FEATURE

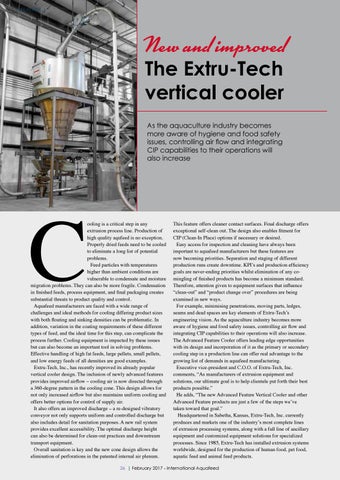

New and improved The Extru-Tech vertical cooler As the aquaculture industry becomes more aware of hygiene and food safety issues, controlling air flow and integrating CIP capabilities to their operations will also increase

C

ooling is a critical step in any extrusion process line. Production of high quality aqufeed is no exception. Properly dried feeds need to be cooled to eliminate a long list of potential problems. Feed particles with temperatures higher than ambient conditions are vulnerable to condensate and moisture migration problems. They can also be more fragile. Condensation in finished feeds, process equipment, and final packaging creates substantial threats to product quality and control. Aquafeed manufacturers are faced with a wide range of challenges and ideal methods for cooling differing product sizes with both floating and sinking densities can be problematic. In addition, variation in the coating requirements of these different types of feed, and the ideal time for this step, can complicate the process further. Cooling equipment is impacted by these issues but can also become an important tool in solving problems. Effective handling of high fat feeds, large pellets, small pellets, and low energy feeds of all densities are good examples. Extru-Tech, Inc., has recently improved its already popular vertical cooler design. The inclusion of newly advanced features provides improved airflow – cooling air is now directed through a 360-degree pattern in the cooling cone. This design allows for not only increased airflow but also maintains uniform cooling and offers better options for control of supply air. It also offers an improved discharge – a re-designed vibratory conveyor not only supports uniform and controlled discharge but also includes detail for sanitation purposes. A new rail system provides excellent accessibility. The optimal discharge height can also be determined for clean-out practices and downstream transport equipment. Overall sanitation is key and the new cone design allows the elimination of perforations in the patented internal air plenum.

This feature offers cleaner contact surfaces. Final discharge offers exceptional self-clean out. The design also enables fitment for CIP (Clean-In Place) options if necessary or desired. Easy access for inspection and cleaning have always been important to aquafeed manufacturers but these features are now becoming priorities. Separation and staging of different production runs create downtime. KPI’s and production efficiency goals are never-ending priorities whilst elimination of any comingling of finished products has become a minimum standard. Therefore, attention given to equipment surfaces that influence “clean-out” and “product change over” procedures are being examined in new ways. For example, minimising penetrations, moving parts, ledges, seams and dead spaces are key elements of Extru-Tech’s engineering vision. As the aquaculture industry becomes more aware of hygiene and food safety issues, controlling air flow and integrating CIP capabilities to their operations will also increase. The Advanced Feature Cooler offers leading edge opportunities with its design and incorporation of it as the primary or secondary cooling step in a production line can offer real advantage to the growing list of demands in aquafeed manufacturing. Executive vice-president and C.O.O. of Extru-Tech, Inc. comments, “As manufacturers of extrusion equipment and solutions, our ultimate goal is to help clientele put forth their best products possible.” He adds, “The new Advanced Feature Vertical Cooler and other Advanced Feature products are just a few of the steps we’ve taken toward that goal.” Headquartered in Sabetha, Kansas, Extru-Tech, Inc. currently produces and markets one of the industry’s most complete lines of extrusion processing systems, along with a full line of ancillary equipment and customized equipment solutions for specialized processes. Since 1985, Extru-Tech has installed extrusion systems worldwide, designed for the production of human food, pet food, aquatic feed and animal feed products.

26 | February 2017 - International Aquafeed