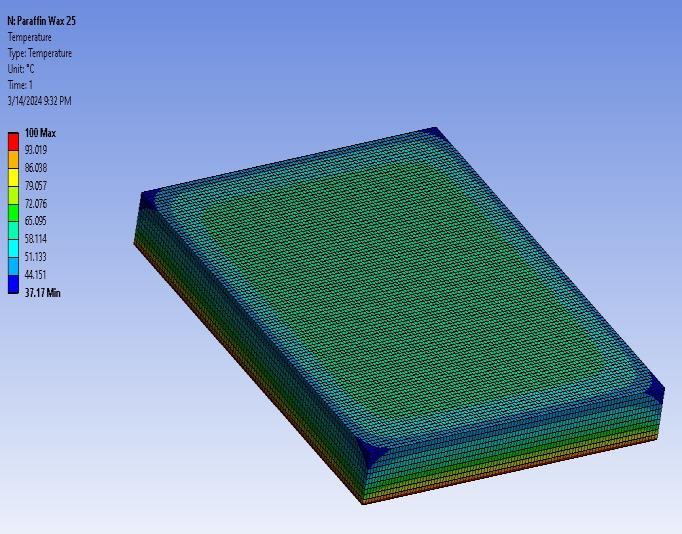

-5:Thermalanalysisofgypsumboardwith25% paraffinboard

Maxtemperatureapplied-100℃

Mintemperatureobtained-37.17℃

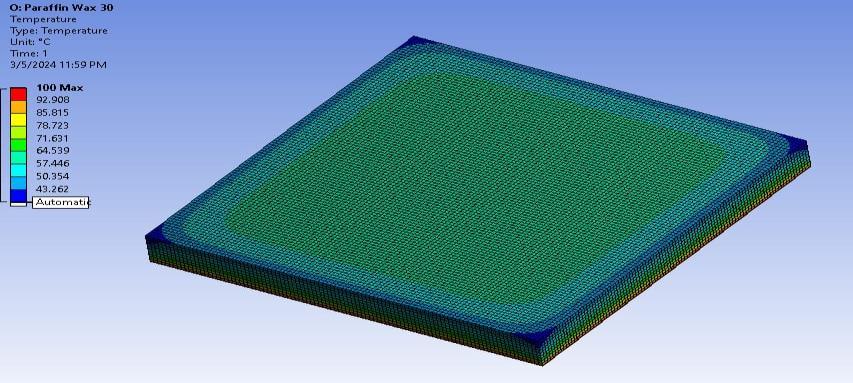

Maxtemperatureapplied-100℃

Mintemperatureobtained-43.262℃

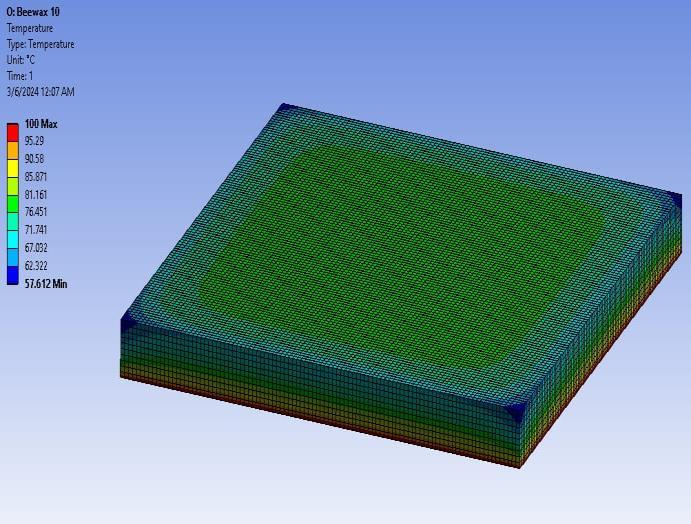

-7:Thermalanalysisofgypsumboardwith10%

Maxtemperatureapplied-100℃

Mintemperatureobtained-57.612℃

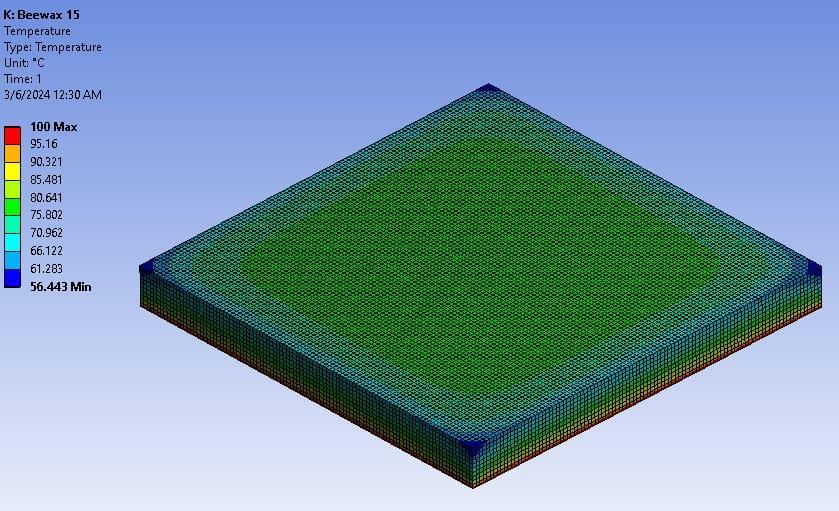

-8:Thermalanalysisofgypsumboardwith15%

Maxtemperatureapplied-100℃

Mintemperatureobtained-56.443℃

Maxtemperatureapplied-100℃

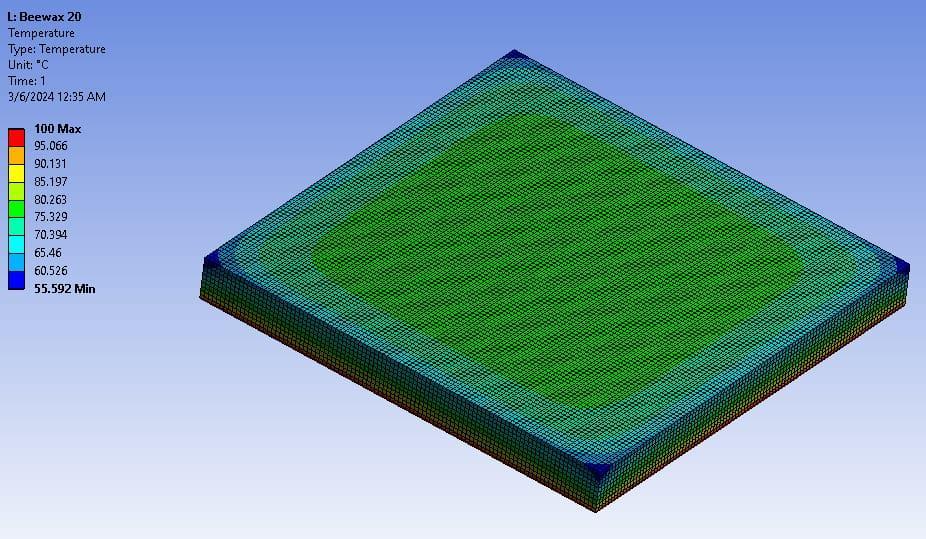

Mintemperatureobtained-55.592℃

-10:Thermalanalysisofgypsumboardwith25%

board

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net

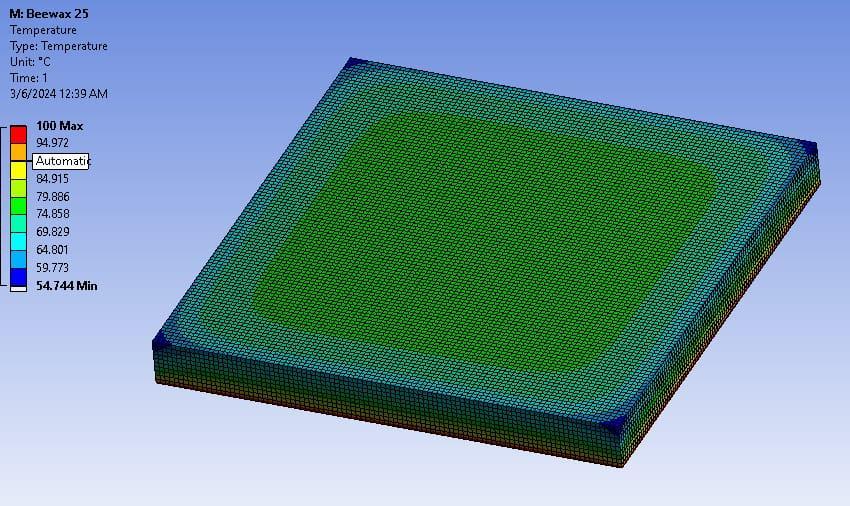

Maxtemperatureapplied-100℃

Mintemperatureobtained-54.744

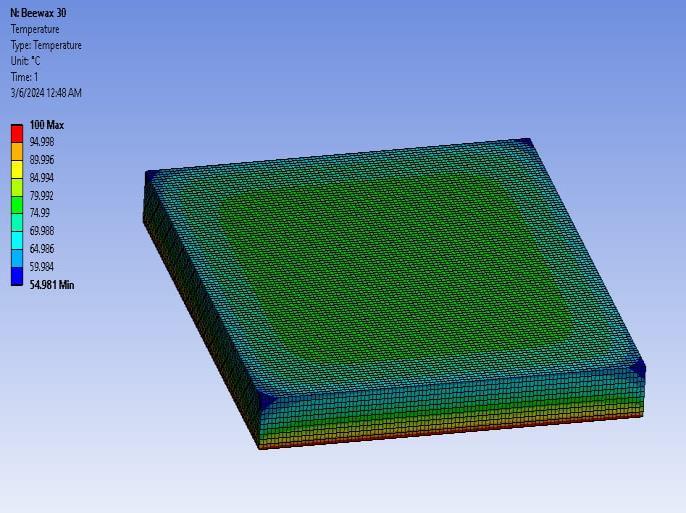

Fig -11:Thermalanalysisofgypsumboardwith30% beeswaxboard

Maxtemperatureapplied-100℃

Mintemperatureobtained-54.981℃

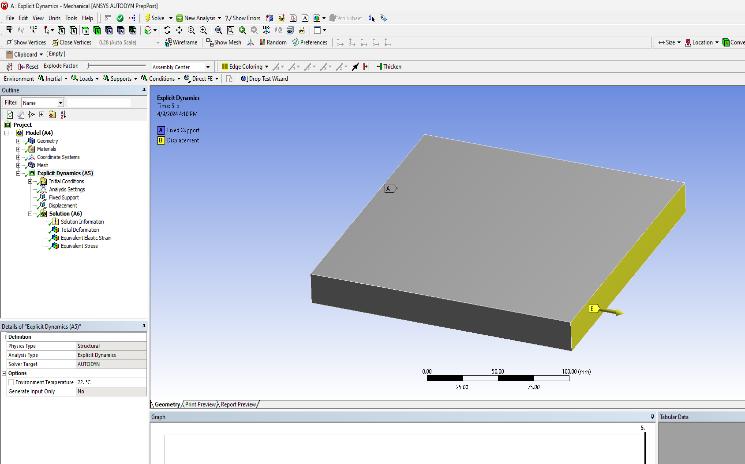

Explicit dynamics analysis in ANSYS involves simulating dynamic events characterized by high-speed deformations, displacements, and short durations, where inertiaanddampingeffectsaresignificant.

ThestepsfollowedforExplicitdynamics.

To design the model in ANSYS workbench for explicit dynamics, open ANSYS and add explicit dynamics to workspace

1. Onceexplicitdynamicsisadded,clickongeometryand open space claim. Space claim is the space where you create3dmodels.

2. Once space claim is open, select the plane you want to create the geometry. Draw a rectangle of dimension 20cm by 20cm. exit sketch and use pull command to add height to the drawing. Height of 2cm is added to thedrawingmakingitintoa3Dmodel

3. Open engineering data to input the material data to createanewmaterial

4. Openmodelworkbenchtomakeameshofthedesign

5. Once mesh is created, open setup module to input the boundaryconditionoftheanalysis.

a. Onefaceofthedesignissetafixed b. Opposite side is set to deformation of 10mm per second

Solution tab isopenedand stressand strainisselected as thesolution

Resultisrunforafixedtimeof5min.Ifthedesigndoesn’t rupture, then an additional time is added to the analysis until the full design brakes. The stress strain data is collectedasaCSVdatafile.Stressv/sstraingraphof25% paraffinwaxwithgypsumand25%beeswaxwithgypsum is only plotted, since these percentage gives minimum temperatureineachcombination.

UsingExcel,agraphisplottofindthestressstraingraph

Fromfigure1minimumtemperatureobtainedforgypsum board is 44.87℃. The minimum temperature obtained for Gypsum with PCMs combination with percentage 10%, 15%, 20%, 25%, 30% are shown below in the following charts.

GypsumwithParaffinwaxthermal analysis

ParaffinWax

Chart -1:Minimumtemperatureobtainedbygypsumwith paraffincombination

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN:2395-0072

From chart1 we can see that there is minimum temperatureobtainedat25%ofparaffinwithgypsum.

Chart -2:Minimumtemperatureobtainedbygypsumwith Beeswaxcombination

From chart2 we can see that minimum temperature is obtained at 25% beeswax. In the case of beeswax after 25% the temperature doesn't change much that means it reachestoitssaturatedpoint.

Whencomparedthegypsumwith25%paraffinshowslow thermalconductivitycomparedtoordinarygypsumboard andgypsum+beeswaxcombination.Therefore,gypsum+ Paraffinismorepreferablethangypsum+beeswax.

Theresultsobtainedfromthermal analysisshowsthat25 % paraffin with gypsum shows the low thermal conductivity, therefore stress v/s strain curve is plotted for25%paraffinwithgypsum.

Theresultsobtainedfromthermal analysisshowsthat25 % beeswax with gypsum shows the low thermal conductivity, therefore stress v/s strain curve is plotted for25%beeswaxwithgypsum.

STRAIN GRAPH - 25 % BEEWAX

:

Chart -4:Stressv/sStraincurveofGypsum+25% beeswax

From the above two chart breaking point of paraffin is highest compared to beeswax. Considering this paraffin waxismorepreferable.

Thestepsfollowed:

Mixture: Mix the gypsum mortar according to the desired specifications, cubes and boards arecastedfor three combinationsthatisnormalgypsummortar,gypsumwith 25% paraffin mortar and gypsum with 25% beeswax mortar. The percentage of PCMs is selected based on the bestresultobtainedfromthermalanalysisusingANSYS.

Dimension:cubeswithsize7.06x7.06x7.06cmareused andboardswithsize20x20x2cm.

MoldsPreparation:Cleanthemoldsthoroughlyandapply a thin layer oil to prevent sticking.

Filling Molds: Pour the prepared mixture into the molds, ensuringitisevenlydistributedandcompactedtoremove anyairvoids.

Compaction: Compact the mixture to ensure uniform densityandremoveanyentrappedairbubbles.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 04 | Apr 2024 www.irjet.net p-ISSN:2395-0072

Curing: Allow the cast specimens to cure by drying. Demolding: After the specified curing time, carefullydemoldthespecimensfromthemolds.Takecare not to damage the specimens during this process.

Labeling: Label each specimen with relevant information such as the mix design, casting date, and any other pertinentdetails

Table-1: Compressivestrengthofdifferentcombinations

SlNo. 1 2 3

3 3 3

From table-1 we can see results obtained from compression test of cubes of gypsum, gypsum + 25% paraffinandgypsum+25%beeswax.Theweightandload obtainedistakenforaverageof3cubes.Theresultsshow that gypsum cube had greater compressive strength compared to other two combinations. But gypsum boards incorporatedwithPCMscanusedasfacadesandnon-load bearingstructures.

● The use of thermal controlling devices and appliances are consuming a large amount of energy to keep the temperaturewithincomfortrange.

● The use of PCM in new and refurnished buildings can decreasetheenergyconsumption.

● This project highlights the effectiveness of thermal controlling after incorporating paraffin wax and beeswax(PCMs),themostcommonlyfound,cheapand easilyavailablematerial

● Bycomparingthe minimum temperaturechart wecan see that there is a minimum temperature in the combinationofGypsum+Paraffinwhichispreferable.

● Beeswax is a non-toxic material but it’s thermal conductivity low compared to Gypsum + paraffin combination.

● These findings can serve as a valuable resource for researchers,architectsandengineers.

[1] A review on phase change materials for thermal energy storage in buildings: Heating and hybrid

applications Khaireldin Faraj, Mahmoud Khaled, Jalal Faraj,FaroukHachem,CathyCastelain(2022).

[2] M. He, L. Yang, W. Lin, J. Chen, X. Mao, Z. Ma, Preparation, thermal characterization and examination of phase change materials (PCMs) enhanced by carbon-based nanoparticles for solar thermal energy storage,Journal ofEnergyStorage.25 (2019).

[3] Phase Change Material (PCM) Microcapsules for Thermal Energy Storage Guangjian Peng, Guijing Dou, YahaoHu,YihengSunandZhitongChen(2020).

[4] R.A. Kishore, M.V.A. Bianchi, C. Booten, J. Vidal, R. Jackson, Optimizing PCM-integrated walls for potentialenergysavingsinUSbuildings(2020).

[5] R. Ye, R. Huang, X. Fang, Z. Zhang, Simulative optimization on energy saving performance of phase change panels with different phase transition temperature(2020).

[6] Study on the energy performance enhancement of a new PCMs integrated hybrid system with the active cooling and hybrid ventilations, Zhou, Yuekuan, Zheng,Siqian,Zhang,Guoqiang(2019).