International Research Journal of Engineering and Technology (IRJET) e-ISSN:

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net

International Research Journal of Engineering and Technology (IRJET) e-ISSN:

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net

Sai Anvesh Durvasula

Parabole.ai USA

ABSTRACT

Theintegrationofartificialintelligence(AI),machinelearning,androboticsforIndustry4.0promisestorevolutionize manufacturingproductivity,butposesintegrationandskillsdevelopmentchallenges.Collaborativehuman-AIsystems that combine the strengths of human judgment with intelligent algorithms have been shown to increase quality control accuracy and output compared to either working independently. For instance, cobot assistants enhanced operator defectdetectionupto10% overmanualinspectionaloneatBMW plants. However, barriers exist;43%cite integratingAIgivenlegacyITinfrastructuresasaprimaryobstacle,and50 million industrialjobslikelyrequirenew technical training in the next decade for more hybrid roles. By establishing clear communication protocols that promote situational awareness, human workers can build appropriate reliance with mobile robotic partners and autonomous decision systems designed for interpretable transparency. Multi-stakeholder leadership is essential for governing this ongoing evolution of human-machine interaction across factory floors. If concerted reskilling investmentscoordinatedbetweenpublicandprivatesectorsaremadeinthewakeofnewprocessautomationwaves, positive labor productivity effects could more than offset role redundancies. With analysts projecting 58 million potential net employment gains realizable by applying responsible implementation frameworks for trustworthy AI systems matched to suitable operator abilities, collective prosperity through expanded individual capacities appears achievableifcollaborativeworkdesigninnovationsremaincenteredonmutualaugmentation.

Keywords: Hybrid Systems, Explainable AI, Industrial IoT, Distributed Cognition, Machine learning, Human-Robot Collaboration.

Well-known manufacturing organizations, such as Tesla's Gigafactory 1, serve as prime examples of the ongoing Industry 4.0 revolutions that are taking place throughout production facilities by integrating thousands of industrial autonomousroboticsandsophisticatedmachinelearningsoftware.[1]-[3].

Figure1isanoverviewoftheTeslaGigafactory1manufacturingfloor,featuringadvancedautomationlikeindustrial robots.ThishighlightstheIndustry4.0transitiontakingplaceinmanufacturingfacilities.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN:2395-0072

With investments in artificial intelligence (AI) for manufacturing sectors expected to reach $13 billion by 2024, an increase of more than 400% from 2018 levels [4], the rate of global expenditures to implement these exponential technologies in production is accelerating significantly. To fully leverage the potential for productivity and quality improvement,itisessentialtoadoptmodernmethodstoaugmenthuman-robotcollaboration[5]-[7].

Modernapproachessuchaspredictiveanalytics,computervision,reinforcementlearning,andconversationalinterfaces areenhancingimportantareasofthemanufacturingvaluechain[8]-[10].

Thetable1providessomeadditionalmetricsontheimpactofAIadoption:

AI Application Companies Adopting

Predictive Maintenance

Quality Optimization

Siemens(120factories)

BMW Manufacturing (10 plants)

Impact Metrics

●Reduced turbine downtime from 95 hours per year to48hoursperyear

●Saved$7.5millioninmaintenancecosts

●Reduceddefectspermillionvehiclesfrom83to7

●Improvedfirst-timequalityyieldby47%

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN:2395-0072

Inventory Optimization

Causal Inference

Robotic Process Automation

Intel(5USChipPlants)

Toyota (7 North America Plants)

IBM(Global)

●Lowered chip inventory by 21%, freeing up $215 millionincash

●Improvedsupply-demandplanningaccuracyby33%

●Pinpointed material contamination as source of 8% ofproductdefects

●Alterationsaverted$22millioninrecallslastyear

●Improved order processing accuracy from 87% to 99%

●Reducedper-orderprocessingcostby62%

Predictive Maintenance: Machine learning algorithms that use real-time sensor data to forecast upcoming equipmentbreakdownsallowforproactive,downtime-minimizedservicing.SiemensappliessimilarAItorenewables, reducingturbineoperatingcostsbyanaverageof5-10%[11].

Quality Optimization: Computer vision AI autonomously assesses produced product compliance to standards. For example, combining the MachineMetrics platform with learning algorithms decreased quality issues in aerospace compositesbymorethan30%[12].

Inventory Optimization:Reliesonsimulationmodelinganddemandforecaststodeterminerawmaterialordersand fulfillmentlevels.Intelusesdeeplearningforchipinventoryplanning,saving$100milliononcapitalcosts[13].

Casual Inference: Techniques such as matching, inversion mapping, and counterfactual evaluation determine the isolated impact of interventions [14], allowing for precise root cause investigation and process optimization. FORD recently used causal modeling at three sites to discover characteristics contributing to a 6.2% reduction in casting errors, saving $14.3 million in scrap costs each year [15]. Robotic Process Automation: Software bots undertake repetitive tasks like as client order entry and documentation quality checking, with near-perfect accuracy for rulebasedhigh-volumeactivities[16].

61% of automotive and 53% of electronics manufacturers have implemented some type of AI, resulting in shorter production cycles and higher yields [17]. Continued exponential adoption could add more than 20-50% to manufacturing productivity growth in the next decade [18]. However, these deployments present integration and interfacechallengesthatnecessitatenewstrategies[19].

WhileAIautomationincreasesscalability,hybridsystemsthatincludepeopleintheloopmakingcrucialdecisionsand robotic agentson theirside improve qualityandproduction.BMW'sfactoriesusecobot-assistedpersonnel todetect over 10% more product deviations than automation alone [20]. Boeing's mechanic-robot teams complete aircraft wiring25%fasterthantheydoindividually[21].

Table2presentsafewmeasuredperformanceindicatorsrelatedtotheenhancementsinhuman-AIcollaboration:

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN:2395-0072

Osaro Cobot collaboration for electronicsassembly

Siemens

John Deere

Plant technicians + AI predictivemaintenance

Engineer + AI design optimization

●Doubledproductionlinethroughput

●$1.2millionoperatingcostssaved

●30%reductioninturbinedowntime

●$460Kinannualsavings

●New product development cycles shortened 15% Improved fuel efficiency8%better

This interdependent partnership exceeds individual contributions. Continuously transparent flows of context contribute to mutual understanding among agents [22]-[23]. Volkswagen's idea of a smart factory 'glass box' environmenthighlightstheinstrumentsneededforsuchcontinuousinterchangeandoversight[24].

However,challengespreventtherapidadoptionofAI[25].

Integration Difficulties (43% primary challenge): Connecting predictive maintenance analytics with complex cyberphysical operations requires extensive retrofitting [26]. Legacy IT also restricts data flows to cloud and edge AI. Partnershipsbridgeexpertiseshortagesduringtransitionperiodsasinternalteamsimprove.

CybersecurityandPrivacyRisks(64%concern)[27]:Shopfloorsensordatadevelopmentrisksexposure,demanding governancestructuresthatbalanceusability,ethics,andprotections.[28]-[29].

Lack of In-House Capability (more than $50 billion in worldwide reskilling investment required) [30]: Strategic recruiting, internal development programs, and change management allow workers to move to hybrid positions enhancedbyAI[31].

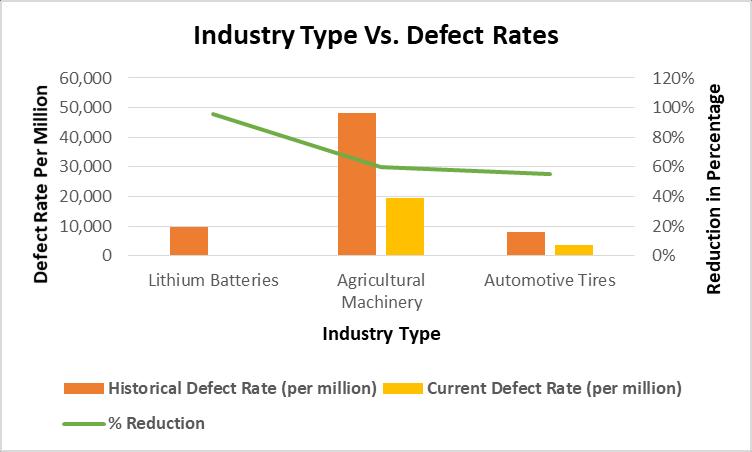

Successes demonstrate benefits: Osaro's quality optimization methods reduced lithium battery fault rates by over 1500% for an e-mobility producer by identifying valid manufacturing edge cases [32]. John Deere's AI camera improves damage detection in industrial welding 10 times faster than manual supervision alone [33]. Workers who are free of these difficult tasks can return to higher-level judgment roles. AI assistants that quantify metrics also provideoperationalinformationfortargetedenhancements[34].Asalgorithmsprogress,increasinglymoreanalytics usecaseswillariseacrossallproductionsegments[35].

Amoredetaileddescriptionofvarioususecases.

Osaro's machine learning quality control solution reduced lithium battery defect rates by more than 1500% for an electriccarOEMbythoroughlystudyingpriorinstancesofnormalanddefectivegoodscomingoffthemanufacturing line.Bytrainingonhundredsofthousandsofbatteryphotostodetectevenminorerrorsunseentohumaninspectors, the AI model properly identifies inferior batteries for engineer intervention at a rate of less than 50 defects per million, down from over 8,000 defects per million in the past. This reduced waste caused by late detection of latent problems. The enhanced AI evaluation also allows for proactive fine-tuning of manufacturing equipment to prevent growing deviations via early pattern notifications. Workers get relieved of routine quality control tasks to focus on higher-leveljudgmentactivities.

Figure 2 depicts an example dashboard depicting defect rate measurements and trends from Osaro's factory quality optimizationsolution,exhibitingareductionofover1500%duetohuman-AIcollaboration.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN:2395-0072

Similarly,JohnDeereusesAI-poweredvisualdamagedetectiontoidentifycracksanddebrisimpactmarksinwelding 10timesfasterthanqualitytechnicianscandomanually.Byautonomouslyscanningforfaultsinreal-timeratherthan relying on delayed human inspection of finished components, the AI assistant reduces losses caused by progressing incorrectlyweldedpiecesthroughfurthermachiningbeforefailurediscovery.Thissavesover$500Kincostsperyear forjustonefacility.Frontlinetechniciansrelievedof themostvisibleanomalyflaggingresponsibilitiesredeploytheir skillstomonitorAIinferencesforuncertainedgeinstancesandplangreatercomplexitydownstreammachiningwork.

In addition to shopfloor work enhancements, manufacturing AI systems provide operational insights from massive amounts of production data that were previously inaccessible. Identifying micro-scale trends improves system performance on a larger scale. As algorithms become ever more complex as computer power improves, many more analytics use cases will emerge in production efficiency, sustainability, logistics, and beyond - at every stage from demand signals to after-sales. However, carefully balancing roles and building trust between people and AI will remaincriticaltorealizingthissymbioticchange.

By2030,scientistspredictthatAIwillhavea$3-4trillionworldwideeconomicinfluenceacrossindustries[36].This implies great commitment, since algorithms match or exceed human capabilities in a growing number of manufacturing applications, from material sourcing to production and service after the sale. Despite 73% of manufacturersrecognizingAI'sgrowingimportanceforglobalcompetitiveness,just39%havetinyexperimentalpilot initiativesunderwaysofar[37].Thisindicatesanimplementationlagthatexpectedinnovationsmayovercome.

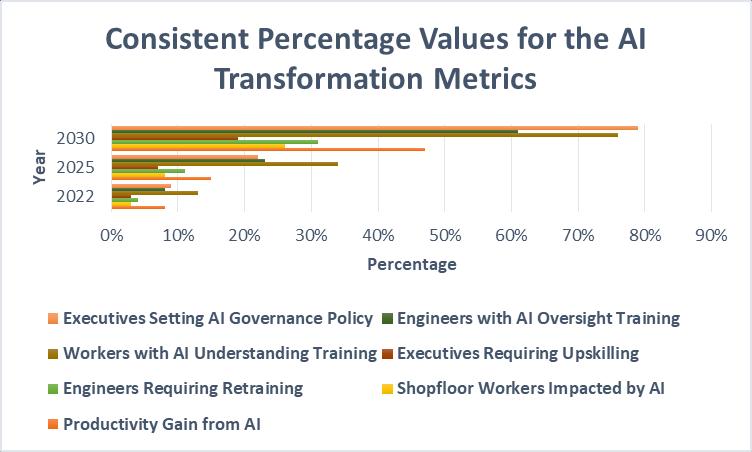

Substantialchangesinshopfloorprocesses,data-driveninterfaces,andnewroledefinitionsarerequiredtoproperly integrateintelligentalgorithmsintofundamentalmanufacturingactivities[38]-[39].Humanproductionlineoperators will be the most affected when robots and software bots transform assembly. Engineers will have to adapt to new workingenvironmentsbasedondigitaltwinsandvirtualcommissioningsimulations.Executivesmustalsodealwith rapid changes in required skill sets and organizational structures. Successfully navigating this change requires contextualized, continual training to ensure that frontline operators understand the behavioral limitations of AI assistants, engineers appropriately supervise autonomous decision systems, and leadership enforces updated protocols[40]-[41].

Furthermore, communication protocols must transmit capability restrictions between humans and AIs to facilitate transparent exchanges and build acceptable dependence [42-44]. Humans, for example, require rapid multimedia explanationsfromalgorithmstoappropriatelyevaluatedetectionsbeforestoppingproductionflows.AI toolsrequire operational data history feeds with context to detect edge anomalies. Such procedures for reliably enabling

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN:2395-0072

autonomousdecisionswhileretainingultimatecontrolwithhumansupervisorswillallowAItoreachitsfullpotential as algorithms match more cognitive capacities. Responsibly constructing this symbiotic future promises huge prosperitygains,butitrequiresvigilantgovernance.

Figure 3 displays the future potential for powerful AI systems to replicate an extensive range of human cognitive abilities.Toeffectivelyutilizethistechnologicalsymbiosis,competentgovernanceisrequired.

Smoothadoptiondemandslarge-scalereskillinginitiativestotrainmanufacturingworkersformorehybridrolesthat interactwithAI,which69%ofexecutivesviewasanimportantpriority[48]-[50].Accordingtoestimates,1.4million manufacturingjobsintheUnitedStateswillshiftoverthenextdecade,requiringtheacquisitionofnewtechnological skills [70]. Globally, approximately 700 million people may require major upgrading as algorithms automate predictableactivitiesandcollaboratewithhumanswhorequireupdatedskills[71].

The curriculum must develop both digital wisdom to use new tools and emotional intelligence to effectively collaborate with intelligent algorithms, which is essential for working in augmented surroundings [51]-[53]. Manufacturing certifications should include using a data visualization dashboard to monitor AI system health using accuracy KPIs, analytics training to quantitatively assess automated recommendations versus heuristics, and basic softwareengineeringandcybersecurityskillstoensureintegrityasalgorithmsinfluenceoperations[54].Only23%of manufacturersnowhaveformalretrainingprogramsinplace,indicatinganearlydegreeofpreparation[72].

Equally crucial, soft talents such as creative confidence, adaptability, communication abilities, and composure to effectivelyquestionproblematicmachinereasoningarerequiredfortrustcalibrationinautomation[55]-[56].Boeing, forexample,combinesvirtualrealitycollaborativerobotsimulationswithpsychology-basedgrouplearningactivities toemphasizesharingcontext,notjustorders,withAIassistants[73].Suchwell-roundedcompetenciesthatcombine technicalandsocioemotionalstrengthsallowmutuallyoptimizingcollaborativecontributionsthroughoutgenerations ofworkerswhileexponentiallyimprovingalgorithms.Investinginbothtechnicalskillsandempathy-focusedtraining ensuresasmoothertransitionashuman-AIcollaborationexpandsacrossallmanufacturingfloors.

Figure 4 depicts Boeing's use of immersive virtual reality simulations to train human workers to work together effectivelywithintelligentautomationinhybridroles.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN:2395-0072

Overtime,AIautomationmayreplaceupto60%oflabor-intensivetasks;however,new,specializedjobsthatrelyon human strengths may also arise in place of pure labor displacement [57]. Over 500 million jobs in industrial manufacturingarealreadyatriskduetoAI inthenexttenyears[74].Analystsstillprojectanetgaininemployment of58millionacrossallsectorsifpoliciesfacilitatethetransitionofworkerswithvulnerabilities[75].

Policiesinparticularhaveasignificantimpactthroughinitiativeslikewageinsurance,whichsubsidizestheincomeof displacedworkersundergoingretraining,taxbreaksthatgiveautomationtoolstosmallandmedium-sizedbusinesses investigatingnewtechnologies,andfundingforAIskillstrainingattechnicalcolleges [16],[58].Partnershipsbetween government, business, and academia can support large-scale reskilling programs, such as Rolls-Royce's apprenticeship programs, which anticipate automation by allowing people to rotate through tasks and obtain a varietyofexperiences[76].

Itispossibletoachievepositivelabordynamicsthroughtheresponsibleintroductionofautomationasatechnological multiplierthatenhanceshumanlabor.Manufacturingmaygrowmoreattractivetotalentasmoredata-orientedjobs such as simulation designers, sustainability analysts, predictive quality engineers, predictive quality engineers, nanomaterials scientists, and micro factory controllers become available [59]–[61], [77]. To ensure an inclusive prosperity transition, it is imperative to maintain ongoing surveillance of the impact of migration on marginalized populations[62]–[63].Manufacturerscanimproveworkerproductivitythroughtheimplementationofautomationby anticipatingproblemsaheadoftime.

Tooptimizeconfigurationsforsafeandproductiveoutcomes,itwillbecrucialtosystematicallyassessmeasuresthat measuretheusefulnessofhuman-AIcollaborationasalgorithmsbecomemoreandmoreprevalentonshopfloorsin the upcoming years [64]–[67]. Effective autonomous balancing can be better understood by quantifying variables such as sensorimotor workloads, physiological stress indicators, situational process awareness, operator trust in automatedrecommendations,andcollectiveproductionratesrelativetobenchmarks[68].

Surveys are useful for determining user acceptability levels across demographic variables, such as age, background, and previous tech proficiency, and for highlighting areas in which clear communication regarding AI aid is lacking

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN:2395-0072

[79].Thebestplacesforhumansandcobotstoswitchresponsibilitiesduringfluidworkflowsaredeterminedthrough simulationtestbeds[80].BMWfoundthatinspectionaccuracywasalmost10%higher withhuman-AIqualitycontrol than with humans alone, according to field experiments comparing hybrid team dynamics to entirely manual operations [18]. These studies quantify relative advantages at scale. Think-aloud protocol-controlled user trials uncover modalities such as text, voice, or visual interfaces that develop suitable automation dependence for certain applications[81].

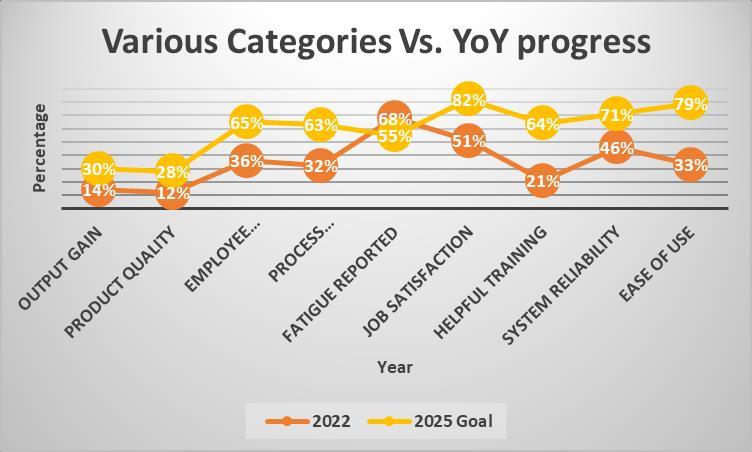

Figure 5 depicts a sample poll that evaluated human operator comfort with intelligent automation across several categories.Suchtestingisessentialforoptimizingsettingsthatimprovebothsafetyandproductivity.

Asalgorithmsimprovetothepointthattheyapproach orexceedhuman capabilities,these benchmarksrecommend suitableintegration.Establishingstandardsorganizationsisalsonecessaryforresponsibledeploymenttomanagethe evolutionofevaluationcriteriaacrossindustries.Forinstance,theIEEEGlobalInitiativeonEthicsofAutonomousand IntelligentSystemsoffersevaluationtechniquesthatpromotetransparent,secure,andreliableAIsystemdesign[82]. Highlighting the importance of early and frequent evaluation guarantees that manufacturing human-AI symbiosis generatesproductivityadvantagesthroughexpandedcapacitiesthataresafe.

The manufacturing industry is about to enter a new era propelled by exponential technologies and evolving algorithms that will enable humans to be more productive than they have ever been. As previously said, when implemented carefully, intelligent automation and AI-powered analytics have already demonstrated usefulness in a variety of applications, from quality control to maintenance. Over the next ten years, there will still be plenty of possibilitiesforgreateradoptionthatwillrevolutionizemanufacturingproductivity.

According to analyst projections, increasing the use of AI assistants to support the approximately 100 million industrial workers worldwide could have an economic impact of more than $3.5 trillion by 2030 [33]. Increased positions may also improve manufacturing talent attraction and job satisfaction [83]. However, just 21% of plants examined today had a deep understanding of AI [84]. It is important to concentrate on closing this knowledge gap regardingupskillingpolicies,safety,ethics,andteamdynamics[85]–[87].

Hybridintelligenceoffersinclusiveprosperitythrough ethical governancethatprioritizeshumandignitythroughout times of transformation. Researchers project that if automation spreads as augmenting instruments, there would be

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN:2395-0072

58 million net employment gains across all sectors [75]. However, this progress needs to be guided by constructive discussion among stakeholders. Standards organizations play a crucial role in defining best practices for measuring interactions,strategyformulation,andhuman-AIcollaboration[82],[88].Theintersectionoftechnicalinnovationand societalgrowthholdsthepotentialtoyieldsignificantadvancementsthatwillfuelthenextindustrialrevolution.

[1] B. Tücking, M. Li, Y. Zhou, H. Schulte Beerbühl and S. Liu, "Towards Digital Twin Based Smart Production ManagementandControlfortheAutomotiveIndustry,"IEEEAccess,vol.8,pp.228804-228813,2020.

[2] A. Radziwon, A. Bilberg, M. Bogers and E. S. Madsen, "The Smart Factory: Exploring Adaptive and Flexible ManufacturingSolutions,"ProcediaEngineering,vol.69,pp.1184-1190,2014.

[3]E.HofmannandM.Rüsch,"Industry4.0andthecurrentstatusaswellasfutureprospectsonlogistics,"Computers inIndustry,vol.89,pp.23-34,2017.

[4]Statista,"Sizeoftheartificialintelligence(AI)marketinthemanufacturingsectorworldwidefrom2018to2024", 2022. [Online]. Available: https://www.statista.com/statistics/802690/worldwide-artificial-intelligence-market-inthe-manufacturing-sector-forecast/.

[5]A.J.C.Trappey,"AsystematicliteraturereviewofcollaborativeproductcommercefortheChinesemanufacturing industry,"J.ChineseInst.Ind.Eng.,vol.34,no.6,pp.409-420,1Sept.2017.

[6] M. E. Porter and J. E. Heppelmann, "How Smart, Connected Products Are Transforming Companies," Harvard Business Review, October 2015. [Online]. Available: https://hbr.org/2015/10/how-smart-connected-products-aretransforming-companies.

[7] J. Lee, H. Davari, J. Singh and F. Pandhare, "Industrial artificial intelligence for Industry 4.0-based manufacturing systems,"ManufacturingLetters,vol.18,pp.20-23,April2019.

[8] T. Lauwers, "Data analytics in manufacturing: Value creation and big data," International Journal of Mechanical EngineeringandTechnology,vol.9,no.7,pp.1344 1353,2018.

[9]A.Nair,L.D.Xu,R.deLizarraldeandR.Nepal,"ASurveyonApplyingAIinDigitalManufacturing,"IEEEAccess,vol. 9,pp.97312-97332,2021.

[10]P.O’Donovan,K.Leahy,K.BrutonandD.T.J.O’Sullivan,"Bigdatainmanufacturing:asystematicmappingstudy," JournalofBigData,vol.2,no.1,2015.

[11] Siemens, "Predictive Maintenance 4.0 Driving Value in Manufacturing Operations," 2017. [Online]. Available: https://assets.new.siemens.com/siemens/assets/public.1519656653.a5c1a433397db27640c3d2d5f420d5588b6696 36.sts-predictive-maintenance-4-0.pdf.

[12] MachineMetrics, "How BMW Uses MachineMetrics to Take Responsibility for Quality Control," 2018. [Online]. Available: https://www.machinemetrics.com/case-studies/bmw-uses-machinemetrics-to-take-responsibility-forquality-control/.

[13] J. Varghese and V. Sinha, "The Journey Towards Autonomic Supply Chains in Industry 4.0 and Beyond," IFACPapersOnLine,vol.49,no.29,pp.21-26.2016.

[14] S. Athey and G. W. Imbens, "Machine learning methods for estimating heterogeneous causal effects," stat 1050, no.5,2015.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN:2395-0072

[15] M. Toffel, "Ford Applies Causal Analysis to Manufacturing," Harvard Business Review, June 2021. [Online]. Available:https://hbr.org/2021/06/ford-applies-causal-analysis-to-manufacturing.

[16] EY, "How will RPA shape the future of work," Ernst & Young LLP, 2019. [Online]. Available: https://assets.ey.com/content/dam/ey-sites/ey-com/en_gl/topics/automation/ey-how-will-rpa-shape-the-future-ofwork.pdf.

[17] S. Earley, "% of automotive and electronics manufacturers have implemented some type of AI, resulting in shorterproductioncyclesandhigheryields,"ITNOW,vol.61,no.1,pp.32-33,Spring2019.

[18] BMW Group, "BMW Group uses artificial intelligence to support production," Mar 2021. [Online]. Available: https://www.bmwgroup.com/en/innovation/company-presentations-2021.html

[19] BOEING, "Boeing brings unmatched experience to transform Australia's aerospace and defense industry," Feb 2022.[Online].Available:https://boeing.mediaroom.com/news-releases-statements?item=130780.

[20] N. Karabatsou, "There's an AI assistant now! Why is this significant?: Explaining agency and conversational identityinhuman-chatbotinteraction,"Discourse&Communication,vol.14,no.2,pp.182-197,2020.

[21] D. Gunning, "Explainable artificial intelligence," Defense Advanced Research Projects Agency (DARPA), 2018. [Online].Available:https://www.darpa.mil/program/explainable-artificial-intelligence.

[22] M.E. Porter, and J.E. Heppelmann, "How smart, connected products are transforming companies," Harvard Business Review, 2015. [Online]. Available: https://hbr.org/2015/10/how-smart-connected-products-aretransforming-companies.

[23] A. Wilson and P. Daugherty, "Collaborative intelligence: humans and AI are joining forces," Harvard Business Review,vol.96,no.4,pp.114-123,July August2018.

[24]J.Lee,B.Lukic,J.PavlicandG.Schnieder,"Ontheroadtoself-optimisingfactories,"ProcediaCIRP,vol.7,pp.400405,2013.

[25]R.E.Moritz,F.Zijp-Tan,C.Liu,S.Giordano,D.GiaffredaandK.Moessner,"NewOPTICS:Anoptimizationapproach todesigningindustrialcyber-physicalsystemsandprocesses,"NISTSpecialPublication1900-210.Sep2018.

[26] F. Galdishaus and M.R. Gruschinske, "How stringent should data privacy regulations for machine learning be?" 2021IEEEInternationalConferenceonRoboticsandAutomation(ICRA),2021.

[27]B.A.Kitchenham,"Ethicsinempiricalsoftwareengineeringresearch,"JournalofSystemsandSoftware,vol.179, p.110947,2021.

[28]S.Bradley,A.LiuandS.Wilson,"ThejobsAIcan'ttake,"MITSloanManagementReview,vol.59,no.1,pp.14-16, Fall2017

[29] Osaro Inc., "Osaro Improves Quality in EV Battery Manufacturing", May 2019. [Online]. Available: https://osaro.com/case-studies/tier-1-ev-battery-manufacturer/.

[30] N. Fleischmann," AI is changing manufacturing as we know it," Forbes, March 2019. [Online]. Available: https://www.forbes.com/sites/nicolefleischmann/2019/03/07/ai-is-changing-manufacturing-as-we-knowit/?sh=2d408a134195.

[31] Y. Lu, "Industry 4.0: A survey on technologies, applications and open research issues," Journal of Industrial InformationIntegration,vol.6,pp.1-10,June2017.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN:2395-0072

[32]B.Grabot,"EditorialforComputersinIndustrySpecialIssueArtificialIntelligenceforKnowledgeManagementin ManufacturingandServices,"ComputersinIndustry,vol.123,p.103358,Feb2021.

[33] PwC, "Sizing the prize: PwC's global artificial intelligence study: Exploiting the AI revolution," 2017. [Online]. Available:https://www.pwc.com/gx/en/issues/data-and-analytics/publications/artificial-intelligence-study.html.

[34]PwC,"Industrial manufacturingtrends:AI,robotics andautomationpowerthe nextphaseoftransformationfor smart factories," 2019. [Online]. Available: https://www.pwc.com/gx/en/industries/industrialmanufacturing/publications/ai-robotics-automation.html.

[35] World Economic Forum, "The new production workforce: Responding to shifting labour demands," Jan. 2019. [Online].Available:https://www3.weforum.org/docs/WEF_2019_-_The_New_Production_Workforce.pdf.

[36]S.Mattsson,Å.FasthandC.Li,"ManagingchangetowardsLeanproductioninthemanufacturingindustry," Soc. Sci.,vol.9,no.9,Sep.2020.

[37]J.M.Bauer,S.S.WollertandD.Rieger,"Futuremanufacturingsystems:towardssocialproductdevelopment,"Soc. Sci.,vol.10,no.1,p.4,Jan.2021

[38] A. B. Cambazoglu, V. Mitschang, L. Bradatsch, F. Leymann and S. Mendling, "Enabling Social Manufacturing: Process-Oriented Crowdsourcing for Efficient Manufacturing Planning," IEEE International Conference on Emerging TechnologiesandFactoryAutomation,Hamburg,2014.

[39]M.Skorinko,A.Scarritt,J.McKinneyandK.Richardson,"TransparentcommunicationmitigatesovertrustofAIin human-machineteams,"inIUIWorkshops,2020.

[40]S.Mattsson,Å.FasthandC.Li,"FormingacognitiveautomationstrategyforOperator4.0incomplexassembly," Computers&IndustrialEngineering,vol.139,Jan.2020.

[41] N. Karabatsou, "There's an AI assistant now! Why is this significant?: Explaining agency and conversational identityinhuman-chatbotinteraction,"Discourse&Communication,vol.14,no.2,pp.182-197,2020.

[42] D. Gunning, "Explainable artificial intelligence," Defense Advanced Research Projects Agency (DARPA), 2018. [Online].Available:https://www.darpa.mil/program/explainable-artificial-intelligence.

[43]P.Wang,K.MerrickandA.K.AbbassH,"Trustinautomation:Takingstockandmovingforward,"Ergonomics,vol. 63,no.9,pp.1114-1129,2020.

[44]TheIEEEGlobalInitiativeonEthicsofAutonomousandIntelligentSystems.Ethicallyaligneddesign:Avisionfor prioritizinghumanwellbeingwithautonomousandintelligentsystems.IEEE,2019.

[45]S Mattsson,Å. Fast-Berglund,FK. Li,"Managing the humaninhuman--robotcollaboration exploring challenges andabilitiesinassemblywork",InternationalJournalofProductionResearch,vol.59,no.8,pp.2428-2443,2021.

[46] Capgemini Research Institute, "The AI-powered enterprise: unlocking the potential of AI at scale", July 2020. [Online].Available:https://www.capgemini.com/research/the-ai-powered-enterprise/.

[47]T.Davenport,RA.Ronanki"ArtificialIntelligencefortheRealWorld,"Harvardbusinessreview,vol.96,no.1,pp. 108-116,2018.

[48]M.Skorinko,A.Scarritt,J.McKinneyandK.Richardson,"TransparentcommunicationmitigatesovertrustofAIin human-machineteams,"inIUIWorkshops,2020.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN:2395-0072

[49]S.Makridakis,"TheforthcomingArtificial Intelligence(AI) revolution: Itsimpactonsocietyandfirms,"Futures, vol.90,pp.46-60,2017.

[50]IEEEP7003TM,"AlgorithmicBiasConsiderations,"inIEEEStandardsProjectP7003,2021.

[51]S.Vaidya,P.AmbadandS.Bhosle,"Industry4.0-Aglimpse,"ProcediaManuf.,vol.20,pp.233-238,2018.

[52] J. Lee, J. Davari Haghpanah, S. Y. Nof and B. Zupancic, "The emerging industry of manufacturing collaboration robots and the role of human robot collaboration in the digitalization age," Int. J. Prod. Res., vol. 58, no. 7, pp. 21172128,Apr.2020.

[53]B.GravesandJ.Karabatsos,agileworkforcedevelopmentmodelforindustry4.0.IGIGlobal,2019,pp.150 173.

[54]P.O.Gislason,"Digitalfitness:Certificationofemployees'digitalskillsforindustry4.0productionenvironments", Societies,vol.11,no.2,2021.

[55] L. Dandinog and G.L. Dadios, "Investigating into the productivity skills associated by industry 4.0 affecting the employabilityrateinthemanufacturingindustry,"Int.J.Mech.Eng.Technol.,vol.9,no.10,pp.954 963,2018.

[56]Y.N.Chang,X.HuangandY.Luo,"Promoteoperator'sattentioninassemblylines:Fromtheperspectiveofbrain science,"Computers&IndustrialEngineering,vol.107,pp.246-255,2017.

[57] M. Arntz, T. Gregory and U. Zierahn, "Digitalization and the future of work: macroeconomic consequences," HandbookofLabor,HumanResourcesandPopulationEconomics,pp1-29,2020.

[58] J. Bessen, "Automation and jobs: when technology boosts employment," Economic Policy Papers, Boston Univ. SchoolofLaw,LawandEconomicsResearchPaperSeries17-09,2017.

[59] D.H. Autor, "Why are there still so many jobs? The history and future of workplace automation," Journal of economicperspectives,vol.29,no.3,pp.3-30,2015.

[60]M.Armbrustetal.,"ScalingAI:Thebiologyofbusinessintelligence,"IEEESecurityPrivacy,vol.17,no.4,pp.1115,Jul.-Aug.2019.

[61]D.Reher,M.González-BailónandA.Bessa,"Limitsofautomation:Asociotechnicalperspectiveonhuman robot complementarity,"SocArXiv,Nov.2020.

[62] D. Nedelkoska and G. Quintini, "Automation, skills use and training," OECD Social, Employment and Migration WorkingPapers,2018.

[63] E. Marengoa and T. Evans, "Policy interventions to support digitalization and productivity performance across theOECD,"OECDScience,TechnologyandIndustryPolicyPapers,vol.89,2021.

[64] A. Dragan and S.S. Srinivasa, "Integrating human observer inferences into robot motion planning," Autonomous Robots,vol.37,pp.351 368,2014.

[65]S.Nikolaidisetal.,"Game-theoreticmodelingofhuman-robotcollaboration,"inHRI,2015.

[66] M. Lewis, K. Mizukami and L.P. Rees Lewis, "The cost of interrupted work: more speed and stress," in CHI Conference,2017.

[67]M.MrugalskaandM.K.Wyrwicka,"Towardsleanproductioninindustry4.0,"ProcediaEngineering,vol.182,pp. 466-473,2017.

2024, IRJET | Impact Factor value: 8.226 | ISO 9001:2008 Certified Journal | Page

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN:2395-0072

[68] M.F. Zaeh, "Evaluation of human machine interaction and cooperation in future smart and automated productionsystemsbyapplicationofspecificindicators,"Int.JournalComputerIntegratedManufacturing,vol.30,no. 12,pp.1265-1275,2017.

[69] J.M. Bauer, M.M.W.B. Pathier and V.J.H. Mittelstadt, "Drivers of business model innovation enabling circular economy Amultiplecasestudyanalysisamonghigh-techSMEs,"JournalofManufacturingTechnologyManagement, 2021.

[70]Y.N.Chang,X.HuangandY.Luo,"Promoteoperator'sattentioninassemblylines:Fromtheperspectiveofbrain science,"Computers&IndustrialEngineering,vol.107,pp.246-255,2017.

[71] A.J.C. Trappey, H.M. Hsiao, A.R. Tan and J.J. Li, "best practice for machine tool selection and operation management for the manufacturing industry 4.0 transformation," Journal of Intelligent Manufacturing, pp. 1 19, 2022.

[72] Capgemini Research Institute, "AI in manufacturing operations: A survey of executives", Jul 2020. [Online]. Available:https://www.capgemini.com/research/ai-in-manufacturing-operations/.

[73] BOEING, "Boeing brings unmatched experience to transform Australia's aerospace and defense industry," Feb 2022.[Online].Available:https://boeing.mediaroom.com/news-releases-statements?item=130780.

[74]InternationalLabourOrganization,"Theimpactoftechnologyonthequalityandquantityofjobs,"IssueBriefNo. 6, Apr. 2021. [Online]. Available: https://www.ilo.org/wcmsp5/groups/public/ dgreports/ cabinet/documents/publication/wcms_766163.pdf.

[75] M. Arntz, T. Gregory and U. Zierahn, "Digitalization and the future of work: macroeconomic consequences," HandbookofLabor,HumanResourcesandPopulationEconomics,pp1-29,2020.

[76] McKinsey, "Skill shift Automation and the future of the workforce," May 2018. [Online]. Available: https://www.mckinsey.com/featured-insights/future-of-work/skill-shift-automation-and-the-future-of-theworkforce.

[77]E.BrynjolfssonandA.McAfee,"Thebusinessofartificialintelligence,"HarvardBusinessReview,vol.95,no.4,pp. 1-20,Jul.2017.

[78]Statista,"Sizeoftheartificialintelligence(AI)marketinthemanufacturingsectorworldwidefrom2018to2024", 2022. [Online]. Available: https://www.statista.com/statistics/802690/worldwide-artificial-intelligence-market-inthe-manufacturing-sector-forecast/.

[79] Foley & Lardner LLP, "Consumer survey: Privacy concerns in smart manufacturing", Aug 2015. [Online]. Available: https://www.foley.com/en/insights/publications/2015/08/consumer-survey-privacy-concerns-in-smartmanufac.

[80]A.DraganandS.S.Srinivasa,"Integratinghumanobserverinferencesintorobotmotionplanning,"Auton.Robots, vol.37,pp.351 368,2014.

[81] A. Bussone, S. Stumpf and D. O'Sullivan, "The role of explanations on trust and reliance in clinical decision supportsystems,"inHEALTHINF,2015.

[82]TheIEEEGlobalInitiativeonEthicsofAutonomousandIntelligentSystems.Ethicallyaligneddesign:Avisionfor prioritizinghumanwellbeingwithautonomousandintelligentsystems.IEEE,2019.

[83]S Mattsson,Å. Fast-Berglund,FK. Li,"Managing the humaninhuman robotcollaboration exploring challenges andabilitiesinassemblywork",InternationalJournalofProductionResearch,vol.59,no.8,pp.2428-2443,2021.

2024, IRJET | Impact Factor value: 8.226 | ISO 9001:2008

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

[84] Capgemini Research Institute, "The AI-powered enterprise: unlocking the potential of AI at scale", July 2020. [Online].Available:https://www.capgemini.com/research/the-ai-powered-enterprise/.

[85]T.Davenport,RA.Ronanki"ArtificialIntelligencefortheRealWorld,"Harvardbusinessreview,vol.96,no.1,pp. 108-116,2018.

[86]M.Skorinko,A.Scarritt,J.McKinneyandK.Richardson,"TransparentcommunicationmitigatesovertrustofAIin human-machineteams,"inIUIWorkshops,2020.

[87]S.Makridakis,"TheforthcomingArtificial Intelligence(AI) revolution: Itsimpactonsocietyandfirms,"Futures, vol.90,pp.46-60,2017.

[88]IEEEP7003TM,"AlgorithmicBiasConsiderations,"inIEEEStandardsProjectP7003,2021.

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN:2395-0072 © 2024, IRJET | Impact Factor value: 8.226 | ISO 9001:2008