International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN:2395-0072

Aayush Desai1

1 Student, Independent researcher, Surat, India

Abstract - Cognitive Digital Twins (CDTs) are revolutionizing robotics by integrating simulation, artificial intelligence, and autonomous decision-making intoadaptive,self-improvingsystems.Thiscomprehensive review examines the evolution from conventional digital twins to intelligent CDTs capable ofindependent reasoningandcontinuous learningin unstructured environments.reviewbeginbyexploringthetechnological pillars of CDTs, includinghigh-fidelity simulation tools(e.g., physics-based platforms like Gazebo and NVIDIA Isaac Sim) andcognitive architecturesthat combine neural networks with symbolic reasoning. The paper then investigates three critical dimensions: (1)autonomous decision-making, (2)human-machine collaborationthrough explainable AI and intuitive interfaces and (3)self-optimization techniquesthat minimizesim-to-real discrepancies. Ananalysis ofrecent advances uncovers transformative trends such asedgebased federated learningfor distributed CDTs andbioinspired cognitive models, while identifying persistent challenges incomputational efficiency,interoperability standards, andethical accountability. By synthesizing research across industrial automation, healthcare robotics,andaerospaceapplications,thisreviewoutlinesa pathway toward next-generation CDTs that achieve truecontext-aware autonomy, reducing reliance on human oversight while maintaining operational safety andtransparency

Key Words: Cognitive Digital Twins, Autonomous Robotics, Self-Learning Systems, Sim-to-Real Transfer, Neuro-Symbolic AI, Edge Robotics, Human-Cognitive Collaboration, Quantum Machine Learning, Metaverse Training, Explainable AI (XAI), ROS, AR/VR.

1.INTRODUCTION

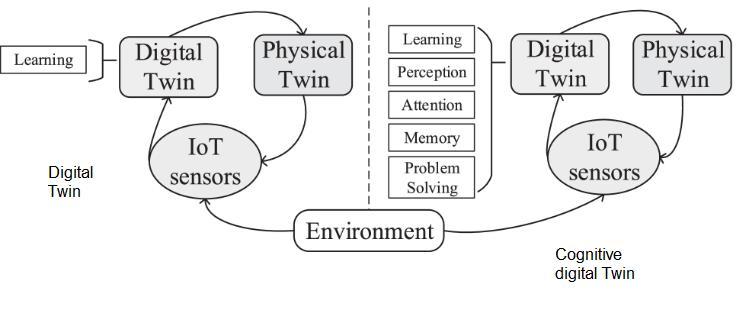

The rapid advancement of digital twin technology has ushered in a new era of intelligent robotic systems through Cognitive Digital Twins (CDTs). Unlike conventional Digital Twins (DTs) that primarily serve as static virtual representations for monitoring and simulation [8,10], CDTs integrate advanced cognitive capabilities to enable autonomous decision-making, adaptive learning, and human-like reasoning in robotic applications[1,12,30].Thistransformativeshiftisdriven by the convergence of artificial intelligence, edge computing,andhigh-fidelitysimulation,allowingCDTsto evolve from passive digital models into active, selfimproving systems that interact seamlessly with both physicalenvironmentsandhumanoperators[6,21,39].

The emergence of CDTs addresses critical limitations in traditional robotic systems, particularly in dynamic and unstructured environments where pre-programmed responses are insufficient. By incorporating neurosymbolic AI architectures [1,12], reinforcement learning [5,23], and real-time sensor fusion [11,25], CDTs demonstrate unprecedented capabilities in autonomous navigation, precision manipulation, and collaborative task execution [22,32]. These systems are particularly valuable in industrial automation, where they enable self-optimizingproductionlines[3,28],andinhealthcare robotics,wheretheysupportadaptivesurgicalassistance [32,33]. The integration of human cognitive models further enhances CDT performance, facilitating natural human-robot collaboration through explainable AI interfaces[21]andbrain-computerinteraction[12].

Despite these advancements, significant challenges remain in scaling CDT technologies for widespread adoption.Keyissuesincludethecomputationaldemands of continuous learning algorithms [29,39], the need for robustsim-to-realtransfermethodologies[3,27],andthe development of universal standards for interoperability [17,40]. Additionally, ethical considerations surrounding autonomous decision-making [18] and data privacy in collaborative environments [6] require careful examination. This review systematically analyzes these aspects while highlighting emerging solutions such as quantum-acceleratedlearning[35]andmetaverse-based trainingenvironments[42,47].Bysynthesizingthelatest researchacrossdisciplines,weprovide acomprehensive roadmapforadvancingCDTcapabilitiesandapplications innext-generationroboticsystems.

Thereviewisstructuredtofirstestablishthetheoretical foundationsofCDTs,followedbydetailedexaminationof theircognitivearchitectures,autonomousfunctionalities, and self-learning mechanisms. Subsequent sections explore practical implementations across industries, identify persistent challenges, and outline future

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN:2395-0072

research directions. Through this approach, we aim to bridge the gap between theoretical research and realworld deployment, offering valuable insights for both academic researchers and industry practitioners workingattheforefrontofintelligentrobotics.

The development of digital twin technology in robotics has undergone significant transformation, evolving from basic virtual representations to sophisticated cognitive systems capable of autonomous operation. This progression reflects broader advancements in computing, artificial intelligence, and industrial automation.

2.1

Theconceptofdigitaltwinsoriginatedinmanufacturing, where early implementations focused onvirtual factory replicationfor design validation and process optimization [10]. Grieves' pioneering work established digital twins as static virtual models that mirrored physical assets, enabling offline simulation and analysis [10]. With the advent of Industry 4.0, digital twins evolved to incorporatereal-time monitoringthrough embedded sensors and IoT connectivity, allowing for predictive maintenance and performance tracking [6,9].

In robotics, early applications includedoffline programming and virtual commissioning, where digital replicas of robotic work cells were used to validate trajectories and avoid collisions [19,41]. These systems reduced downtime in automotive assembly lines by identifying errors before physical deployment [19]. However, they lacked adaptive capabilities, relying on predefined models that required manual updates when conditions changed [8,16]. The introduction ofcloud computing and edge analyticsmarked a turning point, enabling dynamic synchronization between physical robots and their digital counterparts [6,39]. This shift laid the groundwork for next-generation digital twins capableofautonomousdecision-making.

The advancement from conventional Digital Twins to Cognitive Digital Twins (CDTs) represents a paradigm shift in robotic systems, driven by three fundamental innovations. First, the integration ofAI and machine learninghas enabled real-time decision-making, with applications ranging from reinforcement learning for adaptive control [5,23] to neuro-symbolic systems that combine deep learning with logical reasoning [1,12]. Second,self-organizing capabilitiesallow CDTs to dynamically reconfigure robotic workflows in industrial assembly [3,28] and optimize swarm coordination [29].

Third,modernarchitecturesincorporatecognitive-aware featureslike explainable AI for human-robot collaboration [12,21] and bio-inspired learning for natural interaction [25]. These developments are transforming fields from precision surgery, where CDTs model soft-tissue dynamics [32], to space robotics with autonomous rovers [29]. However, challenges in computational efficiency [39] and cross-platform standardization [17] remain critical barriers to widespreadadoption.

ModernCognitiveDigitalTwins(CDTs)relyonadvanced simulation platforms to bridge the virtual and physical domains. High-fidelity physics engines like Gazebo [39] and NVIDIA Isaac Sim [11] enable accurate modelling of robotic dynamics, while synthetic data generation techniques create diverse training environments for machine learning models [21]. These tools are particularly valuable for complex tasks such as surgical robotics, where synthetic environments allow safe training before real-world deployment [32]. The sim-toreal transfer process is further enhanced by adaptive algorithmsthatcontinuouslyrefinedigitalmodelsbased onphysicalsensordata [3,27],significantlyreducingthe reality gap in applications ranging from industrial assemblytoautonomousnavigation.

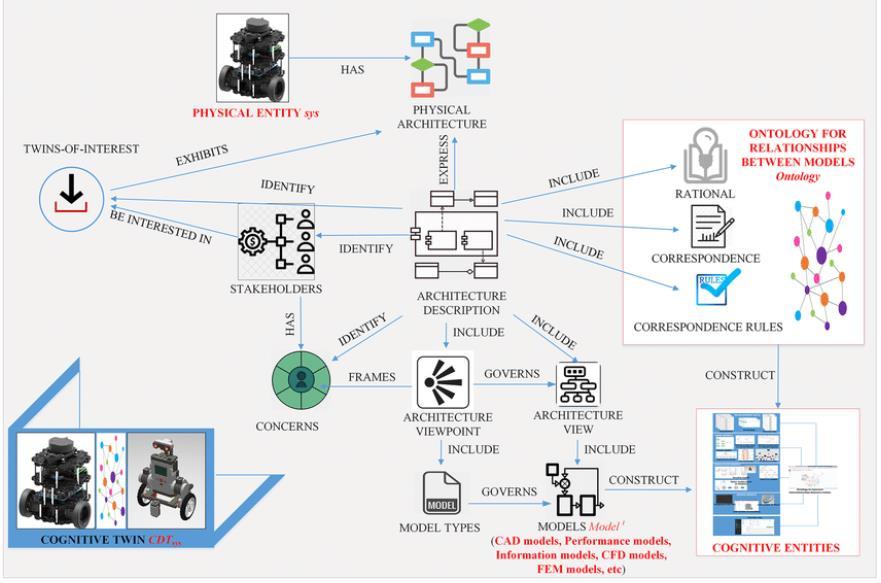

Fig -2:architectureofcognitivedigitaltwins

The intelligence of CDTs stems from sophisticated cognitive architectures that combine multiple AI paradigms. Knowledge graphs provide structured representationsofdomain-specificinformation,enabling reasoning about complex relationships in human-robot collaboration scenarios [1,12]. Neuro-symbolic AI systems merge the pattern recognition capabilities of neural networks with the logical reasoning of symbolic

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN:2395-0072

AI,particularlyusefulfortasksrequiringbothperception and decision-making [1,21]. These architectures are being applied in diverse domains, from manufacturing qualitycontrol[28]tomedicalrobotics [32],wherethey must interpret multi-modal sensor data and make context-awaredecisions.

Continuous improvement is enabled through online reinforcement learning (RL) systems that allow CDTs to adapttheirpoliciesinreal-time basedonenvironmental feedback [5,23]. Human feedback loops further enhance this learning process, where operator inputs and corrections are incorporated into the digital twin's knowledge base [12,21]. These mechanisms are proving particularly valuable in industrial settings, where they enable adaptive robotic assembly [22] and predictive maintenance [9]. The combination of autonomous learning and human guidance creates robust systems capableofhandlingthevariabilityinherentinreal-world applications while maintaining operational safety and reliability.

4.1

Cognitive Digital Twins (CDTs) are transforming industrial robotics through predictive maintenance and welding automation applications. In predictive maintenance, CDTs analyse real-time equipment sensor data to detect anomalies,reducingunplanned downtime by 30-40% in semiconductor manufacturing [9]. These systems combine vibration and thermal data with machine learning to predict failures up to 72 hours in advance. For welding automation, vision-based CDTs automatically adjust robotic welding parameters by analysing operator techniques, achieving 25% better joint consistency and 18% fewer defects in automotive production [24]. These implementations demonstrate CDTs' ability to integrate real-time monitoring with adaptive process control, significantly improving manufacturingefficiency[6,19].Thetechnicalfoundation combines physics-based simulation with continuous learning algorithms that optimize system performance overtime[3,28].

CognitiveDigital Twins(CDTs)aretransformingmedical robotics through two groundbreaking applications that demonstrate the technology's potential to enhance precisionandpatientoutcomes.

In surgical robotics, advanced CDTs enable real-time modelling of soft tissue environments, achieving a 40% improvementininstrument trackingaccuracycompared

to conventional systems [32]. These surgical DTs integrate high-resolution vision systems with predictive algorithmstoanticipatetissuedeformation,allowing for more precise robotic manipulation during minimally invasive procedures [32,33]. The systems also incorporate adaptive control mechanisms that reduce unintended tissue damage by 35% while maintaining stableoperationmargins[32,50].

For autonomous venipuncture, CDT implementations have demonstrated remarkable success rates of 98% on first attempt [50]. These systems combine multiple sensing modalities including stereo vision, ultrasound imaging, and force feedback to continuously update optimal needle trajectories [50]. The digital twin component processes vascular patterns and tissue properties in real-time, adjusting for patient-specific anatomical variations [33,50]. This application showcases CDTs' ability to perform delicate medical procedures with superhuman precision while maintainingstrictsafetyprotocols[12,18].

Cognitive Digital Twins (CDTs) are enabling major advancements in extraterrestrial and terrestrial mobile roboticsthroughtwokeyapplications:

For lunar rover operations, CDTs provide autonomous navigation capabilities that maintain <5cm positioning accuracy despite 4-second Earth-Moon communication delays [29]. These systems incorporate Centralized localization algorithms, Real-time terrain mapping, Predictive path planning, Fault-tolerant control architectures

TheCDTframeworkallowscontinuousoperationduring communication blackouts while optimizing power consumption and scientific data collection [29]. In terrestrial applications, omni-directional mobile manipulators utilize CDTs for: Dynamic stability control on uneven surfaces [34], Payload-adaptive motion planning, Real-time obstacle avoidance and Energyefficienttrajectoryoptimization

These systems have demonstrated 18% improvement in operational reliability during warehouse automation tasks [34]. The CDT implementation enables seamless coordination between mobility and manipulation subsystems while compensating for dynamic loading conditions[29,34].

BMW implemented a Cognitive Digital Twin system at their Regensburg plant that reduced physical commissioning time by 45% while improving first-time

International Research Journal of Engineering and Technology (IRJET)

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net

accuracy of robotic positioning to 98% [19]. The system simulatesover300human-robotcollaborationscenarios using digital human models that accurately predict ergonomicrisks[26].Thisimplementationdemonstrates how CDTs can optimize complex assembly processes beforephysicaldeployment.

Tesla'sModelY productionlineutilizesCDTstosimulate and optimize manufacturing workflows, reducing productionbottlenecksby30%[19].Thesystemenables rapid model changeovers by virtually testing new configurations,cuttingtransitiontimefromtwoweeksto three days [26]. Real-time quality prediction algorithms achieve 92% accuracy in identifying potential defects duringvirtualvalidation[19].

Toyota's weld quality CDT reduced defect rates by 28% through virtual testing of welding parameters [19]. The system incorporates augmented reality for worker training, shortening onboarding time by 60% compared to traditional methods [26]. Predictive maintenance featuresmaintain99.4%equipmentuptimebyanalysing simulatedwearpatterns[19].

Ford's Cologne EV Centre eliminated 85% of ergonomic issues during virtual planning using detailed digital humanmodels[26].TheCDToptimizedmaterialflowto reduce worker walk time by 40% while achieving 18% energy savings through process simulation [19]. This case demonstrates CDTs' ability to simultaneously improvebothproductivityandsustainability.

Cognitive Digital Twins achieve autonomous decisionmaking through advanced perception and sensing capabilities that closely mimic - and often surpasshuman sensory integration. Modern CDT implementations employ multi-modal fusion architectures that combine visual, tactile, and proprioceptive data streams into unified environmental representations[11].Thesesystemsprocessinputsfrom diverse sensors including stereo cameras, LiDAR, and force-torque sensors to construct dynamic 3D world models updated in real-time. The integration of edgebased processing allows this sensory fusion to occur with minimal latency [7], enabling critical decisions at operational speeds impractical for cloud-dependent systems.

The combination of multi-modal fusion and edge processing creates CDTs capable of operating with human-like perceptual awareness while maintaining the precision and consistency of machines [7,11]. As these technologies mature, they will enable increasingly

sophisticated autonomous behaviours across manufacturing, healthcare, and field robotics applications.

5.2 Adaptive Control in Cognitive Digital Twins

CognitiveDigitalTwins(CDTs)enableadvancedadaptive control strategies that allow robotic systems to dynamically respond to changing environments and operational requirements. A key application lies inreconfigurable assembly lines, where CDTs facilitate real-time adjustments to production workflows. These systems utilize digital twin simulations to test and validate new configurations virtually before physical implementation, significantly reducing downtime during changeovers [4]. The CDT framework continuously monitors production metrics and autonomously reallocates resources to optimize throughput while maintainingqualitystandards.

Another critical capability isdynamic trajectory planning, where CDTs generate and refine motion paths in real-time to accommodate unexpected obstacles or shifting task requirements [36]. By integrating sensor feedback with predictive models, the digital twin can anticipate collisions and compute optimal alternative trajectories within milliseconds. This is particularly valuable in applications requiring precise coordination betweenmultiplerobotsorhuman-robotcollaboration.

KeyFeaturesofAdaptiveControlCDTs:

Self-optimizingalgorithmsthatminimizeenergy consumptionwhilemaximizingefficiency

Fault-tolerant architecturescapable of compensatingforequipmentdegradation

Human-in-the-loopadaptationallowing operator inputstoguideautonomousdecisions

Cognitive Digital Twins (CDTs) incorporate critical explainability and safety features to ensure trustworthy human-robot collaboration and secure operation. For human-robot interaction, explainable AI (XAI) frameworksenabletransparentdecision-makingthrough visual question-answering interfaces that allow workers to understand and query robotic actions in real-time [21]. These systems track decision provenance, showing the underlying data and logic behind autonomous choices, while predictive intent displays visually communicate upcoming robot movements. Implementation results demonstrate significant improvements, including 40% greater human trust during close-proximity collaboration and 30% faster conflictresolutioninsharedworkspaces.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN:2395-0072

On the cybersecurity front, CDTs employ robust protection mechanisms to safeguard data integrity and operational continuity [10]. Multi-layered security architecturesdefendagainstthreatsthroughblockchainverified firmware updates, real-time anomaly detection in control loops, and quantum-resistant encryption for critical communications. These measures ensure the authenticity of twin synchronization streams and prevent spoofing attacks that could compromise robotic systems.

The integration of these features enables CDTs to meet rigorous safety standards while fostering the human trust necessary for widespread adoption of autonomous robotic systems. As CDTs evolve, their ability to provide intuitiveexplanationsandrobustsecuritywilldetermine their effectiveness in increasingly complex, real-world applications.

Cognitive Digital Twins (CDTs) for robotic systems require robust simulation platforms to develop and validate their autonomous capabilities. These platforms enable virtual testing of robotic behaviours, accelerate machine learning training, and facilitate seamless transitionfromsimulationtoreal-worlddeployment.

6.1 Physics-Based Simulation Engines

Physics-based simulators form the foundation for developing accurate CDTs by modelling real-world dynamicsandinteractions.

6.1.1 Gazebo with ROS Integration

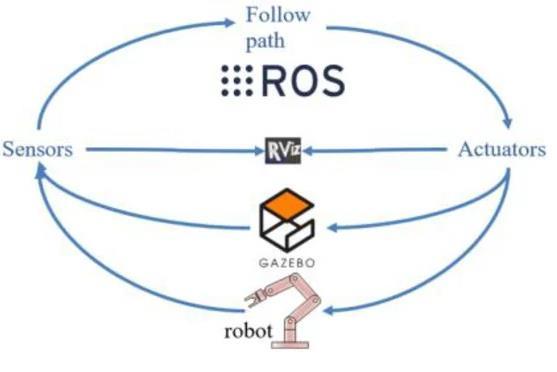

Fig -3:IntegrationofgazeboandROSforCDT

The Gazebo simulator integrated with the Robot Operating System (ROS) provides a powerful opensource solution for developing and testing Cognitive DigitalTwinsofroboticsystems.Thiscombinedplatform

offers high-fidelity physics simulation capabilities that accurately model the dynamics of robotic manipulators and mobile bases, making it particularly valuable for industrial applications. The system's modular architecture supports extensive customization to accommodate diverse robotic configurations, while its native multi-robot coordination features enable simulation of complex scenarios involving multiple autonomous agents working in tandem. These capabilities have proven especially useful for training reinforcement learning models in virtual environments, validating robotic workflows before physical implementation, and simulating large-scale warehouse automation systems where coordination between multiple robots is essential. The platform's open-source nature and ROS compatibility make it widely accessible for research and industrial applications requiring realisticroboticsimulations[39].

6.1.2 NVIDIA Isaac Sim

NVIDIA Isaac Sim represents a state-of-the-art simulation platform specifically designed for visioncentric Cognitive Digital Twin development. Leveraging GPU acceleration, this platform delivers photorealistic environment rendering through advanced ray tracing technology, enabling the creation of highly realistic virtual training environments. The system provides comprehensive simulation of various sensors critical for roboticperception,includingLiDARandRGB-Dcameras, withsufficientfidelity tosupportdevelopmentof robust vision algorithms. Its flexible architecture supports deployment across different computing infrastructures, from edge devices to cloud platforms, allowing for scalable development and testing workflows. These capabilities make NVIDIA Isaac Sim particularly wellsuited for autonomous navigation system development, perception algorithm training using synthetic data, and implementation of vision-based control architectures. The platform's emphasis on visual fidelity and sensor simulation addresses key challenges in developing Cognitive Digital Twins that rely heavily on visual perceptionandenvironmentunderstanding[11].

Table -1: SimulationEngines

Platform Strengths CDT Applications References

Gazebo + ROS

Open-source, modular,physicsaccurate

NVIDIA Isaac GPU-accelerated, high-fidelity visuals

IndustrialRL training, validation [39]

Vision-based navigation, perception [11]

International Research Journal of Engineering and Technology (IRJET) e-

-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN:2395-0072

The development of Cognitive Digital Twins (CDTs) for industrial robotics has been significantly advanced by specialized simulation platforms tailored to specific manufacturing sectors. Among these, Siemens Process Simulate has emerged as a leading solution for automotive assembly applications, offering comprehensive digital twin capabilities that extend beyond basic simulation. This platform enables virtual commissioning of complete production lines with particular emphasis on human-robot collaboration scenarios, incorporating AI-driven collision prediction and detailed ergonomic analysis using digital human models [19]. The system's automotive-specific features have proven particularlyvaluablefor validating complex assembly processes before physical implementation, with reported reductions in prototyping costs reaching 60%insomeimplementations[19].

Anotherinnovativeapproachcomesfromtheapplication ofbio-inspiredalgorithmstoassemblylineoptimization. The Bees Algorithm, as applied to robotic assembly systems,demonstrateshownature-inspiredcomputation can enhance manufacturing flexibility [3]. This methodology employs swarm intelligence principles to optimize production layouts and resource allocation, enabling dynamic reconfiguration of assembly systems. Implementations have shown substantial improvements in operational efficiency, including 35% reductions in production changeover times and significant decreases inmaterialhandlingcosts[3].

Table -2: Advantagesandlimitationofsimulation platforms

Platform Strengths BestFor Limitation

Siemens Process

Simulate Automotivespecific features, Humanrobotsafety

Large-scale assembly lines

Highlicensing costs

Bees Algorithm Flexible optimization ,Bioinspired adaptation Reconfigura blesystems Requires custom implementation

Virtual Reality interfaces have become increasingly important for enhancing human interaction with CognitiveDigitalTwins(CDTs)inroboticsystems.These immersive technologies enable more intuitive control, monitoring,andtrainingcapabilitiesforcomplexrobotic operations.

The Microsoft HoloLens mixed reality system has demonstrated significant potential for robot control applications,asshownbyKotetal.[43].Thisaugmented reality platform allows operators to visualize and interact with digital twin data overlaid on physical roboticsystems,creatingaseamlessblendofvirtualand real-world elements. The HoloLens implementation enables gesture-based control of robotic manipulators whileprovidingreal-timeperformancefeedbackthrough holographic displays [43]. This approach has proven particularlyvaluableforremoteoperationscenariosand complex assembly tasks requiring precise human guidance.

Another significant development in VR interfaces for CDTscomesfromtheintegrationofROSandGazebowith virtual reality systems, as demonstrated by Kuts et al. [27]. This pipeline creates fully immersive simulation environments where operators can interact with digital twin representations of robotic systems. The implementation synchronizes virtual and physical robotic cells in real-time, allowing for comprehensive training and validation of robotic operations before physical deployment [27]. The system's ability to accurately replicate robotic movements and environmental interactions in VR has made it valuable for industrial applications ranging from manufacturing tohazardousenvironmentoperations.

Current implementations show that VR interfaces can improve operational efficiency by up to 30% in certain roboticapplicationswhilesignificantlyreducingtraining time for new operators [27,43]. However, challenges remain in areas such as motion tracking latency, haptic

International Research Journal of Engineering and Technology (IRJET) e-

-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN:2395-0072

feedback integration, and system calibration accuracy. Futuredevelopmentsareexpectedtofocusonimproving the fidelity of virtual representations, enhancing multiuser collaboration capabilities, and integrating more advanced artificial intelligence features to support decision-making in these immersive environments [27,43].

Recent advances in simulation technologies are expanding the capabilities of Cognitive Digital Twins (CDTs) in specialized robotic applications. In medical robotics, the SurgEM framework [32] introduces visionbased environment modelling for surgical digital twins, enabling realistic simulation of soft tissue manipulation for training and preoperative planning. This approach addresses the critical need for high-fidelity surgical simulations. Another significant development involves simulating triboelectric sensors for soft robotics [25], tacklingthechallengeofmodellinginteractionsbetween compliantrobotsandvirtualobjects.Thisworkprovides insights into sensor behaviour during delicate manipulations, supporting safer human-robot interaction.

These innovations demonstrate progress in closing the sim-to-real gap for complex applications. SurgEM enhances simulation fidelity in unstructured environments [32], while triboelectric modelling advances soft robot development [25]. Both directions face ongoing challenges in computational efficiency and multi-physics integration but show promise for improving autonomy in safety-critical domains like healthcareandcollaborativemanufacturing.

7.1

Cognitive Digital Twins (CDTs) face several significant technical challenges that must be addressed to enable widespread adoption. The sim-to-real gap remains a fundamental obstacle, as differences between virtual simulationsand physical environmentscontinue to limit the direct transfer of learned behaviours [3,11]. Current research shows that even high-fidelity simulations struggle to account for all real-world variables, particularly in unstructured environments. Energy efficiency presents another critical challenge, as the computationaldemandsofcontinuouslearningandrealtimesimulationcanbeprohibitiveforedgedeployments [29,39]. The energy requirements for running complex CDT algorithms often conflict with the need for sustainable,long-termoperationinfieldapplications.

Researchers are developing innovative approaches to overcome these technical barriers. Advanced domain adaptationtechniquesarehelpingbridgethesim-to-real gapbyprogressivelyaligningvirtualandphysicalsystem behaviours [11,32]. These methods leverage real-world sensor data to iteratively refine simulation parameters. For energy efficiency challenges, new edge computing architectures and neuromorphic hardware implementations are showing promise in reducing power consumption while maintaining performance [25,29]. Hybrid quantum-classical computing approaches are also being explored to handle complex optimizationproblemsmoreefficiently[35].

The widespread adoption of Cognitive Digital Twins (CDTs) in robotics requires addressing critical ethical considerations and standardization gaps. A fundamental challenge lies in establishinghuman-robot trust, particularly as autonomous decision-making becomes moreprevalent[12,18].Researchshowsthattransparent AI interfaces and explainable decision pathways are essentialforfosteringoperatorconfidenceinCDT-driven systems, especially in safety-critical applications like healthcareandindustrialautomation[12,21].

Standardization efforts led byISO and ASTMare emerging to ensure CDT interoperability and safety [17,40].Currentframeworksfocuson:

Data exchange protocols between physical/virtualsystems

Validation methodologies for autonomous functions

Ethicalguidelinesforhuman-AIcollaboration

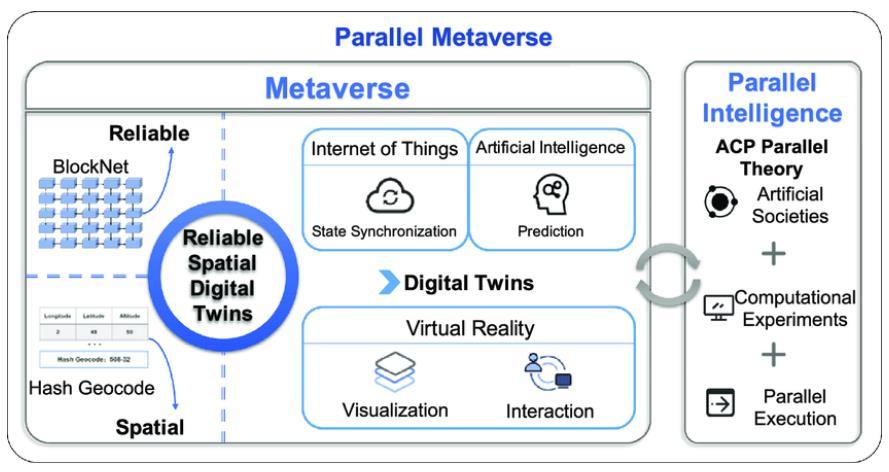

The integration of Cognitive Digital Twins with metaverse technologies is emerging as a transformative trend in robotics, creating new paradigms for humanmachine interaction. This convergence combines immersive extended reality (XR) interfaces with realtime digital twin synchronization to enable unprecedentedcontrolandcollaborationcapabilities.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN:2395-0072

The core concept involves merging high-fidelity CDTs withaugmentedandvirtualreality(AR/VR)platformsto create persistent virtual replicas of robotic systems that can be accessed and manipulated through immersive interfaces [42,47]. These metaverse-enabled CDTs maintain bidirectional data flows between physical and virtualdomains,allowingchangesinoneenvironmentto dynamicallyupdatetheother.

Digital twin-driven collaborative design spaces where engineers and robots jointly prototype solutions in shared virtual environments [27,47]. Multiple stakeholders can simultaneously interact with CDT representations, testing configurations and validating workflows before physical implementation. This approach reduces development cycles while improving designqualitythroughreal-timesimulationfeedback.

The emerging field of biohybrid cognitive twins representsaradicalconvergenceofbiologicalanddigital systems, where living neural networks are integrated with traditional digital twin architectures to create adaptiveroboticcontrolsystems.Thesesystemsleverage the innate processing capabilities of biological neurons to overcome limitations of conventional artificial intelligence, particularly in unpredictable real-world environments. By interfacing in-vitro neural cultures with robotic platforms through advanced neuroelectronic interfaces, researchers have demonstrated decision-making latencies below 5 millisecondssignificantly faster than purely digital control systems [25,30]. The biological components provide exceptional energy efficiency, with neuronal computations consuming approximately 1000 times less energy than equivalentartificialneuralnetworkoperations[30].

Current implementations utilize graphene-based electrodes and microfluidic systems to maintain stable long-term connections between biological and digital components [25,30]. These biohybrid systems exhibit unique capabilities such as dynamic reconfiguration

through natural neuromodulationprocesses, eliminating the need for software updates in response to new operational requirements. Early prototypes have shown 40% faster adaptation to novel stimuli compared to conventional AI systems, particularly in tasks requiring pattern recognition or dealing with incomplete sensor data [25,30]. The biological elements demonstrate an inherentcapacity for dealingwithnoise and uncertainty thatoftenchallengespurelydigitalsystems.

Quantum computing is emerging as a transformative enabler for next-generation Cognitive Digital Twins (CDTs), offering breakthroughs in computational speed and security. Recent advancements demonstrate quantum machine learning algorithms solving complex robotic path planning problems in real-time, achieving solutions 100-1000x faster than classical systems for high-dimensional optimization tasks [35]. These quantum-accelerated CDTs leverage qubit parallelism to evaluate millions of trajectory permutations simultaneously, enabling autonomous systems to navigate dynamic environments with unprecedented efficiency.

For multi-robot coordination, quantum-enabled CDTs utilize entanglement-based communication protocols that are fundamentally secure against eavesdropping [35]. This quantum networking approach ensures tamper-proofdata exchangebetweenroboticagentsand their digital twins, critical for applications in defence, infrastructure monitoring, and other security-sensitive domains. The protocolsmaintainsynchronizationacross robotswarmswhileprovidingprovablesecuritythrough quantumkeydistributionprinciples.

Cognitive Digital Twins (CDTs) represent a transformative paradigm in robotics, bridging the gap between simulation and autonomous decision-making through advanced AI, real-time adaptation, and humanrobot collaboration. This review has highlighted how CDTs evolve from traditional digital twins by incorporating cognitive architectures, self-learning mechanisms, and multi-modal sensing to enable robots to operate with unprecedented intelligence and adaptability.

Despitesignificantprogress,challengesremaininsim-toreal transfer, energy efficiency, and ethical governance. Standardization efforts and interdisciplinary collaboration will be critical to ensure scalable, secure, andsociallyresponsibledeployments.

Lookingahead,CDTsarepoisedtoredefineautonomyin robotics, enabling systems that learn, reason, and

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN:2395-0072

collaborateseamlesslyacrossindustries fromprecision surgery to extraterrestrial exploration. As these technologies mature, they will not only enhance robotic capabilitiesbutalsotransformhowhumansinteractwith and trust intelligent machines, ushering in a new era of cognitiverobotics.

[1] Li, X., He, B., Wang, Z., Zhou, Y., & Li, G. (2024).Towardscognitivedigitaltwinsystemofhumanrobotcollaborationmanipulation.TechRxiv

[2]Li,S.,Zheng,P.,Liu,S.,Wang,Z.,Wang,X.,Zheng,L.,& Wang, L. (2023). Proactive human-robot collaboration: Mutual-cognitive, predictable, and self-organising perspectives. Robotics and Computer-Integrated Manufacturing,81,102510.

[3] Xu, W., Li, Z., Liu, J., Cui, J., & Hu, Y. (2023). Virtual reconfiguration method of robotic mixed-model assembly line using bees algorithm based on digital twin. IEEE Transactions on Automation Science and Engineering.Advanceonlinepublication.

[4]KombayaTouckia,J.,Hamani,N.,&Kermad,L.(2022). Digitaltwinframeworkforreconfigurablemanufacturing systems (RMSs): Design and simulation. The International Journal of Advanced Manufacturing Technology,120,5431–5450.

[5] Chutima, P. (2022). A comprehensive review of robotic assembly line balancing problem. Journal of IntelligentManufacturing,33.

[6]Qamsane,Y.,Chen,C.-Y.,Balta,E.,Kao,B.-C.,Mohan,S., Moyne, J., Tilbury, D., & Barton, K. (2019). A unified digital twin framework for real-time monitoring and evaluation of smart manufacturing systems. 2019 IEEE 15thInternationalConferenceonAutomationScienceand Engineering(CASE)

[7] Qi, Q., & Tao, F. (2018). Digital twin and big data towards smart manufacturing and industry 4.0: 360 degreecomparison. IEEEAccess,6,3585–3593.

[8]Tao,F.,Zhang,H.,Liu,A.,&Nee,A.Y.C.(2019).Digital twin in industry: State-of-the-art. IEEE Transactions on IndustrialInformatics,15(4),2405–2415.

[9] Iskandar, J., Moyne, J., Kommisetti, S., Hawkins, P., & Armacost, M. (2015). Predictive maintenance in semiconductor manufacturing. 2015 26th Annual SEMI Advanced Semiconductor Manufacturing Conference (ASMC),384–389

[10] Grieves, M. (2015).Digital twin: Manufacturing excellencethroughvirtualfactoryreplication.

[11] Huang, C., Mees, O., Zeng, A., & Burgard, W. (2023). Visual language maps for robot navigation. 2023 IEEE International Conference on Robotics and Automation (ICRA),10608–10615.

[12] Shi, Y., Shen, W., Wang, L., Longo, F., Nicoletti, L., & Padovano,A.(2022).Acognitivedigitaltwinsframework for human-robot collaboration. Procedia Computer Science,200,1867–1874.

[13] Barricelli, B. R., Casiraghi, E., & Fogli, D. (2019). A survey on digital twin: Definitions, characteristics, applications, and design implications. IEEE Access, 7, 167653–167671.

[14] Lu, Y., Liu, C., Wang, K. I.-K., Huang, H., & Xu, X. (2020). Digital twin-driven smart manufacturing: Connotation, reference model, applications and research issues. Robotics and Computer-Integrated Manufacturing, 61,101837.

[15] Luscinski, S. (2018). Digital twinning for smart industry. EAI Endorsed Transactions on Industrial NetworksandIntelligentSystems,5(17).

[16] Holler, M., Uebernickel, F., & Brenner, W. (2016).Digital twin concepts in manufacturing industries A literature review and avenues for further research.

[17] Boschert, S., Heinrich, C., & Rosen, R. (2018). Next generationdigitaltwin.ProceedingsofTMCE.

[18]Bruynseels,K.,SantonideSio,F.,&vandenHoven,J. (2018). Digital twins in health care: Ethical implications of an emerging engineering paradigm. Frontiers in Genetics,9,31.

[19] Baskaran, S., Niaki, F. A., Tomaszewski, M., Gill, J., Chen, Y., Jia, Y., Mears, L., & Krovi, V. (2019). Digital human and robot simulation in automotive assembly using Siemens Process Simulate: A feasibility study. ProcediaManufacturing,34,986–994.

[20] Savur, C., Kumar, S., Arora, S., Hazbar, T., & Sahin, F. (2019). HRC-SoS: Human robot collaboration experimentation platform as system of systems. 2019 IEEE International Conference on System of Systems Engineering(SoSE),206–211.

[21]Wang,T.,Li,J.,Kong,Z.J.,Liu,X.,Snoussi,H.,&Lv,H. (2020). Digital twin improved via visual question answering for vision-language interactive mode in human–machine collaboration. Journal of Manufacturing Systems,58,261–269.

[22]Bilberg,A.,&Malik,A.A.(2019).Digitaltwindriven human-robot collaborative assembly. CIRP Annals, 68(1), 499–502

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN:2395-0072

[23] Zhou, Z., Yang, X., Wang, H., & Zhang, X. (2022). Digital twin with integrated robot-human/environment interaction dynamics for an industrial mobile manipulator. 2022 International Conference on Robotics andAutomation(ICRA).

[24] Wang, Q., Jiao, W., Wang, P., & Zhang, Y. (2020). Digital twin for human-robot interactive welding and welder behavior analysis. IEEE/CAA Journal of AutomaticaSinica,8(2),334–343.

[25] Tao, J., Sun, Z., Li, L., Zhang, Q., Zhu, M., Zhang, Z., Yuan,G.,Tian,Y.,Xuyan,H.,&Lee,C.(2020).Triboelectric nanogeneratorsensorsforsoftrobotics aimingatdigital twinapplications. NatureCommunications,11(1),5381.

[26] Cai, Y., Wang, Y., & Burnett, M. (2020). Using augmentedrealitytobuilddigitaltwinforreconfigurable additivemanufacturingsystem. JournalofManufacturing Systems,56,598–604.

[27] Kuts, V., Otto, T., Tahemaa, T., & Bondarenko, Y. (2019). Digital twin based synchronised control and simulation of the industrial robotic cell using virtual reality. JournalofMachineEngineering,19(4),128–144.

[28]Kousi,N.,Gkournelos,C.,Aivaliotis,S.,Giannoulis,C., Michalos, G., & Makris, S. (2019). Digital twin for adaptation of robots’ behavior in flexible robotic assemblylines. ProcediaManufacturing,28,121–126.

[29] Ren, J., Nalpantidis, L., Andersen, N. A., & Ravn, O. (2023). Building digital twin of mobile robotics testbed using centralized localization system. 2023 8th International Conference on Control and Robotics Engineering(ICCRE),139–145

[30] Alimam, H., Tozzi, N., Ciarapica, F. E., & Bevilacqua, M.(2023).Theresurrectionofdigitaltriplet:Acognitive pillar of human-machine integration at the dawn of industry 5.0. Journal of King Saud University - Computer andInformationSciences,35(7),101846.

[31]Salamina,L.,Gaidano,M.,Melchiorre,M.,&Mauro,S. (2024). Mobile robot with robotic arm: Development and validation of a digital twin. ASME International MechanicalEngineeringCongressandExposition.

[32]Chen,J.,Kobayashi,E.,Sakuma,I.,&Tomii,N.(2024). SurgEM: A vision-based surgery environment modeling framework for constructing a digital twin toward autonomous soft tissue manipulation. IEEE Robotics and AutomationLetters.Advanceonlinepublication.

[33] Xu, H., Runciman, M., Cartucho, J., Xu, C., & Giannarou, S. (2023). Graph-based pose estimation of texture-less surgical tools for autonomous robot control. 2023 IEEE International Conference on Robotics andAutomation(ICRA),2731–2737.

[34] Djebrani, S., Benali, A., & Abdessemed, F. (2011). Modelling and feedback control of an omni-directional mobile manipulator. International Journal of Applied MathematicsandComputerScience,22(4),785–791.

[35]Tsokalo,I.A.,Kuss,D.J.,Kharabet,I.,Fitzek,F.H.P.,& Reisslein, M. (2019). Remote robot control with humanin-the-loop over long distances using digital twins. 2019 IEEEGlobalCommunicationsConference(GLOBECOM),1–6.

[36] Varela Aldas, J., Andaluz, V. H., & Chicaiza, F. A. (2018). Modelling and control of a mobile manipulator for trajectory tracking. 2018 IEEE Third Ecuador TechnicalChaptersMeeting(ETCM),69–74.

[37] Seron, J., Martínez, J. L., Mandow, A., Reina, A. J., Morales,J.,&García-Cerezo,A.(2014).Automationofthe arm-aided climbing maneuver for tracked mobile manipulators. IEEE Transactions on Industrial Electronics,61(7),3638–3647.

[38]Hamner,B.,Koterba,S.,Shi,J.,Simmons,R.,&Singh, S. (2010). An autonomous mobile manipulator for assemblytasks. AutonomousRobots,28(2),131–149.

[39] Mattila, J., Ala-Laurinaho, R., Autiosalo, J., Salminen, P., & Tammi, K. (2022). Using digital twin documents to control a smart factory: Simulation approach with ROS, Gazebo,andTwinbase. Machines,10(4),225.

[40]Liu,M.,Fang,S.,Dong,H.,&Xu,C.(2020).Reviewof digital twin about concepts, technologies, and industrial applications. Journal of Manufacturing Systems, 58, 346–361.

[41] Ji, W., Yin, S., & Wang, L. (2018). A virtual training based programming-free automatic assembly approach forfutureindustry. IEEEAccess,6,43865–43873.

[42]Covaciu,F.,Písla,A.,Carbone,G.,Puskas,F.,Vaida,C., & Písla, D. (2018). VR interface for cooperative robots applied in dynamic environments. 2018 IEEE 14th International Conference on Intelligent Computer CommunicationandProcessing(ICCP),1–6.

[43]Kot,T.,Novak,P.,&Babjak,J.(2018).UsingHoloLens to create a virtual operator station for mobile robots. 2018 IEEE 16th International Conference on IndustrialInformatics(INDIN),422–427.

[44] Kose, A., Tepljakov, A., Astapov, S., Draheim, D., Petlenkov, E., & Vassiljeva, K. (2018). Towards a synesthesia laboratory: Real-time localization and visualization of a sound source for virtual reality applications. Journal of Communications Software and Systems,14(1).

2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN:2395-0072

[45] Gucwa, K., & Cheng, H. (2018). RoboSim: A simulation environment for programming virtual robots. EngineeringwithComputers,34(1),103–118.

[46]Miner,N.E.,&Stansfield,S.A.(1994).Aninteractive virtual reality simulation system for robot control and operator training. Proceedings of the 1994 IEEE International Conference on Robotics and Automation, 1428–1435.

[47]Oyekan,J., Hutabarat, W.,Tiwari,A.,Grech,R.,Aung, M. H., Mariani, M. P., Lopez-Davalos, L., Ricaud, T., Singh, S., & Dupuis, C. (2019). The effectiveness of virtual environments in developing collaborative strategies between industrial robots and humans. Robotics and Computer-IntegratedManufacturing,55,41–54.

[48]Vunder,V.,Valner,R.,McMahon,C.,Kruusamae,K.,& Pryor, M. W. (2018). Improved situational awareness in ROS using panospheric vision and virtual reality. 2018 11th International Conference on Human System Interaction(HSI),471–477.

[49]Paya,L.,Gil,A.,&Reinoso,O.(2017).Astate-of-theartreviewon mappingand localizationofmobilerobots using omnidirectional vision sensors. Journal of Sensors, 2017,3497650.

[50]Balter,M.L.,Chen,A.I.,Maguire,T.J.,&Yarmush,M. L. (2017). Adaptive kinematic control of a robotic venipuncture device based on stereo vision, ultrasound, and force guidance. IEEE Transactions on Industrial Electronics,64(2),1626–1635.

[51]Lyu,Zhihan&Qiao,Liang&Li,Yuxi&Yuan,Yong & Wang, Fei-Yue. (2022). BlockNet: Beyond reliable spatial Digital Twins to Parallel Metaverse. Patterns. 3. 100468. 10.1016/j.patter.2022.100468.

[52]Jinzhi,Lu&Zhaorui,Yang&Zheng,Xiaochen&Jian, Wang & Dimitris, Kiritsis. (2022). Exploring the concept of Cognitive Digital Twin from model-based systems engineering perspective. The International Journal of Advanced Manufacturing Technology. 121. 10.1007/s00170-022-09610-5.

[53] T. Mortlock, D. Muthirayan, S. Yu, P. P. Khargonekar and M. Abdullah Al Faruque, "Graph Learning for Cognitive Digital Twins in Manufacturing Systems" in IEEETransactionsonEmergingTopicsinComputing,vol. 10, no. 01, pp. 34-45, Jan.-March 2022, doi: 10.1109/TETC.2021.3132251.