BRAND-NEW

The Combination of a Self-Healing Polymer and Graphene Oxide Could Be the Future of Scratch Resistant Coatings combines a soft, self-healing polymer with a tough layer of

graphene oxide could one day form the

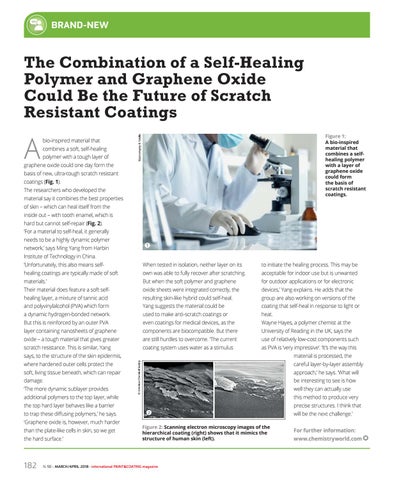

Figure 1: A bio-inspired material that combines a selfhealing polymer with a layer of graphene oxide could form the basis of scratch resistant coatings.

18percentgrey © Fotolia

A

bio-inspired material that

basis of new, ultra-tough scratch resistant coatings (Fig. 1). The researchers who developed the material say it combines the best properties of skin – which can heal itself from the inside out – with tooth enamel, which is hard but cannot self-repair (Fig. 2). ‘For a material to self-heal, it generally needs to be a highly dynamic polymer

1

network,’ says Ming Yang from Harbin Institute of Technology in China. ‘Unfortunately, this also means self-

When tested in isolation, neither layer on its

to initiate the healing process. This may be

healing coatings are typically made of soft

own was able to fully recover after scratching.

acceptable for indoor use but is unwanted

materials.’

But when the soft polymer and graphene

for outdoor applications or for electronic

Their material does feature a soft self-

oxide sheets were integrated correctly, the

devices,’ Yang explains. He adds that the

healing layer, a mixture of tannic acid

resulting skin-like hybrid could self-heal.

group are also working on versions of the

and polyvinylalcohol (PVA) which form

Yang suggests the material could be

coating that self-heal in response to light or

a dynamic hydrogen-bonded network.

used to make anti-scratch coatings or

heat.

But this is reinforced by an outer PVA

even coatings for medical devices, as the

Wayne Hayes, a polymer chemist at the

layer containing nanosheets of graphene

components are biocompatible. But there

University of Reading in the UK, says the

oxide – a tough material that gives greater

are still hurdles to overcome. ‘The current

use of relatively low-cost components such

scratch resistance. This is similar, Yang

coating system uses water as a stimulus

as PVA is ‘very impressive’. ‘It’s the way this material is processed, the

where hardened outer cells protect the

careful layer-by-layer assembly

soft, living tissue beneath, which can repair damage. ‘The more dynamic sublayer provides additional polymers to the top layer, while

© American Chemical Society

says, to the structure of the skin epidermis,

approach,’ he says. ‘What will be interesting to see is how well they can actually use this method to produce very precise structures. I think that

the top hard layer behaves like a barrier to trap these diffusing polymers,’ he says. ‘Graphene oxide is, however, much harder than the plate-like cells in skin, so we get the hard surface.’

182

2 1

Figure 2: Scanning electron microscopy images of the hierarchical coating (right) shows that it mimics the structure of human skin (left).

N. 50 - MARCH/APRIL 2018 - international PAINT&COATING magazine

will be the next challenge.’ For further information: www.chemistryworld.com