-

-

-

-

-

-

-

-

-

-

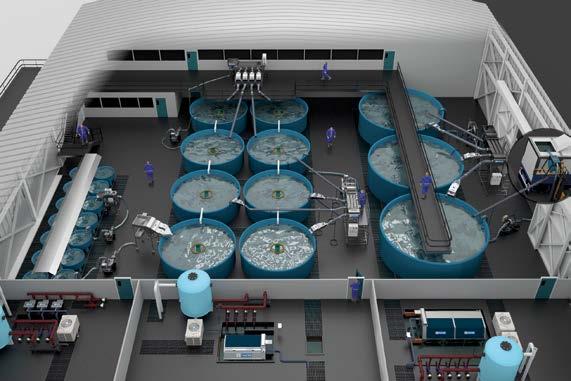

As industry experts, we fully understand the unique challenges you face in the aquafeed industry. That’s why we are committed to assist you throughout the entire journey, from concept to complete installation. Ready to reinvent your aquafeed operations?

As we were preparing to go to press in mid-February, I was travelling to San Antonio, Texas, to attend the 2024 Aquaculture America ’Setting the Table for US Aquaculture’ event which is likely to attract over 2000 delegates and attendees, including a umber from outside the USA and those attending from Latin America in particular.

Roger Gilbert Publisher – International Aquafeed and Fish Farming Technology

Roger Gilbert Publisher – International Aquafeed and Fish Farming Technology

While you might at times think IAF focuses too frequently on events, this one in particular – along with all the others organised by the World Aquaculture Society - is one “must attend” event in my calendar each year. This WAS event has a range of conferences that will host 67 concurrent sessions with multiple presentations over its threedays here in downtown San Antonio.

There is certainly something that will satisfy the interests of everyone involved in the production of farmed fish and other food-based products, while not overlooking related issues around water quality and aquaria.

Over the next three years WAS will host 11 similar events throughout the world.

If you are at all involved is aquaculture, this is the event platform you should be attending, or planning to attend if you have not yet been invited to do so.

Of course, IAF and its break-away sister publication Fish Farming Technology will be distributing copies of their magazines and the industry’s annual directory at this week’s event and all these listed above.

That reminds me that we need to reiterate our plans to separate Fish Farming Technology from International Aquafeed, although for the time being we will publish both together. Each will have its own editorial profile and independent editorial management.

At some point in the future each may be published separately, but for now the goal is to produce both magazines together in their four languages which we publish each month.

You will find the Fish Farming Technology information in digital format on a combined website - which is shared between FFT and IAF - as well.

This development is in addition to the acquisition of the International Aquafeed Buyers Guide and Directory which now comes under the Perendale Publishers brand.

This Directory has developed a great reputation among those in the aquaculture industries and deals with not only the manufacture of fish feeds but also the ingredients and additives being used in their formulation. We are maintaining the established annual schedule of this Directory with the next edition to be produced in July this year for 2024-25.

I’m also pleased to note that we have now published four peerreviewed research contributions in our Aquafeed Journal along with their DOI numbers in place. They are freely available to download from our Journal page on the IAF website.

It may take a little time to achieve wider recognition of our Aquafeed Journal as we know referencing these papers will take

time and that is key to the success of the Journal in future. For now we are already making those published peer-reviewed papers widely available to our industries through our magazine, its website and its social media channels.

As I have mentioned before we want to ensure that the time between submission and publication (which will take into account the peer-reviewing process) is key to disseminating information in a time manner. After all our Perendale moto is: Being timely relevant and visible.

Finally, don’t overlook our great line-up of conferences coming up.

Particularly the two aqua-related one which take place on the same day preceding the VIV Animal Nutrition and Health expo in Bangkok, Thailand on March 11, 2024 (that’s the day before the opening of the event) in the BITEC Centre.

One is the full-day ‘Extrusion of Pet and Aqua Feeds’ conference and the other is the half-day ‘Aquatic - Future World Feed through Aquaculture’ conference .

See the information relating to these two event in our Events Section and be sure to register in advance of arrival.

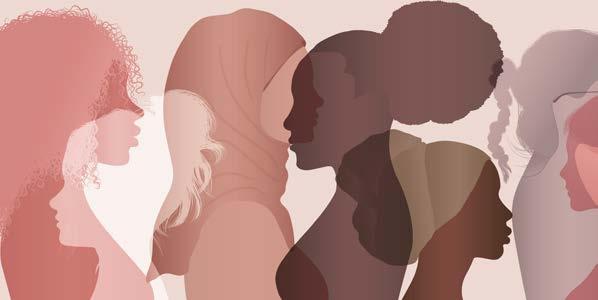

Our feature sessions start with an article by our writer, Shannon Parsons, on women in aquaculture. With women’s days around the corner, I am sure this article will shed some light into the role of women in shaping the aquaculture industry.

We have multiple features in this magazine that will no-doubt catch the eye of our readers, such like a piece on Skretting, a Finnish insect ingredient producer, and how inset meal can be used for sustainable aquaculture.

Moving on from the health of our world, we then later on have a story that focuses on the health of our fish, with a feature from Vernon E Coyne and Sarah L Carrol from MariHealth Solutions.

Jumping ahead to the Fish Farming Technology section of our magazine, this edition begins with a story that focuses on aquaculture in Norway. As some of our readers may know we do in fact also release our magazine in Norwegian and with it being one of the largest sectors for fish farming it seemed only natural to do a feature story on the country and try to give our readers a brief overview of how the industry began, where it is today and where it possibly might end up in the future.

And finally ...

Congratulations to John Cooksey, the Executive Director of the World Aquaculture Society who was recognised and awarded on behalf of USA’s National Aquaculture Association for his outstanding contribution to the development and service to aquaculture, both in the USA and abroad. The award was made at the recent Aquaculture America 2024 held in San Antonio, Texas last month.

www.aquafeed.co.uk

Perendale Publishers Ltd

7 St George’s Terrace St James’ Square, Cheltenham, Glos, GL50 3PT, United Kingdom

Tel: +44 1242 267700

Publisher Roger Gilbert rogerg@perendale.co.uk

Managing Editor Joy (Jyothsna) Nelloolichalil joyn@perendale.co.uk

International Editors Dr Kangsen Mai (Chinese edition) mai@perendale.com

Prof Antonio Garza (Spanish edition) antoniog@perendale.com

Erik Hempel (Norwegian edition) erikh@perendale.com

Editorial Advisory Panel

- Dr Abdel- Fattah M. ElSayed - Dr Alessio Bonaldo - Dr Allen Wu - Prof Charles Bai - Dr Daniel Merrifield - Dr Domique Bureau - Dr Elisabete Matos - Dr Eric De-Muylder - Dr Noor Khan - Dr Pedro Encarnacao - Dr Philip Lyons

Editorial team

Prof Simon Davies sjdaquafeed@gmail.com

Shannon Parsons shannonp@perendale.co.uk

Niamh Cassidy niamhc@perendale.co.uk

International Marketing Team

Darren Parris

Tel: +44 7854 436407 darrenp@perendale.co.uk

Costa Skotidas +44 7826 545952 costas@perendale.co.uk

Latin America Marketing Team

Cristina María Roldán Otero

Tel: +44 1242 267700 cristinaperendale@gmail.com

Egyptian Marketing Team

Mohamed Baromh

Tel: +20 100 358 3839 mohamedb@perendale.com

India Marketing Team

Dr T.D. Babu +91 9884114721 tdbabu@aquafeed.org

Asia Marketing Team

Dante Feng

Tel: +886 0227930286 dantef@perendale.com

Nigeria Marketing Team

Nathan Nwosu

Tel: +234 8132 478092 nathann@perendale.com

Digital community manager

David Harvey

davidh@perendale.co.uk

Design Manager

James Taylor jamest@perendale.co.uk

Circulation & Events Manager

Tuti Tan

Tel: +44 1242 267706 tutit@perendale.co.uk

Development Manager

Antoine Tanguy antoinet@perendale.co.uk

Aquafeed Journal journal@perendale.co.uk

1

s we arrive in March, I am reminded of the saying ‘Beware the Ides of March’ as was told to Julius Caesar prior to his assassination by members of the senate. So, I will watch my back this month just in case anyone has such motives and avoid any senate, council meetings or workshops. The scientific world that I inhabit does certainly generate conflict, friction and especially with respect to research findings, interpretation of data and dissemination into journals and reports. The increasing interactive disciplines that underline aquaculture and nutrition relies on much cooperation and collaboration globally. I find that some 40 years since my PhD I am now more involved in complex multi-author research manuscripts that can have as many as 1218 authors and affiliations. The organisation of scientific papers takes much effort as many of our techniques in fish nutrition, feed technology, cross and even merge into fish immunology, histopathology, genetics and beyond. In this magazine, we receive excellent articles from industry that are very interesting to read and assimilate. There is much new information, and this reflects the advances being made in the commercial sector as well as in academia. In the production of scientific papers and articles it is now indeed a team effort and the days of the lone isolated professor working in the laboratory is more or less over as we need many specialist scientists working across the disciplines. I have had the pleasure of leading such groups and also participating in exciting projects that have forged alliances in Saudi Arabia, Egypt, and my affiliation as adjunct professor at the University of Galway in Ireland. I am also developing strong alliances in Indonesia working on shrimp and also in the southern hemisphere in Chile for studies to develop new protein feed ingredients for salmon. There is no doubt that international collaboration such as my association in Pakistan can lead to more in-depth studies and more stable platforms and can help to reduce the costs of advanced research investigations.

Lately, I have been researching the effects of functional yeast based ingredients for Pacific Whiteleg shrimp Litopenaeus vannamei with my Indonesian colleague Dr Romi Novriadi to assess effects on growth and feed utilisation performance and even more importantly capacity to supress pathogenic infection in controlled challenge studies. The ability to undertake such direct challenge tests with fish and shrimp is really very important but has been restricted to me in the past due to the very stringent UK regulations when I was at my previous academic base. The claims that various functional feed additives and supplements may impart immune-stimulation and positively prime the defensive systems of fish can often be shown at the enzymatic and gene expression levels to some degree, but the only definitive validation to prove their effectiveness in the mitigation of specific disease scenarios is by direct interaction (host/pathogen) methods and measurement of survival post infection. I am very fortunate that some of my work is now leading into that direction and coupled to the feeding trials. Of course, not many universities and even well-funded government institutions have the required bespoke resources and skills to mount fish and shrimp pathogen disease challenge studies. One will need to scale up the pathogen in question, infect the aquatic animal in isolation and maintain a very strict environmental containment and high biosecurity at all times.

In the news I see exciting prospects from the University of Stirling in Scotland for sea lice vaccines for Atlantic salmon that

could be the ‘holy grail’ to combat this major problem afflicting the industry. This would of course involve the aquafeed sector to develop optimised feed to carry the vaccine and ensure its efficacy in diet administration routes at various stages of production from freshwater to sea water phases.

Recently, I read about the innovative use of seaweeds as a functional supplementary ingredient for shrimp arising from Singapore and Indonesia. The products being promoted also include mineral ash from local volcanoes to enhance the trace element profile of shrimp feeds. Mineral ash is very high in vital elements for bone and tissue integrity. A small amount of ground mangrove leaves is also being incorporated into a mix of commercial feed. The current trials demonstrated a 15 percent improvement in survival and growth rates and a decrease in conventional feed that the farmer must purchase, which is the most significant cost and contribution to shrimp production.

Aquaculture is all about people and I am delighted to read about investment in the USA for indigenous Americans with tribal roots and pursuing rural enterprises. American Unagi (AU) is an eel producer selling a range of live as well as value-added eel (known locally as unagi) to clients including Michelin-star restaurants and fisheries markets throughout the United States. Rural Works (Investment group) funding will support American Unagi’s expansion in partnership with the Passamaquoddy tribe of Maine, to create jobs and encourage wealth distribution. This will help bridge the escalating demand for sustainably originated, traceable seafood, notably within the rapidly growing market for Japanese and Asian seafood in North America. I have worked before on eels and their nutrition is as expected, based on a high protein diet, and meeting a carnivorous mode of nutrition and feeding.

Also in the news, I am intrigued by the development of nano-bubble technology in Norway as a means to deliver oxygen more effectively to fish and this would be highly applicable to RAS containment which is now gaining momentum. Land based aquaculture is capturing the imagination, and we could raise fish in our cities, towns, and countryside. Gas exchange is vital and the bioenergetic oxygen demand for fish under intensive rearing conditions is critical to meeting faster growth and efficient feed conversion. The nano-bubble concept is really efficient for gaseous transfer and would ensure higher and more consistent dissolved oxygen in the system. This is very important for salmonid fish to efficiently utilise their metabolic dietary energy from protein, lipids, and carbohydrates.

With Spring in the air and increasing daylength in my part of then world, it is most welcome after a harsh winter. I hope to reach out again in April with more news and reports of the latest developments in this fish nutrition and health sector. Happy reading wherever you are.

Location:

Wesley Vale, Tasmania, Australia

Application:

Aqua Feed, dosing block

“In Tasmania, they had plans to convert a former cardboard factory into a fish feed factory. And so it happened.”

A funding boost from Invitalia, Italy’s Development Agency, is set to propel the realisation of Ittinsect’s pilot plant, which will produce 2500 tonnes of sustainable proteins when operating at full capacity.

This marks a key step toward the biotech company’s goal of scaling up to an industrial-scale production of proteins derived from 100 percent circular economy processes by 2025. This initiative highlights the importance of scaling up sustainable aquafeed for safeguarding our oceans.

Ittinsect will deploy EU€602,500 to build a section of its inaugural production facility. The facility will prove both the technical and economic advantages of Ittinsect’s

products at scale, laying the groundwork for the company’s first industrial plant. This scale-up will also bolster the recruitment of specialised personnel and the pursuit of new patents, solidifying Ittinsect’s position as the preeminent innovator in the market.

Ittinsect’s CEO, Alessandro Romano, underscored the significance of national support from Italy’s National Development Agency, stating, “We are honoured to secure this funding, building upon the trust already received from the Lazio Region during the project’s pre-seed phase. The backing from Invitalia confirms the regional interest has transcended into a national one. Our goal is now to extend the public support to an international level.”

Invitalia’s funding, facilitated through the Smart Start Italia initiative, totals EU€482,000, covering 80 percent of the EU€602,500 project expenses.

Visit

The Leiber Animal Nutrition develops and produces sustainable brewers‘ yeast products that helps to improve the health and productivity of fish and crustaceans in the long term.

Leiber® Beta-S

Highly purified ß-glucans

Immunity booster

Increased resilience

Improved vaccinations

Leiber® Beta-S Plus

The ß-glucan alternative

Synergistic blend of pure ß-glucans and MOS

We have been upcycling at world-market level since 1954 and keeping the environment and climate in mind.

CeFi® pro

Autolyzed brewers‘ yeast

Rich in nutrients and active ingredients

High bioavailability of the same Stimulates the metabolism

Promotes feed intake and performance

For us, sustainable behaviour is a vital component of our core business. After all, upcycling brewers’ yeast is at the heart of what Leiber has always been about – Give Yeast a Second Life.

Aquaculture Stewardship Council (ASC) is delighted to celebrate the first two pioneers to achieve certification against the requirements outlined in ASC’s Feed Standard: Mexicanbased feed producer Vimifos and the Chilean branch of global operation, Skretting. This marks a significant milestone in ASC’s mission to transform seafood farming towards more environmental and social responsibility.

Both Vimifos and Skretting undertook a rigorous audit process over several months for their sites. The conclusion of the audits has established that their processes and performances meet the Feed Standard’s robust environmental and social requirements. SCS was the independent certifier for Vimifos, whilst Control Union carried out the audit of Skretting Chile.

Vimifos was the first to achieve multi-site certification for three of its feed mills in Mexico that produce feed for shrimp, tilapia, trout and marine fish. Skretting has also achieved multi-site certification for two feed mills in Chile that produce feed for salmon.

Chris Ninnes, ASC CEO, said: “This is not only a milestone for Vimifos, Skretting and ASC, but pivotal for the whole industry to strengthen the credibility of fed seafood farming now and into the future. Our Feed Standard sets a higher benchmark for feed production. We applaud Vimifos and Skretting for their commitment to venturing into new territory with us – they are the trailblazers and their certification paves the way for the rest of the industry.

“There is no responsible seafood farming without responsible feed. Companies involved in its production face increased by reporting demands to assess the ‘upstream’ environmental and social impacts from feed-ingredient supply chains. By setting strict requirements for the sourcing of all major feed ingredients, ASC addresses environmental and social risks down to raw material level. Ensuring responsibility soured feed supports responsible seafood farming and thereby responsible sourcing of seafood products on shelves. With these first certifications, the journey towards more responsibility coming from greater transparency and traceability in feed production has gathered significant momentum.”

Skretting CEO Therese Log Bergjord commented: “We are extremely proud to be the first salmon feed company in the world to achieve ASC Feed Standard Certification. This is a highly demanding standard that moves in the right direction towards ensuring a positive impact across our supply chain, but we know that the journey doesn’t end here. We’re already implementing the learnings from Chile to accelerate the certification process across the rest of our operations and, with that, ensure that our customers can keep relying on Skretting to maintain their own certifications for fish and shrimp.”

With two further feed companies currently in audit for four sites in Thailand and Ecuador, the programme is gathering strength and increasing in global coverage. This progress shows that ASC is collaborating with a wider sphere of influence to drive positive change in the feed production industry.

As global demand for farmed seafood continues to grow, it is vital that the entire aquaculture supply chain transforms towards more environmental and social responsibility – the Feed Standards is a significant step in the right direction.

While marine ingredients have long been the benchmark for feed ingredients in aquafeeds, they are not without their limitations. For starters, there isn’t enough of them. However, when we start to look across the “spectrum” of ingredients that we might consider for using in aquafeeds, we quickly deduce that everything has a limitation of some sort. There is no such thing as the perfect ingredient.

It is in this perspective that a recent review was published that undertook a classic SWOT (strengths-weaknessesopportunities-threats) analysis of a range of ingredients, including marine, grain and terrestrial animal by-products and a range of novel ingredients as well (e.g., single-cell and insect). In the review it was noted that the technology readiness of these options varies across and within the different ingredient classes, but importantly it remains important to consider each of the ingredients in terms of the overall options out there.

By comparing the nutritional attributes of each of the various ingredient classes being examined, it became possible to apply an assessment framework based on understanding the critical knowledge required to be able to accommodate any ingredient in the formulation process. Notably, that assessment framework was based on the review “A feed is still only as good as its ingredients”, which proposed a series of steps based on; characterisation - palatability - digestibility - utilisation - accessory studies, and critically in that order. Once that framework was laid down, they progressed to comparing all the various ingredients. To do this they used a SWOT analysis, to make some consideration of what future potential may exist across the spectrum and what risks and opportunities each of the various ingredients might bring.

Perhaps the most critical thing noted was that all ingredients have strengths and weaknesses, and that there is no such thing as the perfect ingredient. However, by better appreciating the positive and negative attributes of each ingredient, it becomes possible to increase the adaptability in being able to respond to the various opportunities to their use in feeds. Another feature discussed was complementarity and the capacity of ingredients to work in synergy with other ingredients. As suggested, there may not be such a thing as the perfect ingredient, but maybe by harnessing the strengths of individual ingredients we have a better chance of making the perfect feed.

The National Aquaculture Association (NAA) awarded the McCraren award for Outstanding Contributions in Promoting the Growth of Aquaculture to Roger Barlow and the MacCaren award for Distinguished Lifetime Contributions to the Aquaculture Industry to Phil Mackey at the Aquaculture America event held in Texas this week. The NAA awards are given in honour of their first Executive Director Joe McCraren annually.

Roger Barlow has served as President of The Catfish Institute (TCI) for 20 years and added the role of Executive Vice President for Catfish Farmers of America 17 years ago. These organisations play vital roles in marketing, public affairs, lobbying and constituent relations for the U.S. Farm-Raised Catfish Industry, the largest aquaculture segment in North America.

His involvement in the industry includes working with marketing agencies to promote products, creating and maintaining marketing relationships, multiple yearly trips to Washington D.C. visiting congressional leaders, including the annual “Fish Fry on the Hill” and coordinating industry events such as the annual CFA convention.

Phil Mackey has been a trout farmer, ambassador, advocate, and pioneer in the aquaculture industry for

over 52 years. He is the principal owner and CEO of Mt. Lassen Trout Farm where he has been employed for the entirety of his career. Phil has many amazing contributions to the world of aquaculture but beyond that is the personal relationships he has formed; the folks he has helped along the way and fellowship he embodies is why he is so deserving of this prestigious award.

Phil has served as the president of the U.S. Trout Farmers Association (USTFA)twice and was the youngest ever elected to the position. He was instrumental in writing many of the initial position statements for the USTFA prior to the formation of the NAA. He chaired many technical sessions and travelled on behalf of the USTFA to industry meetings with USDA, APHIS and many other agencies wanting to regulate the aquaculture industry.

Phil was directly involved in the formation of the NAA and served on the initial Board of Directors. He has also served on the board for the California Aquaculture Association and continues to serve on the CA Aquaculture Disease Committee where he was the chairman for over ten years. He is also currently serving on the board for the CA Aquaculture Development Committee and has provided written and oral testimony as an aquaculture advocate for NPDES permits and similarly related issues in California. Phil also designed, built and ran a 104-acre catfish farm in CA. He has been directly involved in the design and construction of 16 cold and warm water fish farms while consulting on many more.

The Sustainable Aquaculture Innovation Centre (SAIC) has boosted the skillset of almost 500 individuals across the aquaculture sector since the launch of its skills programmes in 2014.

SAIC has equipped 200 academics with the skills to thrive in the seafood industry, including MSc scholarships, PhD funding, and paid work-placements. Its programmes have also upskilled a further 294 private sector workers and university researchers through a range of mentoring initiatives, leadership courses and digital skills training.

To commemorate the milestone, SAIC brought together industry leaders in skills development, a mix of early to mid-career professionals, and new entrants into the sector for an afternoon of networking and discussion at Dunblane Hydro. The ‘Nurturing Talent in Scottish Aquaculture’ event showcased the diverse initiatives in place to upskill the existing workforce and support the next generation of talent.

Jillian Couto-Phoenix, Head of Skills at SAIC, and Alison Gray, Founder and Director of Skillfluence, delivered the welcome address, highlighting the importance of skills and knowledge exchange in driving innovation with impact and safeguarding a sustainable future for the sector.

Up next was a leadership showcase, which involved a reflective Q&A session with a group of individuals who took part in SAIC’s nine-month leadership cohort. This was followed by a fireside chat with a panel of early to mid-career professionals who discussed their personal experiences and successes from the innovation centre’s various skills initiatives.

The event concluded with an open discussion on the power of mentoring programmes, shining a light on the Women in Scottish Aquaculture (WiSA) network and its impact on encouraging more women to enter and progress in the sector.

Heather Jones, CEO of SAIC, provided the closing remarks and encouraged the room to take advantage of the numerous collaborative working groups and partnerships that are helping to drive the whole sector forward.

Julian Couto-Hoenix said: “Over the last ten years, SAIC has existed primarily to connect industry needs with academic expertise via a portfolio of research and development. However, to facilitate the sharing and translation of this knowledge into new and improved practices, a connected pipeline of talented individuals is needed to turn these ideas into reality. Therefore, alongside our research and development, SAIC has been nurturing talent by creating cohorts of professionals from across organisations within the aquaculture sector with the purpose of innovating, leading and guiding careers.

“It was energising to hear from professionals from across a range of disciplines, telling us that our programmes have helped them to develop key skills which they have implemented at work and seen positive results. The keystone is consistent funding for skills and talent programmes – something. a sector with big plans to grow and scale needs to bump up the list, given the demonstrable positive effect.”

International Women’s Day, March 8, approaches and women around the world are praised for the hardships and accomplishments they’ve experienced and gained, yet still face numerous challenges. They are the backbone to aquaculture, making up at least 50 percent of the industry, and remain working behind the scenes mainly in developing and rural countries. Women are the unseen force in aquaculture and deserve the necessary tools to continue acting as such.

There has been an increase over the past decade of more women taking on larger roles in the industry but their recognition and the programs to encourage them into these positions have not grown alongside this increase. In the last few years especially, recognition for women in aquaculture has bounced almost like a yo-yo; programs, training and awards have been created to

encourage, empower and provide the tools and recognition women require and deserve in the industry.

The role of women in aquaculture benefits the industry in a variety of ways yet continue to face a multitude of barriers. These range from gender-based discrimination, to lack of resources and education/training, to having little to no time or chance to involve themselves in networking and marketing opportunities.

The reasoning behind these barriers can stem from either a lack of funding and/or assistance from the Government, cultural and societal norms, availability due to household work and childcare and more. Methods to encourage growth and change to allow women the appropriate education and resources they need within the aquaculture industry can be done through the help of the Government and stakeholders. They could provide financial aid and programs that assist women in the industry in various ways. There could also be changes made within the culture and society to reduce the discrimination women face and decrease the blockages against them that prevent them from gaining education.

There are many organisations, programs and charities that have been made over the years to help empower and provide women with the tools they need to thrive in aquaculture. Some are specific to their location while others remain global, this provides support both on a local and worldwide level. Some such organisations to look into are:

• Women in Fisheries – By and for the women involved in UK fisheries.

• African Women Fish Processors and Traders Network –Collaborative network joining female processors and traders throughout Africa.

• Women Economic Empowerment Bugiri (WEEB) –Alleviating poverty and offering women paid fishery labour in Bugiri, Uganda.

• Women in Ocean Food (Hatch Group) – Latin American focus on women entrepreneurs to develop successful ocean food companies.

• The Bloom (Seafood and Gender Equality/SAGE) - a networking community for women and genderqueer people in the seafood sector.

• Women in North America Aquaculture Summit 2024 – an online event to encourage the next generation of North American women in aquaculture.

Despite the hardships that women have faced in the industry, there are many that have played large roles to bolster aquaculture around the world. It would be a dishonour to not take a moment and look into the achievements these women have made, to apply what they have learnt or discovered to your own findings,

to utilise their resources and work with them. Mentioning some notable women from around the world within the industry and their achievements are:

• Nawa Consollata Muyangana, South Africa – Is the lead tilapia producer in Zambia with plans to increase production to up to 20,000 tonnes.

• Patricia Bianchi, UK – Improving and minimising the environmental impacts of seaweed production/farming working with the Marine Stewardship Council and Aquaculture Stewardship Council.

• Sam Macdonald, Canada– Creating and providing an immediate inspection solution as a method to allow farm operators and aquaculture specialists to have a deeper understanding of their submerged infrastructure and fish stocks.

• Ita Sualia, Indonesia – Worked with the UNIDO GQSP Indonesia team to assist in entering the fish processing units to the export market.

• Karlanea Brown, USA – Self-taught, she is the lead shrimp producer in Indiana for more than a decade.

• Fanny Giudicelli, France – CEO and Founder of Marine AKWA focused on developing research on marine ingredients dedicated to fish and shrimp farming.

Women are the backbone to aquaculture and despite the centuries of work they have put in, working as half of the industry and creating new innovations and solutions every day, they remain underappreciated. They deserve a voice and to have easier and more access to tools to help us improve the industry further.

by Vernon E. Coyne & Sarah L. Carroll, MariHealth

by Vernon E. Coyne & Sarah L. Carroll, MariHealth

Like Sherlock Holmes with his magnifying glass, scrutinizing clues to solve complex cases, proteomics delves into the intricate network of cellular proteins which hold the secrets to metabolism, health, and resilience

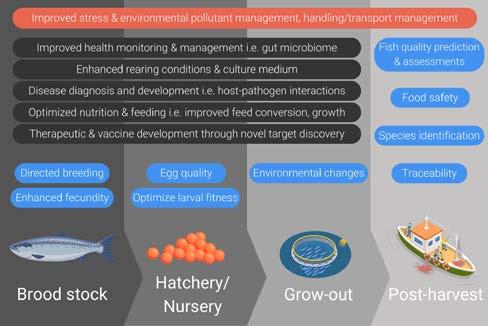

Cape Town, South AfricaThe growing prominence of Blue Food in tackling food security worldwide has undoubtedly led to significant advancements in seafood farming practices and nutrition. However, intensification has led to the aquaculture industry facing challenges associated with high input costs, disease outbreaks and fish welfare management, with the latter being at the core of sustainable production of high-quality protein. Improving fish welfare requires a holistic approach to mitigating animal stress. This includes the use of novel feed ingredients

Solutions,

Solutions,

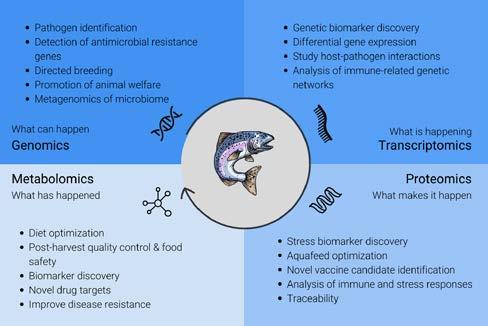

that possess immunostimulant properties and the development of improved feed formulations, as well as optimised farming practices and improved vaccine development and application. As such, advancements in aquatic health are seeking to close the gap between veterinary medicine and aquaculture, with omics approaches paving the way for a more integrated and granular approach to fish health and welfare management (Figure 1).

“Omics” refers to high-throughput technologies that enable concurrent in-depth analysis of several biological molecules in a single sample. The application of omics technologies in aquaculture can support the identification and characterization of pathogens, and the identification of specific biomarkers of stress, disease or metabolic status of farmed aquatic animals that can be used to guide the development of novel feeds and therapeutics. Although proteomics is the most complex of the omics technologies, its application to fish health management, epidemiology, and disease research is becoming invaluable. Proteomics, the study of an organism’s entire proteome – the functional complement to the genome, focuses on characterizing

the structural, functional, and physiological role of all proteins in a cell, tissue, organ or organism at any given time and under specific environmental conditions. Like Sherlock Holmes with his magnifying glass, scrutinizing clues to solve complex cases, proteomics delves into the intricate network of cellular proteins which hold the secrets to metabolism, health, and resilience. Below, we explore how proteomics has the potential to ensure the sustainability of a fast-growing aquaculture industry, and how MariHealth Solutions is leveraging this potential, backed by 10+ years of scientific research at the University of Cape Town.

Proteomics today is a lot more advanced than it was in its formative years, with highly sensitive mass spectrometers offering researchers the ability to analyse more than 2000 proteins per sample! Coupled with improved bioinformatic software, proteomics is a formidable tool that can be used to address many of the challenges associated with health and welfare, nutrition, production, and quality of farmed aquatic animals (Figure 2).

Mitigating the impact of stress, both as a consequence of farming practices and climate change, on farmed fish and shellfish is crucial to improving animal welfare. Stress is characterized by a series of cellular responses that manifest in phenotypic changes in an animal, which can either improve survival or impair welfare. Conventional approaches to monitoring fish stress have largely relied on crude indicators, providing a limited understanding of the stress levels experienced by the animals. For example, cortisol is the most common indicator of the primary response to stress, but increasingly, studies indicate that cortisol is unreliable as a measure of long-term stress. Proteomics offers an unbiased and sensitive methodology for identifying potential biomarkers for monitoring stress. For example, in a study of Gilthead seabream exposed to three different stress conditions, proteins were assessed for their reliability as biomarkers of chronic stress compared to conventional hormonal and metabolic counterparts such as cortisol. The authors found high variability in the levels of cortisol, lactate and glucose in fish sampled from the same treatments. Furthermore, decreased levels of the hormones falsely suggested that the animals were adapting to the stressor, suggesting that these biomarkers were unreliable for assessing chronic stress. Conversely, proteomics provided more informed data regarding changes in the levels of proteins that function in critical immunological pathways, providing a solid foundation for an improved understanding of stress adaptation in farmed fish.

Fish health and welfare are closely interlinked, where poor animal welfare can be both a cause and a consequence of poor animal health. Thus, fish welfare is essential for sustainable aquaculture production. The application of proteomics as a means of assessing fish health has become an important complement to conventional approaches such as histopathology and disease symptomatology. A proteomic investigation of Streptococcus parauberis, a bacterial pathogen of Korean halibut (Paralichthys olivaceus) identified 82 differentially expressed proteins in kidney samples from healthy and infected fish with proteins that function in the immune response being the most up-regulated. In another study, the bacterial pathogen Yersinia ruckeri, the causative agent of enteric redmouth disease in salmonids, was shown to affect the expression of a wide range of kidney and spleen proteins in infected rainbow trout (Oncorhynchus mykiss), including several immune-related proteins which were significantly up-regulated

in the infected fish. The above-mentioned examples reflect the utility of proteomics in identifying and quantifying a multiplicity of proteins whose expression levels change in response to disease, rather than focusing on single or a few proteins that provide a limited assessment of fish health and consequently, welfare.

In recent years, the aquafeed sector has undergone a substantial shift in fish feed formulation to include sustainably sourced ingredients such as terrestrial plants and oils. These can affect the welfare of farmed fish due to feed components that limit effective digestion and intestinal function. As such, substantial research is focused on developing optimal feed formulations with novel additives for improved growth, without compromising fish welfare. The sensitivity and robustness of proteomics analysis makes it a critical tool for identifying metabolic targets that could modify protein networks and pathways for optimal fish growth. When fishmeal is replaced with plant proteins, it is important that the feed is supplemented with essential amino acids to circumvent poor feed consumption, low growth performance and consequently, compromised fish welfare. Thus, the proteome of Gilthead seabream was investigated to determine the effect of a plant-based diet supplemented with threonine, histidine and tryptophan. Proteomics analysis showed that tryptophan supplementation at the levels tested did not compromise growth performance and seemed to stimulate the immune system. The latter could prove advantageous to the welfare of the fish as it may increase the resistance of the fish to pathogenic infection.

Since proteomics has the potential to revolutionise the welfare of farmed fish through improved monitoring and assessment of farm practices and feed formulations, MariHealth Solutions was established to make the technology available to the aquaculture sector, fish feed producers and fish veterinarians. Already we have assisted clients to better understand issues they are facing such as slow growth (rainbow trout), failure to thrive in salt water (rainbow trout) and the effect of a particular feed additive on the immune system of rainbow trout. In summary, we provide critical decision support to the industry as we believe it is better to be proactive rather than reactive if the goal is to ensure the welfare of farmed fish and a sustainable aquaculture industry.

(References are available upon request)

If you can think it, we can pack it!

Skretting, a global leader in aquafeed solutions, and Volare, a Finnish insect ingredient producer, have agreed on a commercial collaboration to further enhance the sustainability and nutritional value of aquafeed products

Around 75 percent of the salmon farming carbon footprint arises from feed, and 95 percent of the feed footprint originates from raw materials, partnerships are essential for industry-wide change. One of the challenges is the cost-driven nature of the industry and the associated pressure on ingredients. The commitment of big companies and the entire value chain to novel ingredients before factories are built poses a challenge. Several aquafeed companies have been testing and even using insect meal commercially in recent years and insect-based products have proven to be well-suited for aquafeeds, while reducing the environmental impact of the industry.

Skretting, a global leader in aquafeed solutions, and Volare, a Finnish insect ingredient producer, have agreed on a commercial collaboration where Skretting has secured a substantial capacity in Volare’s forthcoming industrial factory in Finland for their Norwegian salmon feeds. Volare’s insect-based products offer an environmentally friendly solution to the evolving needs of aquafeeds, aligning with Skretting’s ambitious sustainability targets. By incorporating insect protein from Volare, Skretting aims to further enhance the sustainability and nutritional value of its aquafeed products, contributing to a more resilient seafood industry.

Volare’s innovative technology ensures low energy consumption, eliminates the need for fossil fuels, and produces zero wastewater, further enhancing the sustainability of the collaboration. Volare’s ingredient will reduce the CO2 emissions and reliance on wild fish in aquaculture.

“We are constantly looking for novel sustainable raw materials, and this is a welcomed addition to our current supply of insect meal. We need more volume, and this new Nordic supplier and their work to scale up the industrial production of ingredients is good for our industry. We are looking forward to the collaboration with Volare and their focus on sustainable and highquality products. This aligns perfectly with our values and goals”, says Erling Johansen, purchasing manager for special ingredients

at Skretting Norway.

The collaboration leverages the advantages of a Nordic partnership. Typically, the feed industry does not make advance commitments, but for important new sustainable ingredients companies are willing to break the pattern and commit to further improving the industry’s sustainability results.

“Skretting’s expertise and attitude have been impressive. Witnessing how well they understand their customers’ needs and how we can contribute to serving those needs has been inspiring. We look forward to a long-term partnership, creating a large-scale impact together”, says Jarna Hyvönen, Chief Commercial Officer at Volare.

Volare’s insect-based products offer environmental benefits compared to traditional aquafeed ingredients. In terms of protein, CO2 emissions are up to 8 times lower than soy-based alternatives, and there is reduced pressure on land and water usage. Importantly, there is no harm to oceans, in contrast to the potential negative impact of increasing fish meal use on wild fish stocks. In terms of Volare's oil product, the CO2 emissions are significantly lower than palm kernel oil and other plant-based alternatives, with also reduced land use. Volare’s inspiration to focus on insect-based solutions for addressing environmental challenges in aquafeed production stems from a desire to make the food chain more sustainable as quickly as possible and without requiring significant changes in consumer behavior. They see that moving human diets towards more aquaculture products is a way of making the diets more sustainable, and the growing industry will need to find sustainable and scalable solutions to ensure that it really is sustainable from several perspectives - not only emissions, but also from biodiversity on land and oceans point-of-view.

The feed industry is quite cost-driven and they saw that to make a difference in reality would require a solution that could reach price parity with existing ingredients used in aquafeeds. Insects

are indeed a scalable and cost-effective solution compared to high-cost and small-scale novel proteins. At the same time insects are a sustainable alternative from emission and biodiversity perspectives, while the production can also be located near the aquafeed production.

The genesis

Volare’s journey in developing insect-based products for aquafeeds began with extensive research at VTT technical research centre of Finland, driven inspiration to find a sustainable solution for the protein gap. The founders, Tuure Parviainen and Matti Tahtinen, came together while researching an ultra-efficient way to keep nutrients in the food chain – with the help of the black soldier fly. Volare’s varied research background is in all things circular economy, not limited to insect economy but also including energy technology, biogas and even emerging fields such as novel foods.

The concepts and technology developed in research now forms the backbone of Volare’s process — using food industry side streams. Volare’s team of engineers, agronomists, operators and researchers are building on decades of experience to create a truly circular future for the food industry. The original Volare plant is already in operation and serving customers in aquafeeds and pet food business. The foundres saw that they key elements driving both sustainability and cost-efficiency would be the use of side streams as raw materials and a proprietary dry processing method that reduces energy consumption by 30 percent, is non-fossil, all while producing zero wastewater.

They adopted a customer-centric approach from the outset and wanted to understand what were the product characteristics that are important for our customers and even their customers

nutritionally and technically.

“We have built the entire philosophy of the company on finding the most sustainable and cost-effective solutions while reaching high-quality products.

“We exclusively use side streams as raw materials and employ a proprietary dry processing methodology that uses about 30 percent less energy than traditional wet processing methods. This supports both our sustainability but also cost-efficiency. Our process is fully electric and non-fossil, yielding zero wastewater.

“We have conducted a Life Cycle Assessment (LCA) using the industry-standard PEFCR methodology to validate the environmental footprint of its products for the first industrialscale plant. One of our core values is learning, meaning that we constantly develop ourselves and our processes, finding better ways to do things every day.” Says Volare’s Co-founder and CEO Tuure Parviainen

Skretting and Volare envision this collaboration as the initial step in a long-term partnership. Volare already has an operational demonstration facility in Finland and will start delivering ingredients to Skretting in 2024. Volare will commence the construction of its first large-scale factory in 2024 and plans for multiple factories across Europe by the end of the decade.

Omnivorous fish species are known to be less requiring in terms of nutritional and palatability requirements and yet hydrolysate supplementation resulted in greatly improved production yields and incomes.

Several biological benefits are associated to protein hydrolysates, and they’ve been used in finfish larval and juvenile diets for several decades now, mostly due to their high palatability and digestibility.

Symrise Aqua Feed, which has been producing functional protein hydrolysates for more than 20 years, has recently promoted the long-term use of a new generation of liquid hydrolysates formulated to be used as Palatability Enhancers (PE, Extrapal range, references available upon request) in carnivorous fish species dietary formulations. These species are known to be requiring in terms of dietary compositions, with the need of palatable, raw materials, such as fish meal, but also in terms of welfare, being very sensitive to stressful events, which often result in feeding drops. In this context, the use of

PE is intuitive, and expected benefits are well perceived by both farmers and feed manufacturers.

In contrast, freshwater omnivorous fish species are not perceived as very requiring and considered as more robust. In these species, feed acceptance becomes an issue during very specific periods, such as wintering, and is therefore not perceived as a need. Challenges quoted by this industry are mostly related to feed costs and disease outbreaks.

Symrise Aqua Feed has developed a cost-effective solution to meet these needs by designing ActiTuna Oil. It has been formulated with the right balance of tuna oil and protein hydrolysate, to make its top coating application easier to feed manufacturers as a one step process. ActiTuna Oil has been designed to increase omnivorous fish feed palatability and digestibility with the reduction of feed production costs as a final purpose.

To evaluate ActiTuna Oil performance in omnivorous fish species, two feeding trials were implemented in tilapia and pabda, two fish species commonly farmed in Bangladesh. The study took place at Sylhet Agricultural University.

The same experimental design was implemented in both species. A basal diet was supplemented by top-coating 0.5, 1.0 or 2.0 percent of ActiTuna Oil and was benchmarked to the same basal diet alone. In tilapia, the basal diet consisted

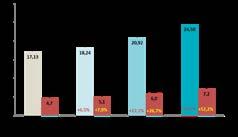

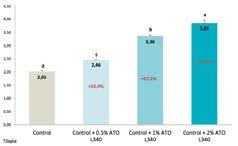

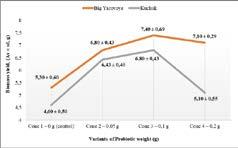

Figure 1a. and 1b. Tilapia and Pabda final mean weights (left bars, in g) and yield (right bars, in mT/ha) after 90 days of grow-out trial (p<0.001).

Figure 1a. and 1b. Tilapia and Pabda final mean weights (left bars, in g) and yield (right bars, in mT/ha) after 90 days of grow-out trial (p<0.001).

in a plant-based diet formulated to be as representative as possible of local commercial practices (31%CP and 6%CF, table 1.,) while in pabda, the basal diet consisted in a commercial diet (36%CP, 7%CF) locally available. Each dietary group consisted in 3 replicates i.e. a total of 12 cages of 3m² for each tested specie, at a stocking density of 100 fish per cage and an initial mean weight of 5.0 g for tilapia and 3.0 g for pabda. Fish were fed in excess twice a day at a fixed feeding rate (total distributed feed were 17g / tilapia individual and 20g / pabda individual) for 90 days. Water quality parameters remained within fish species requirements with following means: T°C:30.7±0.3, DO (ppm): 5.04±0.1, pH:6.95±0.07, ammonia (ppm): 0.06±0.04, nitrites (ppm): 0.08±0.04.

Both feeding trials were successful with very high survival and growth rates observed after 90 days. Thus, survival rates were at least 93% in both species while SGR were ranging from

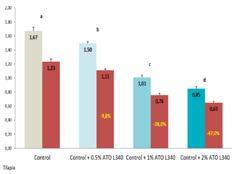

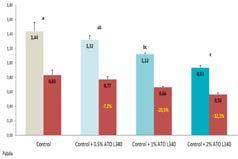

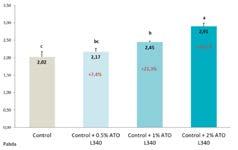

3.46% to 4.15%/d for tilapia and from 1.93% to 2.33% for pabda. Dietary ActiTuna Oil graded supplementations resulted, in both fish species, in significant dose responses for fish mean weights (figures 1a. and 1b.). Maximum weight gains were observed for 2% supplementation with an increase of 86% for tilapia and 43% for pabda. Resulting production yields, as calculated in metric tons per hectare of rearing area, were increased by the same range of values (+97% and 52% for tilapia and pabda respectively). Since feed rations were fixed and remained the same thorough the whole trial duration, growth differences are mostly explained by a better feed utilization through two main patterns: enhanced feed palatability reducing feed waste and diet digestibility increasing diet assimilation, both being illustrated by FCR and PER values (figures 2a., 2b., 3a. and 3b.). Dose responses to dietary ActiTuna Oil graded supplementations were very high, with up to 49% and 34% FCR reductions in tilapia and

pabda respectively. These benefits can be further developed by 2 positive outcomes: 1. much higher PER values (Protein Efficiency Ratio, +92% and +44% for tilapia and pabda respectively) resulting in much lower nitrogen pollution in ponds and 2. much lower feed production costs, as defined by the invested feed costs in US$ per kilogram of produced biomass: -47% and – 33% for tilapia and pabda respectively.

Discussion & perspectives (ROI)

Functional hydrolysates from Symrise Aqua Feed Actipal range are designed to enhance feed palatability, feed efficiency and the overall health status of animals through specific peptide profiles. The synergic effect of water soluble free amino acids, short peptide chains and bioactive peptides brings out the optimal flavour of the feed, stimulating the taste buds and modulating metabolic pathways of the aquatic animals. This stimulation triggers a series of physiological and endocrinal responses, preparing the digestive system to properly digest the feed and modulate the microbiota in the gut.

These results show that there is still some room for feed cost optimization through better feed acceptance and assimilation, even in omnivorous fish species.

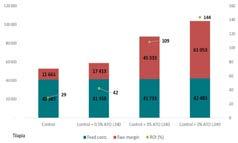

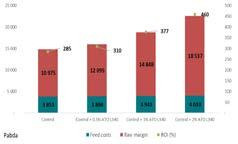

Figures 4a. and 4b. focus on the economic benefit of using ActiTuna Oil as a dietary performance enhancer. Bars show the expected sales revenues considering local tilapia and pabda farm gate prices (1.582 and 3.150 US$/kg of fish for tilapia and pabda, respectively). While feed costs remain the same, and by extrapolation other variable and fixed costs (seeds, electricity, wages…), revenues can be 96% (tilapia) or 51% (pabda) higher leaving a possible raw margin increased by 69% for pabda and 424% for tilapia productions, assuming other variable costs are negligeable compared to feed. Note that observed differences between the two species are explained by the fact that feeding trial started with bigger tilapia fish while this specie grows much faster than pabda.

Returns on investment (ROIs) were calculated doing the ratios

between revenue gains over feed investment costs. Logically, ROI increases followed the same pattern than raw margin ones. Maximum ROIs were observed for 2% ActiTuna Oil dietary supplementations: 144% and 460% for tilapia and pabda respectively.

Besides economic considerations, it is worth mentioning that a lower pond water pollution resulting from lower FCR will also contribute to better fish welfare, significantly reducing the risks of disease outbreaks and production losses.

The two feeding trials presented in this article typically illustrate the positive outcomes, which one may expect from the dietary application of a functional hydrolysate -ActiTuna Oil- by top coating (please see references). What is rather uncommon is the demonstration of such enhanced production figures in omnivorous fish species, generally considered less requiring in terms of dietary composition, nutrients, and palatability. Farm gate prices of these species are also usually lower than those of marine fish species, which leave less margin for sophisticated feed formula. However, estimated values of farm revenues, margins and feed ROIs demonstrated it is possible to generate much higher added values to omnivorous fish species feed formulas and farm productions. 2% dietary supplementation of ActiTuna Oil resulted in the maximum growth rates, yields, revenues, and ROIs. This combined solution can be easily applied by top coating at oil’s place.

We’ve detailed the positive outcomes expected by fish farmers (higher incomes, lower water pollution and disease risks) and mostly explained them by a higher feed acceptance (palatability) and assimilation (digestibility), which answer the industry needs of lower feed costs and disease risks, as introduced at the beginning of this article. Now, if considering feed manufacturers’ perspectives, top coating application of ActiTuna Oil will bring uniqueness and differentiation to standard formula, on which competition is tough, while giving formulators much more flexibility in terms of raw material choices, a great asset in these times of scarcity and cost volatilities!

DISCOVER

Our wide range of value-added services and understanding of production and market challenges worldwide, allows us to find the right technology and the most cost-effective solutions for your business in Livestock, Aquaculture/ Aquafeed and Pet industries

Figure 4a. and 4b. Tilapia and Pabda feed related economics (costs and raw margin, out of sales, in US$/ha and ROI, in %) after 90 days of grow-out trial (p<0.01).

Figure 4a. and 4b. Tilapia and Pabda feed related economics (costs and raw margin, out of sales, in US$/ha and ROI, in %) after 90 days of grow-out trial (p<0.01).

by Ivan Yu. Evdokimova,, Angelina V. Malkovaa, Alena N. Irkitovaa, Maksim V. Shirmanova, Altai state University and Dmitrii V. Dementyev, Arsal Limited Liability Company (LLC), Russia

by Ivan Yu. Evdokimova,, Angelina V. Malkovaa, Alena N. Irkitovaa, Maksim V. Shirmanova, Altai state University and Dmitrii V. Dementyev, Arsal Limited Liability Company (LLC), Russia

One of the main problems of the 21st century is the lack of food. In addition, aquaculture is an important source of nutrition for many people. Moreover, aquaculture today is one of the most promising sectors of agriculture. Breeding and rearing of aquatic animals is widespread in coastal countries, such as India, Thailand, Mexico, etc. [1, 2, 3]. The shrimp aquaculture industry can be distinguished as one of the most in demand. Its production exceeds millions of tons per year. But in the first place is still fish aquaculture

In the industrial breeding of crustaceans, farmers face problems such as infections and mass mortality due to them. Pathogens in the aquatic environment include representatives of the genus Vibrio Salmonella, Escherichia coli etc. Probiotics actively studied and used to improve the sanitary background of aquaculture enterprises.

A group of Indian scientists in a series of experiments carried out work on enriching Artemia with a Lactobacillus sporogenes supplement. Probiotic was used with different concentrations for further feeding to freshwater shrimp M. rosenbergii. According to their data, M. rosenbergii shrimp showed better survival, rapid growth and a greater content of protein, amino acids, carbohydrates, and lipids in the body after enrichment of mobile feed (Artemia crustaceans). They also proved that the concentration of L. sporogenes 6 × 108 CFU/g was optimal for the use of these microorganisms in foraging Spanish scientists conducted an experiment to analyze the effect of probiotic using as a means of combating potentially pathogenic members of the family Vibrionaceae. For this, they introduced a probiotic based on L. rhamnosus in the medium to A. metanauplii. As a result, they show a positive effect of L. rhamnosus on crustaceans. It was expressed in the level of

pathogens decrease by a whole order of magnitude compared to control.

Scientists from India conducted a similar study. They studied the effect of a probiotic supplement based on Saccharomyces boulardii on a pathogenic microorganism. Researchers found that yeast-enriched Artemia nauplii, after artificially infected by representatives of Vibrio, have improved resistance to infection. This proved the positive effect of S. boulardii microorganisms on Artemia.

Scientists from Iran carried out work to assess the impact of the Artemia enrichment with a Bacillus subtilis probiotic supplement on the growth, reproduction, microflora and resistance to Aeromonas hydrophila for ornamental fish Poecilia latipinna. They found that the enrichment of Artemia positively affects the parameters of the test group of fish. It also was found that there are no significant differences in the ontogenesis of enriched and unenriched Artemia groups.

A group of Indian scientists conducted research on the enrichment of nauplii A. parthenogenetica by various microorganisms: L. rhamnosus, B. coagulans. During the experiment, the intestine load and the retention time in the intestine of the Artemia nauplii of probiotic supplements were studied. As a result, scientists revealed that the nauplii of Artemia enriched with L. rhamnosus reached the filled state of the intestine after 39 ± 1.41 minutes, and the enriched nauplii of B. coagulans - after 39.5 ± 0.71 minutes. The load on the intestine and the retention time in the intestine varied in experimental groups.

From the above data, it can be see that well-studied microorganisms of the genera Lactobacillus and Bacillus are the most often appear in the composition of probiotic preparations. For the sustainable aquaculture development, it is necessary to increase the pool of microorganisms used as probiotics for hydrobionts. It is also necessary to expand the range of preparations based on a consortium of microbes, rather than monocultures.

The purpose of the work was to study the use effectiveness of a new probiotic based on the strains B. toyonensis B-13249 and B. pumilus B-13250 consortium in incubating Artemia franciscana cysts using mechanical counting and automatic calculation by dint of a convolutional neural network.

A consortium based on B. toyonensis B-13249 and B. pumilus B-13250 strains (Figure 1) from the collection [19, 20] was selected as the active component of the biopreparation for research

The following nutrients were use in the work:

L-medium (g/l): yeast extract – 5.0; peptone – 15.0; NaCl – 5.0; agar – 15.0; distilled water – 1.0 l. Vegetative nutrient medium (g/l): yeast extract – 5; peptone – 3; NaH2PO4 – 1; K2HPO4 – 4; MgSO4 – 0.25; MnSO4 – 0.03; NaCl – 1; CaCl2 – 1; FeSO4 –0.01; glucose – 15; H2O – up to 1 l. (pH 6.8-7.0). Fermentative nutrient medium (g/l): molasses – 25; corn extract - 12.5; yeast extract – 1; tripton – 0.5; MgSO4 – 0.25; MnSO4 – 0.03; CoCl2 – 1; saline runoff – 10 μl; H2O – 1 l. Cryoprotective medium (g/l): gelatin – 25, sucrose – 100 [21].

Production of an experimental probiotic lot

The development of an experimental-industrial lot of probiotic for testing also carried out based on the laboratory EC Prombiotech of Altai State University (Barnaul, Russia). The finished product includes a composition of B. toyonensis B-13249 and B. pumilus B-13250 strains, which were cultivated separately and mixed after drying.

To prepare the mother culture the strains inoculated by loop in 500 ml flasks with 150 ml of medium. Bacteria were cultured

Above - Figure 1: Morphology of used strains colonies on L-medium (x10): A - B. toyonensis, B-13249; B. pumilus B-13250

Below - Figure 2: Incubation cones with Artemia cysts

in “Innova 44” shaker-incubator at 37 °C about 24 hours at 250 rpm (eccentricity 5 cm). The number of bacilli, the check of the fermentation process and the finished preparation purity were carried out using spread plate method. Petri dishes were incubated in a “Binder BD 115” thermostat at 37 °C for 24 hours.

Deep cultivation of each strain carried out in bioreactors with a volume of 15 and 250 liters. To obtain more B. pumilus and B. toyonensis biomass, fermentation carried out in a 250 l bioreactor with a Fermentative culture medium. Having previously grown microbial cultures of bacilli to the stage of active division on a Vegetative nutrient medium in a bioreactor by 15 liters. Before loading the nutrient medium, bioreactor and individual air filter previously sterilized with sharp steam for 1 hour at 121-125 ° C and a pressure of 0.13-0.15 MPa.

After the fermenter was inoculated, the temperature of the culture liquid maintained at 37 ± 1 °C. At the beginning of the process, sterile air continuously supplied to the fermenter in an amount of 0.5 l/min per 1 l of medium and the pressure maintained at 0.02-0.03 MPa, stirring at 250 rpm. Sterile sampling carried out every 2 hours to observe the development of bacterial culture, morphological state and absence of extraneous microflora, as well as measurements of the optical density of the culture fluid (at 490 nm).

The target product (biomass) separated by centrifugation on the flow GTGQ-1251 Tubular Centrifuge at 15000 rpm. After concentration, the biomass was mixed with the Cryoprotective medium, frozen and sent to the chamber of the freeze-dryer “SP Scientific 25l Genesis SQ Super ES-55”. The drying time was about 40 hours, after which the dried concentrate tested for moisture content on a Shimadzu MOC63u humidity analyzer. The optimum moisture content of the finished concentrate is less than 5%.

The obtained concentrates mixed with each over and with a filler – maltodextrin until the final number of bacteria in the preparation (at least 1 × 1010 CFU/g). The ratio of B. toyonensis to B. pumilus was always 1:3, since the B. pumilus strain develops a higher abundance. Therefore, its predominance in the preparation is economically justified.

The study was carried out in laboratory of Arsal LLC in Yarovoye, Russia. The experiment used the A. franciscana cysts of two lots of two different lakes: Z29.04 (Lake Big Yarovoye) and C9 (Lake Kuchuk). Cysts incubated in cones (Figure 2) during 48 h at a constant bubbling air and standard conditions: the volume of incubatory solution – 1 l, salinity – 30 ‰, temperature – 25-30 °C, рН – 8.0-8.5, the oxidation-reduction potential (ORP) – 148-220 mV, illumination – 1500-2000 lux., quantity of the brought cysts – 2.0 g, the activator – 0.2 ml of 3% H2O2 solution.

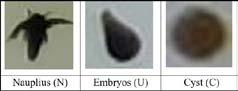

The experiment consisted of four variants for each eggs lot (1 – control, 2, 3, 4 – experimental variants) in 24 repetitions. Incubation of both lots nauplii was carried out using probiotic doses (g): 0 (control), 0.05, 0.1, 0.2 respectively. The probiotic directly introduced into the cone with the incubation solution simultaneously with the start of the incubation process. After 48 hours of incubation, the number of crustaceans or nauplii (N), cysts (C) and embryos (U – umbrellas) counted in each cone. After that, the hatching rate (HR) calculated using the standard method and the biomass coefficient corresponding to the multiplicity of the increase in the total crude mass compared to the mass of the dry egg originally introduced.

Until now, industrial manufacturers of Artemia crustaceans carried out the counting process by visual method – using a binocular and microscope. It takes a large amount of time, measurement accuracy, due to fatigue and constant attention is not always correct. In addition, to save at least any data you have

Mean differences between the control and each of the experimental cones are significant at P<0.05

2:

Mean differences between the control and each of the experimental cones are significant at P<0.05

to use additional devices or gadgets.

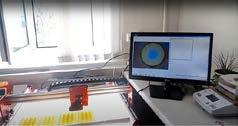

To reduce statistical error, at least 8 times repetition is required. To reduce the time of counting, increase the accuracy and save data, in our work an Artemia robot counter with an algorithm based on a convolutional neural network (CNN) was used for the first time in the Russian Federation. The CNN used the algorithm YOLO (You Only Look Once).

A dataset of 1200 hand-labeled photomicrographs of brine shrimp samples was used to train the neural network (Figure 3). Each sample was 0.1 ml of water from an incubator with a random number of non-hatched cysts, embryos and hatched nauplii.

All objects were marked on each sample; their calculation is the task of the neural network. The total number of marked images (dataset) was divided into two unequal parts – a training sample (about 800 images), from which the neural network learns, and a test sample (400 images), on which the neural network checks itself. Figure 4 shows photos in the sizes and qualities on which the neural network trained.

The images enlarged from their original sizes. Photo resolutions: the number of pixels per unit area is sufficient for the operation of the neural network, since the natural dimensions

of objects in the visual visibility of the detector are commensurate with the samples specified for training the CNN.

Neural network training took place in the cloud service GoogleColab with connection to the Nvidia K80s, T4s, P4s and P100s graphics processors. Upon completion of training, the so-called neural network weights obtained – settings of parameters by which the neural network most accurately determines the objects sought in the image. Subsequently, weights were loaded from the cloud service for the possibility of applying them already offline.

The mechanical part of the robot was also developed and built in the Russian Federation, and the entire complex of automatic counting of nauplii called «Artemetr-1» (Figure 5).

Effect of probiotic on incubation rates of A. franciscana cysts

Classical (mechanical) counting (45 seconds/sample)

The results of the study on the lot of cysts Z29.04 presented in Table 1, and on the lot of cysts C9 – in Table 2. Moreover, with

both lots the best results on biomass yield obtained by adding 0.1 g of probiotic per 2 g of dry cysts. The hatching percentage when adding a probiotic to a Z29.04

Table 3: Comparison of classical (mechanical) and automatic counting of Artemia nauplii

Table 3: Comparison of classical (mechanical) and automatic counting of Artemia nauplii

lot changes not so significantly compared to the control but improves by 1.4% maximum. CV from 3 to 5% indicates a slight spread of values and allows us to talk about the reliability of the result.

When adding a biopreparation to a C9 lot, an increase in HR of about 10% is noted. The coefficient of variation when working with the second experimental lot was significantly higher (6.411.8%), but remained at an acceptable level to speak of the reliability of the result. In this case, the lowest variation observed in the experimental group with the addition of 0.1 g of probiotic.

The biomass yield shows what mass of Artemia crustaceans turned out after incubation. The graph shows the results of the correlation between the applied dose of the probiotic and the biomass yield of Artemia franciscana from two independent batches taken from two different lakes (Fig. 6).

Various samples of A. franciscana cysts (C9 and Z29.04) have different hatching percentage and biomass yield in control cones. However, in both batches, there was a decrease in these indicators with the addition of 0.2 g of probiotic compared to the best result in cone 3 (with added 0,1 g of probiotic). With sample Z29.04 excessive dosage of the biological product contributed to significant indicators decrease to a level below the control values. The effect of the probiotic is most pronounced at initially low rates of hatching percentage and biomass yield, as in the case of the C9 lot.

The biomass coefficient shows how many times the mass of brine shrimp increases after incubation. The tables also present the results of the correlation between the applied dose of probiotic and the biomass coefficient of the studied lots of Artemia.

Validation of counting by convolutional neural network

To verify the validity of the results of automatic counting, the entire lot of 192 images additionally was checked by the classical (mechanical) method (Table 3).

According to the results of the inspection, no reliable differences between the counting methods were found. The entire set of obtained images (example – Figure 7) was saved, and it can be used for further research.

Shrimps are demanding on food mobility during feeding in the early stages of development. In this regard, the technology of feeding shrimp prelarvae with live, freshly hatched brine shrimp nauplii is widely used in aquaculture. The incubation solution for A. franciscana is a very favorable environment for the development of any, including unfavorable, microflora that affects the quality of the final product. The number of pathogenic bacteria in Artemia crustaceans increases exponentially during their hatching and nutrient enrichment processes. For the same reason, brine shrimp producers are interested in adding probiotic and prebiotic preparations to their product to transfer them to shrimp prelarvae and reduce the possible development of pathogens.

A large number of works in recent years have been devoted to the enrichment of Artemia with probiotic microorganisms for further feeding by crustaceans of other aquaculture objects. Therefore, this area of research is quite relevant. Since enrichment with beneficial non-pathogenic bacteria has a positive effect on cultivated species of various aquaculture objects by improving the intestinal microflora, eliminating pathogens and increasing nutritional value [32]. In addition, a number of recent scientific works aimed at fortifying the brine shrimp themselves to combat Vibrio bacteria as well as to generally increase the impact on the intestinal flora, the immune system and increasing resistance to many other pathogenic bacteria .

It known that the Artemia nauplii massively begin to hatch from cysts after 20 hours of incubation and after 6-8 hours after birth they begin actively feed. Therefore, during 48 hours of incubation, Artemia cysts not only inseminate the surface of the nauplii, but also populate their gastrointestinal tract with probiotic bacilli. The study revealed that with both lots of Artemia cysts the probiotic adding give a good effect. It is expressed as an increase in biomass compared to the control. In addition, a consortium of B. toyonensis B-13249 and B. pumilus B-13250 strains in the course of its vital activity probably favorably change the Artemia environmental conditions. This manifested in an increase of A. franciscana cysts hatching percentage in the trial compared to control. This may be due to the antagonistic properties of the used bacilli to pathogens. In our previous studies, we have found that B. toyonensis B-13249 and B. pumilus B-13250 had a pronounced antimicrobial effect on E. coli, Staphylococcus aureus, S. atyphimurium, Shigella sonnei, Pseudomonas aeruginosa.

In the first experimental group Z29.04 (samples of cysts from Lake Big Yarovoye) a noticeably higher percentage of hatching is observed. It is the norm of this Artemia lot and is not associated

Figure 7: Test images Figure 6: Probiotic concentration and biomass yield correlation

In aquaculture, fish and shrimp are constantly exposed to pathogen pressures, environmental fluctuations and other production stressors, negatively impacting survival and productivity.

At dsm-firmenich, we offer solutions to protect aquatic animals, reducing the risk of health and welfare challenges throughout the production cycle.

with the use or non-use of probiotic. The minimum spread of the Kuchuk lot (C9) indicators observed precisely in the experimental group with the addition of 0.1 g of probiotic. This may indirectly indicate a stabilizing effect of the probiotic on the hatching. Distinction in the hatching percentage in different samples of Artemia cysts (Z29.04 and C9) are due to the fact that they were obtained from divers salt lakes. Hence, they can characterize by various properties, because they evolved in different ecosystems.

Shrimp are demanding on the mobility of the feed during feeding in the early stages of development. In this regard, the technology of feeding shrimp prelarvae with live, newly hatched brine shrimp nauplii is widely used in aquaculture. The A. franciscana incubation solution is a very favorable environment for the any (including unfavorable) microflora development. Therefore, this can affect the quality of the final product. For this reason, the Artemia manufacturers are interested in probiotic and prebiotic adding to their products to reduce the possible pathogens development and transfer it to shrimp prelarvae.

The advantages of the developed Artemia robot counter with an algorithm based on a CNN repeatedly cover various complexities. These include the use of several devices at the same time, reducing the processing time of the received data, the ability to save data for future use, and reducing the time the operator is present.

The main difference between the YOLO algorithm and other neural network algorithms used to detect objects is instant detection of objects in real time. The principle of YOLO operation implies the introduction of a full-size image, which completely passes through the convolutional neural network once. In other algorithms, this process occurs many times.

At the time of the start of work, one of the most productive

neural networks for determining objects was the fourth version of this neural network – YOLOv4 (developed in 2020). Testing several neural networks from the MS COCO test sample (2017) of 127287 images showed the maximum performance of exactly YOLOv4. The YOLOv4 algorithm works 2 times faster than one of the most accurate and perfect EfficientDet. Compared to the older version, YOLOv3, the AP indicator (Average Precision) is improved by 10%, and the performance (FPS) is increased by 12% [36]. This led to its use as a platform for creating the “Artemeter-1” robot for the organisms counting.