FISH FARMING TECHNOLOGY

REMOTE CONTROL:

Feed remotely from anywhere on earth

- Native oysters - Selective breeding and their benefits

- Digital lessons – what our hospitals could teach fish farms

- New generation extrusion system promotes an upgradation in aquatic feed production

- Seaweed and its benefits in shrimp feed

International AquafeedVolume 26Issue 8August 2023 www.aquafeed.co.uk www.fishfarmingtechnology.net

AuguST 2023 Proud supporter of Aquaculture without Frontiers UK CIO

WELCOME

There’s increasing urgency for us in food production industries - and that includes aquaculture and fish farming sectors in particular - to move more quickly towards a sustainable future.

Gilbert Publisher

It’s not that we lack the willpower to embrace a future where energy consumption is continually minimised (especially energy provided by fossil fuels), where equipment recycling is fully implemented in a ‘circular economy’ approach from purchase, through use to disposal and where our raw materials are evaluated not only for their nutritional values and the cost of production, but also for their carbon footprint.

After all, we recognise that at present the cost of feed in our fish farming operations make up on average a staggering 80-plus percent of a farm’s operational costs per rotation.

I draw this to your attention as Dr Brett Glencross's column this month tackles this important subject. He focuses on the responsibility our industry needs to accept when sourcing its protein raw materials and to consider their cost of production in terms of their environmental footprint - and we should not ignore that valuation just because a raw material being sourced is considered a by-product from another industry or industria process.

He points out that we have very little information through certification schemes as to the footprint most raw materials hav e coming forward for aquafeed production. This is an area that needs greater evaluation and documentation so that our entire 53 million tonnes (up 7.25 percent on 2021 according to Alltech's Global Feed Survey published in January 2023) of annual aqua feed production in 2022 can be accurately assessed for its environmental impact.

Without this information it is unlikely we can make meaningful decisions about how to make reductions in our overall carbon foodprint and become one of the most sustainable food producing industries worldwide.

Other sectors, notably the livestock industry, have progressed faster using purpose-built software solutions that pull together information from certified sources to provide farmers with meaningful information to make informed decisions about how to adopt more sustainable practices. This includes the purchase and use of their feedstuffs. I point specifically to the ‘sustainability service’ called Sustell offered by dsm-firmenich as one example from the livestock sector that is currently being modified to meet the needs of fish farmers. We reported on this planned development in June last year. Alltech and ADM are two other companies actively pursuing these goals and there are many other working with their customers in this area of development.

International Aquafeed has a role to play here as well. We want to see the industry’s carbon footprint reduced and we support the drive towards greater sustainability in the way we farm fish.

As I see it, our responsibility is to bring to your attention to the developments that are taking place in a timely manner and to provide

examples of individual and company experiences, encourage the industry to be more proactive and to record the views and suggestions that offer practical and realistic ways forward. It’s a task we all need to engage with in order to meet the expectations of retailers and consumers who are already formulating policies with regard to the environmental costs of their future food supply chains.

So be sure to take time to read Dr Glencross’s column this month. Give it some thought and consider the implications he outlines for your operation. Please let me have your response;what are your experiences, what are the challenges you face in this critical area of sustainability/carbon footprint management and the likely impact on your production systems?

Technology from another industry

With future industry developments in mind, I’m pleased to point out that we have a feature by Aidan Connolly, the president of AgriTech Capital of the USA. While his is an investment company, Aidan brings his insights to the direction of food productionincluding aquaculture - with regard to the Internet of Things (IOT) and the adoption of technologies from other sectors outside the food industry. In this article he looks at advances in health care services that might offer solutions to issues being faced in the aquaculture sector. His feature starts on page 16.

Other features in this issue look at the restoration of the oyster in the UK (page 14) and a new generation of extrusion systems for aquatic feed production by Famsun.

Claudia Figueiredo Silva of Zinpro in the USA and Dr Abdel-Fattah El-Sayed of Egypt have come together to report on benefits from boosting tilapia performance with organic trace minerals (page 26). That is followed by our own managing editor Jyothsna Nelloolichalil reporting on seaweeds and the benefits they provide when used in shrimp feeds (page 30).

Don’t overlook this month’s Fish Farming Technology Section where we report on one Scottish company’s method of controlling its feed distribution via remote controlled digital systems (page 36), nor our Technology Showcase (page 40-41) before our Case Study on Sablefish aquaculture (page 42).

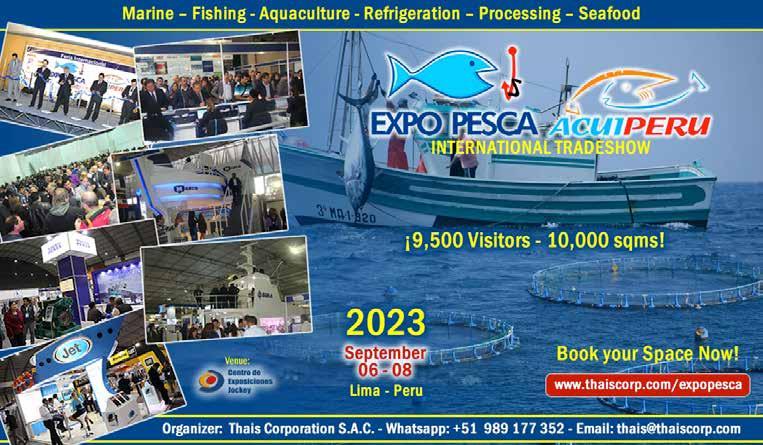

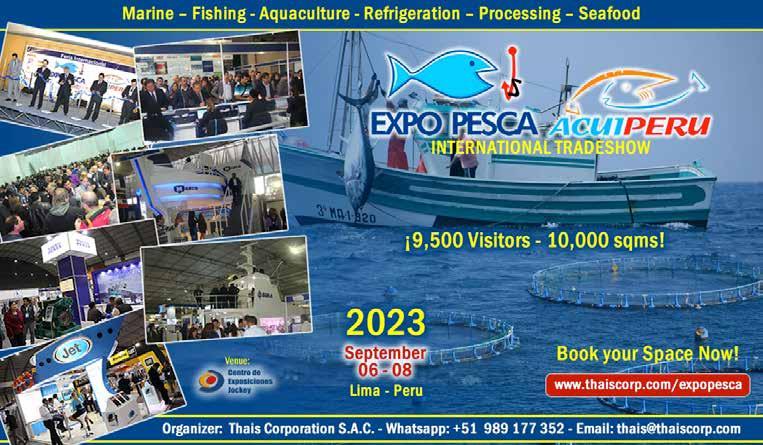

Finally, we move into our Events Section which this month features the VIV Türkiye 2023 and the emphasis placed on aquaculture.

Our team was in attendance to represent for all three of our monthly magazines and to show that aquaculture is part of the wider animal protein production chain.

We report on the Seaagricuture EU23 event with its focus on seaweed and in addition we pre-announce the AquaNor 2023 event being held in Trondheim, Norway in the third week of this month.

This edition will be in the hands of our readers at this important European bi-annual event for the salmon and other industries both in English and in Norwegian! Make sure you ask us for a copy if you are planning to attend this year. Happy reading.

www.aquafeed.co.uk

Roger

– International Aquafeed and Fish Farming Technology

Recently I asked a young student if he knew what the meaning of ‘Emeritus Professor’ was, and he confidently replied, ‘oh it is a professor who had a distinguished record but has now passed away and been honoured’. It was indeed very humorous, and I told him I was very much alive and well, and keen to grade his assignment. I have also been called the Emirates Professor which is lovely and encourages me to fly higher in my career. Far from absolute retirement, I am tasked with many projects and this summer has been quite frantic.

I am presently working very closely with the University of Veterinary and Animal Sciences at Lahore, Pakistan, and the Punjab with respect to several fish nutrition projects on tilapia, snakehead and rohu carp. This is in collaboration with my close friend and colleague Dr Noor Khan and I cosupervise some of his PhD students. As such, I follow Pakistan in the news and observe its current political scene and fiscal status and relationship to the Indian subcontinent. Pakistan has recently reached a preliminary deal with the International Monetary Fund (IMF) worth about US$3 billion that could help stabilise its precarious economy and lift the nation out of a crisis that has pushed millions to the brink. The staff-level agreement is subject to validation by the IMF’s executive council, which is expected to have fully considered the request by mid-July 2023. The agreement, which had been delayed for months, provides the country of about 220 million much needed access to US dollar funding, enabling additional financing from creditors and mitigate the risk of default, after growth stalled and inflation rose sharply over 2022/23. “The new Stand-by Arrangement (SBA) will help to stabilise a policy anchor and a platform for financial support from multilateral and bilateral partners in the period ahead,” the IMF has stated. It comes after Pakistan experienced devasting floods last year, further compounding the economic misery of millions, driving families into poverty, and leaving many unable to afford essentials such as food, fuel, and medicines. The country was also hit by an international commodity price spike in the wake of Russia’s war in Ukraine. Climate change is also making a significant impact and its aquaculture industry was seriously impacted. However, Aquaculture in Pakistan has been growing steadily and has a significant economic value. Pakistan has a long coastline along the Arabian Sea, providing favourable conditions for aquaculture activities. Additionally, the country has numerous rivers and lakes suitable for freshwater aquaculture. In terms of scale, Pakistan has seen a gradual increase in aquaculture production over the years. According to the Food and Agriculture Organization (FAO) of the United Nations, Pakistan's aquaculture production was estimated to be around 404,000 metric tonnes in 2018. However, it's important to note that specific data for subsequent years might not be available and subject to inaccuracy, especially now in the light of the very adverse weather. The economic value of aquaculture in Pakistan has been considerable, both in terms of domestic consumption and export potential. Pakistan is presently exporting fish worth US$ 350 to 400 million per year. Aquaculture contributes to Pakistan's economy by generating income, providing employment opportunities, and contributing to the Gross Domestic Product (GDP). The exact contribution varies annually but has been estimated to be around one percent of the country's GDP.

Fish is an essential source of protein for the population, and the demand for fish and seafood products has been rising due to increasing population and changing dietary patterns. The aquaculture industry will be playing a significant role in meeting this demand. Pakistan has been exporting

fish and seafood products to various international markets, including the Middle East, Europe, and North America. Shrimp, prawns, and various fish species such as tilapia, catfish, and trout are among the key aquaculture products exported. Furthermore, aquaculture provides employment opportunities and income generation for many individuals, particularly in rural areas where fish farming is prevalent. It contributes to poverty reduction and promotes rural development in the country offering stability and less dependency on city employment and crowding issues.

Speaking of a country on the spice trail route from China, I am intrigued by the increasing interest in different spices being added to pet diets, animal feed for production (poultry, swine and ruminants) and of course for fish in aquafeeds. Herbal supplements and spices can be used in fish and shrimp diets for various purposes, including improving feed efficiency, enhancing growth performance, boosting immunity, and reducing the incidence of diseases. While there are many herbs and spices being researched globally. I myself published a comprehensive review of such spices and herbs used in aquaculture with a colleague in Iran led by Seyed Hossein Hoseinifar in the prestigious scientific journal ‘Reviews in Fisheries Science & Aquaculture’ back in 2020. Here I list some examples of commonly studied ones for application in aquafeeds.

Garlic (Allium sativum): Garlic is known for its antimicrobial properties and potential to enhance immune responses in aquatic animals. It has been researched as a feed additive for fish and shrimp to improve growth, feed utilization, and disease resistance. Turmeric (Curcuma longa): Turmeric contains curcumin, a compound with antioxidant, anti-inflammatory, and antimicrobial properties. Studies have shown that including turmeric in fish and shrimp diets can improve growth performance, immune function, and disease resistance. Ginger (Zingiber officinale): Ginger has been investigated for its potential benefits in fish and shrimp nutrition. It possesses antimicrobial and antioxidant properties and may contribute to improved feed utilisation, growth, and immune responses. Oregano (Origanum vulgare); Oregano is rich in essential oils with antimicrobial properties. It has been studied for its potential as a natural growth promoter and immune stimulant in fish and shrimp diets. Cinnamon (Cinnamomum verum); Cinnamon contains several bioactive compounds that exhibit antimicrobial and antioxidant activities. Research has shown that incorporating cinnamon in fish and shrimp feeds can enhance growth performance, disease resistance, and digestive enzyme activities. Neem (Azadirachta indica); Neem has been investigated for its potential use as a natural immunostimulant and growth promoter in aquaculture. It contains various bioactive compounds that possess antimicrobial and antiparasitic properties. Green tea (Camellia sinensis); Green tea and its extracts contain polyphenols and catechins, which have quite strong antioxidant and antimicrobial properties. Studies have indicated that green tea can enhance growth performance, feed utilisation, and disease resistance in fish and shrimp.

It's worth noting that the efficacy and optimal dosage of these herbal supplements and spices can vary depending on the species, life stage, and specific conditions of the fish or shrimp being studied. Therefore, it is important to conduct species-specific research to determine the most effective and safe application of these additives in aquaculture.

So next time you add these spices to our favourite sauces, casseroles, and curries we may consider all their extra benefits to farmed aquatic species to ‘spice up’ their production life. Chinese and Indian herbs and spices are more than just folklore when it comes to health and welfare.

4 | August 2023 - International Aquafeed

Professor Simon Davies Nutrition Editor, International Aquafeed

I was tidying up my bookshelves the other day, and I came across an old book I had not seen for a long time: the proceedings of The First International Conference on Fish Farming Technology, which was held in Trondheim, Norway, 9 – 12 August 1993, just before Aqua Nor 1993 (13 – 17 August 1993). In other words, exactly 30 years ago.

The discovery of the book made me curious. What was the state of fish farming technology 30 years ago? We hear that massive progress has been made over the past decades, and that may be so. But the book contained an impressive collection of papers that showed that even 30 years ago, technology was far advanced.

In the Preface, the editors said: “As fish farming moves into its “industrial phase”, technology will be an important factor in determining its successful development.” And history has shown just how true this statement was.

A total of 81 papers were presented, on some very complex issues of a scientific nature. This is what brought modern fish farming forward.

Aquaculture technology has come a long way, and still has a very long way to go. Scientists from all over the world are turning their attention to ever new issues and approaches. The industry itself is becoming more and more complex and science oriented. Some of the new technologies that are making their way into aquaculture include automation, robotics, cage construction, machine learning and artificial intelligence.

Automation is said to be one of the things that will change our working life the most in the coming years. The industry has major challenges, particularly related to salmon lice and environmentally harmful emissions. New technology will hopefully contribute to reducing these problems in the future. New technology is used in the fight against salmon lice. One example is the “stingray” technology, where a robot quickly registers whether the salmon has lice. If there are lice, the robot fires laser shots that kill them, without harming the fish - and everything therefore happens completely automatically. It both looks and sounds undeniably like science fiction, but the technology is actually already on the market.

Machine learning ensures that the programme used becomes

more and more intelligent over time. The area of use can also be extended to lice counting and biomass measurement, where the latter means how many tonnes of farmed fish are in the cage.

The development of cages will continue, and new technologies will be applied. Some cages are being located further out to sea, where the lice problems are smaller and the currents will thin out and transport waste materials further away. There is also a lot of research being done on the development of closed and semi-closed facilities at the moment, which could have a major impact on problems with salmon lice, escapes and emissions from production. However, much remains to be done before these concepts become so profitable that they can seriously replace today's open cages. While progress was fast, - sometimes explosive -, in the early days, it is now much slower. Much more incremental. Tiny steps are made towards an ever more sophisticated technology that produces tiny improvements in performance. But these tiny steps are necessary. In spite of the enormous efforts that go into making such tiny steps, it is all necessary. So much is known about aquaculture technology today, that every step forward requires more research, more inventiveness on the part of the scientists. The search for improvements will never stop, and we should be thankful that it will not, for the world needs these improvements. They contribute to solving the problem of how to feed a growing population. It is commonly agreed that the ocean and aquaculture is a large part of the solution. So the scientists who study these tiny problems to make tiny advances deserve our support and accolade.

It is not always easy to say which solutions will be winners in the future, but with a wealth of new technological developments, we can at least be quite confident that fish farming is facing an exciting and high-tech future. Tomorrow's fish farming will probably look significantly different from today’s.

With these words, I wish you all welcome to Aqua Nor 2023, where some of the new technology will be on display! Even if you are not going to Trondheim for the physical event, you can be present through the net. Just check www.aqua-nor.no. And the good thing about the online version of the conference is that it will remain accessible online until the end of April 2024.

aquafeed.co.uk

FISH FARMING TECHNOLOGY

Erik Hempel

The Nor-Fishing Foundation

Perendale Publishers Ltd

7 St George’s Terrace

St James’ Square, Cheltenham, Glos, GL50 3PT, United Kingdom Tel: +44 1242 267700

Publisher Roger Gilbert rogerg@perendale.co.uk

Managing Editor

Joy (Jyothsna) Nelloolichalil joyn@perendale.co.uk

International Editors

Dr Kangsen Mai (Chinese edition) mai@perendale.com

Prof Antonio Garza (Spanish edition) antoniog@perendale.com

Erik Hempel (Norwegian edition) erikh@perendale.com

Editorial Advisory Panel

- Dr Abdel- Fattah M. El- Sayed - Dr Alessio Bonaldo

- Dr Allen Wu

- Prof Charles Bai

- Dr Daniel Merrifield

- Dr Domique Bureau

- Dr Elisabete Matos - Dr Eric De-Muylder

- Dr Noor Khan

- Dr Pedro Encarnacao

Editorial team

Prof Simon Davies sjdaquafeed@gmail.com

Shannon Parsons shannonp@perendale.co.uk

Niamh Cassidy niamhc@perendale.co.uk

International Marketing Team

Darren Parris Tel: +44 7854 436407 darrenp@perendale.co.uk

Latin America Marketing Team

Clarissa Garza de Yta Tel: +52 669 120 0140 clarissag@perendale.com

Cristina María Roldán Otero Tel: +44 1242 267700 cristinaperendale@gmail.com

Egyptian Marketing Team

Mohamed Baromh

Tel: +20 100 358 3839 mohamedb@perendale.com

India Marketing Team

Dr T.D. Babu +91 9884114721 tdbabu@aquafeed.org

Asia Marketing Team

Dante Feng Tel: +886 0227930286 dantef@perendale.com

Nigeria Marketing Team

Nathan Nwosu Tel: +234 8132 478092 nathann@perendale.com

Digital community manager

David Harvey davidh@perendale.co.uk

Design Manager

James Taylor jamest@perendale.co.uk

Circulation & Events Manager

Tuti Tan

Tel: +44 1242 267706

tutit@perendale.co.uk

Development Manager

Antoine Tanguy antoinet@perendale.co.uk

Aquafeed Journal journal@perendale.co.uk

FISH FARMING TECHNOLOGY

IN THIS ISSUE

COLUMNS ©Copyright 2020 Perendale Publishers Ltd. All rights reserved. No part of this publication may be reproduced in any form or by any means without prior permission of the copyright owner. More information can be found at www.perendale.com ISSN 1464-0058 REGULAR ITEMS 8 Industry News The Aquaculture case study

4

5

Hempel 66 Industry Faces 64 The Aquafeed Interview 60 The Market Place 11 Dominique P Bureau 12 Brett Glencross August 2023 Volume 26 Issue 8 44 Industry Events 40 Technology showcase 42 Sablefish Aquaculture: Aquaculture projects in the Pacific Northwest

3 Roger Gilbert

Professor Simon Davies

Erik

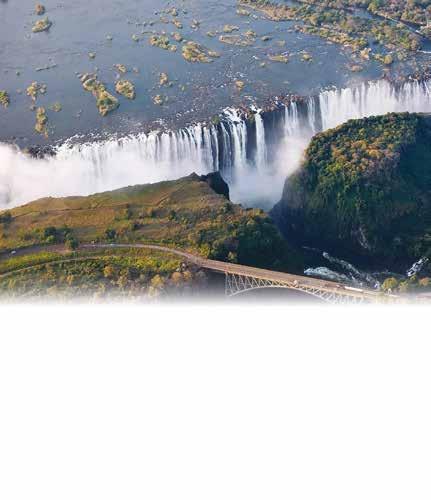

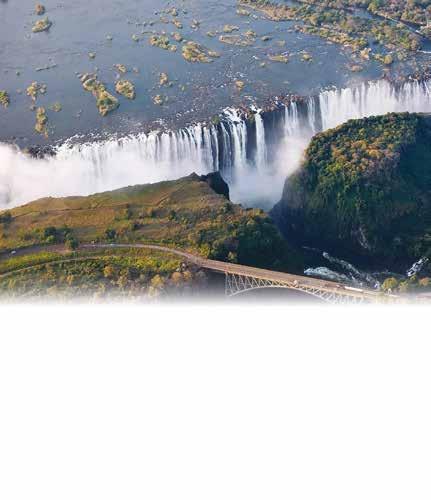

THE BIG PICTURE

Seaweed and its benefits in shrimp feed

See more on page 30

FEATURES

14 Native oysters - Selective breeding and their benefits

16 Digital lessons – what our hospitals could teach fish farms

20 New generation extrusion system promotes an upgradation in aquatic feed production

26 Small adjustments for great benefitsBoosting tilapia potential with organic trace mineral nutrition

30 Seaweed and its benefits in shrimp feed

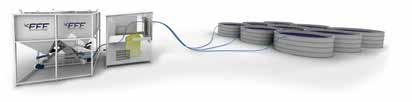

FISH FARMING TECHNOLOGY

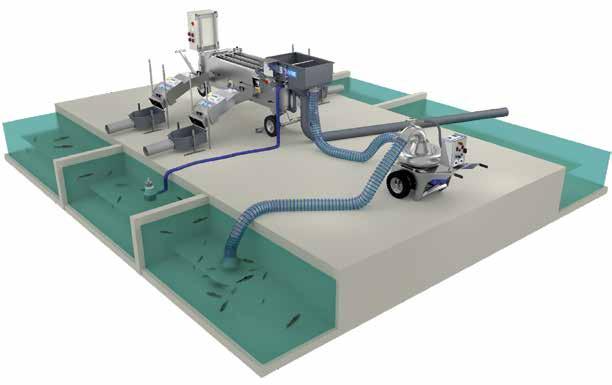

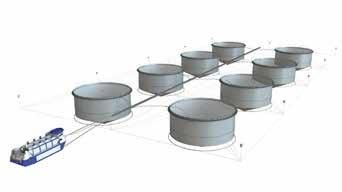

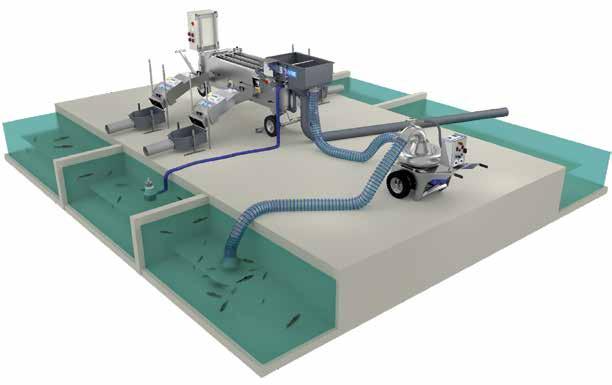

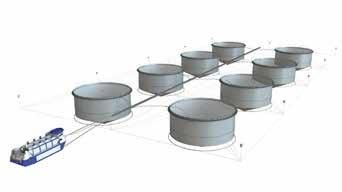

36 Remote control: Feed remotely from anywhere on earth

Gael Force Group moves ahead with SeaQureFarm™

Gael Force Group has taken a substantial step forward in its plans to deliver its integrated SeaQureFarm™ by announcing an exclusive partnership for the prototyping and production of their ground-breaking semi-closed containment solution for the aquaculture sector, SeaQureWell™, in 2024.

SeaQureFarm™ has the potential to unlock global ambition for a greener, carbon-friendly, and more efficient way of producing healthy nutritious food protein through improving the sustainability of farming of the seas. It is designed to deliver improved fish health, reduced predation, prevent seabed depositions and reduce egg-to-plate emissions while enabling on-farm circular economies and turning a waste problem into an energy solution.

As an integral part of SeaQureFarm™, the SeaQureWell™ is an arrangement where seawater is pumped and pushed into a floating enclosed “well” with its floating collar at the sea surface. The collar supports the Well and its pumping arrangements which lifts deeper coastal water into the well creating an in-well temperature profile that is warmer in the winter and cooler in the summer.

The SeaQureWell™ will be constructed of engineered high-quality composite membrane material, cut, and welded to form the ‘Well, with structural floatation at the surface and a rigid sub-surface service and support structure. It aims to provide and maintain a secure controlled environment to safeguard healthy growing fish against external environmental threats to the fish from sea lice, gill amoeba, jellyfish and algae bloom as well as protect against sea mammal predation. Additionally, faecal depositions along with any uneaten food will also be captured in the ‘Well’ for on-site recovery and reduction for reuse.

The Scottish technology and equipment manufacturer

has been researching and developing its unique integrated SeaQureFarm™ concept for several years. Last year it commissioned aquaculture expert, Knut Senstad, to deliver a highly detailed business case for the concept, revealing key economic, health, and environmental savings in a range of farming scenarios.

Partnering with Gael Force on the production of the prototype is Northern Ireland based Cunningham Covers, known for their expertise and large factory capacity in the manufacturing of clever protective covers and containment products from high-tech, high-strength flexible materials. Their experience in creating durable and customised solutions spans more than 50 years, and today they produce and supply a range of specialised cover products for aerospace, offshore, and aquaculture applications, including fresh-water treatment bags, fresh-water storage bags, lice skirts, and other custom tarpaulin textile products.

For this partnership, Gael Force and Cunningham Covers have also entered a supply partner agreement with Serge Ferrari, a global leader in flexible composite materials. They will provide cutting-edge fabric technology to enhance the performance and durability of the SeaQureWell™ system. The use of innovative materials will contribute to the system’s robustness, flexibility, and resistance to environmental factors.

Gael Force Group Managing Director, Stewart Graham, comments, “By announcing this next major step forward in the development of SeaQureFarm™ we continue to demonstrate our commitment to the continual improvement of a greener, carbon-friendly way to sustainably produce a healthy, nutritious food protein. We share the sector’s ambition of minimising environmental footprint and moving closer to a goal of achieving net zero. In partnership with Cunningham Covers, supported by Serge Ferrari as our specialised material supply partner, I am extremely confident that our collective experience and expertise will enable us to move the dial considerably towards that target.”

Cunningham Covers Managing Director, David Cunningham, comments, “We are delighted to be a long-term partner with Gael Force in this project. Our two companies share core values and ethos, as well as a long-term ambition to grow our presence together in the semi-closed containment fish farming sector, combining the considerable and complementary strengths of both companies.”

Gael Force is aiming to produce a working prototype of SeaQureWell™ in 2024. They have stated that it is immediately open to partnering with finfish producers in Scotland to trial a project next year and is welcoming approaches from customers.

Going mobile

8 | August 2023 - International Aquafeed News

ADB invests in ocean-based aquaculture in Vietnam

ADB’s investment will fund the working capital to expand Austalis’ operations at Van Phong Bay in central Vietnam and support the development of a second regional production hub in southern Vietnam.

The Asian Development Bank (ADB) and Australis Holdings, Inc. (Australis) signed a US$15 million convertible note to promote climate-resilient, ocean-based barramundi and seaweed aquaculture in Vietnam. The investment will fund working capital to expand Australis’ operations at Van Phong Bay in central Vietnam and support the development of a second regional production hub in southern Vietnam. An additional US$3 million grant will be provided by the Climate Innovation and Development Fund (CIDF), administered by ADB.

“Three billion people across the world depend on seafood for protein, even as global fish stocks fall due to overfishing and temperature rise,” said ADB Director General for Private Sector Operations Suzanne Gaboury. “ADB’s assistance will support the government’s efforts to develop sustainable aquaculture, particularly large-scale farming of high value species for export. Aquaculture can support low-carbon protein production, while tropical ocean farming is more resilient to climate risks. This is our first aquaculture equity investment in Vietnam, and we are proud to partner with Australis.”

Australis is the world’s largest barramundi producer. Also known as Asian sea bass, the species is adaptable and resilient, well suited to aquaculture, with high export value. Australis pioneered the development of modern, large-scale marine aquaculture in Vietnam.

“ADB’s financing will support the continued growth of our operations in central Vietnam as well as the development of a large new regional production hub where we’ve established a group of leases that will allow us to achieve 50,000 tonnes of annual barramundi production,” says Australis Chief Executive Officer Josh Goldman.

The CIDF grant to Australis’ subsidiary Greener Grazing LLC, will support research and development into the cultivation of asparagopsis taxiformis seaweed for commercial ocean farming. This species of seaweed has been demonstrated to significantly reduce enteric methane emissions when included in cattle feed. Seaweed farms can mitigate ocean acidification and enhance climate resilience of marine ecosystems and have carbon sequestration potential.

Launched in September 2021, CIDF is a blended finance facility managed by ADB, established with an initial US$25 million philanthropic commitment from Bloomberg Philanthropies and Goldman Sachs. The fund has the potential to unlock up to $500 million in private sector and governmental investments in support of sustainable lowcarbon economic development.

Established in 2006, Australis is vertically integrated with operations encompassing breeding, hatcheries, ocean farms, processing, packaging, and export. Australis’ consumer-facing brand The Better Fish® focuses on quality, sustainability, and ease of use.

ADB is committed to achieving a prosperous, inclusive, resilient, and sustainable Asia and the pacific, while sustaining its efforts to eradicate extreme poverty. Established in 1966, it is owned by 68 members – 49 from the region.

Phileo’s probiotics and active yeast fractions are designed for hatcheries and growing farms to support health, feed efficiency and growth performance . Our sustainable solutions bring innovative responses to fishmeal reduction stakes and environmental challenges. Act with nature for animal care. Join the fish revolution Visit our new website www.phileo-lesaffre.com International Aquafeed - August 2023 | 9 News

New bipartisan bill to support aquaculture farmers and harvesters

US Senator Roger Wicker, R-Miss., joined Senator Whitehouse, D-R.I., and Senator Angus King, I-Maine, in introducing bipartisan, bicameral legislation to uplift and support aquaculture and aquaculture farmers and harvesters. The Sustaining Healthy Ecosystems, Livelihoods, and Local Seafood (SHELLS) Act will create a program office for aquaculture within the US Department of Agriculture (USDA) to bolster shellfish harvesters and seaweed farmers, protect food security, and promote blue carbon ecosystems.

“Seafood is an important component of America’s food supply chain and a major economic driver in communities like Mississippi’s Gulf Coast,” Wicker said. “This legislation would give aquaculture farmers a more direct line to access USDA resources and programs so that they can better meet demand in this growing industry.”

“Shellfish farming is a pillar of the Ocean State’s economy and culture,” said Whitehouse, co-founder of the Senate Oceans Caucus. “Our SHELLS Act will expand federal programs that provide Rhode Island aquaculture farmers the tools and resources to sustainably grow the industry, create new jobs, and continue farming the best oysters in America.”

“For generations, Maine’s ocean economy has supported communities along our coast – aquaculture presents an exciting new opportunity to expand on this long tradition and create more good-paying jobs in the 21st century,” King said. “From shellfish to seaweed, the bipartisan SHELLS Act would give aquaculture entrepreneurs and professionals a designated point person in the federal government who understands their needs and can best respond to them. This is a common sense way to invest in Maine’s aquaculture farmers and harvesters, produce more world-class seafood products, and build on our state’s legacy of sustainable maritime innovation. I am grateful for my colleagues’ bipartisan support on this important effort to grow Mine’s invaluable ocean economy.”

The SHELLS Act also establishes an aquaculture Advisory Committee to oversee program activities, support the development of best practices, provide technical assistance, and acknowledge the history, use, and preservation of indigenous and traditional aquaculture practices and ecological knowledge.

Companion legislation was introduced in the House of Representatives by US Representatives Suzanne Bonamici, D-Ore., Ed Case, D-Hawaii, Rob Wittman, R-Va., Frank Pallone, D-N.J., and Chellie Pingree, D-Maine.

ai1659709269130_IRIDA_PRINT_AD_05-08-22_OUT_102.5x280_ENG.pdf 1 05/08/2022 5:21 pm

News 10 | August 2023 - International Aquafeed

IFFO releases Marine ingredients market trends report

Ataste of the many statistics and analyses that can be found in the Market of intelligence reports that IFFO dedicates to its members is reported below, covering IFFO’s analysis on marine ingredient market trends until May 2023.

Peru’s reduced FMFO production drives global output down

For the regions for which IFFO regularly tracks production of marine ingredients, roughly worth 50 percent of the global output, IFFO reports cumulative total fishmeal production during the first five months of 2023 down by more than 10 percent compared to the cumulative production reported through May 2022. The primary factor driving such decline is the production drop of approximately 50 percent reported in Peru, where the first fishing season has not been authorised yet. At the time of issuing this report there is still no clarity on whether the first fishing season in the North-Centre might be authorised.

As for fish oil, total cumulative output in the first 5 months of 2023 was 22 down YoY. The only countries that registered a positive change YoY were Chile and the USA.

Domestic FMFO production remains poor in China

This year farmers are facing additional risks of economic losses due to escalating costs of aqua feed and stagnating farm-gate prices. Should this trend continue, farmers could be soon exposed to even greater financial risks, similarly, the pig sector continues to face challenges due to weak demand during hot summertime. Pig prices have been on a decline since last October, which has resulted in a continuous although insufficient reduction of the sow stock. The pig sector remains in fact affected by overcapacity and unprofitable farm-gate prices.

Following the implementation of the fishing ban on May 1st on all fishing grounds, to allow the biomass to reproduce, domestic fishmeal and fish oil production remains poor and dependent on little frozen fish caught in the last season and by-products from fish and shrimp processing plants. This situation is expected to persist until the fishing ban is lifted in September. Considering the lower-than-average domestic production both in the second part of the year 2022 and in the first half of 2023, China has continued to increase its fishmeal imports.

Smart Feed Management for Sustainable Shrimp Aquaculture

Dominique P Bureau

High priced inputs (i.e., feeds) and decreasing final product prices are creating a perfect storm situation for many shrimp culture operations. These enterprises need to focus on reducing production costs and improving their profitability yet, while there has been considerable focus in terms of research and development on improving the cost-effectiveness of feeds, how efficiently these high value inputs are used at the farm level has been the subject of relatively few efforts.

Rearing animals in an aquatic environment greatly complicates monitoring of growth, standing biomass and feed consumption. A great deal of attention must be paid to the feeding since feed delivered, but not consumed, cannot be recovered or even appropriately quantified. The feeding of crustaceans is even more complicated due to their mode of feeding and feeding behaviour.

Analysis of data from commercial production lots in different regions indicates feeding management is seriously deficient on many shrimp culture operations. Farm employees appear to rely on poor (biased) and relatively archaic approaches to estimate inventory, standing biomass, and appetite of the animals and determine daily feed allocation. The amount of feed distributed appears to frequently be in excess of what the animals truly require. Overfeeding leads to feed wastage, a pure economic loss, and greater waste outputs, which can have dire consequence on water quality and the development of water-borne pathogens and survival of the animals. Conversely, delivering less feed than what is required by the animals to express their growth potential can also be considered an economic loss (opportunity cost) and may greatly affect profitability of the enterprise.

Technological solutions, from smart feeding systems to biomass estimators to production and feeding management software, have been developed and are being implemented on shrimp culture operations. These technological solutions may usher a new era of smart feeding management for shrimp culture operations. Examples of effective use of technology to improve feeding management will be presented.

Dominique P Bureau, Professor, Dept. of Animal Biosciences, University of Guelph & Chief Scientific Officer, Wittaya Aqua International

News International Aquafeed - August 2023 | 11

Brett Glencross

Responsible ingredients depend on sourcing of responsible primary raw materials

While everyone is touting the importance of responsible feeds, it needs to be noted that this depends for the most part on the capacity for the sourcing of responsible ingredients. This of course depends on the sourcing of responsible primary raw materials. But like many of these quasi environmental and social issues, the devilis-in-the-detail. Afterall, what do we actually mean by “responsible sourcing”? There are various definitions, but responsible sourcing is also referred to as supply chain responsibility and is generally considered a commitment by companies within a defined supplychain to consider social and environmental considerations in addition to economic ones when managing their relationships with suppliers.

In terms of the environmental side of things, issues around land conversion in crop production supply chains, have been one issue at point due to their effects on threatening biodiversity and valuable carbon stores in critical ecosystems (e.g., rainforests in Brazil). Similarly, the sourcing of fish from illegal, unreported, and unregulated (IUU) fishing is another. To address such environmental threats, and in the process reward those who are trying to do the right thing, many such commodity markets have resorted to the development of certification systems, usually initiated by the industries themselves, but often involving broad range of stakeholders to ensure that not only the industry’s agenda is addressed (e.g., MarinTrust and RTRS Certified Soybean). Such systems have been instrumental in driving the progression of improved practices across different industries in addressing their environmental responsibilities.

But what of the social equity? Much has been made of issues around modern slavery, and various freedoms we often take for granted in developed nations but are often lacking in other parts of

the world. While we hear of slavery associated with some of the high seas fishing fleets, we hear less about forced labour, bonded servitude, and loss of human rights in other sectors, although we know that these issues exist (amnesty.org). Irrespective, by applying a greater degree of scrutiny on the providence of ingredients, their origins and obtaining independent validation of claims of social as well as environmental standards, seems to be the best way forward here too.

So, based on these examples of setting both environmental and social standards, where do various feed commodities sit in terms of independent certification standards being applied? Presently just under 50 percent of all global fishmeal production (~3 million tonnes) is certified with MarinTrust certification and in many cases also holds Marine Stewardship Council (MSC) certification. About 6 million tonnes soybean production is certified by the Roundtable on Responsible Soybean (RTRS), which although constitutes a huge volume, is only about 1.5 percent of production (391 million tonnes in 2022/23), and despite that low percentage, it is still one of the better certified of all agricultural commodities. However, beyond these two ingredients, there are few other protein sources that have any similar such certification applied to their sourcing. While arguments have been made for the lack of need for such responsible sourcing criteria for many other ingredients, especially those that are by-products of other sectors, the reality is that all ingredients have an environmental footprint, either directly or indirectly as part of their sourcing. Responsibility also implies traceability, which is a cornerstone of food safety policies. The Global Dialogue on Seafood Traceability (GDST) is working to create the first-ever global industry standards for seafood traceability and standards such as MarinTrust will align with GDST’s data requirements. A lack of responsibility in production of one resource, does not necessarily mean that a by-product is free from such responsibility. As we can clearly see, sourcing responsible ingredients depends on sourcing of responsible primary raw materials.

BOURNE AES R C H & RECRUITMENT SELE C T I NO � CHIEF COMMERCIAL OFFICER � GENERAL MANAGERS � MANAGING DIRECTORS � CHIEF MILLERS � FEED & POULTRY MANAGERS � MAINTENANCE MANAGERS � R&D NEWPRODUCT DEVELOPMENT � SALES & MARKETING � PLANT MANAGERS � CFO’S ���� bournerecruitment.co.uk ���� +44 7764 465 897 THE EXPERT IN FEED, FLOUR MILLING AND FOOD PRODUCTION RECRUITMENT POSITIONS RECRUITED: RECRUITING GLOBALLY 12 | August 2023 - International Aquafeed News

OSF Ballan Wrasse trial proves success

An independent trial conducted at Otter Ferry Selfish in Scotland, showed the inclusion of Oregon-Stim Forte, a natural and sustainable feed addictive, to the commercial diets of juvenile ballan wrasse resulted in improved growth performance, survivability, lower feed conversion and higher specific growth rates.

Oregon-Stim Forte is a high-quality functional feed ingredient, manufactured by Anpario and specifically developed for aquaculture, containing 100 percent natural oregano essential oils and quillaja saponins.

Lawrence Brown, Senior Technical & Account Manager

Morrisons to transfer over UK£100,000 Apprenticeship Levy fund to the fishing sector

Morrisons is transferring an Apprenticeship Levy fund of over £100,000 to Supplytrain to help train ten new sea fishers for the South Western Fish Producer Organisation (SWFPO).

The money will support the first fisher apprenticeship programme in England. The 18 month apprenticeship allows students to get a hands-on experience and learn about the whole fishing operation from sea to sale.

As an apprentice, students will be employed by Supplytrain, but get to work across different boats within the SWFPO membership, catching different fish and learning from experienced crew while also studying seamanship, gear construction and how to care for the catch at South Devon College.

The life of a commercial fisher is physically demanding but immensely rewarding providing the skills and opportunities to become an experienced deckhand, a skipper, a marine engineer or even a future vessel owner.

at Anpario commented, “Ballan wrasse are increasingly utilised in salmon farming for sustainable sea lice management. By improving the performance and survivability of ballan wrasse using Orego-Stim Forte we’re able to drive productivity, fish welfare and ultimately reduce the overall environmental footprint. We’re excited to be working with cleaner fish producers and Aquafeed manufacturers to harness the benefits of our functional feed ingredients.”

This research was part-funded by UK Agritech Centre CIEL as a successful recipient of aquaculture project seed funding.

The Government Apprenticeship Levy is paid by employers to help fund apprenticeship programmes and Morrisons has agreed to transfer £100,000 of its funds to pay for the SWFPO’s first cohort of ten apprentices. The deadline for applications is the 31st July and the first cohort will start their programme this September.

Morrisons has supported craft apprenticeships in its stores including Fishmongers, Butchers and Bakery roles. Over 2,500 colleagues in-store have completed the programme to date with a further 200 apprentices planned to enrol in September.

Morrisons Sustainable Sourcing and Fisheries Manager, Sophie Jenkinson said:

“The fishing industry is an important and integral part of Morrisons and that is why we’re pleased to be supporting Supplytrain and SWFPO by transferring some of our Apprenticeship Levy to help recruit and train the sector.”

“Recruitment is a real issue across the entire fishing industry right now, with an ageing demographic and shortage of skilled crew.” Said Juliette Hatchman, CEO at SWFPO, “A lack of skilled crew has a significant impact on the entire seafood supply chain. The

catching sector is the start of the supply chain, so without boats going to sea, there is no supply chain. SWFPO members are not alone in facing challenges with attracting the right personnel. This apprenticeship is a great way to grow new talent within our industry by developing a motivated, skilled and qualified resource that the whole industry will ultimately benefit from. Not only does it improve the attractiveness of the sector as a professional and valuable career pathway, but improves safety within the sector –all of which make it a much needed and worthwhile investment.”

Phil Golding, Managing Director at Supplytrain said: “It’s fantastic to have Morrisons as a partner supporting the first ever Fisher Apprenticeship in the country. As a flexi-job apprenticeship agency, we’re excited to be able to employ and support fresh talent to start a career in this rewarding industry, and hope this is the first of many cohorts in the years ahead.”

In 2021 Morrisons acquired Falfish, a sustainably sourced seafood wholesaler based in Cornwall. To date, Falfish supply the majority of Morrisons fish and shellfish that is then freshly prepared by Morrisons fishmongers based in-store.

International Aquafeed - August 2023 | 13 News

Native oysters

Selective breeding and their benefits

by Matthew Johnston, Managing Director, The Oyster Restoration Company, UK

Selective breeding programs are a standard part of animal production. They are an important contributor to improving growth rates and product quality while decreasing the cost of production. Oysters are no different.

Selective breeding programs have transformed terrestrial animal production, and now they’re starting to transform the Pacific oyster industry. At The Oyster Restoration Company, our aim is to provide a similar transformation for the native flat oyster for farming, but also to preserve the diversity of its genetics for restorative aquaculture.

Native flat oyster (Ostrea edulis) populations in Europe have been decimated by overfishing and habitat removal and disease. Only 5 percent of natural flat oyster beds remain today.

Selective breeding as a solution

To combat this decline, we can employ selective breeding. Selective breeding for natural disease resistance is an effective and sustainable method to increase survival of a species in all regions, including where a known disease agent is present.

The Oyster Restoration Company has now established a large breeding program consisting of multiple family groups. We select fast-growing lines and other favourable traits for the aquaculture market. We select disease-resistant lines with varied genetics that closely resemble existing populations in the release area for the restoration and environment markets.

“The genetic health of our oyster populations within our hatchery is as important as the physiological health of the oyster themselves” said Dr Matthew Johnston (Managing Director of The Oyster Restoration Company).

Typically, selective breeding programs of oysters are used to improve aquaculture production. However, at The Oyster Restoration Company, we are also utilising this approach to benefit the ecological restoration of native flat oysters.

The Oyster Restoration Company has a vast library of broodstock native flat oysters, comprising over 6,000 pieces from five different populations from Europe and the United Kingdom. This vast broodstock library allows The Oyster Restoration Company and its customers great flexibility in ensuring that the genetics of the stock being restored or farmed in a particular area closely resemble the existing natural or native populations.

Our vast broodstock library is particularly important, as previous research on the east coast of The United States of America showed that selectively bred oysters don’t perform equally well across growing environments; they grow best in their naturalised sites. This finding is influencing how we approach our breeding and restocking programs at The Oyster Restoration Company.

Increasing necessity

Restoring native oyster populations is more important now than ever. The native flat oyster has been one of the most sought seafood products since the Roman times and represented an important ecological and aquaculture species in the European areas throughout the last century.

Oyster reefs play an important role in ecosystem services, providing many benefits such as shoreline stabilisation, water filtration, and food and habitat provision for larval marine species, carbon burial, and nutrient regeneration. The habitats for native flat oyster are, however, endangered in Europe and are now identified as a priority for protection and restoration in European marine protected areas.

14 | August 2023 - International Aquafeed

There are many essential considerations when establishing a breeding program. Perhaps the most important is trait selection. Although farmers require fast growth, other traits are likely to influence profitability, and these need to be balanced in selection decisions. Within selective breeding programs for Pacific oysters, growth time, shell shape, survival, time required to reach market condition, and uniformity are the main traits that drive lower costs of production. This is likely to be similar for the farming market of the native flat oyster.

To reduce unintended artificial selection known as domestication selection, the breeding program is carefully managed by a leading genetics company, Xelect Ltd, based in St Andrew’s, Scotland. By working closely with Xelect, The Oyster Restoration Company can assist conservation efforts by ensuring a range of phenotypic selections are occurring. With the various populations of native flat oysters from the United Kingdom and Europe, we can tailor the genetic lines so they closely resemble the local population where the conservation effort is taking place.

“It is important to note that we are not artificially changing the oyster’s DNA, nor are we manipulating the number of its chromosomes or introducing foreign DNA.” said Dr. Nikolas Sachlikidis (Managing Director of Aquaculture, Cadman Capital Group). The goal is to provide a product that is matched to it surrounding environment and has traits that allow it to survive and thrive in the wild or under farming conditions, Sachlikidis said.

An economic and sustainable option

Through working with Xelect Ltd, we’ve estimated that the breeding program will reduce the cost of production of native flat oysters over the next decade and assist the regeneration of a threatened species in the wild. It will also give existing Pacific

oyster farmers in Europe a native, natural alternative to farming an exotic oyster species.

The Oyster Restoration Company, with the assistance of its commercial genetics company, Xelect Ltd, recently developed a custom panel of 439 single nucleotide polymorphism (SNP) markers for native flat oysters as a tool for the genetic analyses of the future breeding program. This is important because to make the links between phenotype (the oyster’s physical appearance) and genotype (the genetic composition of the oyster), the breeding managers need to understand the oyster’s genetic sequence and to locate the genetic variations, single nucleotide polymorphisms (SNPs), that control the traits of interest.

After optimisation of the 439 working SNP’s, 37 were identified as functional candidates. 36 of these were associated with Bonamia disease resistance and one was for growth. This new tool will be used to assess the genetic health of the population and to build an accurate pedigree, which is required for genetic broodstock management and trait improvement.

Now, we must look to the future of the selective-breeding program. We will investigate new traits that can help native flat oysters survive and thrive in various ecological niches through the coastlines and offshore habitats of Europe and the United Kingdom.

Native flat oysters are essential for the ecological health of our oceans. As filter feeders, they help improve water quality because they filter their food from the water. The continued improvement of native flat oyster stocks with advanced breeding technologies will be necessary for the sustainable development of oyster farming and the re-establishment of a keystone species to allow marine biodiversity to thrive.

www.oysterrestorationcompany.co.uk

Optimal nutrition for exceptional RAS shrimp farming

Aller Aqua RAS Shrimp feeds are a carefully selected range of documented solutions:

High palatability and feed uptake

Fast and uniform growth

Low water pollution

LET’S GROW TOGETHER

WWW.ALLER-AQUA.COM

International Aquafeed - August 2023 | 15

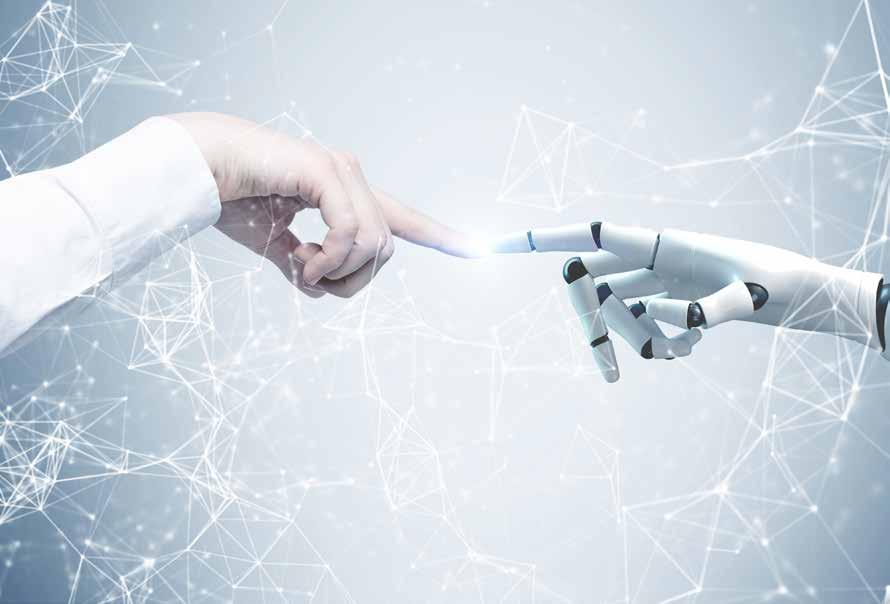

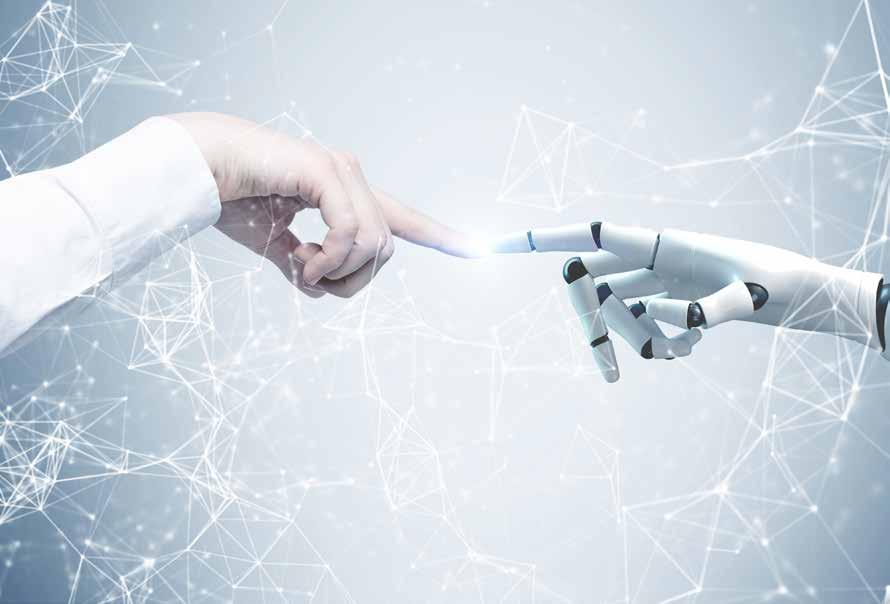

Digital lessons

– what our hospitals could teach fish farms

by Aidan Connolly, President, AgriTech Capital, USA

The healthcare industry has undergone a profound transformation thanks to technology, and now these same cutting-edge developments are making their way to aquaculture. Robots, the Internet of Things (IoT), and artificial intelligence (AI) have become commonplace in hospitals, care facilities, and even private residences. As the aquaculture sector prepares for a similar technological shift, the healthcare industry can serve as a potential blueprint for the future.

The tech-induced evolution in the healthcare industry suggests two trends for aquaculture: the adoption of technology will alter work and leadership but will not decrease the number of individuals employed on aquafarms. The healthcare industry has embraced digital products that use a test-and-adapt approach to ensure client satisfaction, and aquaculture would be well-served to do the same for fish farmers.

Knowing these trends, how can aquaculture industry professionals navigate this future to positively transform the food chain?

Robots

Up to 3,000 blood samples are transported by robots at Aalborg University Hospital from bedside to lab, every day. Without deviating from their path or task, these robots maintain stable temperatures during transport which allows for consistent, accurate sample analysis and improved patient care.

Aquatic robots are being embraced in a similar manner on the farm. Companies like Aquabyte and Deep Trekker are using robots to monitor, feed, and maintain optimal water quality. Robots are offering efficient, precise, and economical solutions to many challenges regarding fishery management and labour shortages. Their uses are expected to expand.

Internet of things (IOT)

IoT technology, smart devices and wearables, like Fitbits and Apple watches, are changing work for hospital bedside staff. Because wearable health devices can provide real-time, relevant data for healthcare providers, it eliminates the need for constant monitoring and frees the bedside staff to attend to other tasks. Likewise, aquaculture is embracing IoT sensors to monitor water conditions for temperature, oxygen levels, pH balance and other factors. Companies like AquaByte use sensors and data platforms to track water quality and fish feeding, all in real-time. E-Fishery, the creator of the eFishery Feeder which revolutionises fish and shrimp farming by automating feeding, is ambitiously marching towards a milestone goal: establishing a digital cooperative with one million fish farmers by 2025. Monitoring and feeding used to be time-consuming tasks with frequent observational errors. Now, IoT sensors can accurately analyse aquafarming outputs in real-time.

Artificial intelligence (AI)

Medical errors cost the healthcare industry $1.9 billion annually and the lives of over 200,000 people. Errors caused by fatigue, memory, lack of experience or training and misapprehensions could be reduced when AI supports decision-making. AI in healthcare, used in diagnostic tools like Nanox AI and Aidoc, has led to better disease detection and patient outcome predictions. AI can likewise reduce human errors within the aquaculture industry through predictive analytics. Startups like Manolin have developed AI platforms to help aquafarmers get real-time insights and data-driven recommendations. In fact, AI computations

Robots are offering efficient, precise, and economical solutions to many challenges regarding fishery management and labour shortages. Their uses are expected to expand.

DRAFT 16 | August 2023 - International Aquafeed

Life, made easier. jefo.com Jefo PEAK Program Production & Performance Improves Feed Conversion Increases Digestibility

Environmental Sustainability Increase you profit in aquaculture with our Jefo Protease. DRAFT

Improves

Hatcheries

Pellet 50-800 µ

Ø Pipe 20 mm

Pre-grow

Pellet 1-4 mm

Ø Pipe 25-40 mm

Pellet 4-20 mm

Ø Pipe 50-90 mm

LAND • SEA • RAS Aquaculture

Feeding Systems

Live feed

Ongrowing

L A N D B A S E D L A N D B A S E D L A N D B A S E D S E A B A S E D Dry feed The only manufacturer worldwide that covers all feeding stages of fin fish and shrimp, for land or sea based systems Aquaculture Europe 2023 - Booths 16-17 18 - 21 Sept 2023 • Vienna (AUSTRIA)

and big data allow aquafarmers to address the complexities of weather, genetics, and market turbulence.

Lessons for the world of aquaculture

While robots, IoT, and AI systems have improved the healthcare sector, they have also resulted in job displacement on a large scale. This development can generate concerns about the future of employment, especially considering that the food system provides employment for a majority of people in developing countries according to the World Bank. This tech-driven transformation could also impact jobs requiring high skill levels. But as we’ve seen in hospitals, we don’t have fewer doctors, nurses or caregivers. Human labour has not been eliminated; the jobs humans fulfil have shifted. A similar transition is expected in the aquaculture industry.

In fact, technology in aquaculture offers solutions to many of the industry's most pressing problems. If professionals in the aquaculture field can learn from the digital transformation experienced by the healthcare industry, the implementation of robotics, sensors, and AI could lead to enhanced productivity and increased profitability.

What is the best way to prepare the aquaculture industry for these changes?

Retention and continuous investment in talent will be key. When hiring future professionals for the aquaculture industry, it will serve the business to recruit individuals with innovative

skills, such as data analysis, software engineering, coding, and robot maintenance.

As for retention, automation could help retain talent. Aquaculture employment in the U.S. has only increased by 0.5 percent from 2018 - 2023 and grew zero percent in 2023. Workers often leave aquaculture because of poor pay and difficult conditions. If automation takes over undesirable tasks, it could pave the way for more engaging, better-paid roles that draw and retain a flexible workforce.

Talent retention goes hand in hand with talent investment. As I noted in my book, The Future of Agriculture, education and training programs cultivate a diverse and flexible workforce that evolves with each innovation. Companies can strengthen their operations from the top-down through leadership development or from the bottom-up through employee training.

Robots, IoT and AI systems pose radical solutions to many of aquaculture's most pressing problems, and if aquaculture learns from healthcare and invests in the workforce now, these technologies could boost productivity and drive new levels of prosperity.

Has technology's transformative impact on the healthcare industry paved a roadmap for the ongoing transformation in aquaculture? By employing robotics, sensors, and AI to cultivate food with efficiency, precision, and cost-effectiveness, the aquaculture industry can provide safe and affordable food and address the sustainability concerns of consumers, climate change, labour and resource scarcity.

agritechcapital.com/books

Master in Sustainable

International Aquafeed - August 2023 | 19

Aquaculture

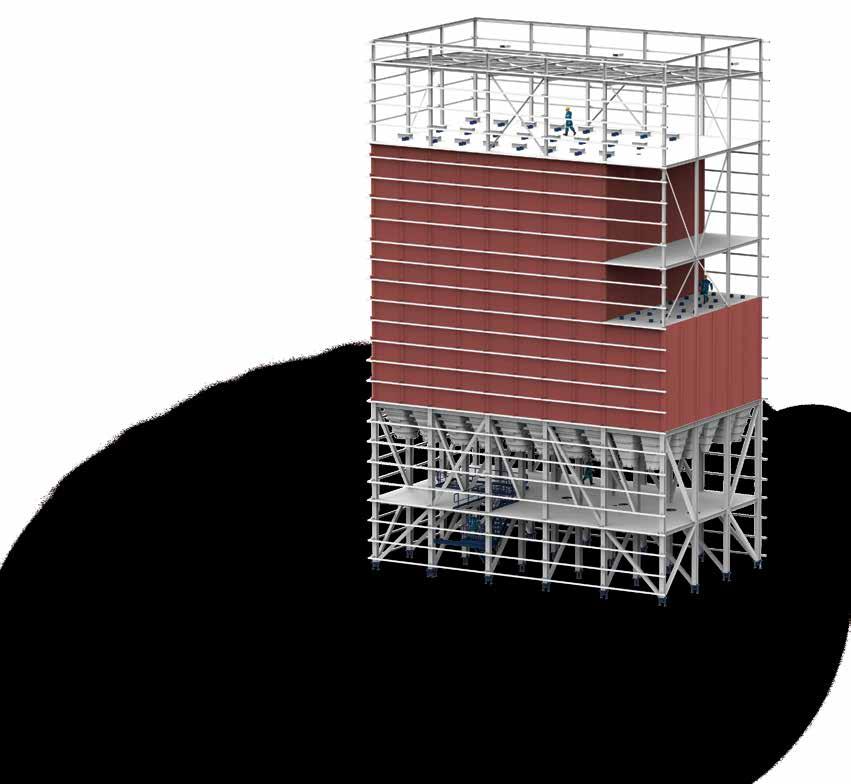

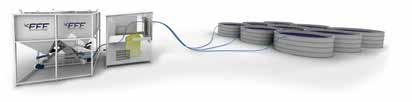

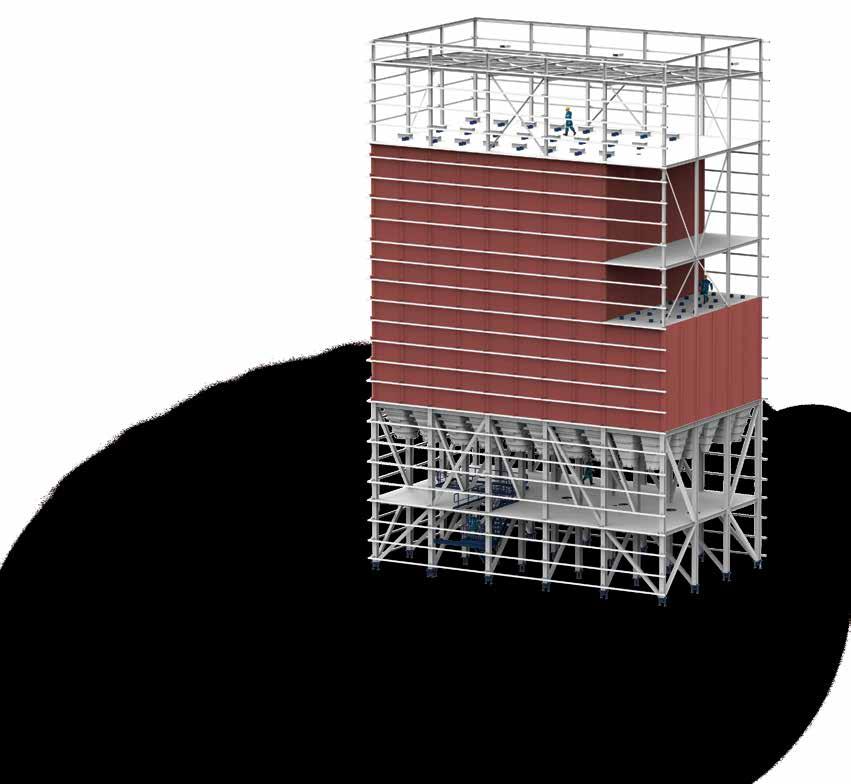

New generation extrusion system promotes an upgradation in aquatic feed production

by Garrick

With the advent of Industry 4.0 and the pervasive adoption of lean manufacturing practices across various industries, digitalisation has emerged as a prominent trend in recent years. In keeping with

the digital transformation, Famsun has developed a new generation of aquatic extrusion systems that are based on lean principles. These cutting-edge systems are designed to provide enhanced value to customers and exemplify Famsun's resolute commitment to actively respond to the demand for digital factories. In doing so, Famsun will become a veritable "engine" that drives the high-quality development of the

Yan, the Supervisor, R&D Global Application Center & David Ma, Deputy Director, R&D Institute, Famsun, China

Yan, the Supervisor, R&D Global Application Center & David Ma, Deputy Director, R&D Institute, Famsun, China

20 | August 2023 - International Aquafeed

Figure 1: Control System User Interface

E ciently Precise control of product density for floating and sinking options Ingredient flexibility for all aquatic species High-capacity systems reduce operating costs Legendary Wenger quality, throughput, and flexibility Wenger extrusion systems are ideal for salmon, shrimp, and RAS feeds Wenger.com THE INNOVATIVE SOLUTION TO CLEANER FISH MANAGEMENT & SEA LICE CONTROL COMPLETE, TAILORED FEED BLOCK DIETS FOR LUMPFISH & WRASSE REDUCED IMPROVED Produced in the UK by www.vitaaquafeeds.uk • SEA LICE POPULATIONS • CATARACT PREVALENCE • AGGRESSION DURING FEEDING • ENERGY CONSUMPTION • STORAGE SPACE & COSTS • MEDICAL TREATMENTS • FISH HEALTH & WELFARE • MORTALITY RATES • STABLE, CONTROLLED GROWTH • LONGEVITY & EFFICACY • PRACTICAL FEEDING METHODS • DAILY OPERATIONAL COSTS International Aquafeed - August 2023 | 21

Make Higher Quality Feed More

World Leaders in Microwave Moisture Measurement Hydro-Probe XT Hoppers, chutes, belt conveyors Hydro-Mix XT-FS Mixers, conveyors, Ducting System Hydro-Mix XT-EX Certified for use in ATEX, IECEx and NEC/CSA Hazardous Locations (Dust) Hydro-Mix HT-EX Mixers, conveyors, Ducting System, High Temperature Non Food-Safe available Non EX available Non EX available enquiries@hydronix.com Contact us for more details hydronix.com Hydronix-Aquafeed-Advert Mar 2023 210x146mm.indd 1 28/02/2023 09:58 www.ge-pro.de Animal proteins and fats as sustainable feed materials For more information, visit us online: VIV MEA 2023 ABU DHABI, U.A.E. 20-22 NOVEMBER INTERNATIONAL TRADE SHOW FROM FEED TO FOOD FOR THE MIDDLE EAST AND AFRICA WWW.VIVMEA.NL Register your visit now! Powered by: Co-located with: Organized by: VNU EUROPE WWW.VIV.NET Partner of 22 | August 2023 - International Aquafeed

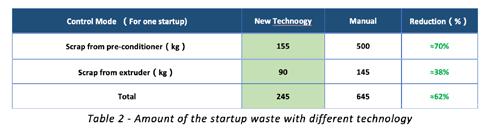

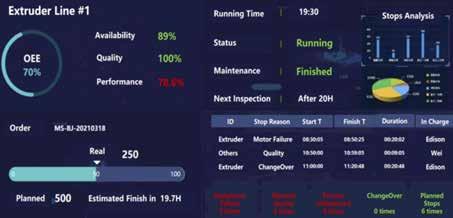

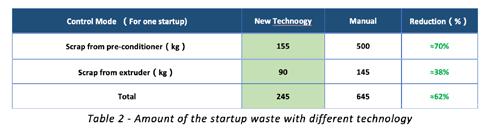

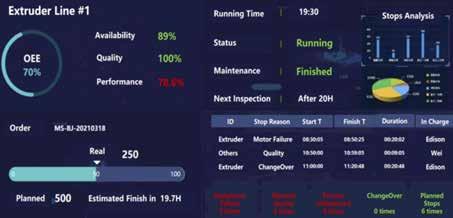

Visualised production data

From a lean perspective, data-driven improvement is critical. However, numerous factories either do not collect production data or still rely on paper-based records. The value of this data is restricted due to inaccessibility, inconsistent readings, and the inability to analyse and use the data in real-time.

To tackle this issue, Famsun upgraded their control system. At first glance, key monitoring data such as pre-conditioning temperature, preconditioning retention time, melt temperatures and melt pressures before the die plate, main motor load, and SME are prominently displayed on the control panel, making it easier for operators to determine if production and safety requirements are being met.

The upgraded system surpasses mere data display and allows digital collection, standardisation, and real-time analysis to identify improvement opportunities. Automated alarms notify operators of deviations from set points to minimise waste and downtime. In summary, the digital control system helps transform data into actionable insights to drive continuous lean improvements.

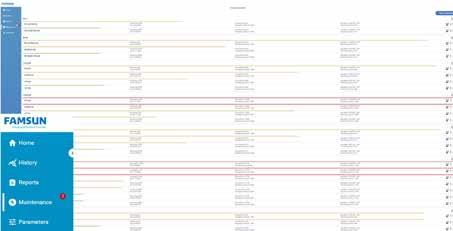

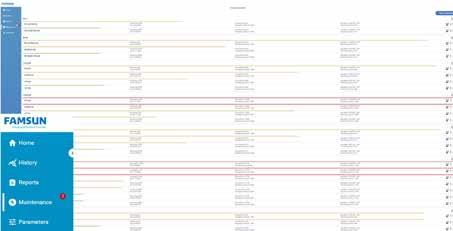

FAMSUN Digital Extruder offers a visual data management platform containing various tools. Customised production reports automatically grab production data in real-time and generate daily, monthly, or annual reports according to the established template. The data sheet also has rich functions such as classification, sorting, filtering, and comparison, which can help the manager efficiently compare and analyse the data.

Moreover, in the new generation of digital extrusion system, we have added the function of maintenance reminder. The program has set up reminders and overdue alarms to facilitate maintenance personnel to arrange their work reasonably and avoid unplanned downtime caused by negligence in maintenance. Do not underestimated this small tool, according to the survey, the total maintenance cost with no plan is more than three times than has a periodic plan.

The production efficiency analysis module monitors and analyses equipment performance in real time. For instance, it can categorise the running status based on a combination of production parameters, then calculating the time spent and material usage at each status. The module also identifies the reasons for and locations of downtime and provides recommendations to improve production efficiency. This module clearly supports lean production teams by helping them analyse the root causes of inefficiencies and continuously improve key performance indicators like overall equipment efficiency (OEE) and yield efficiency (YE).

global

agriculture industry.

Figure 2: Customised Report and Data Analysis

Overall, the production efficiency analysis module aims to transform data from extruder operations into actionable information that can guide decisions for enhancing efficiency, yield and equipment utilisation through a lean lens. By presenting insights in a clear and easy-tounderstand manner, it can help extruder operators and managers make more informed choices to optimize operations on an ongoing basis.

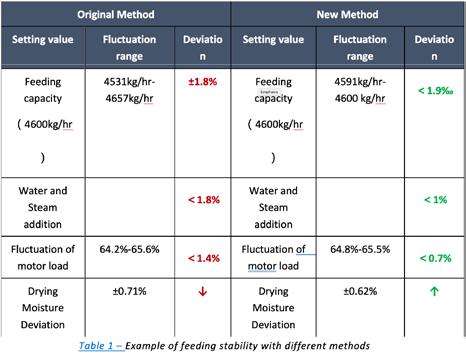

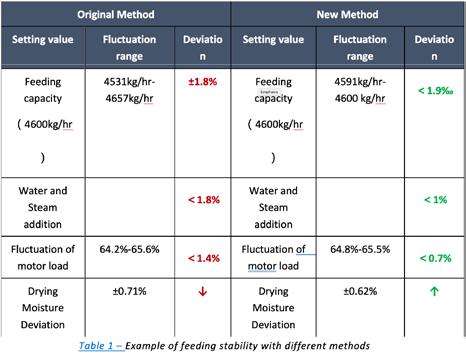

Uniform quality comes from stable feeding

Stable and consistent feeding of dry and wet materials is paramount to the pellet uniformity and quality. Our team of control engineers have conducted extensive research on various operating conditions in different applications and have developed an advanced automatic feeding control program. This program precisely controls the feeding rates of dry and wet materials to maintain a consistent ratio during extrusion. It can compensate for fluctuations in raw material properties and machine variables, ensuring stable material flow into the extruder barrels. By monitoring sensors in real time and automatically adjusting feeder speeds, the control program reduces variations in pellet properties, responding quickly to maintain a uniform material mix and feeding rate under different operating conditions. Less variation in material feeding also helps improve the throughput and energy efficiency. In all, this upgrade not only satisfies the traditional requirement of automatically adding water and steam according to the proportion of dry materials to ensure constant moisture and temperature, but also significantly reduces motor load fluctuations and even decreases the moisture deviation in the finished product. For a 10-tonnes/hr single dryer, this improvement may increase profits by more than US$60,000 per year.

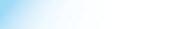

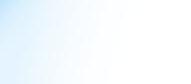

Reduce “ Start-up Waste”

Excessive startup waste is a major issue in extrusion production management. For instance, a typical 10-tonne-per-hour extrusion line can generate over 600 kilograms of startup waste every time it starts from cold. This not only wastes labor but also raw materials if the startup waste cannot be recycled and reused in time.

The startup waste reduction module aims to solve this problem as a unique technology in the industry. It aims to speed up the heating of the system and reduce the amount of waste generated during the initial run. For a standard aquatic feed production run, this technology can shorten the time to reach stable running conditions by more than 20 percent, reduce pre-conditioner startup waste by up to 70 percent, and reduce the total extrusion system's startup waste by over 60 percent.

The module achieves this through optimised control of heating elements, automatic adjustments to process parameters, and active monitoring of material flow and temperatures. It works to quickly bring the extruder barrel and the melt before die plate up to the stable operating temperatures while minimizing material

wastage. Therefore, the startup waste reduction module provides significant benefits in terms of material savings, production efficiency, and environmental impact. By optimising the system's warmup process, it helps maximize yield and productivity from the very beginning of each production run.

Additionally, after reducing the total waste, it is easier to reuse these materials in time. We have several processing solutions to recycle the remaining scraps, reducing labor intensity and avoiding material loss in all aspects, especially when changing the formula frequently.

Make all operations Easy

In order to consistently reproduce the qualified finished product, it is important to have a recipe management system (RMS) that stores the production data from successful runs. Famsun's RMS allows users to save all relevant parameters and recall them with one click.

This ensures that future productions using the same input materials and equipment status can match previous results. Users no longer need to manually re-enter settings each time.

The RMS also features other integrated functions to simplify operations. These include one-click commands to flush the extruder, adjust jacket temperatures, and empty the conditioners.

In summary, the Famsun Digital Extrusion System integrates a stable feeding system, user-friendly control interface, functional modules and data analytics platform to embody the principles of reducing waste, recycling materials and reusing resources. This helps feed producers reduce costs, improve efficiency, optimise processes and produce consistent products of high quality.

Figure 3: Maintenance Warning

24 | August 2023 - International Aquafeed

Figure 4: Comprehensive efficiency analysis interface

RESTRICT inappropriate use of antibiotics and chemicals

REDUCE losses from subclinical disease and outbreaks

INCREASE economical and ecological sustainability

BOOST feed perfomance and farm productivity

Aquaculture with KAESER reliable as the tides www.kaeser.com/aquaculture HEALTH IS AT THE HEART OF OUR CONCERNS

BOOST YOUR BUSINESS BY OPTIMIZING YOUR HEALTH ADDITIVE STRATEGY www.adisseo.com International Aquafeed - August 2023 | 25

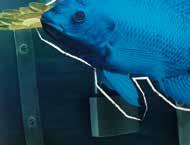

Small adjustments for great benefits Boosting tilapia potential with organic trace mineral nutrition

by Claudia Figueiredo Silva, Zinpro Corporation, USA & Abdel-Fattah M. El-Sayed, Alexandria University, Egypt

The tilapia industry is a fast-paced and steady-growing aquaculture segment.

It has been a leader in developing new technologies such as advanced genetic lines, vaccines, production systems and feed technologies to continuously improve zootechnical performance and operational excellence.

When faced with challenging farming conditions, high-performing animals will have increased nutritional requirements and metabolic demands to grow and cope with environmental stress and pathogen pressure. Suboptimum diets may limit animals’ growth potential and curb their antioxidant and immune responses, thus increasing risks associated with health and diseases outbreak.

Trace Minerals (TM) in Tilapia Feeds Shouldn’t be Overlooked

Nutrients such as minerals and vitamins in practical fish diets are sometimes overlooked due to the priority focus on protein and energy, which are highly impacting feed costs. Trace minerals are involved in several metabolic functions related to fish physiology,

playing an essential role in the regulation of the innate immune system, digestive enzymes activity and antioxidant responses. By ensuring optimised absorption of these nutrients, animals can benefit beyond growth, expressing also a more robust health status and resistance to stress and pathogens.

Tilapia diets are usually formulated with plant-based protein meals including soybean, sunflower, cottonseed, peanuts, and then complemented with carbohydrates sources including wheat, rice, corn, etc. These ingredients are known to have low levels of essential TM, and low bioavailability due to the presence of antinutritional factors including phytates, saponins, glucosinolates, etc.

Traditionally, TM are supplemented in the feed to meet minimum nutritional requirements using premixes containing inorganic salts (e.g., sulfates, oxides). Inorganic TM are more likely to have low bioavailability to animals due to antagonistic interactions with other minerals and components in the feed and limited absorption sites in the intestine.

Organic minerals are metals bound to molecules such as amino acids, peptides, or carbohydrates to help facilitate their absorption in the gut. However, organic minerals behave differently, depending on the molecule they are bound with. Different molecules present different solubility, stability and

26 | August 2023 - International Aquafeed

resistance to stomach pH and extrusion process. Different molecules will also be absorbed and transported in the gut by different mechanisms, which impact their bioavailability.

The utilisation of highperforming organic minerals delivers superior responses compared to inorganic sources, an observation that has been scientifically proven in different species. Having validation under commercial field conditions is incredibly relevant, as it includes challenges to mineral absorption related to the water quality, environmental conditions, feed composition, etc., that aquaculture producers risk facing.

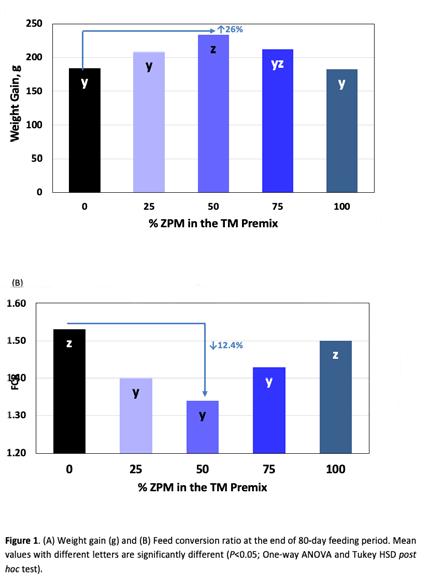

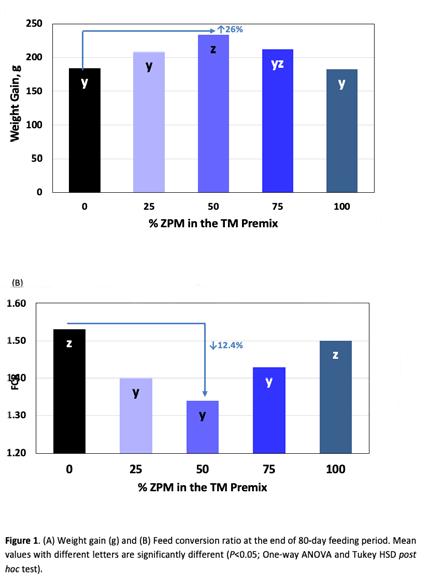

The Field Study: The Benefits of Proven TM Nutrition

A trial was carried out in a commercial earthen-pond fish farm at Edku, Behaira Governorate, Egypt, to evaluate the effects of having metal-amino acid complexes of Zn, Se, Cu, Fe and Mn (Zinpro® Performance Minerals®; ZPM) replacing 25, 50, 75 or 100 percent of the inorganic TM premix in commercial diets for Nile tilapia (Table 1). Diets were formulated to be isonitrogenous (30 percent CP)

International Aquafeed - August 2023 | 27

and isoenergetic (17 MJ kg-1). The main protein sources and respective inclusions in the formula were soybean meal 38.5 percent, poultry by-product meal 5.5% and fishmeal 2.0%. The commercial diets were produced by Aqua International for Food Industries, Motobis Industrial Zone, Kafrel-Shaikh Governorate, Egypt.

Diets were fed twice a day for 80 days to quadruplicate groups of 90g monosex Nile tilapia (Oreochromis niloticus), stocked at a density of 30 fish/ m3 (60 fish/2m3 hapa). Average water quality parameters were: temperature 28.3 ºC (25.1 – 32.2ºC), dissolved oxygen 4.1 mg/L, water salinity 5-8 ‰ and ammonia 1.5 mg/L (0.4 - 2.4 mg/L).

Study Results: Improved Performance

• Replacement of inorganic TM with ZPM has significantly affected tilapia performance.

• The group with 50% of replacement reached the highest specific growth rate followed by the groups 75 and 25% (not significantly different from 50%).

• Groups fed ZPM at 50 and 25 percent had the highest final body weights, with no statistical difference from that fed ZPM at 75 percent (Figure 1-A).

• The control group (Inorganic TM)) had the lowest protein efficiency ratio with the highest feed conversion ratio (FCR).

• Improved FCR’s were observed in the groups fed ZPM at 25, 50 and 75 percent (Figure 1-B). at 50 percent replacement level, ZPM improved tilapia weigh gain and FCR by 26 and 12.4 percent, respectively.

• Digestive enzymes activities were significantly influenced by the replacement of inorganic TM with ZPM.

• The highest amylase, lipase and protease (trypsin) activity were observed in tilapia fed ZPM at 50 percent with an increase of

* Zinpro Performance Minerals, metal-amino acid complexes; zinc as Availa®Zn, iron as Availa®Fe, manganese as Availa®Mn, cooper as Availa®Cu and selenium as Availa®Se.

60.5, 98.4 and 176.2 percent, respectively, compared to the control group.

• Replacement of inorganic TM with ZPM significantly increased Se content in tilapia bone from +42 to +57 percent.

• Also, significantly higher Zn content was found in the bone of tilapias fed ZPM at 25 and 50 percent (34 and 24 percent higher compared to control group), and numerically higher in groups fed ZPM at 75 and 100 percent.

Organic Trace Minerals Drive Immunity and Gut Health Benefits