If September was a full-on month for event organisers around aquaculture, I suspect the remainder of the year will be just as challenging for them, and those of us who value and attempt to attend as many aquaculture events as possible.

The key event prior to Christmas may well be the World Aquaculture Society’s Singapore 2022 event, being planned for November 29-December 2, 2022.

And it’s very timely for me to be able to congratulate Bibha Khumari, of Magadh Mahila College at Patna University in Bihar, India for becoming the new President of the Asia-Pacific Chapter of WAS. WAS Singapore 2022 is yet another event that has been postponed multiple times.

Fortunately, airlines had allowed those of us who had booked for the original dates to defer our travel plans, and this has helped tremendously, given the price rises we are currently seeing in international air travel at the moment.

And its these and other industry-related increases - such as increases in raw materials and the ultimate increase in feeding costs - that are continuing to threaten the financial stability of the aquaculture industry.

Transportation is one cost that is beyond this sector’s control and yet much production from our industry must travel widely, by air, to reach the destined markets and consumers who consume it.

In additional to rising transportation costs for finished products, rising transportations costs for our macro raw materials is also impacting our business. In the middle we are dealing with increased feed production costs through increased energy and fuel costs to name just a few. While we talk about these tangible costs, we should not overlook the potential for rising labour costs which will also impact feed production and fish farming directly. But we pay only passing attention to these outside financial influence occurring elsewhere; the cost of getting a workforce on and off site, the rise in general living costs and inflation are being seen throughout the world.

Not only the cost of transportation contributes to producer worries, but the inflationary nature along the whole chain is stressful.

We must be aware that there is a tipping point beyond which farmers cannot be realistically expected to absorb passed-on costs which they know will not be met from income generated. If that situation happens in any business, then its business owners and directors have an obligation to cease ‘trading’.

Is that likely to happen in our food production system, where our dependence on the international movement of raw materials, being moved across borders, is so central to its continued production?

Costs must be passed on and consumers must and will be asked to pay a higher, fairer price for the aquaculture products they consume. Food production is an essential human activity, but not all food is the same. To maintain our health status and be able to ward off health challenges we need to consume nutritious foodstuffs and aquaculture provides these products in abundance.

There’s going to be a fine balance between managing prices and retaining demand from consumers.

At the European Aquaculture Society’s Aquaculture Europe 2022 in Rimini, Italy late last month several exhibitors and visitors went on record to raise the prospect of high feed prices pushing farmers out of business, particularly those that not only require specifically formulated, high-quality feeds but those that use copious amounts of oxygen in their production systems. You can view some of these interviews on our website at www.aquafeed.co.uk

Our industry needs to promote the benefits of our products in terms of their nutritional values for human health in advance of the situation becoming tighter for fish farming.

Consumers need to be made aware that there is added value in the protein products provided by our industry that are worth the extra spend.

In this edition and in keeping with the above challenges, we review the DSM Aqua Days 2022 (see page 21), highlighting the thoughts of its president for animal nutrition, Ivo Lansbergen about the need for sound science in addressing the nutritional requirements of a growing world population and the need for aquaculture to understand its own carbon footprint.

We also report on the keynote presentation made by Dr Jorge Dias of Sparos in Portugal on managing feed costs. He delves in some detail into aspect of controlling costs and delivered a presentation that was not only timely but offering some partial advice.

There was much more to this meeting and IAF will publish more from this important event in the issues ahead. For now, we set the scene of what was a memorable meeting over three days for over 100 attendees. One of our leading features this month is GM oils.

In these times of difficulties as mentioned above, should we not be looking positively towards a genetically modified supply of long-chain polyunsaturated fatty acids that will help us to overcome the shortages that we know are coming and which, if not solved, will limit the healthy aspects of consuming farmed fish?

Relying on fishmeal for the volumes of fish oil required to support industry is not realistic as we see our aquaculture sectors flourish. This is an informative review by Dr Richard Broughton of the University of Stirling in the UK (see page 24).

We also offer a feature on feed additives by Stephanie Frouel, Eloise Galmiche and Maxime Hugonin of Mixscience in Vietnam (see page 28). They explain the 17 UN Sustainable Development Goals and point out the aquaculture provides 60 percent of the aquatic resources intended for human consumption and is a figure that is likely to increase. The subject they tackle is identifying the main challenges and solutions aquaculture offers in meetings these goals.

Company Andritz has contributed an article (see page 34) on the influence a chosen grinding methods has on quality. This is a detailed look at the grinding chamber in particular and what we should be looking out for in when it come the continuous running of such equipment. A nicely rounded article.

On page 38, K Shankar of Graphical Research in India looks at the development of aquaculture in the Asia-Pacific region and estimates that aquaculture will exceed US$60 billion by 2028. This article attempts to put Asia-Pacific region in context when we consider the global production of aquaculture. An insightful report.

Finally, we come to the Fish Farming Technology section of the magazine which presents tuna aquaculture when Atlantic Bluefin Tuna are being considered for full reproduction in captivity. This article is an eye opener to this high-valued fish farming activity and discusses a method to raise these animals successfully. That ties in with our offshore fish culture feature that follows and before we get into our Technology Showcase (see pages 50-51) and the stories and event reviews that lie beyond.

Don’t overlook the interview this month! It’s with Nikos Papaioauuou of Irida SA in Greece. A great insight into a very successful operation. Enjoy the magazine.

www.aquafeed.co.uk

After a busy schedule of meetings and my trip last month to Thailand, I am now for the moment back in my home city of Plymouth, England at my office/ study. Here I feel the most relaxed surrounded by my textbooks of animal nutrition, biochemistry, and physiology and quite vast collections of scientific papers. A selection complemented by my lovely collection of specific books on fish nutrition and aquaculture biosciences.

Professor Simon Davies Nutrition Editor, International Aquafeed

I am very fortunate to have great resources that allow me to communicate globally with excellent IT and a very efficient fast broadband connection with fibre optic to my door. 36 years ago, when I started my academic career, it would be unthinkable that I could be writing this without a trusted typewriter instead of my various computers and tablet or smart phone. I can format scientific paper manuscripts, review articles, and return these to publishers at the speed of light.

In the old days a scientific paper had to be hard copied three times and sent to the editor of a journal with many delays and a costly exercise for overseas mailing. We would have to wait several weeks for feedback and then to send in our corrections. The creation of a book chapter and the insertion of images was a huge challenge to us and very frustrating.

In a similar manner, the production of a scientific presentation or academic lectures have also undergone a revolution and now with the use of PowerPoint and equivalent software we can construct some very professional lectures, presentations of very high standards and quality in a short space of time.

The portability of information is also amazing with our memory sticks and external hard drives as vital accessories. Indeed, this came to good effect in Thailand last month where one of our guest speakers was unavailable at short notice. With my laptop and external hard drive and access to the cloud I was able to insert another lecture and cover the presentation with a related and updated topic that I ‘fished’ from my files in the comfort of my hotel room.

Our magazine is dependent on the information highway and fish nutrition is an area where this is of paramount importance to keep abreast of the rapidly changing scientific developments and the latest news in this discipline. Our section on Fish Farming Technology has featured AI and the use of remote sensing systems and drones to monitor fish health, welfare and performance in RAS and of course outdoor facilities and open sea pens.

The constant feedback on fish feeding behaviour and associated data can provide accurate measurement of feed intake and be

used in making predictions of growth and feed conversion efficiency. In other areas of animal production and agriculture this has been termed ‘precision farming’.

It is now becoming of age in aquaculture and in its more elaborate form will enable full, almost robotic control of fish farms where systems diagnostics would regulate feeding, water quality parameters, oxygen and carbon dioxide levels, pH, and many other variables necessary for optimal fish and even shrimp production. Many fish farmers using RAS systems already engage with lighting control for both intensity and duration. This is seen especially with salmon smolt production and the induction and promotion of parr-smolt transformation stages.

With Autumn now established I am seeing here in the Northern hemisphere a distinct reduction in the daylength. This reminds me that so many trout and salmon farms are planning for the pending winter season. Salmon farms will be managing their brood stock and making detailed preparations and grading strategies.

The development of brood stock diets bespoke to salmon and trout has come a long way in the last 30 years, but nutrient specifications are quite different to younger fish, and I think much more work is needed to refine formulations with respect to sustainability and the inclusion of novel ingredients and supplements.

A large proportion of our knowledge base for fish diet formulations are based on nutrient requirement experiments on juvenile fish at early growing stages and to harvest. Work on larger fish like salmon attaining harvest size is likely to be very different to fish going through ovulation and sperm development.

This is an expensive area for investigation and relatively fewer peer-reviewed publications are available for most fish species for that matter in terms of many key nutrients such as vitamins and trace elements.

Fish nutrition remains a fascinating subject and in my 37th year as a scientist, I am intrigued by how much we are extending our frontiers of knowledge. This International Aquafeed and Fish Farming Technology magazine helps to stimulate our appreciation of the rapidly changing world of technology and the articles and features presented on our IT platforms, blogs, videos, and the printed magazine reinforces our commitments to keeping you well informed.

The face-to-face Aquaculture conferences and trade exhibitions are now gaining momentum and attendance numbers rapidly increasing. There are many excellent venues remaining for 2022 and most certainly into 2023 and beyond.

I will hopefully meet some of you at some of these events!

Bangkok

At the end of September, the Norwegian aquaculture industry got the shock of their lifetime, although they should have foreseen it. The Government announced that they would put a special tax on fish farming, adding 40% to the 22% they are already taking. With the prospect of having to pay 62% tax on their profits, many fish farmers seemed ready to throw in the towel.

Erik Hempel The Nor-Fishing Foundation

They should have foreseen this, though, for it has been discussed for a couple of years already. But nobody really believed that any government would actually do this. And certainly not on the scale that the present Labour government has proposed it – a 40% surtax! What is hard to understand is why Norway imposes such a surtax on any activity. The country is filthy rich. The energy crisis has brought it NOK 1700 billion (US$170 billion) in extra oil income this year! Norway is now the largest and most important supplier of gas to Europe. And it is selling gas at very high prices.

The reasons given by the government include the need for more money. What? What about the NOK 1700 billion in extra oil revenue? Not to be touched, says the government. That will just be added to the largest investment fund in the world, the Norwegian pension fund. Another reason given was that the new tax would be a tool for redistributing wealth. But nothing of this goes to the common man, everything goes to the government.

The salmon farming industry is a major employer along the coast. In some communities, everybody works in the industry, either directly in salmon farming companies, in processing companies, or in companies which provide supplies. The new tax law could easily mean that these jobs will disappear, and people will have to move away from the districts to urban areas.

The stock market reacted immediately. In just one day, the share values of fish farming companies listed on the Oslo Stock Exchange dropped by NOK 60 billion (US$6 billion).

But what will the extra tax mean for the aquaculture sector in Norway, and for the rest of the modern aquaculture industry, for that matter?

One immediate result is that aquaculture companies have frozen all plans for investments in Norway. Grieg Seafood announced that they had dropped their plans to invest several billions in new technology and facilities. Mowi’s chairman said they would no longer invest in Norway, and other medium sized companies stated that they had frozen their investment plans. One company was planning to invest NOK 1 billion

(US$100 million), which would have created 100 new jobs, but now these plans were now dropped.

For several decades, Norway has been the driving force in technological development in the salmon industry. These technological innovations have spilled over into other parts of the global aquaculture industry, and the billions spent by Norway on technological research and development have benefitted many. Now that activity could come to an abrupt halt.

Or it could mean that other countries will have to take over Norway’s leading role. For the big players in the Norwegian industry are not averse to the idea of moving their activities out of the country. One of the biggest operators in the fishing industry, Mr Kjell Inge Røkke, who owns the Aker industrial conglomerate, including Aker Seafood, recently moved to Switzerland to avoid the heavy Norwegian taxation. Others are following his lead. Røkke and the owner of Salmar, Mr. Witsøe, last year announced that they would join forces and invest some NOK 5 billion in fish farming in the open sea. We now expect that they will move their activities away from Norway. They might take their technological innovations to another country.

Like China, for example. China has shown great interest in ocean farming, and Salmar’s first ocean installation, Ocean Farm, was built in China. With a more favourable tax situation, it would be entirely possible that Røkke and Witsøe would consider such a move. To the loss of Norway.

The Norwegian technological environment, centred around Trondheim, where institutions like SINTEF, Marintek, and the technological university, NTNU, are located, would suffer a great loss. Funding provided by the industry could disappear or be channelled elsewhere, and the technological environment in Trondheim would certainly suffer.

The government’s tax proposal is so far just that: a proposal. It has to be accepted by the Norwegian parliament, the Storting, but the Government has announced that it will go into effect from January 1, 2023. One little blunder in the procedure, by the way. Such proposals are usually sent out for a ‘hearing’ before it is presented to the parliament, and the government has set the deadline for responding to the hearing to January 4 – four days after the new tax law goes into effect.

So much for what they think of everybody’s opinions!

The Norwegian government has created a textbook example of how to kill an industry. Not only that: this industry was supposed to replace the petroleum industry when its time is up in the not-too-distant future.

Roger

joyn@perendale.co.uk

Dr Kangsen Mai

mai@perendale.com

Prof Antonio

antoniog@perendale.com

erikh@perendale.com

•

•

•

Editorial

Prof

Davies sjdaquafeed@gmail.com

Andrew Wilkinson andreww@perendale.co.uk

Shannon Parsons shannonp@perendale.co.uk

Niamh Cassidy niamhc@perendale.co.uk

International Marketing Team

Darren Parris Tel: +44 7854 436407 darrenp@perendale.co.uk

Latin America Marketing Team

Clarissa Garza de Yta Tel: +52 669 120 0140 clarissag@perendale.com

Cristina María Roldán Otero Tel: +44 1242 267700 cristinaperendale@gmail.com

Egyptian Marketing Team

Mohamed Baromh Tel: +20 100 358 3839 mohamedb@perendale.com

India Marketing Team Dr T.D. Babu +91 9884114721 tdbabu@aquafeed.org

Asia Marketing Team

Dante Feng Tel: +886 0227930286 dantef@perendale.com

Nigeria Marketing Team

Nathan Nwosu

Tel: +234 8132 478092 nathann@perendale.com

Digital community manager

Levana Hall levanah@perendale.co.uk

Design Manager

James Taylor jamest@perendale.co.uk

Circulation & Events Manager

Tuti Tan Tel: +44 1242 267706 tutit@perendale.co.uk

Development Manager

Antoine Tanguy antoinet@perendale.co.uk

The Norwegian government has proposed a new resource rent tax on aquaculture, to take effect January 1, 2023, affecting salmon producers as well as trout and rainbow trout producers.

According to the plan, which would need to be approved by parliament, half of the revenues collected will go to public funds. The tax is expected to generate between NOK 3.65 billion and NOK 3.8 billion (US$347 - 361.2 million) annually.

The proposal was sent out for consultation on September 28th. Following its return, the government will bring the legislation to the Storting (supreme legislature of Norway) to enable the proposed rules to apply from the 2023 tax year.

Norway's publicly traded salmon farming firms all saw their share prices tumble in trading on Wednesday, September 28th, with Mowi, Lerøy Seafood, and SalMar's stock prices falling between 15 and 19 percent. According to Reuters, while Norway has a US$1.2 trillion (EUR€1.2 trillion) sovereign wealth fund, the tax increases are necessary to curb inflation.

"The board and management in Lerøy Seafood Group are in the process of assessing the proposal but do not have a complete overview yet," Lerøy Seafood said in a statement. "However, the proposal is undoubtedly hostile to the industry. If approved, it will have a strong

negative impact on the entire industry, unless decision makers at the Storting and people along coastal Norway manage to stop the proposal following the ongoing consultation period." Announcing the move, which also includes tax increases on energy generation, the government stated that its bureau Statistics Norway has identified substantial resource rent – or profits after all costs had been accounted for – in the aquaculture industry over several years. It said that resource rent in aquaculture has risen strongly since 2012 and, for the period from 2016 to 2018, totalled just over NOK 20 billion (US$1.9 billion/EUR €1.9 billion).

The aquaculture sector's resource rent for 2021 is estimated at NOK 11.8 billion (US$1.1 billion, EUR €1.1 billion), according to the government, which said it expected the industry to share the extraordinary return generated through the exploitation of the marine resources it uses.

“The proposal covers the production of salmon, trout, and rainbow trout and involves the taxation of resource rent at an effective rate of 40 percent. The rules are formulated in such a way that only the largest operators will pay resource rent tax. This is done by granting a tax-free allowance of between 4000 and 5000 metric tons,” Norway's Finance Ministry said in a statement.

“A key element of the proposal is

that the local communities which make natural resources available should be guaranteed a share of the resource rent. The tax revenues are estimated to be between NOK 3.65 and 3.8 billion and the government is planning for half of this to go to the municipal sector.”

The ministry has calculated the proposed tax-free allowance of between 4000 and 5000 MT is equivalent to NOK 54 million and NOK 67.5 million (US $5.1 million and US $6.4 million, EUR €5.3 million and EUR €6.6 million).

According to the ministry, around 65 to 70 percent of aquaculture companies have collected biomass under licences of less than 4000 and 5000 MT of maximum permitted biomass.

The government said development licences – used to test new technology – are not covered by the resource rent tax, but that if they are converted to ordinary licences for fish for consumption, they will be covered by the resource rent tax from the date of conversion.

The proposed tax rules grant tax-free allowances in the form of estimated average profit per ton of biomass, which can be deducted from positive resource rent income. Corporate tax will be calculated before resource rent tax on aquaculture, and resource rent-related corporate tax will then be deducted from firms' basis for resource rent tax.

First of all, I would like to congratulate Bibha Khumari from the bottom of my heart for winning the election for President of the AsiaPacific Chapter of the World Aquaculture Society.

I would also like to offer my unconditional support to further consolidate the chapter. As a newcomer to the region, I realise that there is still enormous potential. Aquaculture is an Asian phenomenon, and it is for anyone dedicated to the exciting activity to be on the scene, so to speak.

Asia is responsible for more than 90 percent of all world aquaculture production, and it is also, I believe, where the main technological advances in aquaculture will be developed in the short and medium term.

For those who have not had the opportunity to visit this magical region, full of contrasts and ancient cultures, the Asia-Pacific region may sound homogeneous, but its diversity is such that it is difficult to describe – both in terms of climate, culture, ideology – and why, of course the subject that concerns us all; aquaculture.

This is why the Asia-Pacific Chapter is undoubtedly the most interesting and most challenging of them all.

If the statistics were consistent, 90 percent of WAS members would come from Asia and this should be the most important chapter of the Society, however, it is not. Membership in the chapter is even less than the Latin American and Caribbean Chapter at times and much less than the North American chapter.

The advantages that North America has is that only two languages are spoken, but everyone can communicate in English, while in Latin America and the Caribbean 95 percent of the population can communicate in Spanish and Portuguese, or the mixture of both that we all call Portuñol.

Whilst in Asia, the number of languages is very important and no matter how much they want to homogenise through English, I don't think they still have the level in many regions.

This will be an extremely important challenge to face and to which a solution will have to be found, so that it is not only the scientific community that speaks English that belongs to the Society, but that the entire

value chain is gradually integrated.

If we don't have all the actors involved, we really miss our point. Little by little we must permeate with local producers and multiply the number of partners with great effort.

The theme of the conferences is also important, there are places, like Indonesia, to give an example, where the Chapter, in coordination with local producers, could have practically annual events, and would serve as a motor for development and technological exchange and not only as a visitor every certain number of years.

I think that the Asia-Pacific region needs more attention and a different strategy than the rest of the world. I also know that the pandemic decimated the chapter with difficulty, but starting with Singapore at the end of November, we will experience an interesting reinvigoration and working together we will achieve it.

Many people have told me that I was too hasty in accepting the nomination for the chapter presidency, and I think they are right, but the truth is that only those who do not try fail. I think I will have to continue working and as a newcomer to the region prove to the membership that I am not here to visit, but that I am here to stay.

For now, I will dedicate myself to working so that World Aquaculture 2024 in Muscat, Oman is an unforgettable event that leaves a mark on all those who visit these beautiful lands. See you in Singapore, see you in Darwin, see you in Muscat.

So, until next time!

In a first for the aquaculture sector, a new digital platform inspired by virtual reality (VR) technology used in the subsea energy and oil and gas sectors is being developed to enhance the health and safety of divers on fish farms.

Led by researchers at the National Manufacturing Institute Scotland (NMIS), operated by the University of Strathclyde, the project was recently awarded funding of around £50,000 from the UK Seafood Innovation Fund (SIF) with additional support from the Sustainable Aquaculture Innovation Centre (SAIC).

Designed to replace existing paperbased dive planning, the system will use underwater 3D scanning with images captured by remotely operated vehicles (ROVs) to create a virtual replica of a

seafood farm, supporting divers to plan activities ahead of entering the water.

Divers will be able to use a mobile, tablet, or even a VR headset to gain a better understanding of the fish farm environment through a digital model that can help them to assess the difficulty of the dive, what actions are required in terms of maintenance and cleaning, and whether any additional equipment is needed underwater.

NMIS is working with Ocean Kinetics – a provider of diving services to a range of sectors including aquaculture, energy and renewables – and Viewport 3, specialists in subsea 3D scanning, to create a test platform based on a Scottish Sea Farms site in Shetland.

“3D scanning and VR technology is already used in many industries such as

aerospace and energy, and there could be a significant opportunity for aquaculture to follow, says Awais Munawar, visualisation theme lead – digital factory at NMIS.

“Of course, there are also challenges to overcome, which is the purpose of this feasibility study. For instance, fish farms are not fixed structures in the way that many oil platforms are, and the environment can be quite different depending on the location and depth of the water.

“We are also looking to test a small 5G network to improve communications as part of diving activity in remote locations. This could be used to update the information captured by the remotely operated vehicles in real-time, as well as being used to alert any nearby vessels to the fact that divers are in the water.

Antonio Garza de Yta, PhD in Aquaculture from Auburn University, President of Aquaculture without Frontiers, WAS President and creator of the Certification for Aquaculture Professional (CAP) Program. He is also the Spanish Editor of International Aquafeed Magazine and founder of the International Center for Strategic Studies for Aquaculture. He is currently Secretary of Fisheries and Aquaculture of the State of Tamaulipas.Viva Biba! Still a lot to do in the AsiaPacific Region and the possibilities to grow together

Antonio Garza de Yta

rely on other cheaper resources to serve as bulk nutrient sources.

However, another perspective of this story is the growing diversity within ingredient classes themselves, and this evolution looks to be growing one. Let’s start with wheat, a staple ingredient in nearly all classes of animal feeds (including that of humans).

Wheat these days has not only extensive diversity among the different varieties grown across the world to capitalise on the various agronomic conditions, but even within growing regions there is extensive diversity depending on the market the producer is targeting.

mantra we hear among social-circles and human resource management these days is that there is ‘strength in diversity.’ We are also seeing this as a clear trend in products across all sectors these days, as we rapidly move to a notion of the world no longer being ‘one-size-fits-all.’

While this growth in diversity might be true for social and market dynamics, it also holds true for the process of feed formulation and ingredient development. But what do we mean by diversity in this context?

Among diet formulations, a notable trend over the past 30 years has been the substantial increase in the range of ingredients now used in feeds. Back in the 1990’s it was common to see feed formulations with a quite simple raw material profile; fishmeal, fishoil, wheat and various additives.

Compare that with 2020, where we are more likely to see double to treble the number of ingredients, and we have clearly increased the diversity of our raw material profile. This growth in diversity was inevitable with the growth in the sector, there was simply not enough marine ingredient volume to continue to supply it as a bulk ingredient. Consequently, we have seen marine ingredients become a strategic resource, and we now

This has led to specific breeds of wheat for different products like, bread, noodles, pasta, etc. Different products value different attributes of their ingredients. And this diversification (and importantly, segregation) has been an important evolution in increasing the profitability of that sector. We see also a similar evolution in the marine ingredients sector. Where traditionally we might have seen just a premium and standard fishmeal being produced.

The diversification of raw material sourcing and the realisation that different feed sectors value different features of those products is leading to the diversification of fishmeals and fish oils for the various sectors they supply.

A clear example of this is from the fishmeals coming from Peru presently, where we see more than half a dozen different grades/types of fishmeal being produced for different markets. The practice is now so entrenched that some of those products are even named after their respective markets; products like Thailand Grade and Taiwan Grade fishmeals.

So where will this ‘diversification’ go? Based on the current trends it is likely that that we will see increasing diversification still. Growing demands on not only nutritional properties across the feed sector, but also sustainability/sourcing criteria, carbonfootprint criteria, and organic criteria across products is adding yet another point of diversification. But, as it was said earlier, there is ‘strength in diversity.’

Dr Brett Glencross is the Technical Director of IFFO - The Marine Ingredients Organisation. Over the past 25 years he has worked in various academic, institutional, and industrial roles across Australasia, the Middle East and Europe.

Salmon, Skretting and Zooca have signed an agreement to facilitate the provision of a specifically designed salmon feed for Andfjord Salmon as well as a long-term co-operation to increase incorporating zooplankton Calanus finmarchius in salmon feed.

Calanus Plus, by Andfjord Salmon, marks the first salmon feed that uses the zooplankton Calanus finmarchius as a raw material ingredient. It also contains algae oil as an alternative to fish oil.

The zooplankton is one of the most abundant animal species on the planet with a reproduction of 300 million tonnes. It is Norway’s largest harvestable and renewable marine resource. Current rates show that Zooca only harvests 0.0005 percent of total volume per annum.

“Calanus finmarchius is nature’s own ‘starter’ feed. It is a natural prey that is biologically adapted to provide optimal nutrition for fish. Adding Zooca Hydrolysate will be very useful to stimulate the fish’s appetite in the transition to seawater,” explains Mads Martinsen, Director of Product Development and Sustainability at Skretting.

Andfjord will be the first salmon farmer in the world to use a commercially developed feed with Calanus. Earlier in February, Andfjord entered into a feed supply agreement with Skretting.

The agreement has overseen the development of a feed tailored to the company’s flow-through technology which ensures optimal water quality, fish welfare and growth conditions.

Andfjord recently released the first smolt into its site at Kvalnes at the end of June this year, reporting that smolt had adapted quickly and biological conditions were as expected. The site utilises flow through technology which enables the producer to simulate wild salmon’s natural habitat in a landbased facility.

Martin Rasmussen, CEO of Andfjord Salmon who was involved in releasing the first smolt, refers to “ambition” with mention of the feed. “Our ambition is to develop the world’s most fish friendly and sustainable aquaculture facility of its kind. Having our own specially designed feed, with unique ingredients from a local supplier, is another important building block towards realising this ambition.”

“The fish has settled quickly and has already demonstrated a healthy appetite, which continues to improve daily. Fish mortality rate is extremely low, so it has been a promising start,” Mr Rasmussen adds.

Zooca is responsible for supplying the Zooca Hydrolysate to Skretting, which processes Calanus finmarchius at its facility at Sortland, nearby to Andfjord’s site at Kvalnes. The company has, for the last 20 years, researched and developed technology that can sustainably harvest and process the zooplankton.

“By sustainably harnessing high-performing, high-quality nutrients from Calanus finmarchicus, there is a large potential to improve long-term human health and ensure superior animal nutrition around the globe.

“We are delighted to secure this commercial breakthrough within salmon feed together with Andfjord Salmon and Skretting,” says Hogne Abrahamsen, International Account Director at Zooca.

“We look forward to using Calanus Plus by Andfjord Salmon at our Kvalnes site and to the long-term co-operation with Skretting and Zooca,” concludes Martin Rasmussen.

In a global first, a UK producer of hemp crops is taking its first steps into the aquaculture sector that could see the alternative plant-based protein source used as a key ingredient for Atlantic salmon feeds.

Rare Earth Global, growers of industrial hemp for a range of sustainable products, has received UK £50,000/US $57,000 funding from the UK Seafood Innovation Fund (SIF) to explore how hemp seeds could be integrated into the diets of farmed salmon in Scotland.

With support from the Sustainable Aquaculture Innovation Centre (SAIC) and the University of Stirling's Institute of Aquaculture, the project team has begun an initial feasibility trial to assess the impact of hemp protein on fish health and wellbeing, looking at factors such as digestibility and nutritional value.

A plant-based nutritional supplement

Hemp-based protein is already sold for human consumption as a plant-based nutritional supplement as well as being used in cattle and poultry farming. However, the results of this study could see locally grown hemp being introduced as a core feed ingredient in aquaculture for the first time.

Initial indications suggest that a protein content of up to 50 percent could be achieved from the plants grown on UK soil, exceeding producers' minimum requirements of 35 percent, as well as reducing the sector's reliance on imported ingredients such as soy and fish meal.

The concept of using the hemp seeds as an effective protein source forms part of Rare Earth Global's zerowaste approach to hemp farming, which ensures that every part of the plant is used for maximum value. Hemp plants are known to have multiple uses, with the stems widely used for sustainable insulation, paper, textiles, and other materials.

The largest UK-based hemp processor

By 2024, Rare Earth Global expects to be the largest UKbased hemp processor, contracting up to 5000 hectares, and the team said they have already had positive discussions with some of Scotland's major seafood producers and feed manufacturers.

“There are lots of novel feed ingredients coming into the aquaculture sector, but the hemp seed trial is about making the best use of local ingredients,” says Suneet Shivaprasad, managing director and co-founder of Rare Earth Global. “Hemp is one of the fastest growing plants, using minimal water and capturing up to eight times more carbon than most trees, which makes it a highly sustainable choice for so many different products and materials.

“Our aim is to ensure that every part of the plant delivers maximum impact, which is why we are focusing on aquaculture. Our studies show that protein conversion rates in salmon are much higher than for cattle or poultry, highlighting significant potential for the sector to introduce it as a new, sustainable feed ingredient. The process could be scaled up very quickly and we could see an entirely new UK-based supply chain for fish feed emerging in the near future.”

Researchers from the Institute of Aquaculture will be conducting trials at the University of Stirling's facilities to assess how salmon react to different varieties of the hemp plant and any impact that the ingredient has on gut bacteria and the digestive system.

“We already know that hemp protein is suitable for human consumption, which is highly promising, but this trial will help us better understand its impact on fish diets including gut health and digestibility,” says Monica Betancor, lecturer at the Institute of Aquaculture.

“There may also be additional nutritional benefits, such as anti-inflammatory properties, and our aim is to gather appropriate data that can be used to inform future decisions about the suitability of this new feed ingredient.”

There are around 100 different types of hemp plant that can be grown worldwide, from the harsh climates of the Himalayas to the warmth of the Caribbean, and a further goal of Rare Earth Global is to determine which varieties will deliver the best results in terms of crop yield, fish health, and growth.

“With rising demand for sustainable healthy protein across the globe, aquaculture has a responsibility to reduce the environmental footprint of seafood production while also increasing its capacity to feed a growing population,” says Sarah Riddle, director of innovation and engagement at SAIC.

“Rare Earth Global's entry into the sector represents an exciting opportunity for a new low-carbon feed source that could see reductions in imports from overseas. The circular model of production is equally important, highlighting the opportunity for a range of different sectors to make use of ingredients that may have otherwise been considered as waste.”

This three-day event attracted some 150 guests from more than 20 countries who heard eight conference presentations, toured two DSM research and development centres and participated in a ‘speed dating’ afternoon that explained in short but focused time slots the work the company carried out behind the scenes on product development. DSM Global Aqua Days held in August 2022 will be followed by DSM Ruminant Days this month.

With acquisition of Biomin and Romer Labs by Royal DSM in mid-2020, the aquaculture industry may have expected the annual Biomin Aqua Days meeting to disappear. But not so.

DSM has embraced the platform and delivered its first Global Aqua Days at the end of August 2022 to continue offering this important event and meeting place for customers involved in the production of aquatic feeds.

The three-day event was held in Vienna, Austria and included visits to DSM’s laboratories and research facilities at Tulin, DSM’s facilities in Getzersdorf and the ultra-modern premix production plant at Haag am Hausruck near the German border which was opened in early 2020.

Reports on the important presentations made during the conference days will be published in subsequent editions of International Aquafeed.

The event was opened by DSM’s president for aniaml nutrition and health Ivo Lansbergen, who quickly outlined the need for sound science in addressing the nutritional requirement of a growing world population.

He briefly highlighted the 120-year history of his company, from coal milling in 1902 to petro-chemicals and in more recent times to nutrition and health, with a focus on sustainable living and biosciences, to today’s three business groups of Animal Health and Nutrition HNH (which has an annual turnover of Euros 3.4B), Human Health, Nutrition and Care (at Euros 2.5B) and Food and Beverage (at Euros 1.3B).

In its ANH group, with its focus firmly on sustainability, the company has a further three segment approach of Essential Products, Performance Solutions plus Biomin and Precision Services.

Overall, there are six sustainability and business ‘platforms’ that drives the DSM ANH group:

• Tackling antimicrobial resistance

• Reducing the reliance on marine resources

• Reducing emissions from livestock

• Efficient use of natural resources

• Improving animal product quality while reducing food loss and waste

Improving the lifetime performance of animals

Mr Lansbergen stressed that sustainable nutrition for aquaculture must be achieved within “planetary boundaries.”

It’s the theme that Jan Vanbrabant, the chief customer office for ANH took up when concluding the welcome session.

Mr Vanbrabant added that fish farming had to be circular in nature, restorative for the environment and achieve a net zero carbon footprint while maintaining productivity, low mortality rates, improving feed conversion ratios and minimising losses in yield and during processing.

“It’s important that aquaculture producers understand their own footprint,” he says.

He also pointed out that from now on sustainability will be the key to investment, with the FAIRR Company Rankings showing companies producing feeds for the fish farming sector more environmentally friendly than those producing food products from terrestrial animal production.

Our industry needs to reduce the environmental footprint to mitigate the expected 70 percent increase in demand in animal proteins by 2050 and Scope 3 emissions is a key focus for retailers, he added.

Mr Lansbergen, in summing up the opening session, displayed some products that promote healthy and more sustainable

products to delegates with a focus on omega 3, saying that consumers were more willing to pay a higher price for food products that were sustainable and quoted an example where algae-fed salmon was more appealing to the consumer and created a greater value for the retailer.

The bottom line, he added, is that to grow sustainably the aquaculture industry will need to use novel protein ingredients with an emphasis on Omega 3.

Dr Jorge Dias, with a PhD in fish nutrition, tackled the difficult subject of managing feed costs and outlined what could be achieved. He is the co-founder and general manager of Sparos, a science and technology-driven company dedicated to the development of novel nutritional solutions and premium feeds for the aquaculture market. His work is extensive within Portugal and France.

He says aquaculture is “part of the solution” to feeding a growing

human population in which there will be a scarcity of several natural resources, the requirement to achieve a lower environmental footprint and the need to adapt to climatic changes.

“Fish are among the most efficient farm animals in converting feed nutrients into edible meat .and therefore is an attractive option to cater for future protein needs.”

Relative to 2018, the aquaculture sector is expected to grow by 32 percent over the current 12-year period up to 2030.

The sustainability challenges facing aquaculture, and which can be mitigated by optimising feeds, include:

Biological - animal performance and welfare, health and biodiversity

Environmental - sustainable feed resources, low pollution and integrated production systems

Coastal area occupation - production systems including RAS, IMTA and off-shore systems

Consumers - Food safety, quality, health and ethical farming methods

Speed dating: Smaller groups circulate around specific displays to learn more about what’s behind products development processes DSM’s president Ivo Lansbergen introduces the company and its ANH group Colour spectrum for salmon fillet goes from printed cards to digital with DSM’s new SalmoFan (top centre) DSM’s Biomin branded pre-mix plant at Haag am Hausruck near the German border, and which was commissioned in mid-2020, offers the latest in hygienic control with the aim of eliminating any risk of cross contamination during the manufacture process

A welcome reception: of DSM welcomes 25 countries to Vienna city centre

A welcome reception: of DSM welcomes 25 countries to Vienna city centre

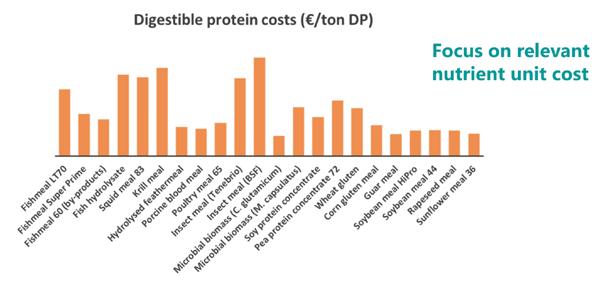

He spoke about “knowing your ingredients beyond nutritional values in detail.”

Managing feed costs require precision nutrition to avoid overformulating, controlling the variation in raw material quality, judicious use of strategic feed ingredients, improved protection given to feeds and mitigating adverse effects such as mycotoxins plus supporting more precise feeding practices to gain the best FCRs.

He also pointed to gaining the most from feed additives and optimising the supply and production processes. Finally, formulators need to consider using emerging alternative ingredients for both their nutritional and technological advantages. Another aspect he spoke about was changing the focus from just feed prices and production costs to production performance. Moving to a more dynamic formation, based on digestible protein in the final feed, would achieve a more stable performance and should be combined with each protein’s nutritional value in terms of its amino acid profile and trace minerals, etc.

Dr Dias spoke about the gradual replacement of fishmeal in diets for not only salmon but also so for Bream, Bass, trout and carp. This move is showing significant reductions which has been achieved with greater use of vegetable proteins, processed animal proteins and their optimisation with vitamins and trace minerals.

In 2021 by-products from global fish production provide about 30 percent of the fishmeal now being used in aqua diets. Further growth in aquaculture is dependent on the arrival of novel protein sources, he adds.

However, marine harvested resources will continue to play a growing role in the areas of zooplankton biomasses, such as Antarctic krill, copepods, amphipods and others. Under evaluation are mesopelagic fish species plus macro algae and seaweeds with interest in the latter’s bioactive compounds for functional feeds.

Novel and emerging protein sources include plant-based byproducts such as distillers’ grains and DDGS which offers higher proteins levels of up to 60 percent. Other protein concentrates including rapeseed, sunflower and barley plus corn protein

concentrates are now being used in trout and Seabass diets.

There are others to be considered as well. Including single cell proteins, yeast and filamentous fungi, bacterial meals and micro algae. Insects is an emerging source but there is still a lot of variability in the products available on the market, he adds.

The gradual replacement of fish oil over the past decade has occurred, but there is still high dependency with 75 percent of all fish oil produced globally going into aquaculture as it is critical in the further growth of marine aquaculture.

While one 130g-150g portion of salmon per week provides the recommended 1.5g of EPA and DHA in the human diet there is an urgent need for additional n-3 HUFA sources.

“The good news is that we have a solution we can grow. Algae oils are gaining industrial relevancy and scale,” he adds, and they may contain specific lipids classes with a bioactive effect.

Novel and emerging ingredients means we have to look beyond nutrition at the biological performance and cost of production.

Novel ingredients are still in their pilot stages in many cases and energy inputs are still a major element for their CO2 footprint. There will always be a trade-off between impact categories, he adds.

While something new is always great to have, Dr Dias says we can do better with the feed additives we have to get the most out of our existing resources.

Phytase in tilapia improves phosphorus release values. In plant ingredients P is mostly present as phytate which is extremely poorly digested by fish (0-30 percent) and is an anti-nutritional factor which also negatively impacts the absorption of other minerals and proteins.

.Costs are no longer just formulation costs. Formulators need a deep knowledge of ingredients from nutritional to functional to technological. Advantage should be taken of feed additives for higher efficiency, such phytogenics counteracting gut morphology changes … and do the best you can, he concludes.

reception: Herbert Kneissl welcomes delegates from to Austria in downtown centre Jan Vanbrabant, the chief customer office for ANH talks about the challenges facing aquaculture Keynote presentation: Fish nutritionist Dr Jorge Dias, General Manager of Sparos of Portugal reviews the options when managing feed costs Gerd Schatzmayer, head of global R&D Centres at ANH A delegate and their pack – ready for work! by Del Williams, Technical writer, Torrance, CaliforniaForowners and managers of feed, grain, and allied grain processing facilities, walking onto the production floor with conveyor tubes winding this way and that, in and out of machinery can seem at first like they have stepped into a Dr Seuss book or Willy Wonka and the Chocolate Factory movie.

For example, at a glance even feed and grain industry veterans can be challenged to distinguish whether the conveyor tubes they see are screw (augur), pneumatic, vacuum, aeromechanical, tubular drag chain and disc or tubular drag cable and disc.

In fact, many owners, managers, specifiers, architects, engineers, and other professionals lack substantial technical or hands-on experience with such conveyors.

This knowledge gap can result in extreme consequences when delicate or precise feed and grain blends must be reliably conveyed but instead, costly product destruction or inaccurate blends occur.

Misconceptions relating to tubular drag cable and disc conveyors will be the focus of this assessment, addressing six widely held viewpoints in the industry. Correcting these misconceptions can help feed and grain facility owners and managers not only improve product quality but also productivity, efficiency and profitability.

Tubular drag cable conveyors gently move product through a sealed tube using a coated, flexible stainless-steel drag cable pulled through on a loop. Solid circular discs (flights) are attached to the cable, which push the product through the tube without the use of air. These conveyors excel in transporting delicate, precise feed and grain blends in versatile layouts and configurations.

When transporting a blend of feed and grain product or supplement with a conveyor system, maintaining a consistent mix ratio is essential, whether a coarse mix, fine powder, or larger variable-sized amalgams of different weights and shapes.

However, conventional conveyor systems are not specifically designed to precisely transport blends without changing the mix ratio. Various product material weights, sizes, and shapes can shift and disperse in open systems like bucket conveyors, and vibration can cause the blended product to shift throughout transport.

Vacuum and pneumatic systems can cause smaller lightweight

Cablevey Conveyors’ tubular drag cable conveyors are engineered to maintain precise blend ratios, maintaining a consistent mix ratio whether conveying a fine powder, coarse mix, or larger amalgams of different weights and shapes.

particles in a feed and grain blend to move at different speeds than heavier or larger particulates, resulting in significant blend restructuring when the product reaches its discharge point.

In contrast, tubular drag cable conveyors are engineered to maintain precise blend ratios, which can be important to feed and grain industry professionals from nutritionists to farmers feeding livestock, according to Karl Seidel.

He is marketing director of Cablevey Conveyors, a mechanical conveyor manufacturer that serves the feed and grain, pet food, specialty food, coffee, powder and nut markets.

As an example, the company’s engineers have resolved the blending issue with a completely enclosed, compartmentalised

The cable and disc systems gently and precisely convey feed and grain blends for a wide range of conditions and facility layouts

Tubular drag conveyors Debunking six common misconceptions relating to their use in feed processingModular systems like tubular drag cable conveyors are space efficient, and an excellent option for complex layouts that require curves or changes in direction,

It is common to see portions of tubular conveyor equipment extending outdoors when conveying product from outside to inside or vice versa such as when unloading raw material or loading finished product.

within their facility’s available space or accommodate its layout, which may include significant inclines or elevation changes.

However, this is not the case.

Modular systems like tubular drag cable conveyors are an excellent option for complex layouts that could require curves or changes in direction, according to Mr Seidel.

“Tubular conveyors do not have to be installed at 90 degrees and can use angles so can go in between, around, above or below existing feed and grain equipment or other obstacles. That is important for existing facilities that may not have the flexibility to move something out of the way,” adds Mr Seidel.

In addition, tubular conveyors are quite space efficient. Seidel notes that to conserve space, the conveyor turnaround and its inlet can stand on end, so it is only one foot across instead of three.

If conveyor discharge occurs best using gravity, tubing can be run through walls and discharge out of the building roof, which saves interior space.

It is a misconception that tubular conveyors are only installed indoors. In fact, it is common to see portions of feed and grain equipment extending outdoors. This may occur when conveying product from outside to inside such as when unloading raw material from a truck or railcar or loading finished product into similar transport.

Materials may also travel from a feed mill to a production or packaging room which may be ten feet or even one hundred feet away.

According to Clint Hudson, Cablevey Conveyors Engineering Manager, when some equipment is used outdoors, and when moving moist product, it can be helpful to wrap the tubes in heat tape to prevent moisture from condensing or freezing in the tubes.

The conveyor manufacturer can also provide a range of accommodations to account for the effects of wind, dust, rain, insects, and direct sunlight.

Between product changeovers, many traditional conveyor systems must be disassembled, cleaned, or soaked, and then reassembled – a labour and time-intensive process. However, this is not necessary for tubular conveyors.

With tubular conveyors dry, wet, and in-line cleaning options are available, according to Hudson. Among dry options, brush boxes and air-knives can clean the cable. Brushes and wipers can wash the tubes. To sanitise, a sponge soaked in sanitiser can be used without getting the system fully wet.

For the most thorough cleansing, the cable conveyor’s wet cleaning process internally washes the tube in several steps, starting with a water rinse followed by a foaming agent, a sanitizing rinse, and a final water rinse. Once the system is thoroughly flushed out, drying is achieved by attaching urethane wipers to the tubular conveyor’s discs, which ‘act like a squeegee’ to remove any residual water.

Whilst first impressions of tubular drag cable and disc conveyors can evoke images of Dr Seuss or Willy Wonka’s chocolate factory, the equipment has been carefully designed and engineered for industrial performance, reliably conveying delicate products and blends in a variety of conditions.

With an understanding of the true potential of these conveyors, feed and grain industry professionals will be well-positioned to take advantage of the systems’ abilities to increase quality production and decrease downtime.

growth from the seafood sector is envisioned to come from the aquaculture sector, and with it, an increased demand for fish oils.

Owing to a finite supply of long chain polyunsaturated fatty acids (LC-PUFAs), with the most well-known being EPA and DHA, which are commonly associated with the health benefits of eating seafood, alternative sources are required to supplement the diets of LCPUFA rich fish such as Atlantic salmon.

One solution to this supply issue, is the utilisation of genetically modified (GM) oilseeds, derived from oil rich plants from the Brassicaceae, of which Brassica napus (oilseed rape) and Camelina sativa are members. Fish-like oils have been engineered into these crops, producing comparable levels of both EPA and DHA, which can then be added to feed and substitute traditional fish oil.

To assess the suitability of these new oils, two diets were utilised in our study, with the GM diet incorporating LC-PUFA rich oil from Camelina sativa, and the control diet comprising a commercial blend of both standard oilseed rape and fish oils. Both diets were isolipidic at 36 percent and isoproteic at 36 percent.

Fish with an average weight of 187g were grown in six

seawater floating pens, with diets fed in triplicate, until a final fish weight, on average, of 3510g was obtained, over the period of June 2018 to March 2019, with six fish per tank humanely euthanised.

With the advancement of genetic technologies, comes the need to advance the methods by which we study and monitor those alterations, and their downstream uses. Traditional methodologies for analysing lipids focus on the fatty acids themselves, and typically involve cleaving them from their lipid backbone, resulting in a loss of structural information.

Advances in chromatography and mass spectrometry have made it possible to determine in greater detail the structure of these lipids, specifically, their intact structure. We therefore applied these techniques to assess the differences between fish fed these two diets, and ultimately, whether any lipid structural alterations could be detected.

In this study, we looked at five tissues, across two timepoints (intermediate and final), and found that there were key differences between tissues. It was found that brain, typically regarded as non-plastic in regard to lipid composition, generally conformed to this view, by illustrating small lipid changes, as represented in fold change (Figure 1), overall.

It was also found, that, in general, the brain responded

Ottevanger Milling Engineers is supplier of machines, installations and complete process lines for the compound feed industry and grain processing companies.

Our expertise in project management, engineering and production ensures the successful realization of machines, process lines and complete installations

positively to elevated LC-PUFA within the diet (Figure 2), with the control diet generally not eliciting increases in lipids which were shorter and less saturated, typically found within standard plant oils.

This indicated that a homeostatic baseline exists within brain tissue, allowing increases in longer chain, polyunsaturated fatty acids, but not shorter chain, mono- and diunsaturated fatty acids for example.

On the other hand, the gill seemed to benefit from the control diet, with the majority of the lipid changes occurring with this diet. Those shorter chain to medium chain lipids, containing 32-40 carbons, and those containing 1-3 and 6-7 double bonds were those primarily enriched within gill tissue. Many of these lipids were found to contain fatty acids with 18 carbons, a reflection of the diet, with the dietary effect appearing in contrast to that of brain.

The eye was found to be a relatively conserved tissue, though distinguished itself from brain through differences in glycosylated lipids. Liver, and to some extent intestine, were found to be

Specialist in the design and build of installations for the grain-processing and compound feed industry

modulated to a greater degree, by experiencing greater fold changes, likely due to their metabolic activity and role within lipid transport and metabolism.

To explore the lipid composition in more depth, we looked at how the fatty acids were attached to their lipid backbone. We found that, on average, across all tissues and timepoints, lipids were enriched with 20 and 22 carbon fatty acids when fish were fed the GM diet.

The same diet also enriched fatty acids containing 3-5 double bonds, with five double bond containing acids more enriched within phosphatidylcholine. In contrast to this, the control diet resulted in increased levels of fatty acids containing 14 and 16 carbons containing one double bond.

In the brain and eye, specifically at the latter time point, and gill, did exhibit deviations from the general trends observed. Brain appeared to enrich 18 carbon fatty acids into complex lipids in response to the GM diet, whereas the control diet favoured enrichment of the same fatty acids in gill.

The final brain and eye time points defied the overall trend, by enriching saturated and di-unsaturated fatty acids in response to the GM diet, whereas gill was found to strongly enrich fatty acids containing five and six double bonds in response to the control diet.

Interestingly, it was also found that there were putative stereoisomers (Figure 3), lipids that have the same fatty acids attached as each other, but in a different order. Of those detected putative stereoisomers, several trends were found, with the most consistent found in PC 16:0/20:2, PC 16:0/20:3, PC 16:0/20:4 and PC 20:4/22:6, where one of these isomers was preferentially favoured over another.

However, owing to the methodology, greater structural detail

could not be obtained, and further work needs to be undertaken to determine the configuration of these lipids.

The presence of these stereoisomers may have implications for fish health, owing to the functional role of phospholipids in inflammation, as specific fatty acids are released from the complex lipid backbone during times of injury or infection.

Further work is being conducted on these pro- and antiinflammatory mediators, the eicosanoids, and whether these novel diets impact the immune system and ability to resist pathogens such as sea lice.

A further potential use is the validation of Atlantic salmon which may have been fed oils derived from GM crops, where no genetic material from the original oilseed is present, providing a measure of provenance for consumers and regulatory bodies.

The work has been published in open access journal Metabolites, and can be read in full at: https://aqfeed.info/e/1675

Frouel, Eloise Galmiche and Maxime Hugonin evaluate the added value of some innovative feed solutions to reach a more sustainable aquaculture that fits with Global Sustainable Goals adopted by United Nations in 2015.

Several recent reports described the consequences of climate change and lack of sustainability on human societies and ecosystems everywhere in the World.

The conclusion is once again very clear. The impacts of human activities have significant adverse effects on nature and people in all regions, particularly affecting the most vulnerable ones. In parallel, the adaptation measures already set up are far from being sufficient.

In 1987, the United Nations (UN) defined the Sustainable Development as the “Development that meets the needs of the present without compromising the ability of future generations to meet their own needs.”

This definition is based on three main dimensions: society, environment and economy (and eventually a fourth on when culture is considered) [Figure 1].

The 2030 Agenda for Sustainable Development calls the UN countries to already start making efforts to achieve the 17 Sustainable Development Goals (SDGs) over the next years [Figure 2].

The goals address the needs of people in both developed and developing countries and ask all industries to contribute, whatever their size.

1. No Poverty: End poverty in all its forms everywhere.

2. Zero Hunger: End hunger, achieve food security and

nutrition and promote sustainable agriculture.

Good Health and Well-Being: Ensure healthy lives and promote well-being for all at all ages.

Quality Education: Ensure inclusive and equitable quality education and promote lifelong learning opportunities for all

Gender Equality: Achieve gender equality and empower all women and girls

Clean Water and Sanitation: Ensure availability and sustainable management of water and sanitation for all.

Affordable and Clean Energy: Ensure access to affordable, reliable, sustainable and modern energy for all.

Decent Work and Economic Growth: Promote sustained, inclusive and sustainable economic growth, full and productive employment and decent work for all

Industry, Innovation and Infrastructure: Build resilient infrastructure, promote inclusive and sustainable industrialization and foster innovation

Reduced Inequalities: Reduce inequality within and among countries

Sustainable Cities and Communities: Make cities and human settlements inclusive, safe, resilient and sustainable

Responsible Consumption and Production: Ensure sustainable consumption and production patterns

Climate Action: Take urgent action to combat climate change and its impacts

Life Below Water: Conserve and sustainably use the oceans, seas and marine resources for sustainable development

Life on Land: Protect, restore and promote sustainable use of terrestrial ecosystems, sustainably manage forests, combat desertification, and halt and reverse land degradation and halt biodiversity loss.

16. Peace, Justice and Strong Institutions: Promote peaceful and inclusive societies for sustainable development, provide access to justice for all and build effective, accountable and inclusive institutions at all levels

17. Partnerships for the Goals: Strengthen the means of implementation and revitalise the global partnership for sustainable development

Among concerned industries, Aquaculture is a key player since it currently contributes to more than 60 percent of the supply of aquatic resources intended for human consumption. This share will probably increase in the future, due to the stagnation of catches linked to fishing.

Moreover, the aquaculture industry is considered one of the

most sustainable agro-food industries.

But is it really the case and what are the main challenges and what solutions are likely to strengthen sustainability in aquaculture?

If we translate the definition of global sustainability applied to Aquaculture industry, it means that:

From an environmental point of view, Aquaculture should not create significant disruption to the ecosystem or cause the loss of biodiversity or substantial pollution impact

From an economical point of view, Aquaculture must be a viable business with good and long-term perspectives

From a social point of view, Aquaculture must ensure that fish is affordable and available for all, and economic and nutritional benefits are equitably shared

Today, Aquaculture is already being recognised for addressing some of these goals [Figure 3], with those applicable listed below.

Though fish compose a small amount of global protein intake (6.7%), they are an important source of animal protein, providing 17% of the World’s meat consumption. Also, fish play a vital nutritional role for many people.

3.1 billion people rely on fish for 20% of their daily protein intake, with some coastal communities reliant on fish for upwards of 70% (www.sustainablefisheries-uw.org).

Aquaculture is one of the most important long-term growth areas for food production. With the catches from wild fisheries remaining largely flat and some stocks already overexploited. With a growing population, it is important to increase the amount of seafood available, using aquaculture to provide enough protein while keep reducing the wild fish catches.

It’s predicted that we will need to double protein production by 2050, so our reliance on aquaculture is likely to increase. In fact, the FAO forecasts that aquaculture’s share of production will increase to 59% (109 million tons) by 2030 (www.reutersevents.com)

In recent years, the global appetite for seafood has increased dramatically. Some recent initiatives have been proposed to bring innovations to support the demand.

The Global Aquaculture Challenge, for instance, invites innovators from every area of aquaculture including industry, academia, and public institutions to present and develop their ideas. Successful applicants will be able to glean knowledge from industry experts via relevant mentoring programs and have access to investment opportunities to fully develop their proposals (www.globalaquachallenge.com).

As evoked, Aquaculture aims to replace wild catches to preserve natural resources while the demand in animal protein increases. Being one of the more sustainable animal productions, seafood proteins seems to be a good alternative to other animal protein to limit the impact of their production on the environment.

Moreover, Aquaculture is also a good tool to repopulate impoverished habitats and areas.

A-Live Natural gut balance promotor based on phytogenics

- Helps to waste degradation in pond - Limit adherence of pathogens - Support immune responses

- Regulates the gut microflora - Improves gut microbiota abundance and biodiversity - Positively modulates the gut microbiota

- Improves water quality - Decrease use of chemicals

- Secure farm environment

- Improves survival rates/ maximises yield

- Helps to control the pathogenic pressure - Decrease use of antibiotics - Secure farm environment - Improves survival rates/ maximises yield

2, 3, 6, 8, 9, 14

Table 1: MiXscience’s product family and their individual associated sustainable goal MiXscience’s products families Modes of actions Sustainable benefits Targeted UN-SDG Noliflore Aqua Biocontrol / Bioremediation solution based on innovative biotechnologies and microorganisms

2, 3, 6, 8, 9, 12, 14

A-Coverost Antiparasitic solution based on natural oleochemicals and a specific galenic developed with partners

Mix-Amune Natural immunostimulant based on phytogenics

- Controls the parasite germination - Association of biological and mechanical actions

- Controls the parasite load in the animal and the environment - Decrease use of chemicals - Secure farm environment

- Improves survival rates/ maximises yield

2, 3, 6, 8, 9, 12, 14, 17

- Natural defense stimulation - Controls the inflammatory response - Antioxidant effect

- Enhance the natural defenses of the host - Decrease use of medication

- Maximises yield under stress conditions

2, 3, 6, 8, 9, 12, 14

Despite all of these listed advances and their respective benefits, aquaculture must keep evolving.

In term of contribution to UN Goals, Aquaculture is already a key actor but to get bigger and go further, some remaining challenges need to be faced to achieve improvements as shown in Figure 4. Despite much progress, the sector is still suffering from a negative image on different topics such as:

Compliance with environmental standards, that addresses issues like habitat conservation, water quality and effluents, recycling of wastes.

Animal health and welfare, where best practices to manage animal husbandry and disease control are not always applied.

Social responsibilities of the entire aquaculture value chain, to make fish affordable for all and to ensure that local laws for worker and protection of child labor are respected.

Reinforcement of food safety to secure the resources and make assurance that no banned antibiotics or other medicines chemicals are used and all approved medicines are carried out in responsible way.

Are Feed additives and functional feeds a pertinent solution to achieve higher levels of sustainability in Aquaculture?

At farming level, to face environmental changes, societal pressure, economical constraints, and reach a long-term resilience, two strategies are possible:

- The first, adaptive, consists of implementing solutions that allow changes in the environment to be taken into account (adapted species, selection of sites, formulation of feed

supplemented with compensatory functional aids) and therefore ensuring that the animals have a better adaptation to changes;

- The second consists in imagining farming systems where environmental factors are strictly controlled in terms of temperature and oxygen in particular.

In the scope of the presented research, we will mainly focus on the first strategy, which seems to be the most agile and the most appropriate one for the actors in the value chain.

One of the approaches consists in developing functional feeds, based on additives and, if necessary, appropriate galenic. The purpose of such feeds is to allow/help the animal to have a more adaptive physiological response (of the host) to biotic and abiotic factors.

This is the MiXscience strategy and thanks to its portfolio that contains innovative products with specific modes of actions, and solutions specially developed with key partners to address Aquaculture challenges. Thanks to the company’s complete product range, in MiXscience, it aims to contribute to eight out of the 17 UN-Goals.

In Table 1, the modes of actions of MiXscience’s product families have been related to their associated sustainable goal to demonstrate that event at the scale of a small and individual solution, we could bring a stone to the wall of global sustainability

Speaking as established players in the aquaculture industry, Maxtex believe that its own actions and its wish to provide natural solutions that address the key challenges of the industry specifically, can form an important part of the process towards reaching a reliable and sustainable aquaculture industry for future generations.

refers to any feed given to aquatic farmed animals as part of aquaculture and is usually a mixture of various raw materials and additives. The requirements for these blends are very specific, depending on the species and age of the animal, to guarantee its nutritional, immune resistance, and growth promoting properties.

The hammer mill is commonly used in aquafeed factories for grinding. Particle size reduction results from the action of the cutting knifes (hammers), where aspiration airflow from outside of the grinding chamber forces the particles that are smaller than the screen perforations to cross into a collecting bin to be transported pneumatically to the next process.

The extrusion process has advantages in the aquafeed industries because it induces desirable physical and chemical changes to ingredients, changing their proprieties and qualities, increasing their nutritional value with efficiency at a lower relative cost.

This is due to the high thermomechanical energy used in the extrusion process, leading to changes in the aquafeed such as increased digestibility of cereals, inactivation of anti-nutritional factors, destruction of microorganisms, denaturation of proteins

that favor digestibility, and expansion of the types of raw materials that can be utilised.

The selection of the ingredients and the proper grinding have a major impact on the final product’s texture, nutritional quality, and economic viability. The raw materials are grinded and mixed creating a flour that is converted into a dough with the addition of water and steam.

Genitalisation of the starch components results in water absorption and an increase in the viscosity of the dough. The particle size of the ingredients does have a direct impact since smaller granulometry allows for higher starch genitalisation during the extrusion process. Nutritionally, the smaller the particle size, the greater the contact with the digestive juices and thus improved digestion and absorption.