Everything we do at Instarmac is shaped by a strong, purposeful drive for continuous improvement. We are proud of the strides we’ve made over the past few years, but refuse to become complacent.

As a business, we are as ambitious about our environmental and social responsibilities as we are about our commercial success. We understand that manufacturing and sustainability can sometimes seem at odds, but we are committed to proving otherwise by driving real change and setting new standards in real, tangible, innovation in sustainability.

Guided by our VALUES — Work Hard, Have Fun, Make a Difference — we will continue to build a business that inspires pride in our people, delivers a true benefit to our customers, and leads the way in responsible manufacturing.

Since our last report, we’ve made significant progress on our journey to Net Zero. From further investment in renewable energy and cleaner transport to the increased use of greener, more sustainable raw materials, we are embedding sustainability across our way of thinking and every aspect of our operation. These are not just individual milestones. They represent a long-term strategy and a genuine commitment to building a greener, more responsible future.

As Managing Director, I am committed to driving continued growth and the exceptional customer experiences that are at the heart of that. We understand that sustainability is important to our customers, and we aim to make their lives easier by providing a sustainable supply chain.

Guided by our values — Work Hard, Have Fun, Make a Difference — we will continue to build a business that inspires pride in our people and supports them to achieve their potential, which delivers a true benefit to our customers, and leads the way in responsible manufacturing.

Our people remain our greatest asset, we must continue to utilise their talent, passion and skill to make meaningful contributions — not just to our customers and partners, but to the environment, local communities, and the wider industry.

This report is a reflection of what we’ve achieved so far—and a reaffirmation of where we’re going. The future is bright, and at Instarmac, we’re ready to pave the way.

Step into the world of our multi award-winning, market-leading company, where for over 45 years we have pioneered cement and bitumen based products for global markets.

Our solid reputation stands on the foundation of research, development and production of innovative materials that have transformed the highway maintenance, urban regeneration, tiling and commercial flooring sectors.

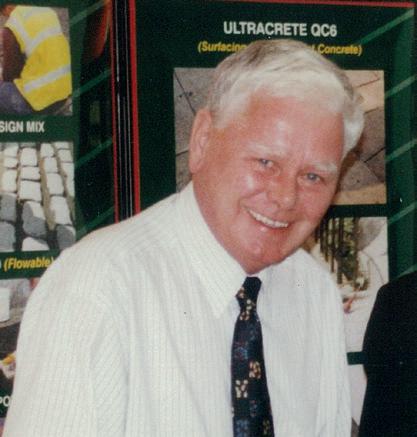

In 1977, visionary entrepreneur Charles “Charlie” Hudson founded Instarmac Repair Services Ltd –a clever name derived from the phrase “Instant Tarmac”. The inspiration struck after Charlie watched an episode of BBC’s Tomorrow’s World featuring an innovative pothole repair material. Captivated by its potential, he immediately acquired the ground-breaking technology from Tiny Draper of Emcol Int. and thus began an extraordinary journey into road repair solutions.

We now sell to 40 different countries, have a 40- strong fleet, employ over 200 people and have 4 product brands

Over the next two decades, we embarked on an exciting journey of growth, investing in cutting-edge production capacity and launching innovative new brands. We witnessed a remarkable surge in sales across all our product lines – from highway maintenance to paving, tiling and flooring solutions. As demand soared, our facilities struggled to keep pace with our rapid expansion. This momentum led us to a pivotal moment in 1998, when Instarmac relocated

to a spacious new home in Kingsbury, Tamworth – a move that would fuel our continued success story.

Over the next decade, our business flourished dramatically, culminating in our 2008 relocation to a spectacular multi-millionpound facility in Dordon, Tamworth. This impressive site hosts our world-class manufacturing processes, distribution networks, financial operations, export division, dynamic sales and marketing

teams, and our innovative research and development department.

Since then, the business has gone from strength to strength. We now sell to 40 different countries, have a 40- strong fleet, employ over 200 people and have 4 product brands – UltraCrete, UltraScape, UltraTile and UltraFloor.

New site in Kingsbury and export to Europe begins UltraTile launched 1998 1999

Tenerife holiday home bought for staff use HAPAS approval for Instant Road Repair 2002 2002

BS 7533 compliant independent approval received 2004

Rainwater collection system installed Acquires Emcol and export to Asia and New Zealand begins 2008 2010

Named as a Great Place to Work® St Ives Holiday home bought for staff use 2018 2018

Pallet recycling scheme launched RoSPA Gold Medal Award 2010 2012

Acquired Wondertex 2013

ISO 27001 accreditation

Named as a ‘Great Place to Work®’ 2019 UK Best Workplaces for Women, 2019 Excellence in Wellbeing 2019 2019

Instarmac appoints two new board members and Managing Director Receives Queen’s Award for International Trade 2023 2022 New Instarmac I2 building New Instarmac Holdings

Acquires 10% share of Roadmender Asphalt 2020

2022 2021 Introduced CNG vehicles to fleet 2020

Our highly skilled and experienced training team annually deliver over 100 customer training sessions to ensure the correct installation of our products, increasing their lifespan and reducing waste.

Imagine a world where our most precious resources simply vanish. This alarming scenario inches closer to reality each day as we deplete Earth’s natural resources at an unsustainable pace.

Shockingly, we’re consuming these vital resources 1.7 times faster than our planet can possibly regenerate them*. With the world’s population set to top nearly 10 billion by 2050, this resource drain will only intensify. Though we haven’t yet experienced widespread shortages, the writing is on the wall. Unless we dramatically transform our relationship with raw materials, we’re racing toward a future where essential resources become scarce luxuries rather than everyday necessities.

The circular economy concept has dramatically reshaped our production landscape, fundamentally altering how society consumes products and manages waste. Impressive gains in recycling efficiency,

coupled with advances in processing recycled materials, have empowered companies to substitute virgin raw materials with recycled alternatives. The European Commission sees that this move towards a circular economy and the subsequent increased recycling rates creates “more economic value by facilitating secure and stable access to raw materials.”

Our products can include up to 50% recycled material.

Annually we use over 6,000 tonnes of recycled materials in our products. That’s the equivalent weight of 487 London Buses! That’s 81

more than our last report.

Our Technical Team has risen to the challenge, pioneering innovative formulations that are transforming our products. The exciting result? We now incorporate 4 “green” materials reclaimed from other industries into our formulations, demonstrating our unwavering commitment to efficiency and sustainability in everything we produce.

Our breakthrough environmental innovation is Envirobead® - a process that has transformed products such as ProLevel Ultimate, Level IT Hydra Bond and Level IT Multi Pro. This remarkable process doesn’t just create exceptional flow in these

Annually we use over 6,000 tonnes of recycled materials in our products.

formulations – it also champions sustainability with an impressive 20% recycled content, proving that superior performance and environmental sustainability can brilliantly coexist.

“Instarmac upholds a strong focus on new product development and innovation remains a cornerstone of the company’s strategy focused on key raw materials to enable its drive for growth, resilience and contribution to sustainable development. More recently, product development has included sustainable sourcing of raw materials with consideration to the overall carbon footprint of the business and the impact the manufacturing operation has on the local environment and world climate.

Close collaboration and stronger partnerships with suppliers coupled with customer intimacy allows Instarmac to anticipate evolving market trends to develop market-leading products that combine technical performance and sustainability to not only meet the current market needs, but also future needs. This requires careful material selection and adopting optimised and effective manufacturing processes to pursue safe and competitive manufacturing operations.

We are already seeing a reduction in our greenhouse gas emissions in the cements we use and will continue working collaboratively with key suppliers in our pursuit to identify the next generation of innovative forms of cements, and other key raw materials, with the

aim of contributing to our Net Zero Emissions commitment.

The challenges on maintaining innovation, whether it be incremental or disruptive have been reset by our commitment to Net Zero. Instarmac embraces the challenges of creating sustainable solutions in terms of production and use of products and services within the full supply chain that enables for a better environment in the future.”

Zia Hussain, Head of Technical

In alarming news, levels of carbon dioxide have reached a frightening all-time high! While CO2 is vital for plant and animal survival, excessive amounts wreak havoc on our environment. Can you believe the UK have been burning fossil fuels for nearly three centuries?

This relentless consumption has triggered a dangerous surge in greenhouse gases, throwing our atmosphere into chaos. Climate change isn’t just about rising temperatures – it’s the dramatic shifts in weather patterns, devastating extreme events, encroaching sea levels, and disruption of wildlife habitats and populations. Here’s the shocking truth: in May 2025, CO2 levels in hit a record-breaking 430.79 parts per million* - the highest average ever recorded.

The Intergovernmental Panel on Climate Change estimates that if the planet’s average temperature rises by just 1.5°C, up to 30% of species could be at risk of extinction.** Therefore it is crucial that our carbon dioxide levels are controlled and where possible, reduced. It is also imperative that companies employ effective procedures aimed at streamlining operations and increasing efficiency – something we have done successfully, for many years.

ISO 9001 Accredited

ISO 9001 is the gold standard for quality management systems worldwide. Organisations who embrace this powerful framework are able to demonstrate their unwavering commitment to delivering services and products that consistently exceed customer expectations and meet regulatory requirements. More than just certification, ISO 9001 serves as a dynamic business improvement tool that can transform operations – streamlining processes, cutting costs, and building more sustainable practices that position businesses for long-term success. Globally, over a mullion businesses are using this standard to improve their performance.

This ISO standard sets out the requirements needed for an efficient environmental management system (EMS). It is the most widely used EMS in the world with over 14,000 organisations certified in the UK and over 300,000 ISO certificates issued globally. The standard provides guidance on how to maximise the sustainability of multiple aspects of the business from product development to manufacturing to storage and distribution. It helps to control our impact on the environment but also promotes employee engagement, builds resilience to uncertainty and strengthens our ability to change.

“I have proudly worked at Instarmac for 40 years and during my tenure, driving green manufacturing processes has become more and more important –and quite rightly so. If you have seen previous issues of this report, you will be aware of the initiatives we have already implemented across our production facility.

It would be easy for Instarmac to stop there but that isn’t how we do things here! In the last 12 months I am proud to say that we have made further green advances including:

• Training all Production Operatives in LEAN, 5s, and continuous improvement techniques. This not only improves organisations but will improve efficiencies and drive down waste.

• We have made further investments to our bulk storage and handling of raw materials. This has resulted in reduced pallet movements, packaging and waste.

• New machinery has been installed including ROTOLOK technology on our Haver packaging machines, Intelligent Drive Technology which controls speeds of drives where necessary and Smart Motion Sensors to control conveyors and belt systems.

And the improvements don’t stop with production. Our Maintenance Team are investigating how to re-use parts where we can and how to utilise PPM Software and planning software. What’s more, our Warehouse team are now utilising Lithium-Ion Technology instead of traditional lead acid, on all MHE equipment.

Paul Evans, Works Director

The new racking has reduced FLT movement by 54% in our picking operation. This means that altogether our picking FLTs move over 54km less per day.

The concept of ‘carbon footprint’ is widely recognised, and most understand the need to minimise our individual environmental impact. However, many remain unsure of how to calculate their own carbon footprint or the steps required to measure it.

Carbon footprint represents the total greenhouse gas emissions generated by a person, company, event, or product. Greenhouse gases are the atmospheric gases that contribute to the greenhouse effect, global warming, and climate change.

Your carbon footprint is a metric used to quantify the environmental impact of an individual’s lifestyle choices. For instance, commuting to work by personal vehicle typically results in a larger carbon footprint compared

Controlling and lowering our carbon dioxide emissions is a top priority for our organisation.

to using public transport, as driving emits more greenhouse gases.

As a manufacturer, we’re committed to minimising our environmental impact. We employ strategic procedures to streamline operations and boost efficiency, all with the goal of significantly reducing our carbon footprint. Controlling and lowering our carbon dioxide emissions

is a top priority for our organisation.

Safeguarding the environment is our top priority. We’re committed to aligning our operations and products with government guidelines and promoting best practices. By working closely with our customers, suppliers, and partners, we aim to drive positive change and reduce our collective footprint.

With that in mind, we have made a pledge to be Net Zero by 2050 and working with external partners to measure and report on our carbon emissions.

The Greenhouse Gas Protocol (GHG) is the leading authority on how to measure and manage carbon emissions and categories emissions as follows:

Scope 1: All direct GHG emissions

Scope 2: All indirect GHG emissions arising from electricity, heat or steam consumption

Scope 3: All other indirect emissions

Using accurate and qualified data, we have been able to identify and measure our carbon footprint across Scopes 1 and 2 and are now actively working towards measuring Scope 3 emissions as part of our net zero carbon commitment.

We are actively looking for ways to reduce our reliance on natural resources to be as green as possible.

In 2022, we installed 1,656 solar panels across a 3,707sqm area at our state-of-the-art manufacturing facility in Tamworth. The 768KW solar panels will generate 680,000KW of clean green energy for us to use and is projected to save at least 36,000KW of power per month and 15 million KW over the lifespan of the system.

This has saved over 702 tonne of CO2 emissions since being commissioned.

We have also joined forces with Green Leaves Logistics, a freight company passionate about the preservation of our beautiful planet.

Green Leaves Logistics have the environment at the heart of everything they do – a philosophy shared by everyone at Instarmac.

For every sea, air or road shipment they forward, Green Leaves Logistics removes more carbon dioxide from the atmosphere than each shipment emits. We are delighted to work with Green Leaves Logistics for container sea shipments to long haul destinations –a partnership that is predicted to result in 750 trees planted around the world and 15,000 CO in the next 12 months. This is a huge step forward for us, and brings us closer to reaching our goal of being a Net Zero, world-class business.

In 2022, we installed 1,656 solar panels across a 3,707 sqm area at our stateof-the-art manufacturing facility in Tamworth.

While transport emissions continue to decline in the UK, the sector remains one of the slowest globally to reduce its environmental impact.

This modest progress can be attributed to advancements in vehicle fuel efficiency, the adoption of alternative fuel sources, and lower-than-anticipated traffic growth. Nevertheless, our organisation remains steadfastly committed to driving further emission reductions through ongoing, diligent efforts.

Our 40-strong fleet annually maintains a CO² per mile low of 0.001 tonnes.

Each CNG lorry will save 100 tonnes of emissions per year.

Using invertors to charge pallet trucks throughout journeys saved up to 70,000 kw per year.

96% of our car fleet is petrol hybrid, with several fully electric vehicles part of our fleet.

“Our Transport team are the most visible to the public, and as with all heavy haulage, the reputation of this mode of distribution is unfairly tarnished as being a major pollutant. We are proud members of the trade body, RHA, and are strong advocates of the advances we are making in contributing to reducing our environmental impact.

This has resulted in a significant reduction of 1,700 tonnes in our annual emissions.

We now have a fleet of 40 vehicles that distribute products direct from our factory, eliminating any unnecessary miles travelled. We have invested heavily in 17 CNG (Compressed Natural Gas) trucks that provide an 80% reduction in CO2 emissions. The rest of the fleet are all fitted with Euro 6 engines, the highest specification available that not only reduces CO2 emissions but also our Nitrous Oxide by up to 67%.

We are pleased to report that our fleet’s transition to CNG has exceeded our initial targets. By March 2025, 42.5% of our vehicles had been converted, surpassing our goals of 20% by 2023 and 30% by 2024. This has resulted in a significant reduction of 1,700 tonnes in our annual emissions.

We are always looking to innovate and work with our manufacturing partners to develop the best solution with the least environmental impact. We renew our vehicles on a cyclical annual basis to take advantage of the latest fuel-efficient technologies. The next 13 vehicles will be purchased in 2025/2026 and will reduce our environmental impact by a further 9-11%. We are constantly evolving and challenging all parts of the transport business. Our planning and vehicle scheduling system updates with the latest road restrictions and advises our drivers of any delays to reduce our idling time and to provide more efficient routes.

In line with our legal obligations, and the requirements of FORS, our drivers are provided with the necessary training to ensure they are fully equipped to meet our environmental and safety ambitions. Whether it be via the annual CPC modules, or our own internal training programmes, we continue to focus on environmental based subjects to keep our drivers at the forefront of this key topic.

In early 2025, we switched our tyre manufacturer to provide us with a longer life and a safer solution for our fleet. This will deliver further fuel savings of 4% and when it comes to braking, will ensure our staff, customers and public are kept safer.

One of the biggest factors in our operation is our people. They have direct impact in how we address these issues through driver awareness. In 2025, we are investing heavily in our lead drivers to give them DVSA qualifications in safe and efficient driving with AA Drivetech. They will also work with our truck manufacturers to get the best out of the technology supplied. Each driver will be assessed and trained on a 1:1 basis on the road, every 6 months. This will ensure that we drive efficiently and reduce our wear and tear on the vehicle and tyres.”

Murray Lythgo, Head of Logistics

The impact a product has on the environment during its use depends on the type of product.

For instance, while a chair sits quietly in your home with minimal ecological consequence after production, a car continuously consumes resources and releases emissions throughout its life. At our core, we’re passionate about creating enduring solutions that stand the test of time – products designed to solve problems permanently rather than temporarily. By engineering exceptional durability into everything we make, we’re not just reducing the need for replacements; we’re actively minimising the environmental footprint during the most critical phase of our products lives – their everyday use.

Beyond durability, the lifespan of our products hinges critically on proper installation techniques. To address this, our dynamic Technical Training and Site Support Team delivers engaging seminars and hands-on practical training sessions designed to ensure flawless product application – ultimately extending product longevity and dramatically reducing waste. At Instarmac, we’re passionate about fostering growth through continuous learning opportunities, creating an environment where both our team members and customers thrive through innovative training and educational experiences.

We have facilities to hold bespoke training on our site. Whether to learn more about our product range, develop a skill set, or to attend a RIBA accredited CPD seminar, our premises are ideal. Our Training Academy features an outdoor skills area and indoor training facility that have been developed for our customers’ use. We offer training for all our brands, with our external demo area ideal for our highway maintenance and paving

installation materials and our indoor high-spec training room is perfect for learning more about our tiling and flooring products. Our dedicated and knowledgeable team also assist with onsite demonstrations and material trials. All this support is delivered with the aim of maximising the life and performance of our products.

In addition to ensuring the correct application of products, we have also looked for other routes to maximise sustainability. One way has been to develop products that meet the environmental targets of specific projects to be BREEAM certified.

Launched in 1990 and recognised internationally, BREEAM is a protocol that assesses the sustainability of master planning projects, infrastructure, and buildings. BREEAM uses third parties to complete the examination of a project’s environmental, social and economic sustainability performance. The assessment covers a number of categories developed to reflect some of today’s most important issues such as carbon emissions, durability and adaption to climate change. As BREEAM certified developments enhance the wellbeing of people who live and work in them, BREEAM certification is a top priority for architects and designers. Understanding the importance of sustainable building solutions, UltraScape has focused its product development around delivering sustainable solutions.

A project at Friars Walk, Newport, used UltraScape’s BS 7533 compliant mortar to install over 10,000sqm of paving at this major shopping and leisure scheme. We supplied our product in 28 tonne bulk silos in order to reduce packaging waste. Our product and delivery helped the project in their aim of achieving a BREEAM rating of ‘Excellent’ for energy consumption.

All this support is delivered with the aim of maximising the life and performance of our products.

Our online Training Academy empowers learners to enhance their skills and get hands-on experience with our products, ensuring they use them in the most efficient and effective way. Through interactive sessions and tailored curriculum, participants can develop their expertise and take their knowledge to the next level.

37 people have registered for events.

In the last 12 months: Academy Days hosted.

5 Star feedback is Our attendance rates range from 54% to 88% head and shoulders above the industry standard. 798

88.40%

Recycling is a crucial component of the circular economy and is a vital tool in the fight to reduce landfill waste.

Through government promotion and increased accessibility, recycling has become the foundation of waste disposal. Recycling and other forms of recovery are now the most common final waste treatment, with 44.4% of UK waste being reused or recycled.

Since 2013, both household and commercial recycling

rates have stagnated. The UK government have set ambitious targets for waste management; by 2050 they want to have eliminated avoidable waste of all kinds, as well as aiming for all plastic packaging to be recycled and reusable by 2025. The UK annually generated 222.9 million tonnes of waste, of which around two thirds are produced by businesses.

52.3 million tonnes of this waste still ends up in landfill.

To protect natural resources and the environment we must strive to increase recycled rates at all possible moments.

“Our dedicated Health and Safety, Facilities, Purchasing and Quality Team continue to drive standards and compliance across our business. We are accredited with several international standards:

ISO 9001 for quality management

ISO 14001 for efficient environmental management

ISO 45001 for managing occupational health and safety risks and improve overall safety performance

RoSPA Membership (Royal Society for Prevention of Accidents)

We have a company car fleet consisting of 56 vehicles and change our vehicles every three years, so we benefit from the highest specifications available and most fuel-efficient technology.

96% of our fleet is petrol hybrid, with several vehicles also fully electric. Our team are now exploring long range electric vehicle options to assist in reducing C02 emissions and support our net zero journey. Our fleet is fitted with driver telematic technology to aid and support in more efficient driving behaviours and fuel consumption.

In addition, our car fleet is maintained and serviced to requirements and all drivers are made aware of the importance of correct tyre pressure and tread depth. We are continuing in our exploration into AI technology to manage out fleet more efficiently and for safety.

The management of our facilities and the high standards they are maintained to are paramount to our overall operational efficiency as a business. Whether it is gas, electric, water, heating, cooling, drainage, security, and safety, the team ensure every building is functioning as it should. There are daily audits and surveys completed across the sites each day to ensure any issues or concerns are addressed in a timely manner.

Health and Safety has a voice at Instarmac with several platforms where matters can be raised and discussed by every employee. This is achieved through 1:1 discussion with line managers, regular Health & Safety Committee meetings, weekly incident meetings, senior leadership management meetings and our online portal.

96% of our CAR fleet is petrol hybrid, with several vehicles also fully electric.

We collect pallets from our customers free of charge so they can be reused or recycled.

• Since 1st October 2021, our drivers have collected 84,325 pallets.

• That’s 758,925 tonnes of wood being recycled.

• That’s saved around 321,081 trees. That’s the equivalent of a 210 acre forest or 120 football pitches.

We are working hard with our packaging suppliers to introduce as much recycled content to our packaging as possible.

• All 5 litre bottles are now made with 100% recycled content.

• Over 86% of plastic packaging is now purchased with >30% recycled content.

• Completed registration to HMRC and reporting of plastic packaging.

All electricity is from renewable sources.

• 2022 saw the completion of over 1,656 solar module panels (3,707sqm) on our main factory roof to complement our 100% Renewable Energy Contract. Since being commissioned in February 2022, our average solar energy consumption is 27.2% YTD, with 4% returned to the grid. This state-ofthe-art system has so far spared the planet 702 tonnes of CO2 emissions.

• Improved intelligent lighting to reduce KwH usage.

• All interceptor tanks have been evaluated and upgraded so we can continue to flush toilets with rainwater harvested from the roof.

• Instarmac’s Sustainability Policy has been updated in line with the Company’s targets.

At Instarmac, we aim to provide a world-class and exceptional customer and employee experience. We want our employees to love what they do and for our customers to love what we do. We believe that the right strategy, a strong culture, and set of values drive continuity and empowers our employees to deliver excellence and give it their all.

Our genuine desire to be exceptional is evidenced in our forward-thinking and ambitious growth plans, and an unending desire to learn and develop new ideas and ways to improve the business. We also know great work can’t be done alone and we are stronger when we work together.

We have come a long way since our humble beginnings and over the years we have developed a unique culture and our values – Work Hard, Have Fun, Make a Difference – have stayed with us throughout our journey. This is the glue that keeps us together and is the foundation for everything we do and what we stand for as a business and a workforce.

Working hard means more than simply giving additional effort. It represents attitudes and desire. It reflects a ‘can do’ mentality, a willingness to roll up your sleeves, solve problems and a need to get the job done right. That is why we only employ the best people, operate to the highest standards, invest in our people, equipment, vehicles, provide a modern office, and state-of-theart manufacturing facility, so we can provide our employees and customers with the best.

Embedded in our culture is a sense of fun. A fun atmosphere encourages energetic, enthusiastic, employees who want to come to work each day and enjoy what they do in each other’s company.

We want to provide an environment where all employees feel safe, supported, and are treated fairly, with dignity and respect. We want all employees to feel engaged, listened to, and provided the best possible environment to achieve their full potential.

We want our workforce to be proud to be part of Instarmac Group plc, its future, and to live our values ‘Work Hard, Have Fun, Make a Difference.’

We sponsor employee engagement events and activities throughout the year that support this ethos. Together, working hard and having fun opens doors to achievement, success and fulfilment. It shows our potential, our character and our passion. They are proof that we care about what we do and who we are. We expect our employees to get involved, enjoy what they do and demonstrate their commitment to our company and to one another.

Instarmac provides a wealth of opportunities and possibilities through which anyone can make a difference every day. Whether it’s one person or one team, everyone has the capacity to create positive and lasting change. Every department plays an important role at Instarmac and every individual is empowered and trusted to do their job, to think outside the box, to challenge constructively in the interests of ‘can we do better’ and to grow and prosper.

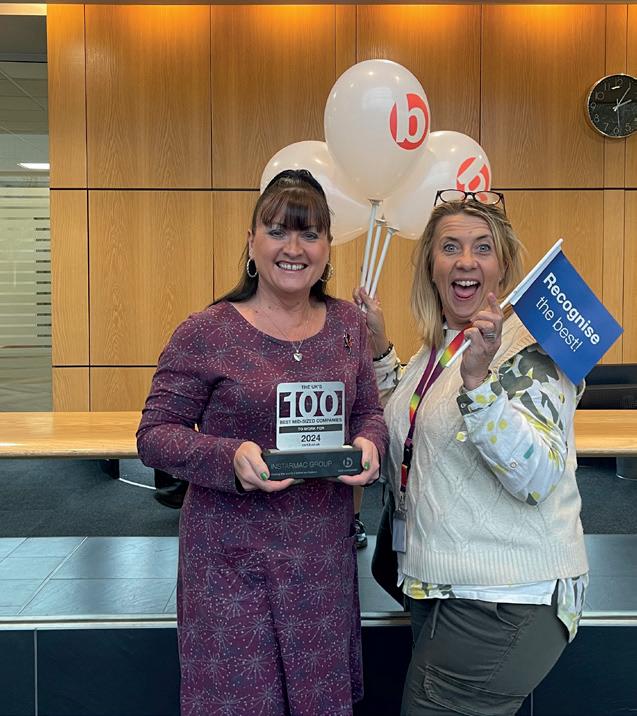

We are proud to have been awarded and recognised as a Top Five Manufacturer to Work For, an accolade only achieved by our employees telling us that we are a Great Place to Work® and a Best Company to Work For.

Check out our awards on our website to see how we measure up as an employer. Our people priorities are as follows: 1. Having the right people, with the right abilities, in the right place, at the right time and with the right motivation

4. Investment in an integrated HR, Payroll and Workforce Management System

At Instarmac we know that it’s our people with their unique backgrounds, skills, experience and knowledge who drive our ongoing success.

Every team member is trusted and empowered to apply their expertise, knowledge and experience to drive continuous improvement within our business. This approach drives a culture of accountability where any employee can question and challenge each other in the interests of improving our business, customer and/or employee experience.

We strive to attract, develop and retain a highly talented workforce and provide an inclusive and innovative workplace, providing opportunities for all employees to thrive.

EMPLOYEES 230

33% of Board of Directors are held by women

25% of our workforce is female

38% of Managerial/ Supervisory roles are held by women

All female employees are paid the same as men in the same roles

53% of our workforce is aged between 31 – 50 We value the importance of people continuity and the retention of expertise as this ensures we are able to continue to deliver an exceptional world class service to our customers.

Average employee age is 43

We are committed to making a positive and lasting contribution to our local community.

We take a proactive and committed approach to increasing the representation of local people in our workforce and currently 87% of staff live within a 15-mile radius of the Tamworth office.

87% of staff live within a 15-mile radius of

As a company that has ambitious growth plans, it is critical to future-proof our business to support our long-term business strategy.

We have a thriving learning environment with 2. High potential employees where individual The aim is to fill key roles effectively if a suitable post becomes available in the future.

Our Career Development Plan helps employees to take ownership of their development and in working towards their personal goals and aspirations to place them in the best possible position should a post arise in the future.

True leadership is not about position or job title, it is about the influence each of us has to impact the people and working environments that surround each of us every day, both at work and in our personal lives. Our Learning and Development pathway plans are bespoke and as individual as the learner. There’s no blanket, one size fits all, training around here! We have celebrated a 100% pass rate for all Apprenticeship Cohorts during 2024/2025, which included ILM Level 3, ILM Level 5, Marketing and IT courses. We regularly celebrate our learners’ successes throughout the year via event days, such as Learning at Work Week and National Apprenticeship Week, and not forgetting a very special Graduation Day!

In addition to our Leadership Development Framework, our ‘Next Steps’ programme supports managers and their teams to develop in their roles and for them to achieve their potential. This includes:

• Clear progression paths

• Succession planning

• Career development plans

• Wellness action plans

• Career consultations

• Giving and receiving feedback

• Role appreciation programme

• Factory to Fleet training programme

• Tailored development programmes including 360 feedback circles, personality profiling, secondments, additional responsibilities, assigned coach/mentor, gap analysis and ‘master classes’

• Internal programmes such as recruitment and selection, disciplinary and grievance investigations and absence management, coaching and mentoring

• Suite of e-learning modules which includes Mental Health Awareness to support managers and their teams

Learning and Development are key ingredients when enhancing a positive team environment where all individuals feel valued and effective in their role and their contributions appreciated along the way.

At Instarmac, we see the potential of supporting young people initiatives (such as work experience, apprenticeship and graduate programmes) to fulfil the short-term requirements of the business and the need to develop skills to prosper over the long-term.

Our employees remain our principal asset, our soundest investment, and our passport to the future.

Instarmac recognises the importance of having the right individuals in the right positions at the right time, and for them to be motivated to success in those roles.

Skills and Experience:

Recruiting individuals with the necessary skills, experience and capabilities.

Cultural Fit:

Ensuring that individuals align with the company culture and values.

Leadership Qualities:

For leadership roles, the right people should possess the traits and abilities to lead effectively and inspire teams.

Appropriate Role:

Individuals are placed in roles that match their strengths, interests and career goals.

Supportive Environment:

A positive and supportive work environment.

Resources and Opportunities:

Providing the necessary resources, training and opportunities for personal growth.

Opportunity Alignment:

Ensuring individuals are in a good position to take advantage of emerging opportunities.

Long-Term Perspective:

Considering the long-term needs of the business and the career aspirations of individuals.

Purpose and Meaning:

We want our employees to enjoy coming into work and to love what they do.

Autonomy and Control:

Providing individuals with the autonomy and control over their work.

Recognition and Reward:

Acknowledging and rewarding employees for the contributions. A positive and

We are passionate about continuous improvement and we invest in our people and provide a supportive workplace to help unlock potential through adopting the following approach:

• Operate real time performance checkins and feedback.

• Any employee can request or receive feedback from anyone in the business which are linked to our values.

• All employees have objectives that tie into our business goals. This ensures that individuals understand how their contributions fit into the bigger picture.

• Employees can also create and manage their own personal development and career plans, which provide a basis for conversations.

• Any employee can schedule a conversation with their line manager and vice-versa at any time. This might include a performance or wellbeing check-in, to a career conversation.

At Instarmac, hard work does not go unnoticed. Whether it’s a small token of thanks, or something more significant, such as a ‘Make a Difference Award’, it feels good to be rewarded for our efforts and achievements at work.

Through our Clear Review system, all employees are able to give and receive timely recognition. Being thanked in the moment creates a stronger, clearer and more positive association between the contribution made and the recognition received.

In our annual wellbeing and engagement strategy, there are regular activities to reward our employees and also get their kids involved, such as:

• Easter eggs

• Monthly food events

• Kids competitions through the year with prizes

• Summer and Christmas prize draws

• Bake Off competitions and quizzes

• Big ticket giveaways

• Christmas voucher

• Fun team building events

• Annual Holiday Home draws for our three holiday homes

In addition to this, we operate a number of recognition schemes to reward our employees hard work, such as:

• Refer a Friend – we know good people, know good people!

• Bright Ideas – we love getting bright ideas from our bright employees.

• Make a Difference Award – a special shout out for those that go above and beyond.

At Instarmac, hard work does not go unnoticed.

Employees have access to a suite of wellbeing support and an exceptional benefit package to show them how proud we are of their work, and how committed we are to supporting their wellness and wellbeing.

There is also a raft of selfhelp information on the employee portal in regard to all aspects of wellbeing, including financial wellbeing. Our Holiday Homes (at

Tenerife, St Ives and Padstow) provide all employees and their families the opportunity to take an affordable break, switch off and relax which prevents burnout and supports a healthy work/life balance.

“The lodge was absolutely lovely in a perfect setting. My family couldn’t believe that I (as an employee) got the lodge for free for a week. The furnishings in the lodge

are very nice. I will definitely be coming back to Padstow again. It certainly is the best lodge on site. The 4 of us really enjoyed the holiday and absolutely loved the lodge.”

By focusing on these elements, we will ensure we are providing a more effective and fulfilling work environment, leading to increased productivity, innovation, and employee satisfaction.

We know that ‘a little kindness can go a long way’ and this is true. As a company who strives to be an employer of choice, we understand that our teams want a greater sense of wellbeing, and to be part of something that matters, and so we actively aim to provide opportunities to contribute beyond daily work activities. Giving something back is at our heart, we never forget our humble beginnings. Making a difference stands not only in our work ethic and values but extends to our local communities too.

We are always looking to explore new ways in which we can help support others and charities within our local area that can often get overlooked for funding. It’s a great way for our team to get to know the wider community and strengthen social connections. We want to support causes that make a real difference, and we particularly focus on supporting charities and organisations that have an impact in the communities our employees reside.

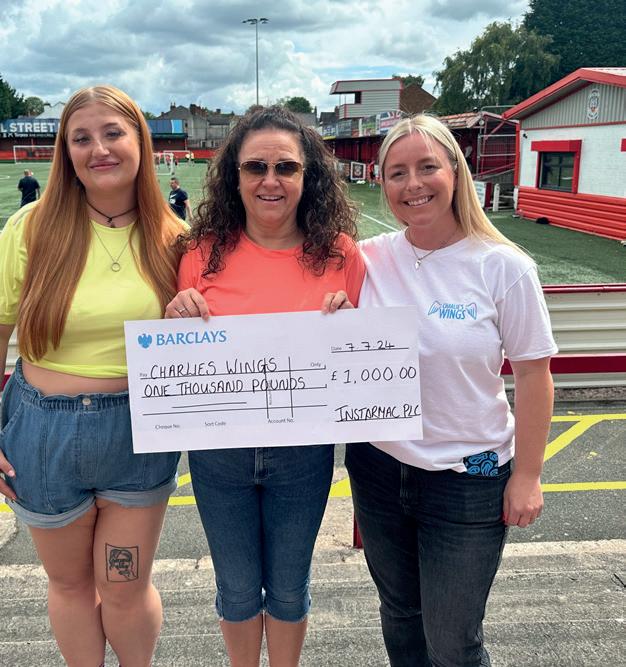

We support a broad range of charities in a variety of ways, whether that is through regular donations, sponsorship, access to our product, services or people, or through having the use of one of our holiday homes for those that need it the most.

Instarmac proudly operates an employee Charity Committee, which meets four times a year to oversee the distribution of donations and match funding requests to ensure they meet our Charity Giving policy. The Charity Committee is given an annual budget which is broken down to a quarterly amount to award those charities that are important to our employees.

In addition, Instarmac has also generously donated £25,000 to the Help Harry Help Others Cancer Charity – an organisation dedicated to supporting adults and children affected by cancer. In 2015, the Help Harry Help Others team opened the first drop-in cancer support centre of its kind in Birmingham and we were honoured to donate £25,000 towards the running costs of this essential centre for the second year running.

Our future aim is to have established charity partners who can provide our colleagues with valuable opportunities for education, raising awareness, meaningful selfdevelopment and team building through volunteering, creative campaigning and fundraising for causes that are important to them.

We spend a third of our lives at work, so it’s safe to say it has a huge impact on our quality of life. It’s important for employees to enjoy coming into work and enjoy what they do.

Here at Instarmac, a great workplace community starts from day one to create the sense of belonging and connection that’s crucial to all of us. That is why we share our 3 year strategy with all our new starters so they can understand how their contributions fit in and how they can make a difference.

We aim to provide an environment of shared purpose and mutual trust where:

• Every employee is respected and listened to

• Feedback and participation are encouraged

• Teams collaborate and work together towards common goals

• Employees are equipped with the tools, resources, and training to get the job done

• Knowledge is shared freely, and team members support each other

• Communication is open and transparent

• People have opportunities to connect and socialise with colleagues in fun and relaxed ways

We believe in having a sense of community and giving something back, and that is why we are committed to recruit from our local and surrounding areas, promoting our job opportunities through our website, social media, recruitment agencies and job boards, along with employee referrals. We are also passionate about supporting work experience, apprenticeships and graduate schemes, and in supporting our local schools to get students ‘job ready.’

We believe people continuity is integral to success. To attract and retain talent, it is more important than ever that Instarmac are seen as a local employer of choice and our employee value proposition is unrivalled.

Instarmac has always had an exceptional benefit package as outlined as follows:

• Private medical cover

• Dental cover

• Life cover

• 5% - 7.5% company pension contribution

• Annual leave up to 29 days

• Performance and Profit Related Pay bonus

• Free use of three holiday homes

• Holiday home fuel and flight contributions

• Recognition Awards – Long Service, Make a Difference, Refer a Friend, Bright Ideas

• Employee Benefit Trust (discretionary hardship fund)

• Group Income Protection Policy

• Virtual GP services

• Second medical opinion service

• Rehabilitation service to support ‘stay at work’ plans

• Employee Assistance Programme

• AXA Wellbeing app

• Thrive Health Assured app

• My Healthy Advantage app – setting health goals and achievements

• WorldAware app

• Free 1:1 appointments with Financial Advisor

• Monthly incentives when we hit our sales targets

Employee health and wellbeing is extremely important to us and that is why we offer a suite of wellbeing support to all employees. In addition to the exceptional benefits package, we are passionate about raising awareness and we do this through our very successful employee portal which holds lots of resources, tools, information to support employees and we facilitate initiatives throughout the year.

We are looking forward to forming a wellbeing committee who can help shape our wellbeing plans to ensure that this is aligned with what employees want and/or need.

We encourage staff to openly discuss their concerns, worries or ideas, and have increased the number of Mental Health First Aiders so employees should never feel alone and always have someone to talk to regardless of their role or working pattern.

We believe people continuity is integral to success.

Employee voice is key and we operate a number of forums in which views can be obtained, from team meetings, check-ins and our employee survey to name a few.

As part of our growth, it is important to streamline and automate business processes and to support our sustainability commitments. The investment in a new HR and Payroll system will drive many efficiencies and from a sustainability perfective has/will enable us to:

• Reduce paper usage with a self-service portal that automates leave requests, personal detail updates, and the onboarding process - this will save of 5000 pieces of A4 paper every year!

• Continue the transition from paper HR administration to a HR digital system, where most documentation will be retained electronically.

• Adopt eco-friendly recruitment approach through a centralised Applicant Tracking System and automated management of CV handling of applications and the creation of talent pools.

As a manufacturer and supplier of tile adhesives, cementitious, resin and bitumen-based specialist construction materials, Instarmac is committed to ensuring the health, safety and welfare of our employees and recognises that the effective management of health and safety is an integral part of our overall business performance.

To address the risks of our operations, we employ a health and safety management system. Through this, we will identify any significant risks and set clear objectives, against which we will monitor and manage our health and safety performance and legislative compliance.

Giving employees a voice and the platform to raise any safety issues they have is integral to keeping everyone safe at Instarmac. With this in mind, our Health and Safety Committee meets once a month to discuss and solve any issues colleagues may have. We are dedicated to ensuring our staff have all the necessary equipment and training to be able to complete their jobs as safely as possible.

As a manufacturer with extremely busy warehouse, production and transport facilities, we know that we need to pay special attention to ensure colleagues working in areas most at risk are kept safe. We are continually assessing and improving procedures and have lowered the speed of our forklift trucks. This has resulted in a significant improvement in the reduction of near misses and incidents without impacting on efficiency.

This ISO standard sets out the requirements for occupational health and safety management good practice. Its aim is to eliminate or minimise operational risks and hazards in order to create the best possible working conditions for our employees. We also work with Occupational Health and Rehabilitation Services to ensure our staff are kept safe and well.

The 27001 ISO standard sets out the requirements needed to safely secure, record, store, transmit and handle data. The standard outlines industry best practice, in order to minimise the risk of losing or mishandling data.

We are committed to meeting the FORS standard (Fleet Operators Recognition Scheme). This is all about keeping our drivers, and other road users safe.

To show empathy, understanding and support for vulnerable road users (e.g. cyclists), our drivers are committed (via the FORS Standard) to attend a Safe Urban Driving Course, which places the driver in the position of the cyclist, allowing them a better understanding of the dangers they face on our very busy roads. We carry out this important training every 5 years – helping to keep our drivers and road users as safe as possible.

Giving employees a voice and the platform to raise any safety issues they have is integral to keeping everyone safe at Instarmac.

All our fleet are now equipped with:

• Left turn audible alarms to let cyclists and pedestrians know a vehicle is turning

• Front facing and recording camera

• Near side sensors to alert the driver when something is passing on the near side

• Reversing cameras to act as an aide when manoeuvring the vehicle in a reverse action

• Reversing alarms

• Fresnel lenses on all glass panels on the near side door

• EAP card in every vehicle so that our Drivers can access support whenever they need it

• Ethical trading

• Health and safety

• Modern slavery and human trafficking

• Equality

• Whistleblowing

• Bribery

• Privacy

Whilst we are proud of all that we have achieved, as a company we are ambitious and seek to be the best that we can be. With this in mind we have set ourselves ambitious targets for the years to come focusing on the three key areas:

The targets reflect both short and long term goals and seek to have a range of constructive effects. From reducing our carbon footprint, to raising awareness of mental health issues, our targets are reflective of our desire to have a well-rounded impact that is positive for our staff, our customers and wider society.

Our Next Steps: Building a Stronger, Data-Led Sustainability Framework

1. Centralising Sustainability Data

We are implementing a centralised data system to consolidate environmental performance data across departments and internal systems. This will reduce manual work, improve data quality, and enhance our ability to respond to client and regulatory reporting requirements.

2. Carbon Footprinting and Emissions Baseline

We are undertaking a full organisational carbon footprint assessment. This baseline will help us measure the impact of existing initiatives and inform realistic emissions reduction targets in line with science-based approaches.

3. Setting Science-Based Targets (SBTs)

In response to increasing client and industry expectations, we will define and submit Science-Based Targets (SBTs) to establish a credible, externally validated path to Net Zero. These targets will align with the latest climate science and support long-term value creation.

4. Quantifying Impact of Existing Initiatives

We will conduct performance audits on our current sustainability measures— including solar panels, rainwater harvesting, and energy-efficient infrastructure—to understand their true carbon reduction value and enhance future investment decisions.

5. Improving SECR and ESG Reporting

We are upgrading our compliance process for SECR and other frameworks through automation and integration, ensuring reporting is accurate, efficient, and less reliant on manual inputs. Future ESG communications will be underpinned by verified data to improve transparency and trust with our clients and industry partners.

6. Delivering Tangible Results

We are shifting from high-level sustainability messaging to verifiable results. Through data-driven reporting, lifecycle analysis, and third-party verification, we aim to show measurable progress toward our environmental goals.

We know the road to Net Zero is complex — but we are committed to the journey. Our strategy is evolving to meet both the scale of the climate challenge and the expectations of our forwardthinking customers.

Instarmac is not just reacting to pressure—we are proactively building a sustainable business fit for the future. Through transparency, investment, and collaboration, we will turn ambition into action and ensure our legacy is one of progress and accountability.

Instarmac is not just reacting to pressure—we are proactively building a sustainable business fit for the future.

Head Office

Danny Morson Way

Birch Coppice Business Park

Dordon, Tamworth

Staffordshire, B78 1SE

enquiries@instarmac.co.uk

t: +44 (0)182 725 4400

www.instarmac.co.uk