International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN:2395-0072

V. Saravanan1 , A. Justin Roy1 , R. Gopalachandar1 , S. Jagatheeswar1 , N. Vinayaga

1Student, Sri Sairam Engineering College, Chennai, Tamil Nadu

2Assistant Professor, Sri Sairam Engineering College, Chennai, Tamil Nadu

Muruga pandy2

ABSTRACT

This abstract explores the innovative design of shaftdriven dirt bikes, ushering in a new era of off-road motorcycling. Unlike traditional chain-driven counterparts, these bikes employ a shaft and bevel gear mechanism, minimizing maintenance needs and wear. The absence of an exposed chain enhances rider safety by reducing the risk of debris accumulation. Beyond maintenance benefits, the shaft-driven system contributes to improved off-road performance, offering enhanced traction, stability, and responsiveness. While acknowledging challenges in weight distribution and customization, ongoing research seeks to optimize the design, positioning shaft-driven dirt bikes as a compelling alternative for riders seeking efficient, reliable,andexhilaratingoff-roadexperiences.

KEYWORDS

Shaft-driven system, Bevel gear mechanism, Power transmission efficiency, Maintenance reduction, Wear minimization, Debris management, Traction optimization, Stability improvement, ANSYS analysis, Designcalculations.

INTRODUCTION

The evolution of off-road motorcycle technology has taken a significant leap with the advent of shaft-driven dirt bikes, a groundbreaking innovation designed to redefine the off-road riding experience. Departing from conventionalchain-drivenmodels,shaft-drivendirtbikes feature a sophisticated shaft and bevel gear mechanism, promisingridersahostofadvantages,includingreduced maintenance requirements and enhanced safety. This paper delves into the unique design characteristics and performancebenefitsofshaft-drivendirtbikes,exploring theirimpactontraction,stability,andoverallhandlingin challenging off-road terrains. To provide a comprehensive understanding, this study incorporates design calculations and employs advanced analysis through ANSYS, shedding light on the engineering intricacies that contribute to the bike's efficiency and durability. As we navigate through this exploration, it becomes evident that shaft-driven dirt bikes are not merely a technological advancement; they represent a paradigm shift in off-road motorcycling, offering riders anefficient,reliable,andexhilaratingalternative.

The flow of design methodology is shown in Figure 1. Designmethodologyreferstoasystematicandorganized approach to the design and development of a shaft drivendirtbike.

Dimensions consideration

Design calculation

Rough draft

Design

Pipe model

Material selection

Analysis

Fabrication

Final evaluation

Fig.1.flowofstudy

Material selection for chassis

The selection of materials is a critical aspect in the design and construction of any engineering component, and in the context of a shaft-driven dirt bike, the propertiesofvariousmaterialsplayapivotalrole.ASTM A36, known for its general structural applications, exhibits a tensile strength of 400 MPa and a yield strengthof250MPa.AISI4130, a chromolysteel,boasts higher tensile and yield strengths at 670 MPa and 435 MPa,respectively.AISI1018offersgooddurabilitywitha tensile strength of 483 MPa and a yield strength of 413 MPa. Aluminum alloys, such as Al-6061 and Al-7075,

International Research Journal of Engineering and Technology (IRJET)

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net

provide lower density (2.7 g/cc) and (2.81 g/cc) respectively, with Al-7075 demonstrating the best combination of strength (570 MPa) and yield strength (505 MPa). Docol R8, recognized for its exceptional strength, exhibits an impressive tensile strength of 800 MPa and a yield strength of 690 MPa. These materials also differ in cost per kilogram, with considerations of weldability playing a crucial role, making the selection process intricate, as engineers must weigh factors such asstrength,weight,cost,andweldabilitytooptimizethe overall performance and durability of the shaft-driven dirt bike. From the above information, the material chosen for the chassis was AISI 4130 as it is costeffective, the most reliable, and readily available in the market. [1]

Theprincipleofashaftdrivedirtbikeinvolvestheuseof a shaft and bevel gear mechanism for power transmission from the engine to the rear wheel. Unlike traditional chain-driven systems, which employ a chain andsprocketarrangement,theshaftdriveutilizesashaft thatconnectstoabevelgearinthefinaldrivehousing.As the engine rotates, it turns the shaft, which, in turn, drives the bevel gear, ultimately transferring power to the rear wheel. This mechanism is enclosed within the bike's structure, reducing exposure to external elements and minimizing maintenance needs. The principle aims toprovideamorereliable,cleaner,andlow-maintenance solution, particularly advantageous in off-road environments wheredurabilityandeaseof maintenance arecrucial.

The main components of a shaft drive system in motorcyclestypicallyinclude [4]

Shaft

The primary component responsible for transmitting powerfromtheenginetothefinaldrive.

Bevel Gears

Bevel gearsareused toredirecttherotational motion of theshaftatanangle,facilitatingthetransferofpowerto therearwheel.

Final Drive Housing

Encases the bevel gears and provides structural support fortheentireshaftdrivemechanism.

Universal Joint

Connects the shaft to the bevel gears and allows for flexibility in accommodating changes in angle and direction.

Wheel Hub and Spline

-0072

The wheel hub incorporates splines or other connection mechanismstotransferpowerfromthefinaldrivetothe rearwheel.

Seals and Bearings

Sealsandbearingsareessentialforsmoothrotationand to prevent the ingress of contaminants into the shaft drivesystem.

Housing Covers

Covers enclose and protect various components, contributingtothesystem'soveralldurabilityandsafety

Support Brackets

Brackets and mounts are used to secure the shaft drive componentstothemotorcycleframe.

Lubrication System

A lubrication system ensures the smooth operation of movingpartswithintheshaftdrive,reducingfrictionand wear.

Thesecomponentsworkinconcerttoefficientlytransfer power from the motorcycle's engine to the rear wheel while providing advantages such as reduced maintenance requirements and increased durability in comparisontotraditionalchain-drivensystems.

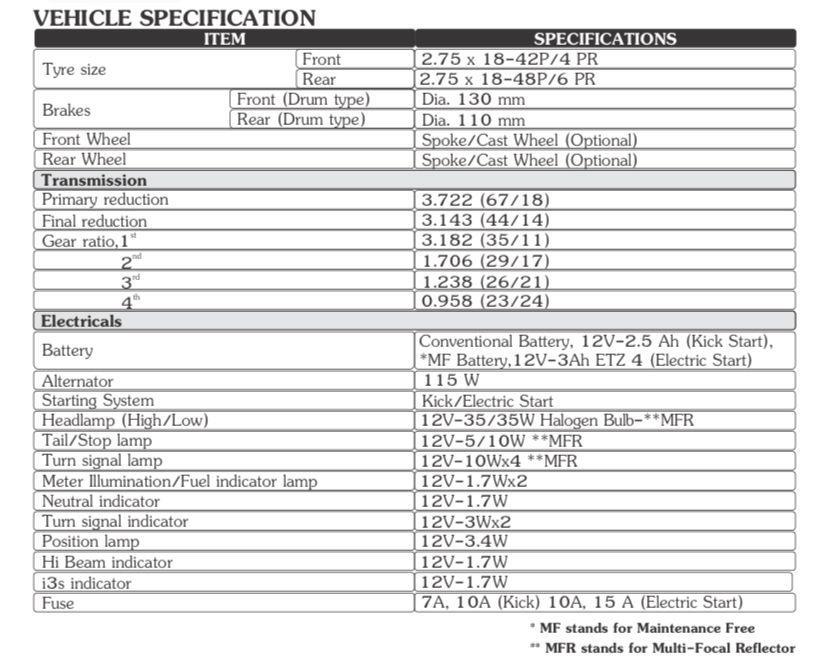

By considering the specification for HERO SPLENDOR PLUSengineMaximumpowerfromtheengine=6.15KW at 8000 rpm and Maximum torque from the engine = 8.05N-mat5000rpmwearecalculatingthediameterof the shaft and also calculating the bevel gear specifications

Fig.2.specificationsofherosplendorplus

International Research Journal of Engineering and Technology (IRJET)

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net

Fig.3.specificationsofherosplendorplus

Fig.4.imageofshaftdrivecomponentsintegration Design

On standardizing, the diameter of the shaft d = 15mm

Design of bevel gear Calculation

Maximum power = 6.15kw at 8000rpm

Gear ratio = 3

Transmission ratio i = 3

Material = C 45 steel

Step 1: Material [ DDB 8.16]

For both pinion and wheel = C45 steel

HRC = 40 to 55 HRC

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

N = 60����

=60×8000×80000

N = 3840 × 107������������

Let consider

HB of C45>350HB

Kcl = 0.585 for N = 3840×107>=25×107

���� =230×50×0585

����=�������� ��������/������

To find ���� [DDB 8.13]

���� = 14 �� ������ ���� �� 1

�� 1=0.25(����+ ����)+500

���� =7000������/����2

���� =3600������/����2

Substitute the value in the above formula

�� 1=025(7000+3600)+500

�� 1=3150������/����2

Factor of safety(n) [DDB 8.19]

For C45 (forged & surface hardened)

FOS = 2.5

n = 2.5

k�� = fillet stress concentration factor [DDB 8.19] for C45 surface hardened 0≤�� ≤01

k�� = 1.5

kbl = life factor for bending for steel C45 hardness ≤350 life = 3840×107

∴������ =1

Substitute all the values in ����

[����]= 14×1 25×15 ×3150

���� =1176

����=��������������/������

Step 2: calculation of cone distance (minimum) [DDB 8.13][6]

�� ≥����[(√��2 +1)√ 072 (���� 05)(����) 3 ��[����] ��

i = speed ratio or gear ratio

i = 3

����= �� �� [DDB 8.15]

E = young’s modulus

For C45, E = �� ����������������/������ [ DDB 8.14]

�� =3

[����]=���� ������

Kdk = 1.3

Mt = 97420× ���� ��

Mt = 97420× 615 8000 =7489������ ����

[Mt] = 7489×13

[Mt] = 97.35 kgf.cm

Substitute all the value in the above formula to find the (R)

R = 948×0503

R = 4.77 cm

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN:2395-0072 © 2024, IRJET | Impact Factor value: 8.226 | ISO 9001:2008

Step 3: calculation of minimum module [DDB 8.38]

Transverse module

R = 0.5Mt Z1√��2 +1 where,

R = cone distance (cm)

Z1 = no of teeth on pinion

i = gear ratio

R = 4.80 cm

Let us assume Z1 = 14

4.8 = 0.5Mt 14√32+1

4.8 = 22.1Mt

Mt = 0.2171cm

Mt = 2.2mm

Standard module [DDB 8.2]

Let Mt = 4mm

Step 4: corrected centre distance

R = 0.5������1√��2 +1

R = 0.5(0.4)14√10

R = 8.85

Approx. R = 9cm > Rmin = 4.77

Design is safe.

Step 5: calculation of average module(mav) [DDB 8.13A]

Mt = mav+ �� ��1 sin��

Mav = Mt�� ��1 sin��

To find b ���� = �� ��

3 = 9 ��

b = 3

To find ��[�������� ����]

tan��2 =��

��1 +��2 =90°

By calculating

�� =1843°

Mav = [0.43 14 sin1843]

Mav = 0.33 cm

Mav = 3.3mm

Step 6: corrected design torque [Mt] [DDB 8.15]

[Mt] = Mt kd k

Mt = 74.89 kgf.cm

k – load correction factor [DDB 8.15]

based on ���� = �� ��1

b = 3

d1 = Z1(mav)

d1 = 14(0.3)

Research

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net

d1 = 4.2 cm ����= 3 42 =0714 ≤1

k = 1.6

kd – dynamic load factor [DDB 8.16]

= 17.5 m/s For v = 17.5m/s, kd = 1.1

[Mt] = Mt kd k = 74.89×11×16

[Mt] = 131.80 kgf.cm

Step 7: checking for stresses [DDB 8.13]

= ��√��2 +1[����] (�� 0.5��)2 �������� 1 ��������

yv = worm factor [DDB 8.18]

to find yv we need to find Zv based on Zv, pressure angle = 20°

Zv = ��1 ��������1 = 14 cos1843 = 14.75 approx. = 15

Standardize Zv = 16, yv = 0.355

���� = ��√32 +1(13180) (9 1.5)2 ×3×0.4×0.355 1 cos20°

CAD MODELOF THE CHASSIS

Fig.5. CAD model

Staticstructuralanalysisisatypeofengineeringanalysis that focuses on the study of structures under static loading conditions. In this context, "static" means that the loads and conditions applied to the structure are assumed to be constant over time, and the goal is to determine the resulting stresses, strains, and deformationswithinthestructure.[5]

Fig.6.Structuralanalysis

Pipe model of chassis

CAD Design of Shaft driven transmission

Fig.8.CADdesignofShaftdrivetransmissionmechanism

International Research Journal of Engineering and Technology (IRJET)

-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN:2395-0072

In crafting a high-performance shaft-driven dirt bike, CAD design is paramount. Precision modelling of bevel gears, universal joints, shaft splines, and wheel hub designs ensures optimal power transfer, durability, and agility in off-road conditions. This digital approach allows engineers to fine-tune components for an exhilaratingandreliableridingexperience.

Comparison between chain drive and shaft drive transmission systems in Dirt bikes

Chain Drive: Requires regular adjustments, lubrication, and replacement, prone to wear and debris accumulation.

Shaft Drive: Significantlyreducesmaintenanceneeds,no chain adjustments, and less exposed components, minimizingwearanddebris-relatedissues.[2]

Chain Drive: Offers a direct power transfer, often considered more responsive in certain off-road conditions.

Shaft Drive: Provides smoother power delivery, enhancingtractionandstability,particularlybeneficialin variedoff-roadterrains.

Chain Drive: Exposes riders to the risk of injury due to theexposedchainandsprockets.

Shaft Drive: Minimizessafetyconcernsby enclosingthe drivetrain,reducingtheriskofentanglementwithdebris.

Chain Drive: Generally, results in a lighter overall bike, potentiallyaidingmanoeuvrability.

Shaft Drive: Can contribute to a slightly heavier bike, impacting agility, but advancements aim to address this concern.

Chain Drive: Simple and well-established technology, easierforcustomizationandrepairs.

Shaft Drive: More complex mechanism, potentially limiting customization options, but advancements strive tobalancecomplexitywithperformance.

Whilebothchaindriveandshaftdrivesystemshavetheir merits, the choice often depends on the rider's preferences, riding style, and maintenance preferences. Advances in shaft drive technology continue to bridge the performance gap, making it an increasingly viable andattractiveoptionforoff-roadenthusiasts.

Improved Efficiency and Performance:

Engineers might work on refining the design of shaftdriven systems to minimize power losses and improve overallefficiency.

Enhancementsinmaterialsandmanufacturingprocesses could contribute to reduced weight and increased durability, addressing concerns about the added weight ofshaftsystems.

Adoption of Electric Powertrains:

With the growing interest in electric motorcycles, manufacturers might explore incorporating shaft-driven systemsintoelectricdirtbikes.

The torque characteristics of electric motors could be well-suitedforshaft-drivensetups,providingasmoother and more controlled power delivery in off-road environments.

Integration with Advanced Electronics:

Future shaft-driven dirt bikes may feature advanced electronic systems, including smart traction control, stability control, and customizable power delivery settings.

Connectivity options for data logging and performance analysis could be integrated to enhance the rider's experience.

Enhanced Off-Road Capabilities:

Manufacturers could focus on optimizing shaft-driven systems for improved off-road performance, addressing concerns related to suspension travel, ground clearance, andmaneuverability.

Thedevelopmentofvariabletransmissionsystemsmight allowriderstoadapttodifferentterrainswithease.

Environmental Considerations:

As environmental awareness continues to grow, manufacturers might explore ways to make dirt bikes more environmentally friendly. This could involve the use of sustainable materials and energy-efficient technologies.

Market Acceptance and Consumer Education:

The success of shaft-driven dirt bikes will depend on market acceptance, which could be influenced by effectivemarketingstrategiesandconsumereducation. Manufacturers might invest in educating consumers about the advantages of shaft-driven systems, such as reducedmaintenancerequirementsandsmootherpower delivery.

Customization and Personalization:

Future designs might incorporate modular components, allowingriderstocustomizeandpersonalizetheirshaftdriven dirt bikes according to their preferences and ridingstyles.

International Research Journal of Engineering and Technology (IRJET) e-

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN:2395-0072

It's essential to stay updated with the latest developments in the motorcycle industry to understand how technology evolves and whether shaft-driven dirt bikesgainpopularityinthemarket.

Theinnovativedesignofshaft-drivendirtbikespresents a paradigm shift in off-road motorcycling, offering reduced maintenance needs and enhanced safety compared to traditional chain-driven counterparts. The absence of an exposed chain minimizes wear and reducestheriskofdebrisaccumulation,promotingrider safety.

The shaft-driven system contributes to improved offroadperformance,providingenhancedtraction,stability, and responsiveness. Despite challenges in weight distributionandcustomization,ongoingresearchaimsto optimize the design, positioning shaft-driven dirt bikes as compelling alternatives for riders seeking efficient, reliable,andexhilaratingoff-roadexperiences.

Material selection for the chassis involved a comprehensive analysis, with AISI 4130 chosen for its cost-effectiveness, reliability, and availability. The design calculations and ANSYS analysis ensured the structural integrityoftheshaftandbevelgearmechanism.

The comparison between chain and shaft drive systems highlights the advantages of reduced maintenance, enhanced safety, and improved performance offered by shaft-driven dirt bikes. Future scopes include further advancements in efficiency, integration with electric powertrains, enhanced off-road capabilities, and increased market acceptance through consumer education.

Insummary,theinnovativedesignandongoingresearch in shaft-driven dirt bikes signify a transformative era in off-road motorcycling, balancing performance, safety, andenvironmentalconsiderations.

Conclusion

Finally,researchintoshaft-drivendirtbikesrepresentsa majorstepforwardforoff-roadmotorcyclingbybringing a designthat reducesmaintenancerequirements,boosts rider safety, and enhances overall performance. The innovativeshaftandbevelgeardesignsolvesissueswith standardchain-drivensystemsandoffersridersastrong substitute. The thorough material selection, structural analysis, and design process all add to the system's dependability and effectiveness. The benefits of lower maintenance and increased safety provided by shaftdriven devices are highlighted by contrast with chaindriven competitors. Looking forward, the future scope holds potential for greater breakthroughs in efficiency,

integration with electric powertrains, and increased market adoption through consumer education. Shaftdrivendirtbikesarearevolutionaryforceintheoff-road industry,providingoff-roadriderswithacombinationof efficiency, dependability, and an exciting riding experienceastechnologyadvances.

References

[1]Bhagyalaxmi,S.S.,&Kini,V.I.J.A.Y.A.(2018).Effect of heat treatment and mechanical characterization of AISI4140steel. IntJMechProd, 8(9),603-10.

[2] Parashar, A., Purohit, S., Malviya, S., Pandey, N., & Kundu,A.K.(2016).Design&FabricationofShaftDriven Bicycle. International Journal of Science Technology & Engineering.ISSN(online):2349X, 784.

[3] Design and Fabrication of Shaft Drive for two Wheelers Vinoth Kumar, Kari Naga Nikhil, Kakoli Manoj Kuma , Kaza Sai Sravan, K.Subha Theja Mechanical Engineering R.M.K College Of Engineering & Technology, Tiruvallur,India

[4] Design, Analysis and Fabrication of Shaft Driven Motorcycle Nitesh Patil,SuneetJadhav, ManojJambrekar,Hrishikesh Jawale, Prof .Harikumar .K .Mechanical Lokmanya Tilak CollegeofEngineering

[5]Patil,S.B.,&Joshi,D.G.(2015).StructuralAnalysisof Chassis: A Review. International Journal of Research in EngineeringandTechnology, 4(4),293-295.

[6] Dandage, R. V., Patil, A. A., & Kamble, P. N. (2017). DESIGN, ANALYSIS & FABRICATION OF SHAFT DRIVEN BICYCLE. In 5th International Conference on Recent Development in Engineering Science, Humanities and Management,16thApril