International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN: 2395-0072

Madan Singh Baraskar 1 , P. K. Roy 2

M.Tech Student, Building Construction & Technology, NRI Institute of Research & Technology, Bhopal (M.P.) 2 Assistant Professor, Building Construction & Technology, NRI Institute of Research & Technology, Bhopal (M.P.)

Abstract - Thisstudyintroducesaninnovativeapproachto sustainable construction through the development of lightweight bricks incorporating biomedical waste as a key component. In an effort to address both the environmental impact of conventional brick manufacturing and the challengesofbiomedicalwastedisposal,thisresearchexplores the feasibility of utilizing sterilization wrap, plastic syringe components,andmedical glassasaggregatereplacementsin cement brick production.

The methodology encompasses the collection and processing of biomedical waste, followed by its integration into brick mixtures with varying proportions. The bricks thus produced are evaluated for compressive strength, density, and durability,adheringtothestandardssetbyIS1077:1957.The resultsdemonstrateapromisingpotentialinusingbiomedical waste, showing that bricks with up to 15% waste content maintain good structural integrity, with a maximum compressive strength reduction of 25% compared to pure cement bricks. These bricks not only satisfy the required compressive strength for construction purposes but also contribute to waste reduction and environmental sustainability.

Key Words: SustainableConstructionMaterials,Biomedical WasteRecycling,LightweightBricks,Eco-FriendlyBuilding Materials,CompressiveStrengthofBricks

1.

In recent years, the global construction industry has undergoneasignificanttransformation,drivenbythedual imperatives of sustainability and environmental stewardship. This transformation is rooted in a growing recognition of the construction sector's substantial environmental footprint, particularly in terms of energy consumption,greenhousegasemissions,andthedepletion of natural resources. As a consequence, there has been a concerted effort to shift towards more sustainable and environmentallyfriendlymaterialsinconstruction.Oneof thekeyareasoffocusinthisshiftisthedevelopmentanduse ofbuildingmaterialsthatcansignificantlyreducethecarbon footprint of construction projects. Among the various sustainablematerialsthathaveemerged,lightweightbricks have become increasingly prominent. These bricks have attracted considerable attention due to a combination of beneficialproperties,includingtheirenergyefficiency,ease ofhandling,andsuperiorthermalinsulationcapabilities.

Theenergyefficiencyoflightweightbricksisacriticalfactor, astheconstructionandmaintenanceofbuildingsaccountfor a substantial portion of global energy use. Lightweight bricks,withtheirimprovedinsulationproperties,contribute to reducing energy consumption for heating and cooling, thusloweringtheoverallenergyrequirementsofbuildings. Additionally, their ease of handling and installation translates to reduced labor costs and time savings on construction sites, further enhancing their appeal in the industry.However,despitetheseadvantages,theproduction of conventional lightweight bricks is not without its environmental challenges. Traditionally, these bricks are manufacturedusingnaturalresourcessuchasclay,shale,or fly ash, the extraction and processing of which can have significant environmental impacts. The extraction process can lead to land degradation, loss of biodiversity, and the depletion of finite natural resources. Moreover, the manufacturingprocessofconventionalbricksofteninvolves high-temperaturekilnfiring,whichconsumesconsiderable energyandcontributestocarbonemissions.Theseconcerns have led to a growing awareness of the need to develop alternative methods for producing lightweight bricks that are not only efficient and functional but also more sustainableandenvironmentallyresponsible.

This research introduces an innovative approach to producinglightweightbricksbyutilizingbiomedicalwaste,a byproductoftenregardedasanenvironmentalandhealth hazard, in combination with cement. The utilization of biomedicalwastenotonlyprovidesasustainablesolutionto wastemanagementbutalsoaddsvaluetowhatistypically considered non-recyclable. This study aims to explore the feasibility,mechanicalproperties,andenvironmentalimpact ofthesenovelbricks,offeringapotentialpathwaytowards more sustainable construction practices. The concept of incorporatingbiomedicalwasteintobrickmanufacturingis notonlyasteptowardssustainablematerialsciencebutalso alignswiththeglobalgoalsofreducingwasteandpromoting circular economy in the construction sector. This paper presents a detailed analysis of the composition, manufacturing process, and properties of the lightweight bricksdevelopedusingbiomedicalwasteandcement.The findingsofthisstudyhavethepotentialtorevolutionizethe building materials industry, offering an eco-friendly alternativetotraditionalbrickswhileaddressingthecritical issueofbiomedicalwastedisposal.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN: 2395-0072

Theexplorationofwastematerialsascomponentsinthe production of lightweight bricks has gained significant momentuminrecentyears.Thisareaofresearchisdrivenby thedualgoalsofenvironmentalsustainabilityandinnovative material science. Several key studies have made notable contributionstothisfield,demonstratingthepotentialand practicality of incorporating various waste materials into brickandmortarproduction.

Eliche-Quesadaetal.(2012)conductedapioneeringstudy thatexploredtheincorporationofdiversewastematerials, suchassawdust,spentearthfromoilfiltration,compost,and marble,intothefabricationoflightweightbricks.Thisstudy was instrumental in understanding how these waste additions affected the technological properties of bricks. Remarkably, it was discovered that the optimal sintering temperatureforthesewaste-infusedbrickswasaround1050 °C,afindingthathasimplicationsforenergyefficiencyand materialpropertiesintheproductionprocess.

In a similar vein, Ameri et al. (2019) extended this research to the realm of lightweight mortars. Their investigationfocusedontheeffectsofusingceramicwaste powder and clay brick waste powder as constituents. The resultswereinsightful,revealingsignificantalterationsinthe microstructureanddurabilityofthemortars.Thesewastebasedmortarsnotonlyexhibitedenhancedperformanceat elevatedtemperaturesbutalsounderscoredthepotentialof ceramic and brick wastes as valuable resources for sustainableconstructionmaterials.Furtherexpandingonthis theme,Eliche-Quesadaetal.(2012)delvedintotheutilization ofwastegeneratedfrombiodieselproductionplants.Their study on lightweight structural bricks indicated that incorporating such waste could lead to a decrease in bulk densityandanincreaseinapparentporosityofthesintered samples.Thesefindingsarecrucialastheypointtowardsthe possibilityofcreatinglighter,yetstructurallysoundbricks, thereby reducing material costs and improving energy efficiencyinbuildings.

Liuetal.(2020)tookauniqueapproachbyexaminingtheuse of oyster shells and sorghum waste in lightweight brick production. Their engineering-focused study revealed that these agro-industrial wastes could effectively replace fine aggregates in brick manufacturing. This research is particularly noteworthy as it opens up new avenues for utilizingseafoodandagriculturalwastes,whichareabundant yet underexploited resources.Lastly, Ibrahim et al. (2013) exploredtheuseofwasteclaybrickasacoarseaggregatein lightweightfoamedconcrete.Theirexperimentsshowedthat a 25% substitution of waste clay brick yielded the highest compressivestrengthintheproducedlightweightconcrete. This result is significant as it highlights the potential of repurposing construction waste, thus contributing to a circulareconomyinthebuildingsector.

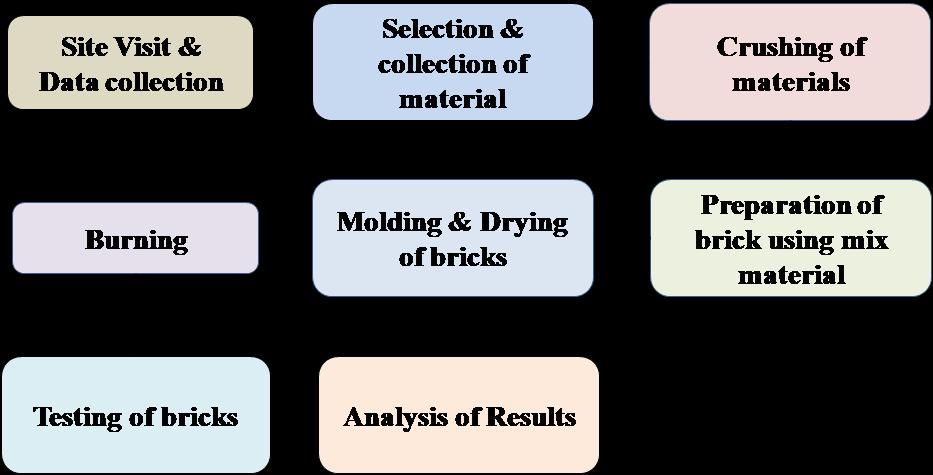

This section outlines the comprehensive methodology adoptedinthisresearchforthedevelopmentandtestingof lightweightbricksusingbiomedicalwasteandcement.The methodology is systematically structured into several key stages,eachcriticaltoachievingthedesiredoutcomes.The Fig1.Showstheproposedmethodologyframeworkforthe developmentoflightweightbrickusingbiomedicalwaste.

\Fig.1.:Frameworkoftheproposedmethodologyforthe developmentoflightweightbrickusingbiomedicalwate.

i. Site Visit and Data Collection: The initial phase involves visiting potential sites for collecting biomedical waste. During these visits, data regardingthetype,quantity,andpropertiesofthe biomedical waste available are meticulously gathered.Thisstageiscrucialforunderstandingthe material's characteristics and ensuring its suitabilityforbrickproduction.

ii. Selection and Collection of Material: Based on the data collected, specific types of biomedical waste are selected for the brick-making process. The criteria for selection include the waste's composition,itsphysicalandchemicalproperties, anditspotentialimpactonthebrick'squality.The selected waste materials are then collected in adequatequantitiesforsubsequentprocessing.

iii. Crushing of Materials: The collected materials, including biomedical waste and any additional aggregates, are then subjected to a crushing process.Thisprocessaimstoreducethesizeofthe materials to a uniform and workable consistency, suitableformixingandmolding.

iv. Burning: Inthisstep,thecrushedmaterialsundergo a controlled burning process. The objective is to incinerate any organic components in the biomedical waste, leaving behind ash and other

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN: 2395-0072

inorganic materials that can be incorporated into thebrickmix.

v. Molding and Drying of Bricks: The processed materialsarethenmixedwithcementandwaterto form a brick mix. This mix is molded into the desiredbrickshapeandsize,followedbyadrying process. The drying can be either natural or accelerated, depending on the available facilities andtheproject'stimeline.

vi. Preparation of Bricks Using Mixed Material: This stage involves refining the brick mix by adjusting the proportions of biomedical waste,cement, and any other additives to optimize the brick's properties. The prepared mix is then used for moldingadditionalbricks,whicharealsosubjected tothedryingprocess.

vii. Testing of Bricks: The produced bricks undergo a series of tests to evaluate their physical and mechanical properties. These tests include assessments of compressive strength, water absorption, density, and durability. The testing phaseiscrucialtoensurethatthebricksmeetthe necessarystandardsforconstructionuse.

viii. Analysis of Results: Finally, the results from the testing phase are analyzed in detail. This analysis aimstounderstandtheimpactofbiomedicalwaste onthebrick'sproperties,toidentifyanypotential improvements in the production process, and to assess the overall viability of using biomedical wasteinbrickproduction.

Theexperimentalresultsrevealthatbricksmadewithpure cement exhibit a compressive strength of 7.50 N/mm². However,variationsincompressivestrengthwereobserved upon incorporating biomedical waste into the brick composition.Specifically,thecompressivestrengthofbricks decreasedwiththeincreasingadditionofvariousbiomedical wastes, such as sterilization wrap, plastic syringe components,andmedicalglass.

Thereductionincompressivestrengthwasapproximately 10.5%and8.2%whenincorporatingsterilizationwrapand plastic syringe components, respectively. The inclusion of medicalglassledtoamoresignificantdecreaseinstrength, with reductions of up to 20% and 25%. Despite these reductions, all the bricks, including those incorporating biomedical waste, satisfied the minimum compressive strengthrequirementof3.5N/mm²asperIS1077:1957.

Among the different biomedical waste materials tested, bricks incorporating medical glass content exhibited the highest compressive strength. Notably, a combination of sterilization wrap and plastic syringe components in the bricksresultedinahighercompressivestrengthcompared tousingasingletypeofbiomedicalwaste.Ontheotherhand, amixofallthreetypesofbiomedicalwastedemonstrated lowercompressivestrengthcomparedtostandardcement bricks.

In terms of varying biomedical waste proportions, it was observed that bricks with up to 10% biomedical waste contentmaintainedgoodstrength.However,increasingthe biomedical waste content to 15% resulted in a noticeable decreaseinstrength.Graphicalrepresentationsareincluded to demonstrate the variations in compressive strength between 100% cement bricks and bricks with different percentagesofmedicalglass.

TableI:VariationwithDoubleMixesofWasteMaterials

(%)

Table II: Variation with Triple Mixes of Waste Materials

Cement (%)

Table III: Variation of Compressive Strength with Different Waste Materials

nt (%)

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN: 2395-0072

90

Table IV: Variation with Quadruple Mixes of Waste Materials

(%) Sterilization Wrap + Plastic Syringe components + Medical Glass + Mixed Biomedical Waste

Table V: Compressive Strength and Load at Failure of Cement Bricks with Biomedical Waste Inclusions

This research presents a novel approach in the field of sustainable construction materials by utilizing biomedical wastein theproductionoflightweightcement bricks.The study demonstrates that incorporating sterilization wrap, plasticsyringecomponents,andmedicalglassintocement bricks effectively reduces the bricks' weight while maintaining acceptable compressive strength levels. The findings highlight the potential for biomedical waste as a valuable resource in brick manufacturing, contributing to wastereductionandsustainableconstruction.

Futureresearchshouldfocusonfurtheroptimizing themixproportionstoenhancethemechanicalproperties anddurabilityofthesebricks.Investigationsintothelongtermenvironmentalimpactsandthelifecycleassessmentof these bricks are crucial. Additionally, scaling up the productionprocessandevaluatingtheeconomicfeasibility ofcommercialproductionwillbeessentialsteps.Exploring other types of biomedical waste and different binder materials could also open new avenues for sustainable constructionmaterials.Conclusioncontentcomeshere

[1] DoloresEliche-Quesada;F.A.Corpas-Iglesias;L.PérezVillarejo; F. J. Iglesias-Godino; "Recycling of Sawdust, Spent Earth from Oil Filtration, Compost and Marble Residues for Brick Manufacturing", CONSTRUCTION ANDBUILDINGMATERIALS, 2012.

[2] Farshad Ameri; Parham Shoaei; Seyed Alireza Zareei; Babak Behforouz; "Geopolymers Vs. Alkali-activated Materials(AAMs):AComparativeStudyonDurability, Microstructure, and Resistance to Elevated Temperatures of Lightweight Mortars", CONSTRUCTIONANDBUILDINGMATERIALS, 2019.

[3] DoloresEliche-Quesada;S.Martínez-Martínez;L.PérezVillarejo;F.J.Iglesias-Godino;CarmenMartínez-García; F. A. Corpas-Iglesias; "Valorization of Biodiesel Production Residues in Making Porous Clay Brick", FUELPROCESSINGTECHNOLOGY, 2012.

[4] Hua-YuehLiu;Han-ShengWu;Chen-PeiChou; "Study onEngineeringandThermalPropertiesofEnvironmentfriendly Lightweight Brick Made from Kinmen Oyster Shells & Sorghum Waste", CONSTRUCTION AND BUILDINGMATERIALS, 2020.

[5] Norlia Mohamad Ibrahim; Shamshinar Salehuddin; Roshazita Che Amat; Nur Liza Rahim; Tengku Nuraiti Tengku Izhar; "Performance of Lightweight Foamed ConcretewithWasteClayBrickAsCoarseAggregate", APCBEEPROCEDIA, 2013.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 02 | Feb 2024 www.irjet.net p-ISSN: 2395-0072

[6] Mohan,H.T.,Jayanarayanan,K.,&Mini,K.M.(2022).A sustainable approach for the utilization of PPE biomedical waste in the construction sector. Engineering Science and Technology,an International Journal,32,101060.

[7] Wawale,S.G.,Shabaz,M.,Mehbodniya,A.,Soni,M.,Deb, N.,Elashiri,M.A.,&Naved,M.(2022).BiomedicalWaste Management Using IoT Tracked and Fuzzy Classified Integrated Technique. Human-centric Computing and InformationSciences,12(32),32.

[8] Maddodi, B. S., Devesh, S., Rao, A. U., Shenoy, G. B., Wijerathne, H. T., & Sooriyaperkasam, N. (2022). Repurposing plastic wastes in non-conventional engineered wood building bricks for constructional application-A mechanical characterization using experimentalandstatisticalanalysing

[9] Sarwar,S.,Shaibur,M.R.,Hossain,M.S.,Hossain,M.R., Ahmmed,I.,Ahmed,F.F.,...&Shamim,A.H.M.(2023). Preparationofenvironmentalfriendlyplasticbrickfrom high-density polyethylene waste. Case Studies in ChemicalandEnvironmentalEngineering,7,100291.

[10] Desai, J., Mehta, M., & Desai, B. (2024). Fabrication of Sustainable Unfired Brick Using Covid-19 Non-woven PPEKitWasteandPaperIndustrySludge.InInvitation to National Level Conference on Sustainable Waste Management Practices (pp. 187-202). Springer, Singapore.

[11] Ahuja,P.,Singh,A.,&Goel,S.(2014).BiomedicalWaste Management.TextbookofHospitalAdministration,281.

[12] Das, S., & Das, B. (2017). Waste plastic’s green construction: introducing the process that converts 100% plastic waste into an alternative renewable various types of construction materials. European JournalofBiomedical,4(12),307-319.

[13] Li, Z., Zhang, T., Wang, Y., Yue, X., Yang, D., & Qiu, F. (2020). Waste-to-resource strategy to fabricate functionalizedmaterialfromwastebrick.ScienceofThe TotalEnvironment,703,135032.

[14] Zaneldin, E., Ahmed, W., Alharbi, N., Alkaabi, R., & Alnuaimi, M. (2023, April). Potential Construction ApplicationsofSustainable3DPrintedElementsMade from Plastic Waste. In Materials Science Forum (Vol. 1082,pp.277-283).TransTechPublicationsLtd.

[15] Sahu, B. R., Chandrakar, L. L., Nirmalkar, S., & Das, B. (2017). Waste management and their utilization. InternationalJournalofEngineeringResearch,6(4).