International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN: 2395-0072

Sudhanshu Bhushan1 , Ajay Singh2 , Parag Mishra3

1 Scholar, Department of Mechanical Engineering, Radharaman Institute of Technology and Science, Bhopal, M.P., India.

2Head and Prof., Department of Mechanical Engineering, Radharaman Institute of Technology and Science, Bhopal, M.P., India

3Assosiate Professor, Department of Mechanical Engineering, Radharaman Institute of Technology and Science, Bhopal, M.P., India.

Abstract - This study presents a comprehensive computational fluid dynamics (CFD) analysis of a shell and tube heat exchanger with anovelenhancementtechnique -the insertion of twisted tape turbulators within the tubeside -and the incorporation of Aluminum Oxide (Al2O3) nanoparticlesin water as the base fluid. The primary objective is to investigate and compare the heat transfer rate, convective heat transfer coefficient, and pressure drop characteristics under various operating conditions. The numerical simulations were conducted using commercial CFD software, where the governing equations of mass, momentum, and energy were solved employing the finite volumemethod.Thek-ε turbulence model was adopted to account for turbulent flow behavior inside the heat exchanger. The results obtained from the CFD simulations were validated against experimental data, ensuring the accuracy and reliability of the computational approach. Subsequently, a parametricstudywasperformedto explore the effects of varying nanoparticle concentrations, flow velocities, and twist ratios of the tape turbulators on the heat transfer and pressure drop characteristics. The findings reveal that the incorporation of Al2O3 nanoparticles significantly enhances the overall heat transfer rate, with notable improvements observed at higher nanoparticle concentrations. Moreover, the convective heat transfer coefficient is found to be enhanced due to the presence of the twisted tape turbulators, demonstrating a significant impact on the overall performance of the heat exchanger. However, it is also observed that an increase in nanoparticle concentration leads to an augmentedpressuredropacrossthe heat exchanger. Therefore, a trade-offbetweenenhancedheat transfer and increased pressure dropneedstobeconsideredin practical applications. In conclusion, this study provides valuable insights into the use of twisted tape turbulators and SiO2 nanofluids in shell and tube heat exchangers. The results offer a fundamental understanding of the thermal and hydrodynamic behavior and can aid in optimizing the design and operational parameters to achieve an optimal balance between enhanced heat transfer performance and acceptable pressure drop levels in industrial applications.

Key Words: Heat Exchanger, Nanofluid, Twisted Tape Turbulator, CFD Analysis, Thermal Analysis

Heatexchangersplayapivotalroleinnumerousindustrial processesandenergysystems,facilitatingefficientthermal energytransferbetweentwofluidstreams.Overtheyears, researchershaveexploredvariousenhancementtechniques toaugmenttheheattransferrateandimprovetheoverall efficiencyoftheseheatexchangers.Amongtheprominent techniques,theinsertionofturbulatorswithinthetubeside and the utilization of nanofluids have shown promising resultsinenhancingheattransfercharacteristics.Inrecent years,computationalfluiddynamics(CFD)hasemergedasa powerfultoolforinvestigatingfluidflowandheattransfer phenomena.CFDsimulationsprovidedetailedinsightsinto complexfluiddynamicsandofferacost-effectiveapproach to evaluate different heat exchanger configurations and operating conditions. This study focuses on conducting a comprehensive CFD analysis of a shell and tube heat exchanger, which incorporates twisted tape turbulators insidethetubeandutilizesananofluidcomposedofsilicon dioxide(SiO2)nanoparticlesdispersedinwaterasthebase fluid. The incorporation of twisted tape turbulators in the tubeside ofheat exchangershasgainedpopularitydue to their ability to induce turbulence and enhance convective heat transfer. Twisted tapes promote the formation of secondaryflowpatterns,breakingtheboundarylayerand leadingtoincreasedheattransferrates.Consequently,these turbulators have been widely adopted to improve the thermal performance of heat exchangers, particularly in applications involving high heat transfer requirements. In additiontotheuseofturbulators,nanofluidshaveemerged as a promising heat transfer enhancement medium. Nanofluids are colloidal suspensions of nanoparticles in a base fluid, which exhibit unique thermal properties comparedtoconventionalfluids.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN: 2395-0072

In this experimental study, the Electro-Magnetic Vibration (EMV) method utilizes a stretched string vibrating at its natural frequency within a heated tube, induced by an AC magneticfield.Thisnovelapproachgeneratesturbulenceand radialflow,boostingheattransferrates.Analysisinvolving varying vibrating string turbulator (VST) diameters and exciterpositions,alongsidethermalperformanceevaluation (TEF),revealedapotentialenhancementfactorofupto1.47. This underscores EMV's effectiveness in intensifying heat exchanger performance through robust radial flow generation [1]. This study introduces the Special Shape TwistedTapeTurbulator(SSTT)withaDNA-likestructureto enhance heat transfer in conduits. Through segmented components, it induces swirling motion, showing a 125% improvement over plain tubes at a 2mm pitch ratio. CombiningSSTTwithahelicalcoiledwireturbulatoryieldsa 142% increase in heat transfer but also a 960% rise in pressure drop, achieving a 20% enhancement in thermal performance to 1.31 [2]. This research employed the innovativeelectromagneticvibration(EMV)techniqueina double-tube heat exchanger (DTHEX) for enhanced heat transfer.Assessingfactorslikeoscillatorgeometry,magnet placement, nanofluids, and fluid flow, it achieved a remarkable 277.5% improvement using CuO-water 1% nanofluidcomparedtoastandardheatexchanger.Withthe potential to increase heat transfer by up to 13.3 times the energy input, this method presents a transformative opportunityinconservingmaterials,energy,andoptimizing heat exchanger and solar system designs [3]. This paper exploresrenewableenergyuseinresidentialandgreenhouse heating/cooling, focusing on soil air conditioning systems. Findings highlight air-driven ventilation as superior in summer,withsmallerpipediametersandlongerpipelines enhancingperformance.ThestudyconductedinfourIranian cities demonstrates Rasht's system as highly effective for heating and Abadan's for cooling. Additionally, cost comparisons between soil cooling and conventional HVAC systems were examined [4]. The study investigated heat transferandexergylossesinadouble-tubeheatexchanger withcorrugatedinnertubes.Semi-ellipticalcorrugationson theinnertubesignificantlyimpactedheattransferandexergy losses, while modified corrugations, combining quarterelliptic shapes and inclined lines, delayed flow separation, boostingheattransfer.However,heightenedheattransferled to escalated exergy losses, emphasizing the trade-offs in performance enhancement [5]. This paper delves into a numericalinvestigationofathree-dimensionalbaffledshell andtubeheatexchanger,exploringtheinfluenceofphysical variableslikebafflenumbersandbaffletypechangesonheat transfer and exergy using the SST turbulence model. Analyzingoilandwaterashotandcoldfluids,thefindings revealthatincreasingoilflowratesescalateheattransferand exergy loss. Furthermore, augmenting baffles from 3 to 5 amplifiesbothheattransferandexergylossinthesystem[6]. The study investigates enhanced thermal performance in

ShellandHelicallyCoiledTubeHeatExchangers(SHCTHEXs) using an Al2O3-TiO2/water hybrid nanofluid. Simulations reveala 7.7%to9%increaseinheattransferratesforthe horizontallyandverticallyorientedSHCTHEXs,respectively. The best performance is seen in the horizontally oriented SHCTHEX with the hybrid nanofluid, providing superior coolingcomparedtootherconfigurations,emphasizingthe significantimpactofnanofluidutilizationonheattransfer[7]. This paper consolidates findings on enhancing thermophysical properties of nanofluids by examiningkey parameters like particle characteristics, base fluid, temperature, additives, and pH. It serves as a valuable resource amidst conflicting reports, aiding researchers in navigating diverse studies. Additionally, it delves into nanofluidapplications,emphasizingtheiradvantagesinsolar collectorsandautomotiveheatexchangers,aimingtobridge thegapbetweenlab-scaleresearchandpracticalindustrial implementation while outlining avenues for future exploration [8]. The study constructed carbon nanotubesreinforced composite honeycomb sandwich panels via silicone molding to enhance mechanical properties. The results showcased a direct correlation between increased nanotube content and wall thickness with higher compressiveandflexuralstrength,highlightingpotentialfor strongersandwichpanelswithtailoredproperties[9].The manipulationofelectricalandthermalconductivityinCNTmodified polymeric composites (CNTMPCs) hinges on variousfactorssuchaschirality,length,type,fabrication,and interfaceinteractions.Moleculardynamics(MD)simulations highlight how chirality impacts shorter CNTs more than longer ones, withzigzag CNTs showinglower conductivity than armchair types. Additionally, MD modeling demonstrates a notable increase in thermal and electrical conductivitywithlongeroverlaplengths,underscoringthe potential for designing highly conductive CNTMPCs with specificproperties,thoughfurthercomprehensivestudiesare necessary due to the multitude of influencing factors [10]. The use of carbon nanotubes (CNTs) in silicone-molded composites for honeycomb sandwich structures enhances thermal stability and energy absorption. Increasing CNT contentupto0.075wt.%notablyraisedthermaldegradation temperature by 14°C and improved energy absorption by 4.6%. Innovative dispersion techniques resulted in higher thermalconductivitywithlowerCNTamountscomparedto prior studies, offering engineers an optimal strategy for designing superior thermal properties in composite structures [11]. In this research, a novel aerodynamically designedperforatedteardrop-shapedturbulator(PTST)was numerically analyzed for its impact on hydro-thermal parameters.Variationsinholegeometryandareawithinthe PTST revealed significant effects on heat transfer and pressuredrop,highlightinga1.39-foldincreaseinThermal EnhancementFactor(TEF)witha 5 mm diametercircular hole. Comparatively, PTST and simple teardrop-shaped turbulator (STST) showed 298% to 310.1% higher heat transferthanaplaintube,whileacorrelationbetweenTEF andperforationarea wasestablishedthroughcurvefitting

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN: 2395-0072

[12].Thispaperdelvesintoenhancingtheexergo-economic performanceofcompactairheatexchangersbyemploying passive techniques like TTI, PTTI, and DTTI with various tripartite hybrid nanofluids. Simulation results show that DTTIwithTHNF6exhibitsthehighestoverallheattransfer coefficient (26%), 2.94% exergy efficiency, 5.04% performanceindex,andasuperiorsustainabilityindexatlow Reynoldsnumbers,whileTHNF2,duetoitshighoperating cost,islesspreferreddespiteaPECrangeof1.42–2.35[13]. ThestudyenhancedconventionalShellandHelicallyCoiled TubeHeatExchangers(SHCTHEXs)byintegratingdiscsand ringsas baffles, elevatingthermal performance.Numerical simulationsrevealeda7.1%increaseinheattransferanda 20%riseinoverallheattransfercoefficientcomparedtothe conventionaldesign.Experimentalvalidationcloselyaligned with simulations, showcasing a promising 2.4-3.5% difference,affirming thesuccess ofthe modifiedSHCTHEX with circular baffles, achieving an overall heat transfer coefficient of1050-1400 W/m²K [14]. Thisstudy explores enhancingU-typetubularheatexchanger(THEX)efficiency byemployingCuO-Al2O3/waterhybridnanofluid.Numerical simulationsandexperimentalanalysesdemonstratethatthis hybrid nanofluid significantly boosts overall heat transfer coefficients in THEX compared to single-component nanofluids. While fin additions elevate heat transfer, they escalatepressuredropparticularlyinsmallerdiameterTHEX, highlightingtheefficacyofhybridnanofluidsinaugmenting thermal performance without such drawbacks [15]. This paperexploresanexperimentalanalysisofaheatexchanger tube using a newly devised perforated conical ring in combinationwithtwistedtapeinserts.Itinvestigatesdiverse geometricandflowparameters,spanningReynoldsnumbers from6000to30000,nanoparticlevolumeconcentrationsof 0.25-1.0%,andvariousratiosforinletflowdiametertoinner printdiameterofthering,ringpitch,andtwistratios.Optimal thermal-hydraulic performance (1.45) was achieved at specific parameters, paving the way for empirical correlations for Nusselt number and friction factor in CuO/H2O nanofluids flow heat exchanger tubes with perforatedconicalrings[16].

Table1:Propertiesofbasefluid,nanoparticlesand nanofluid

The problem of performance of heat exchanger can be improvedbyeithercreatingaturbulenceintheflowregime, or by improving the quality of fluid flowing through the system.Enhancementoftheheattransferenablesthesizeof theheatexchangertobesignificantlydecreased.

In the present work, passive techniques/twisted tape turbulators (TTT) producing swirl motion are used to improve the thermal performance characteristics of concentrictubeheatexchangerswithdifferentnanoparticles.

Thus, the effect of fluid quality improvement is studied in doubletubeheatexchangerbyadditionofaluminumoxides nano particles (Al2O3). A comparative analysis is done by changingtheconcentrationofnanoparticlesinbaseliquidof water.Thebestconcentrationvalueofnanofluidwillprovide theoptimizequalitiesofnanofluidwhichkeepingtheshear stressincontrolledlimits.Atotalof4readingsaretakenon differentvaluesofmassflowratesinordertoverifythetrend ofperformance.Themassflowrateofcoldnanofluidiskept on0.05,0.1,0.15,0.20kg/srespectively.

Table2showsthegeometryoftheheatexchanger.Outside diameterofthetubeis40mm,insidedimeterofthetubeis 41 mm. outside diameter if shell is 80mm and inside diameterofshellis82mm

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net

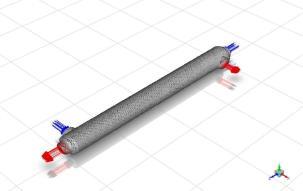

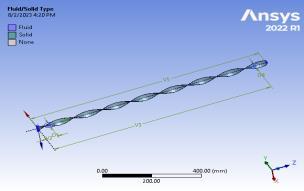

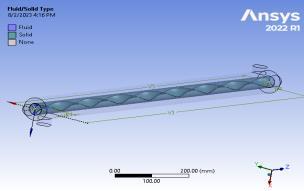

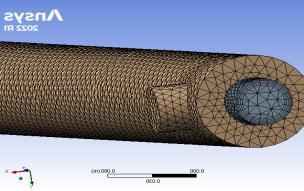

Figure1:GeometryofHeatExchangerwithtwistedtape andmeshing

Thedatasetpresentsdetailsofanaluminumtubeandshell heattransfersystem,featuringatubewithanouterdiameter of40mmandaninnerdiameterof41mm,aswellasashell withanouterdiameterof80mmandaninnerdiameterof82 mm.Theeffectivelengthsofthetubeandshellare1020mm and 1000 mm, respectively, with a heat transfer area of 853,160mm².Additionally,thedatamentionsaparameter called"Sweepwithnumberofturns,"whichis4,8and12.

5. CFD REPORT

Table 3 shows the meshing report of the geometry. It showstheelementsize,meshquality,inflationinformation andstatisticslikenumberofnodesandelements.

Object

Defeature

Curvature

CaptureProximity No Bounding

Check

ViewAdvancedOptions No Advanced

NumberofCPUsforParallel PartMeshing ProgramControlled

StraightSidedElements

RigidBodyBehavior DimensionallyReduced

TriangleSurfaceMesher ProgramControlled

TopologyChecking Yes

PinchTolerance Default(4.5e-005m)

GeneratePinchonRefresh No Statistics Nodes 2364475 Elements 3916835

6.1. Heat Transfer Rate

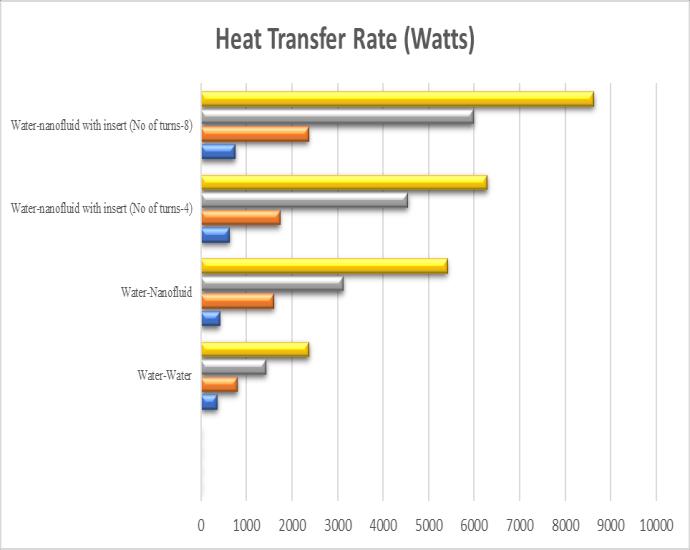

Figure2showsthecomparativevaluesofheattransferrates ofconcentriccircularplanetubeswithoutanyinserts,with

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN: 2395-0072

waterflowingashotfluidinboththecasesbutincaseofcold fluid,onearrangementhaswaterflowingascoldfluidandthe nexttime,theAl2O3nanofluidwithvolumefractionof0.4is flowingas coldliquid respectively. The comparisonshows thatthemaximumvalueofheattransferrateforthesame flowratesisachievedforwater-nanofluidarrangementat 0.4kg/swithavalueof8632.15wattsandWater-nanofluid withinsert(Noofturns-4)Water-nanofluidwithinsert(Noof turns-8)andWater-nanofluidwithinsert(Noofturns-12)is 6288.7W,8632.7Wand9876.17W.

2:RateofHeatTransferversusmassflowrateof Hot

6.2. Convective Heat Transfer Coefficient

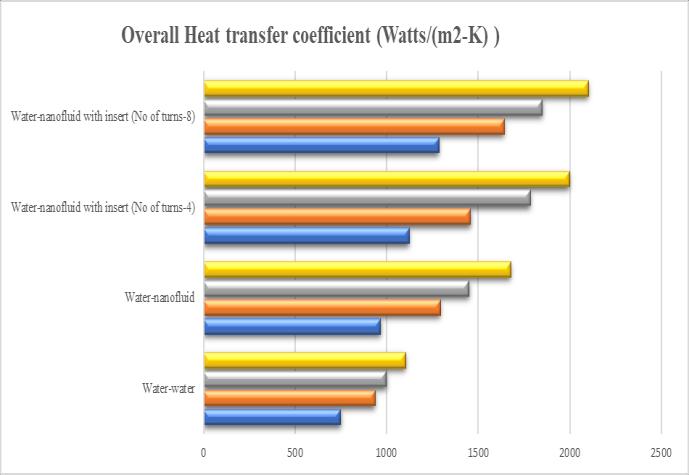

Fig.3showsthecomparativevaluesofOverallHeattransfer coefficient of concentric circular plane tubes without any inserts,withwater-waterarrangementandwater-nanofluid arrangement respectively. The comparison shows that the maximum valueofOverall Heattransfercoefficientforthe sameflowratesisachievedwater-nanofluidarrangementat 0.2kg/swithavalueof2245.81(Watts/(m2-K)).

3:

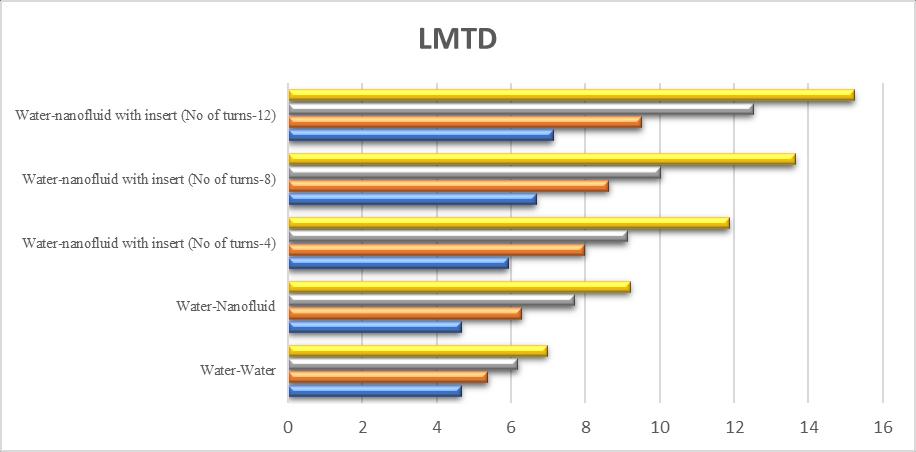

Fig4showsthecomparativevaluesofLMTDofconcentric circularplanetubeswithoutanyinserts,withwater-water and water-nanofluid arrangement respectively. The comparisonshowsthatthemaximumvalueofLMTDforthe sameflowratesisachievedforwater-nanofluidarrangement, anditwasatitsmaximumon0.2kg/swithavalueof9.21088. Thisgrowthisduetothefactthattemperaturedifferenceat the inlet and exit increases. Since LMTD is directly proportionaltochangeintemperatureatinletandexit.Thus, italsoshowsincreasew.r.tthemassflowrate.

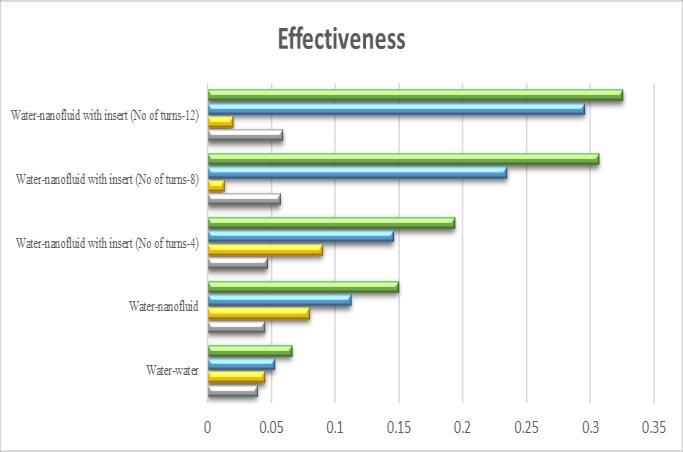

Figure5showsthecomparisonofheattransferratesamong waterasahotfluidandcoldfluid,hotfluidasawaterand coldfluidasananofluidwithdifferentnumberofturnsofthe insertlike4turns,8turnsand12turns.Fromthegraph,it canclearlybeseenthatasthethermalpropertiesofthefluid increases,rateofheattransferincreasesduetohighthermal propertiesofnanofluidincomparisonwithwater.Butaswe putainsertoftwistedtapeturbulator,itprovidesturbulence inthefluid.Turbulenceincreasestheconvectiveheattransfer coefficient of the fluid. And we know that convective heat transfer coefficient of turbulent flow is greater than the laminar.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN: 2395-0072

Fig.5:EffectivenessversusmassflowrateofHotFluidin CounterFlowarrangement

1) InthisresearchworkthepropertiesofAl2O3nanofluid werefoundoutanddefinedinsoftwareforvariousvaluesof concentration factor. The performance of nanofluid is observedtobeoptimumatconcentrationfactorof0.4,which wasselectedtocalculatetheperformanceofheatexchanger.

2) In the present research work it is found out that the overallheattransfercoefficientishavingamaximumvalueof 7624.53 Watts/m2k for the counter flow arrangement of water-watertypeheatexchangerwhichis42%lessthanthe valueweobtainedforwater-nanofluidarrangement,which hasavalueof13039.99Watts/m2K.

3) ItisnotedthatLMTDforwater-nanofluidarrangement was found to be 9.21 K which is greater than water-water arrangementby24%.

4) Theeffectivenessofwater-nanofluidarrangementwas also found to be maximum with a value of 0.149 which is morethanthatofwater-waterheatexchangerarrangement by56%atavolumeflowrateof0.2kg/sofcoldwater.

5) The maximum heat transfer rate was noted to be increasedbyanamazingamountof55%foramassflowrate of0.2kg/swater-nanofluidarrangementincomparisontothe water-water arrangement which had a value of 2219.11 Wattsforthesameworkingconditions.

[1] N.M. Maleki, M. Ameri, R.H. Khoshkhoo, Experimental andnumericalstudyofthethermal-frictionalbehavior of a horizontal heated tube equipped with a vibrating oscillatorturbulator,Int.Commun.HeatMassTran.135 (2022),106154.

[2] N.M. Maleki, M. Ameri, R.H. Khoshkhoo, Experimental studyofthethermal-frictionalbehaviorofahorizontal

straight tube equipped with a vibrating string turbulators: a novel active method, Exp. Therm. Fluid Sci.140(2023),110767.

[3] N.M.Maleki,S.Pourahmad,R.H.Khoshkhoo,M.Ameri, Performance improvement of a double tube heat exchangerusingnovelelectromagneticvibration(EMV) methodinthepresenceofAl2O3-waterandCuO-water nanofluid;anexperimental study,Energy281(2023), 128193.

[4] M.Bodaghi,K.Esmailpour,N.Refahati,Feasibilitystudy and thermoeconomic analysis of cooling and heating systems using soil for a residential and greenhouse building,arXivpreprintarXiv(2023).2304.05507.

[5] S. Pesteei, N. Mashoofi, S. Pourahmad, A. Roshan, Technology,Numericalinvestigationonthe effectofa modifiedcorrugateddoubletubeheatexchangeronheat transfer enhancement and exergy losses, Int. J. Heat MassTran.35(2)(2017)243–248.

[6] N. Mashoofi, S. Pourahmad, S.M. Pesteei, Numerical studyofheattransferandexergylossinadoubletube heat exchanger with corrugated inner tube: the new configurationofcorrugatedtubes,J.Mech.Eng.48(3) (2018)301–307.

[7] A. Güng¨or, A. S¨ ozen, A. Khanlari, Numerical investigation of thermal performance enhancement potentialofusingal2o3-tio2/waterhybridnanofluid inshellandhelicallycoiledheatexchangers,HeatTran. Res.53(12)(2022).

[8] S. Kalsi, S. Kumar, A. Kumar, T. Alam, D. Dobrot˘a, Thermophysical properties of nanofluids and their potentialapplicationsinheattransferenhancement:a review,Arab.J.Chem.(2023),105272.

[9] L.Najmi,S.M.Zebarjad,K.Janghorban,Effectsofcarbon nanotubesonthecompressiveandflexuralstrengthand microscopic structure of epoxy honeycomb sandwich panels,Polym.Sci.B(2023)1–10.

[10] L. Najmi, Z. Hu, Review on molecular dynamics simulations of effects of carbon nanotubes (CNTs) on electrical and thermal conductivities of CNT-modified polymericcomposites,JournalofCompositesScience7 (4)(2023)165.

[11] L.Najmi,Z.Hu,Effectsofcarbonnanotubesonthermal behavior of epoxy resin composites, Journal of CompositesScience7(8)(2023)313.

[12] H.Wang,etal.,Heattransferenhancementofacopper tube with constant wall temperature using a novel horizontal perforated teardrop-shaped turbulators (PTST),Int.J.Therm.Sci.192(2023),108418.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN: 2395-0072

[13] V.Kumar,R.R.J.J.o.T.S.Sahoo,E.Applications,Energyeconomic and exergy-environment performance evaluationofcompactheatexchangerwithturbulator passiveinsertsusingTHDNF15(2)(2023),021011.

[14] A. Güng¨or, A. Khanlari, A. S¨ozen, H.I. Variyenli, Numerical and experimental study on thermal performance of a novel shell and helically coiled tube heatexchangerdesignwithintegratedringsanddiscs, Int.J.Therm.Sci.182(2022),107781.

[15] E.Y.Gürbüz,H.˙I.Variyenli,A.S¨ozen,A.Khanlari,M.¨ Okten, Experimental and numerical analysis on using CuO-Al2O3/waterhybridnanofluidinaU-typetubular heatexchanger,Int.J.Numer.MethodsHeatFluidFlow 31(1)(2021)519–540.

[16] A.Kumar,etal.,Experimentalanalysisofheatexchanger usingperforatedconicalrings,twistedtapeinsertsand CuO/H2Onanofluids,CaseStud.Therm.Eng.49(2023), 103255