International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN: 2395-0072

Shushmita1

M. Tech Student

H G2 Dr.

Kiran

T3

Ph. D Research Scholar Associate Professor Department of Civil Engineering, Department of Civil Engineering, Department of Civil Engineering, UVCE, Bangalore University, UVCE, Bangalore University, UVCE, Bangalore University, Bengaluru, India. Bengaluru, India. Bengaluru, India.

Abstract – Composite walling is a novel building system comprising of two outer skins of profiled steel sheeting infilled with concrete. This paper deals with an experimental investigation to understand the Axial behaviour of a Composite Wall Panel (CWP) which are casted and tested without reinforcing bars using Basalt Fibre reinforced concrete (BFRC). Its development has come about as an extension of the well-knowncomposite system used worldwide. Steel components are relatively thin and prone to buckling, whereas the infill concrete provides restraint against buckling and thermal insulation at high temperatures. Composite wall panels have many advantages, when used in conjunction with composite floor panels and can be used as core walls in steel frame building structure, although they have the potential to be used in load bearing construction. Thus, these panels can serve as an alternative to load carrying brick walls and therefore, low rise buildings can be constructed by using these light weight wall panels.

Key Words: Composite wall panel (CWP), Basalt Fibre Reinforced Concrete (BFRC), Basalt Fibre (BF), Axial Behaviour.

Intheday-by-dayemergenceofrecenttrendsinconstruction industry, composite construction method has gained it popularity for its economical usage of materials and providing excellent sustainability than conventional constructionsystem.

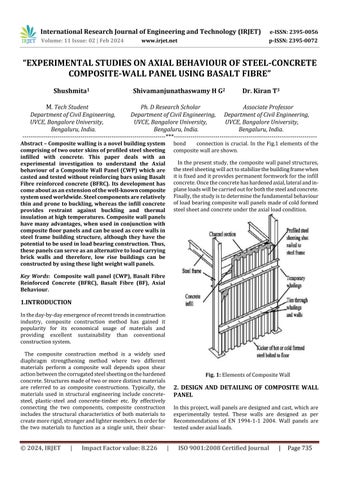

The composite construction method is a widely used diaphragm strengthening method where two different materials perform a composite wall depends upon shear actionbetweenthecorrugatedsteelsheetingonthehardened concrete.Structuresmadeoftwoormoredistinctmaterials are referred to as composite constructions. Typically, the materials used in structural engineering include concretesteel, plastic-steel and concrete-timber etc. By effectively connecting the two components, composite construction includes the structural characteristics of both materials to createmorerigid,strongerandlightermembers.Inorderfor the two materials to function as a single unit, their shear-

bond connection is crucial. In the Fig.1 elements of the compositewallareshown.

Inthepresentstudy,thecompositewallpanelstructures, thesteelsheetingwillacttostabilizethebuildingframewhen itisfixedanditprovidespermanentformworkfortheinfill concrete.Oncetheconcretehashardenedaxial,lateralandinplaneloadswillbecarriedoutforboththesteelandconcrete. Finally,thestudyistodeterminethefundamentalbehaviour ofloadbearingcompositewallpanelsmadeofcoldformed steelsheetandconcreteundertheaxialloadcondition.

2. DESIGN AND DETAILING OF COMPOSITE WALL PANEL

Inthisproject,wallpanelsaredesignedandcast,whichare experimentally tested. These walls are designed as per Recommendations of EN 1994-1-1 2004. Wall panels are testedunderaxialloads.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN: 2395-0072

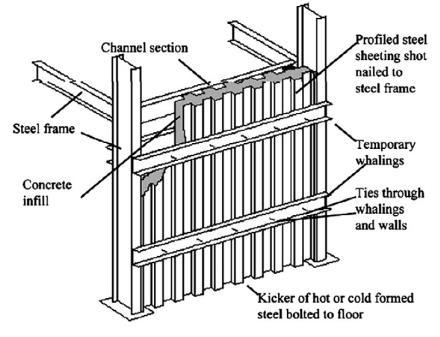

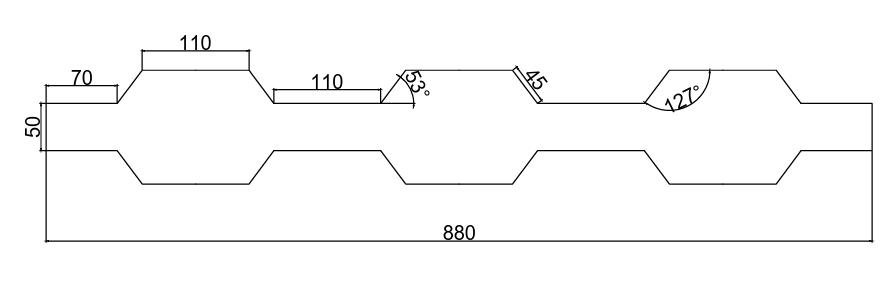

A Cold formed steel wall was identified to carry out experimental program on composite wall panels. The test specimenshavingthelength880mmandwidth880mmand the thickness of the profile sheet is 1 mm. Fig 2 shows the geometricalpropertiesofprofiledsteelwall.

3. MATERIAL PROPERTIES

A Basalt Fibre Reinforced Concrete

Inthecastingof testspecimen ofcomposite walls,Basalt FibreReinforcedConcrete (BFRC)hasbeendevelopedto getthecharacteristicstrengthofM-25gradeconcrete.For developing Basalt fibre reinforced concrete, ordinary Portland cement (OPC) is used, Fly ash 30% is used to reducecementcontent,M-sandusedasFineAggregateand 20mmand12mmdownsizedCoarseAggregateareused. Forgettingdesiredworkability0.6%ChrysooptimaKR77 superplasticizer(SP)isusedand1%BasaltFibreisusedas

additive to improve the mechanical properties of the concrete.

A. Specimen Design and Construction

The dimension of the test specimens are 880 mm length, 880mmwideandconfigurationofpanelsareshowninFig. 2.Thecompressivestrengthachievedwas35.26Mpa.

The profile steel sheet was connected with a shear connectorof8mmthicknessand80mmheightwithrubber washerstogetahighgripbetweenthenutandbolt.Totally 20studswererequiredforonesheet.Ithelpstogetagood shearbondbetweensteelandconcrete.Inthesespecimens reinforcing bars were eliminated to know the structural behaviorofpanelsunderaxialloads.

ThecompositeWallpanelswithBFRCconcretewerecasted andcuredandalsotheseweretestedatthe28th dayafter casting.

B. Test Set-up

The Experimental test set-up is shown in Fig. 3 and the procedureisasfollows.

Thecentrelinebothhorizontallyandvertically,aline from one third from the top and at the top are markedonthewallpanelasshowninthefigure.

Dialgaugesof3no’sareplacedatthefrontfaceof thewallpanel.OneattheTop,seconddialgaugeat one third distance from the Top and third at the Midspanof the Composite wall panel to obtainthe axialcompressionofthespecimen.Fig4showsthe DialgaugeandLVDT.

TheAxialloadisappliedatthetopastheuniformly distributed load and the axial compression is observed.

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN: 2395-0072

Thegeneralobservationonthetestspecimensarediscussed here. It is clearly observed that the axial strength of wall panelisinfluencedbythedegreeofconfinementprovidedby thestudsandthesteelsheet.

At the beginning of the loading, specimen showed linearelasticcompressionwithrespecttoload.Thelateralpressure exerted by concrete caused the sheet to bulge out, but provision of large number of studs prevented the outward bulging.UnderAxialloadingtheconcreteexperiencedsudden brittlefracturemodeoffailure.AsseeninFig5andFig6the specimenwhichhasstudconnectionsinthetroughportion andwithoutthestoppingedges,thefailuremodeisfollowed bytheformationofedgeshearcracksintheexposedconcrete portionfollowedbylocalbucklingofsteel.

5. RESULT AND DISCUSSION

WiththeuseofbasaltfibreintheM25gradeconcrete,the MechanicalpropertiesofConcretearelistedinTable.1and it shows the improvisation in mechanical strength using basaltfibrescomparedtoconventionalconcretemix.

Table1.ResultsofMechanicalPropertiesofBFRCandCC

No. of Days Average compressive strength of cubes (N/mm2)

TheCompositeWallSpecimenundergoesbrittlefailureasit is evident from the test results. From the load Vs Axial Compressioncurve,itisobservedthat,atthebeginningstage

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN: 2395-0072

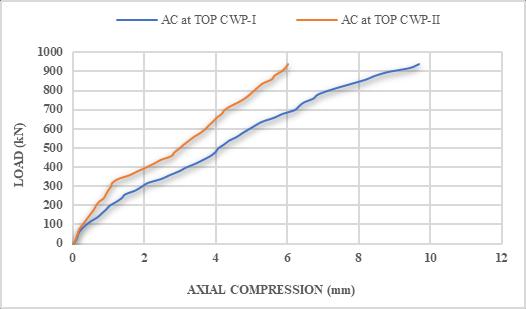

load is linearly related to compression and as the load increasesthecompressionalsoincreased.ForCWP-Itheload is 940kN with 9.68 mm compression and load 940kN with 6.02mmcompressionfortheCWP-II.Fig.5showsthebulging ofsheetinbetweenthestuds.Fig.6showscripplingofsheet anddiagonalcompressionshearfailure.Compressionsofthe specimensunderaxialbehaviourareshowninFig.7.

WithreferencetothenormalRCCWall,theCompositeWall structures are novel construction system where it is more economicalandspeedyconstructionformediumtohighrise buildings.

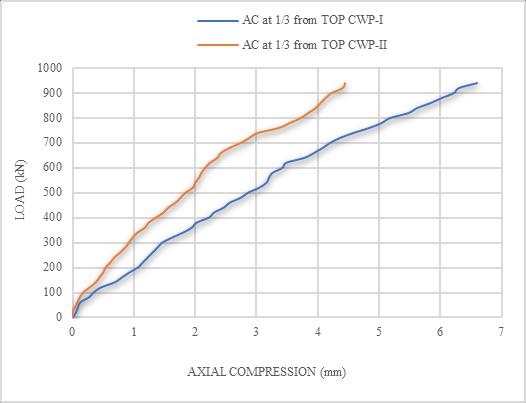

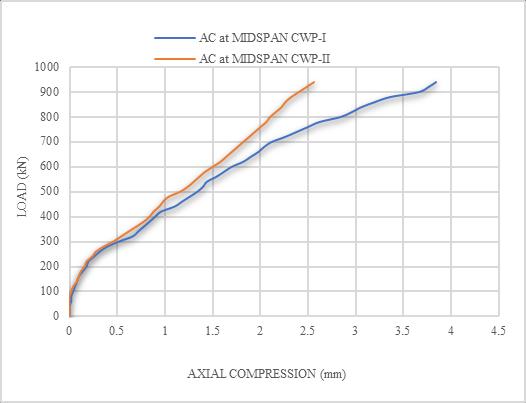

The axial compression of the composite wall panels, compressionatthetop,onethirddistancefromthetopofthe wallpanelandmid-pointareshownintheFig.7,Fig.8and Fig.9forCWP-IandCWP-IIrespectivelyandthecomparison ofAxialCompressionofCWP-IandCWP-IIarelistedinTable. 2.

Table2.ResultsofAxialTest

Sl.No LOADS (kN)

Comparison of Axial Compression of CWP-I and CWP-II (mm) At TOP At one third from Top At Midspan

Loadv/sAxialCompressionCurvefor

and CWP-IIatonethirdfromtheTop.

9: Loadv/sAxialCompressionCurveforCWP-Iand CWP-II atMidspan

From the above experiments, it is concluded that the mechanicalpropertiesofconcretecanbeimprovedwiththe useof Basaltfibresandalso itcan improvethestrength of structuralelementslikeCompositewallpanels.Conclusionof theaboveexperimentalworkarelistedbelow-

The use of 1 % Basalt fibre as additive material in concrete improves 4 to 8 percent more strength comparedtoConventionalconcrete(CC).

Using Basalt Reinforced Concrete, the ultimate load carryingcapacityofthecompositewallpanel-1is940 kNandcompositewallpanel-2is940kN.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN: 2395-0072

The load carrying capacity and shear bond capacity betweencoldformedsheetandconcreteareadequate with the above-mentioned shear studs or shear connectors(noslipobserved).

Fromtheresultanalysis,thesekindofcompositewall panelscanbeusedinthemiddle high-rise buildings andcommercialbuildingsusingcoldformedsteelwith shearconnectors.

TheauthorsthanktothePrincipalofUniversityVisvesvaraya CollegeofEngineering,Bengaluru.Theauthorsthanktothe ChairmanandFacultiesofDepartmentofCivilEngineering.

[1] Yuxin Gao, Bao Jun Cheng, Pengfei Ma, Boyuan Shi, ShengRongKangandYulinTu,2020‘StudyontheHighperformanceCompositeWallPanelEnvelopeofBuilding and its Relevant Joint Construction’ E3S Web of Conferences198,01003.

[2] P.Prabha,V.Marimuthu,M. Saravanan,G.S. Palani,N. LakshmananandR.Senthil,2013‘Effectofconfinement onsteel-concretecomposite light-weightload-bearing wall panels under compression’, Journal of ConstructionalSteelResearchElsevierLtd,Vol:81,1119.

[3] Aswathy M. Nair, 2011 ‘Axial load capacity of steelconcretecompositelightweightwallpanels’

[4] Md.AzreeOthumanMydin,Y.CWang,2011‘Structural performance of light-steel composite walling system undercompression’ElsevierLtd,Vol:49,66-76.

[5] HowardWright,1998‘AxialandBendingbehaviourof CompositeWalls’,JournalofStructuralEngineering,Vol: 124,Issue7.

[6] H. D. Wright, M. A. Bradford, B. Uy, 2001 ‘Combined axialandflexuralstrengthofprofiledcompositewalls’, ICEProceedingsStructuresandBuildings146[2]:129139.

[7] XiaLiu,XinWang,KangyuXie,ZhishenWuandFengLi, 2020 ‘Bond Behaviour of Basalt Fibre-Reinforced Polymer Bars Embedded in Concrete under Monotensile and cyclic loads’ International Journal of ConcreteStructuresandMaterials.

[8] HaoZhouandBinJia,HuiHuangandYanlingMou,2020 ‘ExperimentalstudyonBasicMechanicalPropertiesof BasaltReinforcedConcrete’.

[9] Prabhakar S.K, Channamallappa B, Akshy V.P, Rafeek, Mithunkumar and Mallinath Shastri, 2016 ‘An

ExperimentalstudyofBasaltChoppedFibresReinforced Concrete on Compressive, Tensile and Flexural behavior’,InternationalResearchJournalofEngineering andTechnology,Volume:03Issue:07.

[10] B.M.SumanandR.K.Srivastava,2008‘Effectofair gaponthermalperformanceofcompositewallsection’, IndianJournalofScienceandTechnology,Vol:1No5.

[11] K. M. Anwar Hossain and H. D. Wright, 2004, ‘Experimental and theoretical behaviour of composite wallingunderin-planeshear’,JournalofConstructional SteelResearch,Vol:60,Issue1.