Visionaries Driving Additive Manufacturing MichaelWayne

Throughtheirexpertise,theseinnovatorsareaddressing someoftheworld’smostpressingchallenges,from reducingmaterialwastetodecentralizingproductionand enablingrapidprototypingatanunmatchedscale.Their contributionsarenotonlyreshapingsupplychainsbutalso unlockingnewpossibilitiesforpersonalizedhealthcare, lightweightaerospacecomponents,andsustainable constructionsolutions.

Thiseditionisatributetotheirrelentlesspursuitof progress.Weinviteyoutoexploretheirjourneys,insights, andgroundbreakingachievements.Astheworldembraces thepotentialofadditivemanufacturing,theseleaderswill beattheforefront,shapingthefutureofhowwedesign, build,andcreate.

Dr. Nesma Aboulkhair

Pioneering the Future of Advanced Manufacturing

Decade of Industrial Transforma�on The Evolu�on of Addi�ve Manufacturing Technology

Combining Tradi�onal and Addic�ve Manufacturing Technology in Modern Industries

PoojaMBansal Editor-in-Chief

CONTENT

Deputy Editor Anish Miller

Managing Editor Prince Bolton

FOLLOWUSON WE ARE ALSO AVAILABLE ON

www facebook.com/ciolook/ www.x.com/ciolookmagazine

DESIGN

Visualizer Dave Bates

Art & Design Director Davis Mar�n

Associate Designer Jameson Carl

SALES

Senior Sales Manager Wilson T., Hunter D.

Customer Success Manager Nelson M.

Sales Execu�ves Tim, Smith

TECHNICAL

Technical Head Peter Hayden

Technical Consultant Victor Collins

CONTACTUSON

Email info@ciolook com

For Subscrip�on www.ciolook.com

Copyright © 2025 CIOLOOK, All rights reserved. The content and images used in this magazine should not be reproduced or transmi�ed in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without prior permission from CIOLOOK. Reprint rights remain solely with CIOLOOK.

Research Analyst Eric Smith

SEO Execu�ve Alen Spencer

FeaturedPerson

DrNesmaAboulkhair

Director-Additive Manufacturing

GuhaManogharan

AssociateProfessor

Prof.PauloJorgeDa SilvaBartolo

ExecutiveDirector, SingaporeCentre for3DPrinting

SamAnand

DirectorofCenterfor GlobalDesignand Manufacturing

SandraCabeza scientist

CompanyName

TechnologyInnovation Institute(TII) tii.ae

ThePennsylvania StateUniversity psu.edu

NanyangTechnological University,Singapore ntu.edu.sg

CollegeofEngineeringand AppliedScienceCincinnati, ceas.uc.edu

InstitutLaue-Langevin psill.eu

Brief

Aboulkhairspecializesinadvancingadditivemanufacturing technologies,focusingoninnovativematerialsandprocesses forvariousapplications.

Manogharanisknownforhiscontributionstoadditive manufacturingandengineeringeducation,fosteringinnovation throughresearchandcollaboration.

Bartoloisaleadingexpertinadditivemanufacturingand biomanufacturing,recognizedforhisextensiveresearchand numerouspublications.

Anandisanaccomplishedresearcheringlobaldesignand manufacturing,emphasizingsustainablepracticesandthe integrationofadvancedtechnologiesinproductdevelopment.

Cabezaisascientistdedicatedtoexploringnewmaterialsand methodsinadditivemanufacturing,enhancingcapabilitiesin variousindustrialsectors.

“ “ “ “

Prof.PauloJorge

DaSilvaBartolo

DirectoroftheSingapore

Centrefor3DPrinting

NanyangTechnological

UniversitySingapore

Shaping Manufacturing Future!

3Dprintinghastransformedremarkablyoverthepast

fewdecades,emergingasacoreofmodern manufacturingandbiomanufacturing.Initially developedforprototyping,3Dprintingnowencompasses anarrayofapplicationsfromindustrialproductionto biomedicalinnovations,whereitenablesprecisetissue engineeringandregenerativemedicinesolutions.Its evolutionisdrivenbycontinuoustechnological advancements,withadditivemanufacturingtechnologies enablingthecreationofintricate,functionalpartsacross multiplesectors.Theindustry'sshifttowardsustainability andmaterialefficiencyalsohighlightsitspotentialto addressglobalchallenges,suchasreducingwasteand promotinglocalizedproduction.

Prof.PauloJorgeDaSilvaBartoloisadistinguished leaderinthefieldof3Dprinting,currentlyservingasthe DirectoroftheSingaporeCentrefor3DPrinting.His expertiseandvisionaryapproachhavesignificantly influencedthedirectionofadditivemanufacturingand biomanufacturing.Throughhisinnovativeresearchand collaborativemindset,Prof.Paulohasplayedakeyrolein advancingnewtechniquesandsystems,pushingthe boundariesofwhatispossibleintheindustry.His leadershipismarkedbyanopennesstonewideasanda constantdrivetoexplorethepotentialthat3Dprinting offersforsolvingsocietalchallenges.

NanyangTechnologicalUniversitySingapore,hometo theSingaporeCentrefor3DPrinting,hasbecomealeading researchinstitutionintheAsia-PacificregionunderProf. Paulo'sdirection.Theuniversityhasexpandeditsresearch initiativesinmetaladditivemanufacturing,sustainable production,andbioprinting,earningareputationasaglobal hubforinnovationin3Dprintingtechnology.By cultivatinginnovativeresearchandcollaborations,the universitycontinuestomakeextensivecontributionstothe futureofmanufacturing,enhancingitspositionasaworldclassinstitutioninthefield.

Let’s delve into Prof. Paulo’s remarkable journey in the field of 3D printing:

Innovationsin3DPrintingandBiomanufacturing

Prof.Paulo’scareerbeganin1992whenhewascompleting hisMechanicalEngineeringdegreeattheInstitutoSuperior Técnico(IST),UniversityofLisbon,Portugal.Duringthis time,hepreparedanessayonrapidprototypingfora

“Welding and Casting” unit,asubjectthatwasrelatively new,withthefirstpatentfromCharlesHulldatingbackto theearly1980s.

Thissparkedhisfascinationwithadditivemanufacturing,a fieldhehasremainedcloselyconnectedtoeversince.A yearlater,atIST,hebeganworkingwithabasicplastic lamination-type3DprintingsystemprovidedbyaSwedish company,whichsoondisappearedfromthemarket.Atthe time,additivemanufacturingwasinitsinfancy,andthe focuswasonexploringitspotentialforproducing architecturalmodels,thoughthesystemhadseveral limitations.

Prof.Paulostartedamaster’sdissertationonadditive manufacturing,intendingtouseavat-photopolymerization systemthattheUniversityofLisbonplannedtoacquire. However,delaysinitspurchasepreventedfurtherprogress. In1997,afterjoiningthePolytechnicInstituteofLeiria (Portugal)in1994,hereceivedagrantfromthePortuguese FoundationforScienceandTechnology(FCT)topursuea PhDattheUniversityofReading,UK,focusingonadditive manufacturing.

HisPhDdissertation,titled “Optical approaches to macroscopic and microscopic engineering,” developedthe theoreticalbasisforanewphotofabricationsystem.This systemusedopticalandthermaleffectstoinducephase changesinliquidphoto-curableresinto"write"complex 3Dshapesinsidethepolymervat.Additionally,he developedathermal-kineticmodeltosimulatethephysical andchemicalchangesinthematerialinfluencedby radiationandheat.

Between1994and2014,Prof.Pauloheldvariousrolesat thePolytechnicInstituteofLeiria,wherehestartedhis academiccareerasalecturer.HeservedasHeadofthe MechanicalEngineeringDepartment(2001-2009), PresidentoftheResearchAssessmentCommission(20092013),PresidentoftheScientificCounciloftheInstitutefor Research,Development,andAdvancedStudies(20092013),MemberoftheAcademicCouncilandSenate(20092013),Co-DirectoroftheExecutiveCommitteeofthe CentreforPost-GraduateStudies(2004-2006),andMember oftheScientificCounciloftheSchoolofTechnologyand Management(2001-2011).

From2007to2014,hewastheDirectoroftheCentrefor RapidandSustainableProductDevelopment(CDRSP), whichhefoundedin2007.CDRSPbecamethefirst researchcenterinPortugaldedicatedtoadditive

manufacturing,gaininginternationalrecognition.In2013, helaunchedthePortugueseAdditiveManufacturing Initiative(PAMI),fundedbythePortugueseGovernment andpartoftheNationalRoadmapforPortugueseResearch Infrastructures.

AtthePolytechnicInstituteofLeiria,Prof.Paulofounded theInternationalConferenceonAdvancedResearchin VirtualandPhysicalPrototyping(VRAP)in2003,which becamealeadingglobaleventinthefield.Healsoinitiated otherconferences,includingtheECCOMASThematic ConferenceonTissueEngineering(ICTEConference)and theInternationalConferenceonSustainableIntelligent Manufacturing(SIMConference).In2005,heestablished thePortugueseRapidPrototypingAssociation,representing PortugalintheGlobalAllianceofRapidPrototyping Associations(GARPA).Healsoplayedakeyrolein launchingtheVirtualandPhysicalPrototypingJournal, servingasEditor-in-Chiefuntil2018.

InLeiria,hedevelopedvariousadditivemanufacturing systems,includingaMultimaterialBioextruder,Biocell Printing,aninsituskinprintingsystem,andtheRapid PrototypingbyReactiveExtrusion(RapidPRE)system.

Thesesystemsadvancedfieldssuchastissueengineering, biomanufacturing,andlarge-scaleplasticpartfabrication.

In2014,Prof.PauloacceptedapositionasChairProfessor attheUniversityofManchester’sSchoolofMechanicaland AerospaceEngineering(MACE),wherehefocusedon developingbiomanufacturing.Heheldseveralleadership roles,includingIndustry4.0UniversityAcademicLeader andHeadoftheManufacturingGroup.

Healsocontributedtoseveralinitiatives,includingthe DigitalFuturesprogramandtheAdvancedMedical Materials@Manchesterplatform.Hisresearchat ManchesterincludedthedevelopmentofthePlasmaAssistedBioextrusionSystem(PABS),whichcombined multi-headextrusionprintingandplasmasystemsfor biomaterialprocessing.

HealsocollaboratedwithMatokeHoldingsonwound dressingswithenhancedantibacterialandregenerative properties,resultinginseveralpatents.Heplayedakeyrole inlaunchingthe "Textiles Circularity Centre: Circular Bioeconomy for Textile Materials," focusingonmaterial circularityandinnovationintheUK’smanufacturingsector

Since2021,Prof.PaulohasbeenChairProfessoratthe SchoolofMechanicalandAerospaceEngineering(MAE) atNanyangTechnologicalUniversity(NTU),Singapore, wherehealsoservesasExecutiveDirectoroftheSingapore Centrefor3DPrinting(SC3DP)andProgrammeDirector oftheNationalAdditiveManufacturingInnovationCluster (NAMIC)HubatNTU.

Underhisleadership,SC3DPexpandeditsresearch activitiesandbecamealeadingresearchcenterinadditive manufacturingintheAsia-Pacificregion.Hehasbeen involvedinprojectsrelatedtometaladditive manufacturing,sustainablemanufacturing,bioprinting,and foodprinting.Prof.PauloalsolaunchedtheInternational ConferenceonDesignfor3DPrinting,whichhehas chairedsince2022.

Currently,heisdevelopinganewmetallaser-basedpowder bedfusiontechnologycapableoffabricatingmulti-metal partsandfunctionallygradedstructures,representinga breakthroughinmetaladditivemanufacturing.

PromotingCreativityandInnovation

Theabilitytocreatetotallynewanduniqueproducts,to designnovelmaterialstailoringtheirpropertiesinentirely newways,andtheabilitytodevelopnewsolutionsand productsclosetothepointofuse,promotingcreativityand innovationwithsignificanteconomicandenvironmental advantages,inspiredhisfocusonAdvancedManufacturing and3DPrintingthroughouthiscareer.

MaximizingTeamPotentialandMotivation

Prof.Paul’sapproachtoleadingaprominentcenterfor3D PrintingresearchandinnovationatNanyangTechnological Universityinvolvesbeingopentonewchallengesand availabletolistentopeoplewhoworkandcollaboratewith thecenter,contributingtotheestablishmentofacreative environment.Heavoidssaying“no”butinsteadlooksfor solutionsoralternatives.

Byknowingthestrengthsandweaknessesofall collaborators,heprovidesallthenecessarymeansto maximizetheirpotential,pushing,motivating,and stimulatingthem.AcenterliketheSingaporeCentrefor3D Printingneedstohavestate-of-the-artequipment,butits greateststrengthliesinitspeople,itsideas,itsabilityto imaginethefuture,anditsabilitytousetechnologyto providesolutionsaddressingkeytechnological,economic, social,andenvironmentalchallenges.

“ “ “ “

Finally,hepromotescollaborationsandresearch partnershipswithotherresearchcenterswithinNanyang TechnologicalUniversity(NTU),Singapore,andoutside NTU,workingtogetherandembracingnewandrewarding opportunities,aswellashostingresearchersfromallover theworldtosharenewexperiences,ideas,andknowledge.

TacklingIndustryandSocietyChallenges

Teamwork,collaboration,andinterdisciplinarityhave alwaysbeenfundamentalpillarsinProf.Paulo’scareer The successhehashadthroughouthiscareeristheresultofthe work,dedication,andenthusiasmofallthepeople, colleagues,andstudentswithdistinctbackgroundsfrom differentpartsoftheworldwhoworkedorhavebeen workingwithhim.Withouttheirsupport,hiscareermight certainlyhavebeendifferentandmuchlessattractive.

Inaway,hehasbeenshapedbythosearoundhimwho workedwithhim.Collaborationandinterdisciplinary researcharealsovitalinallfields,particularlyinthe additivemanufacturingandbiomanufacturingfields.The successoftheResearchCentreshelaunched,ortheCentre heisleadingtoday,wasbasedonthecollaborationofmany, bringingexpertisefromdifferentareasofknowledge,thus creatinginnovativeandcreativeresearchenvironments allowingtotacklethechallengesfacedbyindustryand society

OvercomingKeySocietalChallenges

TheInternationalAcademyforProductionEngineering (CIRP)hastheambitiontobeatthetopofadvanced manufacturingtechnologies.AtCIRP,theyareconstantly discussinghowtodevelopandpushthelimitsofadditive manufacturingandotheradvancedmanufacturing technologiestoovercomekeychallengesfacingsociety today

Thisambitionhasbeensupportedbyseveraldedicated workinggroupsbringingtogetheracademicswithdifferent expertiseandindustrialists.Keyaspectsbeingaddressedare related,amongothers,tosustainability,mass personalizationandcustomization,costreductionof materials,machines,andproducedparts,standardsand qualifications,andtraining.

Achallengeandanexcitingopportunityarerelatedtothe convergenceoftechnologies.Thisincludesnotonlythe integrationofmultiplemanufacturingtechnologies, includingdifferentadditivemanufacturingtechniquesbut

alsotheintegrationofadditivemanufacturingandother digitaltechnologies(e.g.,artificialintelligence,theInternet ofThings(IoT),blockchain,etc.).

Thisintegrationhasbeenusedforin-processmonitoring, materialsdesign,predictivemaintenance,andthe developmentofdigitaltwinsforprocessoptimization, predictingbehaviorsofparts,machines,oroperators,and decision-making.Significantprogressisexpectedinthe future,allowingforsmarter,moreefficient,accurate,and reproduciblesystemstosupportmaterialsandparts traceabilityandsupplychaintransparency

Besides,thisconvergenceoftechnologiesisopeningnew frontiersformaterialdevelopment(e.g.,smarterandmore energy-efficientmaterials)andforprocessingdifferent familiesofmaterialsinasinglemachine. Overall,thisconvergenceoftechnologieswillkeep changingthewaywethink,design,build,anddelivera product.

RecognitionforResearchandInnovation

Amongthevariousawardshereceived,excludingthe variousteachingawardshewonovertheyearswitha specialmeaningforhim,helikestohighlightfourawards. Firstly,twoawardsweregivenbytheLeiriaCityCouncil, thecitywherehegrewupandstudieduntilhewenttothe university,wherehestartedhisacademiccareerand dedicated20yearsofhisprofessionallife,namelyin2009, theAfonsoLopesVieiraawardonResearchandInnovation, andthecityofLeiriaMedalofMeritin2022,todistinguish hiscareerandhisnationalandinternationalachievements.

Secondly,theGoldMedalofMeritofthePortuguese CommunitiesfromthePortugueseGovernment distinguishesindividualswhoprovidedoutstanding contributionstopromotetheculture,values,language,and prestigeofPortugalinternationally.Thislastawardhasa veryspecialmeaningtohimashehasbeenworkingoutside Portugalsince2014.

Finally,theKobayashiAward,namedafterProfessorAlbert KobayashiattheUniversityofWashington,whomade significantcontributionstoresearchandeducationin experimentalmechanicsforover50years,distinguishes individualsforworthycontributionsinthecategoryof experimentalscience.

Thisawardacknowledgeshiscontributionstothedesign anddevelopmentof3D-printedbiologicalconstructsfor tissueengineering,anareatowhichhededicatedmostof hisworkoverthelast15years.

Finally,thetwocommendationshegotalsohaveaspecial meaningforhim.Hereceiveda2015commendationfrom thePortugueseGovernmentforhiscontributiontothe ResearchandInnovationareasanda2014commendation hegotfromthePolytechnicInstituteofLeiriaafterserving for20years.

MentorshipwithIntegrityandDedication

Prof.Pauloprioritizesacultureofwork,integrity, dedication,respect,inclusivity,diversity,andteamwork valuesinmentorship.Asamentor,healwaystriestobring outthebestineachpersonandtounlocktheirpotential, developingtheircriticalspirittheirsenseofresponsibility, encouragingcuriosity,perseverance,andrisk-taking,as wellasthedrivetocontributetoabetterworldandthe abilitytolearnfromfailure.

EmpatheticandInspiringLeadership

Helikestoberememberedassomeonewithempathy, inspirationandmotivation,abletounlockthebestofthose whoworkwithhim,someonewithinitiative,dedication, andpassionforscienceandengineering,andatrueleader, leadingbyexample.Hefeelsluckytohavebeen surroundedbyfantasticpeopleandtohavebuiltexcellent researchteams.

Hisvaluesandvisionhavebeentransmittedtohismultiple students,whopresentlyhaverelevantrolesinindustryand academia,soheissuretheywillbeabletotransmitthe samevaluesandvisiontostudentsandcolleagues,which willbehislegacyformanyyearstocome.

EnjoyingLeisureActivitiesBeyondWork

Outsideofhisprofessionalendeavors,Prof.Paulolikesto travelanddiscovernewplacesandcultures.Untilnow,he hashadtheprivilegeofvisitingaboutsixtycountries globally.Hereallyenjoyscinemaandlisteningtomusic,as wellasreadingnewspapersandbooks,especiallythose relatedtohistoryandpoliticalscience.

OptimismandConfidencefortheFuture

Hebelievesmilestonesaregoodopportunitiesforpersonal andprofessionalgrowth.Hisfirstsignificantmilestone happenedinMay2007whentheCentreforRapidand SustainableProductDevelopmentinPortugal,ofwhichhe wastheDirector,wasclassifiedasaCenterofExcellence bythePortugueseFoundationforScienceandTechnology.

Prof.Pauloalwayshadaproactiveandopenmindtoward change,whichwasacatalystforseekingnewchallenges andsettingfreshgoals.Thenextmilestoneoccurredwhen hewaselectedCIRPFellowandmovedtotheUniversityof ManchesterasaFullProfessor,whichprovidedadditional motivationtokeepgoingforward.Itwasatimenotonlyfor celebrationandexcitementbutalsotoreflectandlearn,to beopentochangeandnewopportunities.

ThelastmilestonetookplacewhenhemovedtoSingapore tobetheExecutiveDirectoroftheNTUSingaporeCentre for3DPrinting.Thishasbeenasignificantandrewarding milestone;itisveryinspiringtobesurroundedbyagreat teamandasupportiveenvironment.Together,witha passionandcommitmenttodriveimpact,theyapproachthe nextyearswithenergyandenthusiasm,lookingforwardto thefuturewithoptimismandconfidence.

“Additive manufacturing is transforming the way we design, manufacture, and consume products.”

“

Dr. Nesma’s leadership is defined by her commitment to advancing technology and her ability to inspire and guide teams toward pioneering breakthroughs.”

Dr.NesmaAboulkhair Director-Additive Manufacturing TechnologyInnovation Institute

Dr. Nesma Aboulkhair

Pioneering the Future of Advanced Manufacturing

Additivemanufacturing,acutting-edgeapproachin

themanufacturingsector,isredefininghow productsaredesigned,created,andbroughtto market.Thistechnology,alsoknownas3Dprinting,is transformingvarioussectorsbyenablingthecreationof complexstructuresthatwereonceimpossibletoproduce withtraditionalmanufacturingmethods.Thecontinuous advancementofthisfieldispushingboundaries,driving innovation,andopeningnewavenuesforindustriesranging fromhealthcaretoaerospace.Astheindustrymatures,it playsacrucialroleinaddressingcontemporarychallenges suchasresourcescarcity,environmentalimpact,andthe needforagileproductionsystems.

Dr.NesmaAboulkhair,aprominentfigureinthis transformativefield,servesastheDirectorofAdditive Manufacturing.Sheisrecognizedforherdeeptechnical expertiseandrelentlesspassionforadvancingthescience andapplicationofadditivemanufacturing.Dr.Nesma’s leadershipisdefinedbyhercommitmenttoadvancing technologyandherabilitytoinspireandguideteams towardpioneeringbreakthroughs.Herworkpushesthe technicalboundariesofadditivemanufacturingandfocuses onmentoringthenextgenerationofspecialists,ensuring thatthefieldcontinuestoevolveandthrive.

AttheTechnologyInnovationInstitute(TII)inAbu Dhabi,Dr.Nesmaleadsinitiativesthatbridgethegap betweenfundamentalresearchandpracticalapplicationsin additivemanufacturing.Underherguidance,TII’sadditive manufacturingdivisionhasbecomeahubforinnovation, wherecutting-edgetechnologiesaredevelopedand exploredtomeetthespecificneedsofindustries.The company’sworkinthisareaishelpingsolidifytheUAE’s positionasaleaderinadvancedmanufacturing, contributingtothenation’sbroadergoalsoftechnological advancementandeconomicdiversification.

Let’s explore Dr. Nesma’s transformative journey in the manufacturing sector:

LeadingAdditiveManufacturingInnovations

Dr.Nesmaisamechanicalengineerspecializingin materialsandmanufacturingthroughtraining.Eversince

shewasalittlekid,shehasalwaysbeenintriguedbyhow thingsaremade.WhenshefirststartedherPhDin2012at theUniversityofNottingham(UK),shewasfocusedon naturalfiber-reinforcedcompositesuntilshesatinonatalk titled‘AdditiveManufacturingofMetals.’Thetopic instantlycaughtherattentionbecauseshehadneverheardof thisapproachtomanufacturing.

ShewassointriguedthatshedecidedtochangeherPhD topictostudythiscaptivating,yetatthetimeundeveloped, manufacturingtechnology.ShecompletedherPhDin additivemanufacturingofaluminumalloysandthenworked attheUniversityonvariousothermaterialsforayearorso. In2017,shewasawardedtheprestigiousAnneMcLaren Fellowshiptofocusonanewmetaldrop-on-demand technology(MetalJet).

Attheendofit,shebecameanAssistantProfessoratthe Universitywheresheenjoyedboththeresearchaspectof additivemanufacturingaswellasteachingthenew generationsabouttheenormousopportunitiesitunfoldsand passingontheinspiration.In2021,shemovedtotheUAE tostartandleadanadditivemanufacturingteamatthe TechnologyInnovationInstitute(TII)inAbuDhabi.

Sheisveryproudofherjourneydiscoveringadditive manufacturingandhasbeenblessedtobuildastrongtrack recordofscientificpublications,funding,andkeynotesat internationalconferencesandreputableinstitutions.

EmpoweringFutureManufacturingSpecialists

Dr.NesmacurrentlyservesastheDirectoroftheAdditive ManufacturingDivisionatAbuDhabi’sTechnology InnovationInstitute(TII).TIIisaleadingglobalR&D companydedicatedtopushingthefrontiersofknowledge andispartoftheEmirate’sAdvancedTechnologyResearch Council(ATRC),whichoverseestechnologyresearchinthe capital.

Fromatechnicalperspective,sheisresponsibleforleading theadditivemanufacturingactivitieswithinthecompany. Theseactivitiesfallunderfourverticals:Processes, Materials,Design,andDigitizationandApplications.Itis importanttonotethattheirworkbridgesthegapbetween

thefundamentalscienceandtheappliedresearchforuse casesthataddressspecificpainpointsofaclientorend user

Togetherwithherteam,shehasestablishedastate-of-theartadditivemanufacturinglaboratorywithfacilitiesfor manufacturing,post-processing,andcharacterization, whichisnowcompletedandfullyoperational.Sheworks closelywithkeyplayersintheUAE’slocalindustry, providingthemwithsupportandbusinesssolutionsthat meettheiradvancedmanufacturingneeds.

Shealsomanagesateamofresearchers,empoweringthem tobecomeadditivemanufacturingspecialistsandfuture pioneersinthefield.Lastly,sheisinvolvedinanumberof outreachactivitiestoincreasethepublic’sawarenessabout materialsandmanufacturingmorebroadly.

BuildingaSkilledandComplementaryTeam

AccordingtoDr.Nesma,theadditivemanufacturingfieldis aconstantlyandrapidlyevolvingsector Tostayontopof it,onemustbeagile,responsive,andadaptable.Sinceshe focusesonmetaladditivemanufacturing,whichisavery complexmanufacturingprocess,severalknowledge domainsneedtobenicelywoventogethertocreateastrong impact.Thiswashercentralapproachwhenshefirststarted thecurrentteamatTII.

Shebuiltateamofexpertsthathavetherightskillsto complementeachothersothattheycanhaveapowerful 360-degreeviewoftheircapabilities.Shealsointentionally recruitedpeoplewhoweremoreknowledgeablethanshe wasintheirrespectivedomainssothattheywereconstantly learningfromeachotherandcouldblendtheirrespective expertiseandknowledge.

Shestronglybelievesthatbeingapproachableasaleaderis oneofthemostintegralingredientsforsuccess,sothey operateinaveryfriendlyenvironment,whichdoesindeed bringoutthebestineveryone.

PromotingNewAlloysinAdditiveManufacturing

OnechallengeTIIfacesislimitedtalentinthisparticular field,i.e.,findingtherightpeoplewithexactlytheright additivemanufacturingskillsetisquitechallengingsince it’sstillanup-and-comingfield.Ofcourse,somedomains inthefieldareeasiertofindtalentinthanothers.

Butgenerally,puttingtogetherthestrongteamatTIIhas nowrequiredalotofsearchingandvetting.Dr.Nesmawas luckytohaveastrongnetworkthatwasextremelyhelpful inbuildingtherightteam.

Shebelievesanotherobstacleismarketresistance.Metal additivemanufacturinginthispartoftheworldisstillnot fullyembraceddespitethehypearoundit.Sometimes,TII isputinpositionswherekeyindustryplayersareimpressed byadditivemanufacturing,butwhenencouragedtoadopt thetechnology,theybecomeresistant.Forexample,they havedonesomeremarkableworkdevelopinganewalloy formetaladditivemanufacturing(AMALLOY3D).

However,thereissomeresistancewhenitcomesto replacingmaterialsusedformanyyearswithanew materialthatisn’tcommon.Toovercomethisobstacle,TII ishostingalotofshow-and-tellevents,liketheirannual AdditiveManufacturingtheFutureseminar.TIIstartedthis seriesbackin2021,andithasbeengrowingsince.This year,TIIisexpandingittoaconferenceandexhibition, whichwillbeheldonthe7thand8thofOctober

PromotingSustainabilitythroughInnovation

TII’smissionistowidentheadoptionofadditive manufacturinglocallyandcontributetoadvancingthefield globally Thishasamulti-facetedimpactonsocietyandis indeedalignedwiththeoverallstrategicgoalsofthe company Additivemanufacturingisanadvocateof sustainabilityasitensuresusingonlytheresources necessaryfunctionallyandstructurally,minimizingwaste.

This,inturn,resultsinthesustainableuseoftheearth’s resources,securingabrighterandmoreresourcefulfuture forgenerationstocome.Thebenefitspromisedtovarious sectorsarereflectedinamyriadofapplications,someof whichareineverydayuse.Improvingtheseisguaranteedto improvequalityoflife,ascanbeseeninlighterelectronic gadgets,customprosthetics,security,andmore.

Inaddition,TIIisactivelycontributingtodevelopingand empoweringEmiratitalentinthemanufacturingsector. ThiswillfurtherenrichtheUAE’sresearchcommunity withthenextgenerationofEmiratiscientists,contributing toaknowledge-basedeconomyandacceleratinginnovation alignedwiththecountry’svision.

Dr.Nesmabelievesadditivemanufacturinghascreateda paradigmshiftintoday’sbusinessmodelsacrosstheglobe intermsofdecisionspeed,adaptability,agility,complexity, andinclusivityoftechnologies.TheUAEisveryfocused

onmanufacturingnowadaysaspartofitsstrategyto diversifyitseconomy.

Fromanationalimpactviewpoint,bridgingthisgapand wideningtheadoptionofadditivemanufacturingwillfurther strengthentheUAE’spositionandenhancetheglobal competitivecapabilityoflocalindustries.Additive manufacturingadoptionwillalsoenablemanufacturing independence,or,inotherwords,self-sufficiency,andenrich themanufacturingecosystem.

SharingKnowledgeandLearningTogether

Dr.Nesmafindstheeasiestpartofherjobtobemanaging andmotivatingherteamtoachievetheirbestinarapidly evolvingindustrylikeadditivemanufacturing.Thisis becauseherteamwascarefullyselectedandhandpicked.The teamisgreatandvibrant;sheconsidersherselfveryluckyto beworkingwiththem.

Theyareallverypassionateaboutadditivemanufacturing andabsolutelydevotedtotheirrolesinthecompany They worktogethercollaborativelyandwithoutboundaries. Everyoneisquiteapproachable,andtheyomitbureaucracy fromtheirwaysofworking,whichmakesallthedifference.

Theygettogetherfrequentlytosharenewfindingssothat theyarealwayslearningfromeachother.Sheisvery thankfultothemallforalwaysgoingaboveandbeyondto pushpastthelimitsofadditivemanufacturing.

HarnessingtheBestThroughCollectiveLeadership

Dr.Nesmabelievesitisessentialtohaveaflexiblemindset tocopewiththemarketresistancethatonemayfaceatsome point.Additivemanufacturing,whileupandcoming,isstill newtomany.Itisalsoevolvingsofastthatitremainsnewin awaywitheachdevelopment.

Thisisquitehardfortheaudiencetoaccept,andthisis whereflexibilitywillbekey.Itisalsoimportanttorecognize thatthisisnotaone-personjobandthat,togetitright, cooperationandcollaborationarenecessary Thefieldistoo vastforjustonepersonorentitytocover,butifleadersinthe fieldjoinforces,thentogethertheywillharnessthebestof whatadditivemanufacturinghastooffer,shestates.

Sheisafanofbreadthofknowledgeoverdepth,butshe recognizestheimportanceofworkingwiththosewhomaster thedepth.Inherview,thisisanotherimportantaspectofthe

knowledgerequiredforanemergingleaderinthisfield,as therearemanyinterconnecteddomainsthatcanservethe progressionofthefield.

EnhancingEfficiencyandReducingEnvironmental Impact

Dr.Nesma’sprimarygoalistocontinuedrivinginnovation andsustainabilitywithintheindustry.Sheiskeentolead initiativesthatpushtheboundariesofwhatadditive manufacturingcanachieve,particularlyintheareasofnew materialsdevelopmentandcomplex,high-performance applications.

Hervisionistonotonlyenhancetheefficiencyandquality ofadditivemanufacturingbutalsoreduceitsenvironmental impact.Toachievethesegoals,shewillfocuson continuouslearning,collaborativeinnovation, sustainability,andmentorship.Thelastoneisverydearto herheart.ShespentyearsattheUniversityasaresearcher andacademic,whereshestartedthenucleusofateamof researchersandPhDstudents.

Today,sheisveryproudtoseeherformerstudents excellinginvariousadditivemanufacturingindustries.She willcontinuetoteachandmentor,justinadifferentsetting, andexpandhermentorshipofthenextgenerationof engineersandinnovators.Bysharingherexpertiseand experiences,shehopestoinspireotherstoexploreand contributetothefieldofadditivemanufacturing.

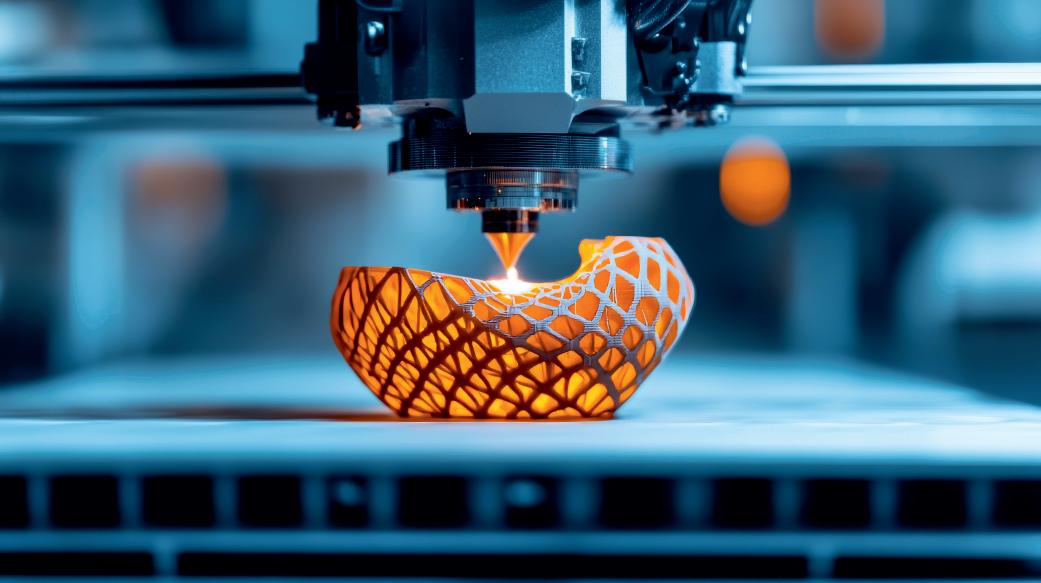

The Evolution of Additive Manufacturing Technology

Additivemanufacturing,orAM,ismorecommonlyknown

as 3D printing. This technology is one of those which initiallybeganasanicheandtodaytransformsitselfinto an engine that runs through all sectors of the economy.Although developedwiththesoleintentionofhelpingtocreateprototypes, AM has greatly progressed in materials, processes, and applicationsofdesignsinmanufacturingandproductdistribution.

TheEarlyStartandSlowImplementation

AM first started with stereolithography and selective laser sintering, the precursors of the current 3D printing technologies, during the 1980s. Innovations in hardware and software in the 2010s propelledAM to prominence, and it started its shift from prototypingtofull-scaleproduction.

MaterialsandAdvanceProcesses

ThemostprominentstepmadeinthelasttenyearsofAMhasbeen the growth of printable materials. While the first AM systems could only work with a few plastics and polymers, recent innovations have introduced metals, ceramics, composites, and bio-compatible materials. Printable materials can create wideranging applications that are possible through industries such as aerospace, healthcare, and automotive, to be able to useAM for high-performance,end-useparts.

Processes have diversified and, in electron beam melting, direct energy deposition, and material jetting methods, boundaries that define what has been possible have shifted. These technologies provided precision, speed, and scale to AM; hence, these have made them an alternative to the conventional methods used in complex,customizedproductsinindustries.

TheApplicationinDiverseIndustries

AviationandAutomobileIndustry

The aerospace and automotive industries have been the first movers in adoptingAM technologies.Aerospace companies use AMtoproducelightweight,intricatecomponentsthatreducefuel

A Decade of Industrial Transformation

consumption and enhance performance. Similarly, automotive manufacturers leverage AM to create custom parts, optimize designs, and accelerate the development of electricvehicles.

HealthcareandBiotechnology

Healthcare: applications of personalization in AM include individualprostheticsandimplantsandpre-surgicalsurgical guides, for instance. A giant step further could be towards feasibility of tissue, or even organ scaffolding. This would takethefieldtowardregenerativemedicine.

ConsumerProductsandBeyond

Consumer goods manufacturers have adoptedAM for rapid prototypingandmasscustomization.Ithaschangedcustomer expectations from customization in custom shoes to eyeglasses, tailoring products according to individual tastes and preferences Thirdly, the construction industry has already started experimenting with 3D printed houses and other infrastructure, that is, with large-scale possibilities of AM.

IntegrationwithDigitalTechnologies

One major game change was the integration of AM with digital technologies such as artificial intelligence (AI), Internet of Things (IoT), and generative design The algorithms from AI enhance designs with performance and materialefficiency,andIoT-enabledprintersensureprecision and real-time monitoring. This advancement ensured that streamlined production workflows and reduced waste, thus AMbecametheheartofsmartmanufacturing.

ChallengesandOpportunities

Despite the success AM has enjoyed to date, several challenges have to be addressed for it to fully realize its

potential. These include very high costs for equipment, scalabilityproblemsforparticularapplications,andmaterial availability The other very important challenge is quality control and standardization, especially for aerospace and healthapplicationswherethelevelofaccuracyandreliability becomesverycritical.

However,suchchallengesopendoorsforinnovationaswell. R&D investment drives the cost downward and creates choices for the type of materials that could be used. The industrial cooperation allows creating standards and best practices; however, developments in hybrid manufacturing are opening doors by integrating additive with conventional techniques.

TheFuture

The coming decade will truly witness the acceleration of innovationinAM.Sustainablemanufacturing,decentralized production, and 4D printing where objects adapt over time will transform the industrial landscape. When these AM technologies become more accessible and integrated into supplychains,theywillbecentraltosolutionsforchallenges such as decreased carbon footprint and on-demand manufacturinginremotelocations.

Conclusion

The last decade is an evolution of additive manufacturing. With its transformative capability, it has really made tremendousstridesintothefuture.AMhasrevolutionizedthe way industries function and presented new frontiers for innovation. Business and researchers harnessing its capabilitieswillensureadditivemanufacturingremainsatthe forefrontofthenextindustrialrevolution.

“The holy grail of additive manufacturing is mass customization .”

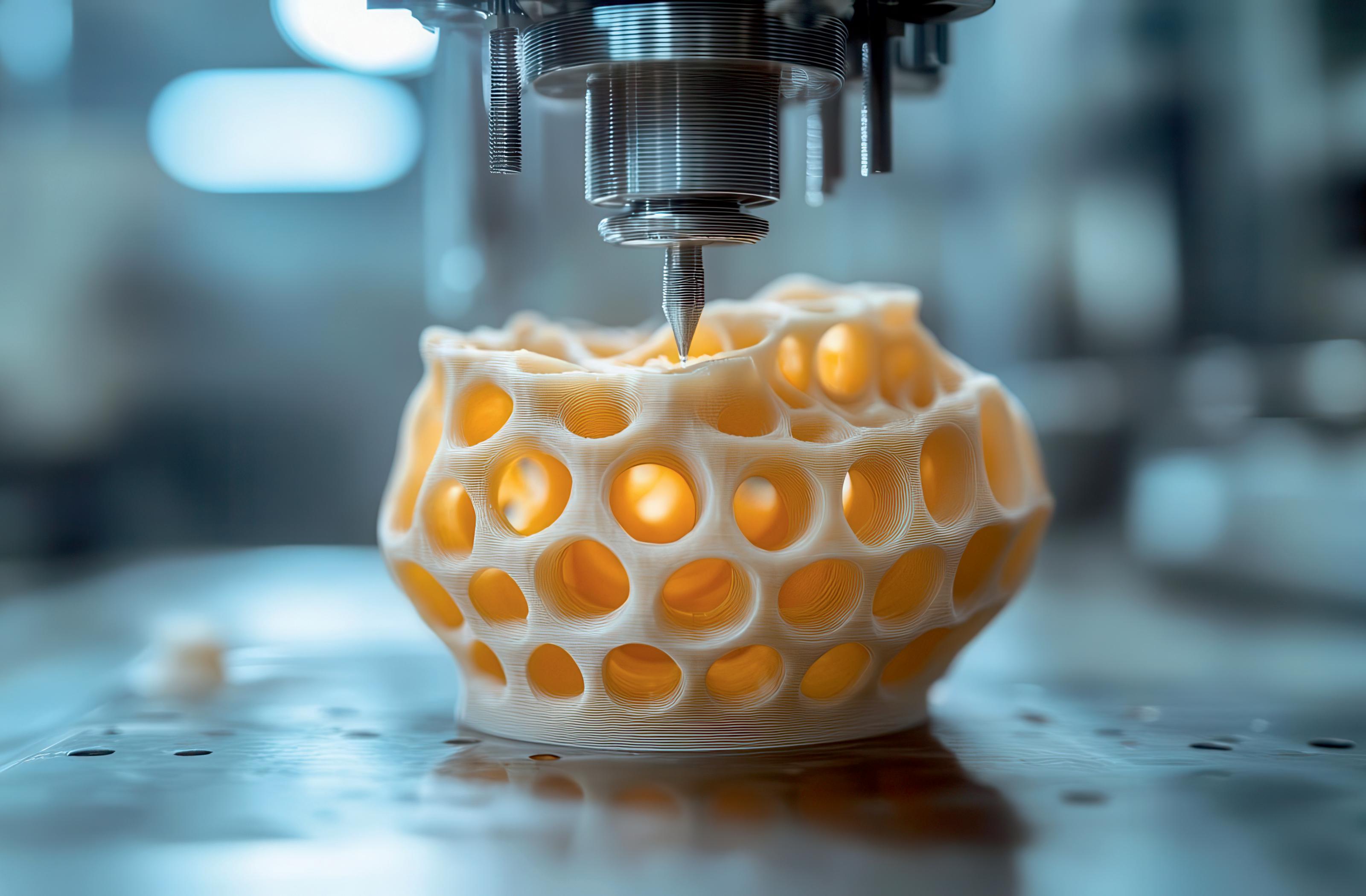

Combining Traditional and Addictive Manufacturing Technology in Modern Industries

Additivemanufacturing(AM),alsoreferredtoas3D

printing,createsanobjectbylayeringmaterial addition.Traditionalmanufacturingsubtracts materialfromasolidblockorshapesmoltenmaterialin molds.Theadvantagesofadditivemanufacturingareless wastegeneration,fasterproductiontimes,andcomplex geometriesthatcannotbecreatedthroughtraditional manufacturing.Theuseofbothmethodsissuitablefor high-precisionlarge-scaleproduction.Thisapproachwill maximizetheefficiencyofproductioninmanyindustries.

AdvantagesofAdditiveManufacturing

• ComplexGeometries:AMcanbuildcomplexinternal structuresandorganicformsthatarechallengingor impracticaltomanufactureusingclassicalapproaches.

• Customization:AMiseasytocustomizeand personalizeproductswithoutincurringadditionalcosts forthetoolingorimposingdelays,whereastraditional approachesaremoreorientedtowardmassproduction.

• LessWasteGeneration:AMreducesmaterialwaste sinceitusesonlyasmuchmaterialasnecessaryto buildanobject.

• SimplifiedMachine:AMcompletesallproduction stepsinonepieceofequipmentwheretraditional manufacturingmostlyrequiresdifferentmachinetools.

• FlexibilityandVersatility:AnAMsystemismore agileforproductionasmodificationsindesigndon't necessarilyleadtoawholechangeinequipmentfor production

• CostEffectiveness:ThecostinAMdoesn'tchangedue tothelevelofcomplexity

• FasterLeadTimes:AMsignificantlyreducesthetime fromdesigntoimplementation,cuttingdownthecycle tohoursordayscomparedtomonthswithtraditional methods.

• SupplyChainControl:AMallowsbusinessesto controltheirsupplychains,reducingdependenceon externalsuppliersandminimizingrisk.

Advantages

ofTraditionalManufacturing

• High-VolumeProduction:Traditionalmanufacturing excelsinmassproduction.

• MaterialVariety:Thereisagreatervarietyof materialswiththetraditionalmethods.

• HighPrecision:Thetraditionalmanufacturing techniqueissuitableforhigh-precisionapplications andclosetolerances.

HybridApproach

Thestrengthsandlimitationsofthetwoapproachessuggest acombinationofbothAMandtraditionalmanufacturingin ordertooptimizetheproductionprocess.Thehybrid approachwillhelpmanufacturersselectanappropriate technologytofittheirneeds.

ApplicationsandExamples

• PerformanceEnhancement:WithAM,engineers nowdesignpartsthataremeanttobemore performance-optimizedandmass-reducedwhile makinggasturbines,anaeroengine,andheat exchangersefficient.

• MedicalImplants:AMcantailormaterialproperties, inparticularusingbiocompatiblematerialsformedical implants,improvingtheirdurabilityandperformance

• Aerospace:AMenhancestheefficiencyofgasturbines andaeroengines4.

• Tooling:AMoptimizesconformallycooledinjection molds,whichresultsinbetterproducts,lessscrap,and shorterinjectioncycletimes.

TrendsandFutureDirections

• AIandMachineLearning:Itallowsintegrationallow foranoptimumdesignandproductionprocessthat providesbetterqualitycontrolandeliminatespossible errors.

• GenerativeDesign:AI-generatedgenerativedesign toolstocreateextremelyoptimized,verycomplex structuralsystemsthatwillmaximizeperformanceand usetheminimumpossiblematerials.

• SmartFactoriesandIndustry4.0:Theadoptionof AMinsmartfactoriesandIndustry4.0initiativeswill increase,thusfurtherintegrating3Dprintinginto advancedmanufacturingecosystems.

• ImprovedDurability:AMcontributestoimproved durabilitybyenablingthedesignofpartssuitedfor specificworkingenvironments,improvingresistanceto stress,fatigue,andwear.

AMistransformingmodernindustries,providing opportunitiesforinnovation,customization,and sustainability.Overcomingtechnical,economic,and regulatorychallenges,andfosteringinnovationand collaboration,areessentialtoitsfullrealization.

“3D printing is not just a new way of manufacturing; it's a new way of thinking.”