E FARMACEUTICA

5500 Texlon® self-adhesive soft tapes

A self-modelling gasket tape made of soft and flexible non-sintered expanded 100% PTFE. Texlon® resists chemical products with the exception of alkaline substances and is usually supplied with bi-adhesive film which facilitates application. The PTFE raw material is WRAS Approved.

3356 SUREBAND CLEAR Shields

Manufactured from All-PTFE materials (no fibreglass) comprising clear ETFE outer and multi-layered ETFE mesh inner. This material provides unparalleled chemical resistance. All our shields are tested on our hydro-static pressure test facility, test certificates available on request. The internal mesh is compressed against the flange and prevents direct and lateral spray. The liquid pressure inside is rapidly diffused, resulting in a safe drip-release.

5100L PTFE Sheets

PTFE plate, polymer belonging to the class of perfluorocarbons (PFC), resulting from homopolymerization of tetrafluoroethylene. The same plates can be made with the addition of other stabilizing and thinning components, to expand their application range. Alternatively, they are available with added glass, silica, carbon, bronze or barium sulphate charges to increase their mechanical, pneumatic and chemical resistance. The main features of PTFE are the excellent thermal, chemical resistance and the low coefficient of friction.

When producing joint gaskets, some fundamental criteria must be borne in mind without which it would be impossible to obtain a perfect seal between two flanges. In particular, the gasket must comply with the following requirements: adaptability to the surfaces of the flanges and any irregularities; impermeability to contact agents; resistance to the specific pressure applied by the flange tightening bolts. Furthermore, it is very important to avoid the release of substances that could contaminate the product.

Reshaping technical support with lifecycle catalyst solutions

“The Action Plan for the Chemical Industry includes all levers to put the sector back on a growth track, from production-support measures to keep our steam-crackers and chemical sites in Europe, to trade defence instruments to protect our chemical businesses from unfair global competition, all the way to securing domestic demand for clean & ‘made in Europe’ chemicals.” Stéphane Séjourné, Eu Commission Executive Vice-President for Prosperity and Industrial Strategy, page 13.

by Alessandro Bignami

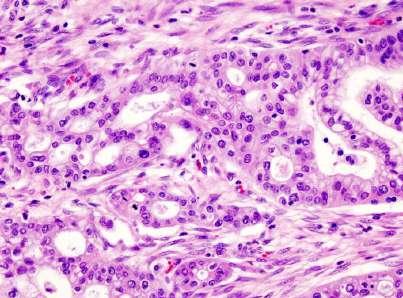

Pharmaceutical research is undergoing a period of great dynamism, with an increasingly evident impact on patients’ quality of life and life expectancy – thanks, for example, to the rapid development of gene and cell therapies. Certainly, many challenges remain, starting with the treatment of Alzheimer’s disease, multiple sclerosis, certain cancers, and various rare diseases. However, scientific and technological progress – further accelerated by artificial intelligence – is fueling hopes of achieving, in the not-sodistant future, improvements even in the treatment of diseases that are currently extremely difficult to manage. The progress made in research over recent decades has been driven by major investments from the pharmaceutical industry, which has long been a key high-tech sector in developed countries. Europe has played a leading role in this evolution, establishing itself as a beacon in the field of pharmaceutical research and the production of highly innovative drugs. Today, the European pharmaceutical sector directly employs 950,000 people – a figure that triples when including the broader supply chain – and invested €55 billion in research and development in 2024, according to PwC data. In recent years, however, the landscape has changed, and Europe has lost ground in the pharmaceutical sector compared to major economic and technological powers such as China and the United

States. It has also been challenged by emerging markets like India and Brazil, where many production and R&D activities are relocating. In 2024, the largest market was North America, accounting for 54.8% of global pharmaceutical sales, compared to Europe’s 22.7%. Only 15.8% of new drugs were launched in Europe, far behind the United States at 66.9%, according to Iqvia Midas data. Last year, Europe ranked third in the number of new molecule launches, with 18 – behind China (28) and the United States (25).

For this reason, European stakeholders had hoped for a favorable and specific agreement on tariffs for pharmaceutical trade between the EU and the U.S. Instead, medicines were included in the 15% tariff rate, with exemptions granted only to certain generic and off-patent drugs – although it remains unclear which ones. Ongoing uncertainty, aggressive global competition, and the complexity of European regulations have all contributed to this decline – one that risks being exacerbated by Trump’s tariffs. Now, the continent must reclaim its position at the top of the global industry, leveraging its vast potential in terms of expertise, technology, and research infrastructure. To achieve this, not only is industry commitment required, but also a stronger and more unified political voice that can fully support the value of European pharma.

PVS has launched a collaboration with ITS Nuove Tecnologie della Vita Academy to support the development of students’ skills in the pharmaceutical plant sector.

In a constantly evolving sector like pharmaceuticals, training is a fundamental pillar in preparing tomorrow’s professionals.

With this in mind, PVS – a company that provides consultancy, validation, qualification, and on-site calibration services for the pharmaceutical industry –has partnered with ITS Nuove Tecnologie della Vita Academy, a post-diploma technical school. The Academy offers various two-year courses, including programs focused on the chemical-pharmaceutical sector.

Specifically, PVS is involved in the following activities:

Technical teaching - PVS is currently delivering the second part of the Chemical Plants module in the Pharmaceutical Plants course, contributing concretely to

skill development in the sector by bringing direct experience into the classroom and offering students a hands-on, operational perspective.

PCTO training module for high schools - PVS has launched a module on Safety in Drug Manufacturing, aimed at raising awareness among younger students about critical topics in the pharma world. The module provides a structured introduction to GMP, regulatory frameworks, and technologies used in pharmaceutical production.

Company presentation and career orientation - Through dedicated meetings with ITS students, the company shares insights on what it means to work in consulting, the skills required, and the professional opportunities available. For PVS, this collaboration is a strategic investment. The company believes that education is a driver of growth and innovation and wants to actively contribute to shaping a new generation of skilled and aware specialists.

That’s why PVS sees knowledge transfer as essential to creating shared value –both for the education system and the industrial landscape

Experts in validation and qualification activities

PVS was founded in 2013 by bringing together diverse experiences and expertise. It is a flexible and dynamic organization, capable of adapting to the needs of different stakeholders and players in the target market. Thanks to strong relationships and positive interactions with major national and international pharmaceutical groups, the company has steadily expanded its team with new professionals.

Its activities range from consultancy to GxP-compliant validation and qualification services. With the addition of skilled professionals, the company also provides consultancy, support, and validation services for Total Organic Carbon (TOC) analyzers used to measure this parameter in water for pharmaceutical and electronic use, as well as for special applications.

Concrete answers to employment needs in the sector

ITS Nuove Tecnologie della Vita - G. Natta Academy is a post-secondary technical specialization school and the only Higher Technological Institute in the chemical field in Italy.

Its training offering belongs to the tertiary level of education, running parallel to academic programs. It is closely connected to the production system and labor market, making it capable of responding to the need to train highly specialized technical-scientific professionals to support the competitiveness of companies, especially those seeking young talent able to navigate the evolving landscape of technological innovation.

The institute is committed to providing concrete responses to the real employment needs of the region by offering highly specialized training programs. The Academy focuses on the internationalization of the ITS system and actively involves companies in the design and planning of its educational pathways.

AstraZeneca announces $50 billion of investment in the United States by 2030, building on America’s global leadership in medicines manufacturing and R&D. This investment is expected to create tens of thousands of new, highly skilled direct and indirect jobs across the country powering growth and delivering next generation medicines for patients in America and worldwide.

The cornerstone of this landmark investment is a new multi-billion dollar US manufacturing facility that will produce drug substances for the Company’s innovative weight management and metabolic portfolio, including oral GLP-1, bax-

drostat, oral PCSK9 and combination small molecule products. The new state-of-the-art centre will produce small molecules, peptides and oligonucleotides. This multi-billion dollar capital investment is in addition to the $3.5 billion announced in November 2024.

The drug substance facility, planned to be in the Commonwealth of Virginia, would be AstraZeneca’s largest single manufacturing investment in the world. The facility will leverage AI, automation, and data analytics to optimise production. The $50 billion investment across our R&D and manufacturing footprint in the US over the next five years also includes: ex-

pansion of our R&D facility in Gaithersburg, Maryland; stateof-the-art R&D centre in Kendall Square, Cambridge, Massachusetts; next-generation manufacturing facilities for cell therapy in Rockville, Maryland and Tarzana, California; continuous manufacturing expansion in Mount Vernon, Indiana; specialty manufacturing expansion in Coppell, Texas; new sites to supply clinical trials; our growing research and development investment in novel medicines.

Collectively, these investments will help deliver AstraZeneca’s ambition of reaching $80 billion in Total Revenue by 2030, of which it is expected 50% would be generated in the US.

The US is AstraZeneca’s largest market and home to 19 R&D, manufacturing and commercial sites. The company employs more than 18,000 people and support 92,000 jobs overall across the United States. In 2024 it contributed $5 billion directly to the economy and created approximately $20 billion worth of overall value for the American economy.

Air Liquide will invest up to 200 million U.S. dollars in Louisiana, U.S., to modernize and connect an Air Separation Unit (ASU) to its existing network. This investment also includes the expansion of its pipeline infrastructure by an additional 30 miles along the Gulf Coast. These enhancements supporting a long-term contract renewal with Dow will strengthen the Group’s long-term relationship with them. Additionally, this reinforced network will position Air Liquide to support industrial growth in Louisiana. In the context of a long-term renewal contract, Air Liquide will continue to supply

oxygen and nitrogen to Dow’s St. Charles Operations site located in Taft, Louisiana. Site enhancements and extension of its Mississippi River pipeline system will allow Air Liquide to provide more efficient gas production and delivery. The construction is expected to be completed in early 2027.

By expanding its robust industrial pipeline network throughout Texas and Louisiana, Air Liquide will also be able to further support its nitrogen and oxygen customers along the Mississippi River with increased flexibility and competitiveness. This stra-

tegic investment will strengthen Air Liquide’s position in the U.S. Gulf Coast and enable future growth opportunities.

Matthieu Giard, Group Vice President, Americas, said: “Air Liquide is proud to extend its long standing relationship with Dow. We strive to provide a safe and reliable gas supply that meets our customers’ needs. By enhancing the overall efficiency of our robust and flexible distribution network, we are taking concrete action in support of that ambition. Air Liquide’s operations in Louisiana are part of the industrial backbone that have supported the development of many industries on the Gulf Coast, and this investment illustrates our commitment to support our customers’ growth.”

After more than 25 years with the NürnbergMesse Group, Stefania Calcaterra stepped down as managing director of its subsidiary NürnbergMesse Italia on 30 June and passed the baton to her successor, Danny D’Alessandro. Calcaterra has successfully headed and rigorously developed NürnbergMesse Italia since it was established in 2009. Under her leadership, Italy consolidated its position as

number one among the international exhibiting countries at the Nuremberg exhibition venue: “Stefania Calcaterra’s departure marks the end of an era, and also the start of a new chapter in our largest exhibiting country. Our thanks go to Stefania for more than 25 years of tireless effort, passion, foresight and commitment,” says Dr. Thomas Koch, Chairman of the Annual Shareholders‘ Meeting of NürnbergMesse Italia.

Stefania Calcaterra worked as international representative in Italy for NürnbergMesse and also for Spielwarenmesse eG from as early as 1999. With her passion for trade fairs and a deep understanding of service quality, she developed NürnbergMesse Italia into an essential link between the important Italian trade fair market and the international trade fair community. Her most recent success story is the “Focus on PCB” trade fair. Ever busy in her role as managing director, Calcaterra launched this trade fair during the Covid-19 pandemic and, when in-person trade fairs resumed, very

quickly turned it into a meeting place for the European printed circuit board industry in the Italian city of Vicenza. She will continue to be responsible for this trade fair for a further two years.

Danny D’Alessandro assumed the managing role at NürnbergMesse Italia from 1 July 2025. With qualifications in law and an Executive MBA, D’Alessandro comes with more than 15 years of experience in the trade fair and fashion industries. Most recently he was General Manager at Aimpes Servizi, organizer of Mipel, the international leather and fashion accessories event, where he was responsible for all business-relevant processes. Dr. Thomas Koch, member of the Executive Board, is pleased to welcome the most recent appointee to the NürnbergMesse Group: “With his expertise in heading trade fairs, his international focus and his sense for industry trends, Danny D’Alessandro is the ideal person to take the success story of NürnbergMesse Italia forward and provide new inspiration.”

The Eu Commission Plan addresses key challenges, namely high energy costs, unfair global competition, and weak demand, while promoting investment in innovation and sustainability.

Last July, the European Commission presented an Action Plan for the Chemicals Industry to strengthen the competitiveness and modernisation of the EU chemical sector. The Action Plan addresses key challenges, namely high energy costs, unfair global competition, and weak demand, while promoting investment in innovation and sustainability. The Action Plan is accompanied by a simplification omnibus on chemicals – the sixth that the Commission has presented in this man-

date so far – to further streamline and simplify key EU chemicals legislation, alongside a proposal to strengthen the governance and financial sustainability of the European Chemicals Agency (ECHA).

The Action Plan proposes the following measures: Resilience and level playing field: The Commission will establish together with Member States and stakeholders a Critical Chemical Alliance to address the risks of capacity closures in the sector. The Alliance will identify

critical production sites needing policy support and tackle trade issues like supply chain dependencies and distortions. The Commission will also swiftly apply trade defence measures to ensure fair competition, while expanding chemical import monitoring through the existing Import Surveillance Task Force. The Alliance will align investment priorities, coordinate EU and national projects, including Important Projects of Common European Interest (IPCEIs) and support EU critical production sites to boost

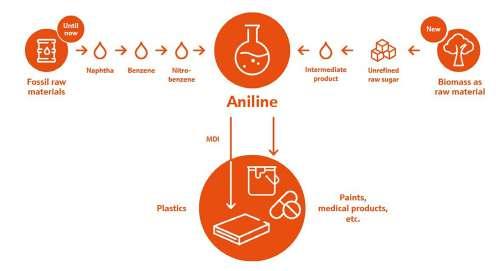

innovation and regional growth. Affordable energy and decarbonisation - The Commission will implement at full speed the Affordable Energy Action Plan to help reduce high energy and feedstock costs. It has introduced clear rules for low-carbon hydrogen and will update state aid to lower electricity costs for more chemical producers by the end of the year. The plan also encourages using clean carbon sources like carbon capture, biomass, and waste, alongside support for renewables. A public consultation on improving chemical recycling has also been launched.

Lead markets and innovation - The Action Plan highlights fiscal incentives and tax measures to boost demand for clean chemicals. The upcoming Industry Decarbonisation Accelerator Act will set EU content and sustainability rules to support market growth and clean technology investment. The upcoming Bioeconomy Strategy and Circular Economy Act will boost the EU’s resource efficiency, chemicals recycling, and strengthen the market for bio-based and recycled alternatives to fossil-based inputs. The Commission will also launch EU Innovation and Substitution Hubs and mobilise EU funding under Horizon Europe (2025–2027) to accelerate the development of safer, more sustainable chemical substitutes.

Taking action on per- and polyfluoroalkyl substances (PFAS) - The Action Plan reaffirms the Commission’s commitment to minimise PFAS emissions through a robust, science-based restriction, while ensuring continued use in critical applications under strict conditions where no alternatives are available which will be proposed swiftly after ECHA’s opinion. The Commission will also invest in innovation, promote remediation based on the polluter pays principle, and prioritise the development of safer alternatives.

As part of its ongoing efforts to boost the EU’s competitiveness, the Commission adopted a sixth simplification omnibus to reduce compliance costs and administrative burden for the chemical industry while ensuring strong protection of human health and the environment. This includes simplifying hazardous chemical labelling rules, clarifying EU cosmetics regulations, and easing registration for EU fertilising products by aligning information requirements with standard Reach rules for chemicals. These measures are expected to save at least €363 million annually for the industry. The proposal for the ECHA Basic Regulation equips ECHA with the resources, flexibility, and structural adaptations required to fulfil the duties under its growing mandate, which now includes responsibilities under multiple EU regulations, namely spanning classification and labelling, biocidal products, import and export of hazardous chemicals, waste management and water. The chemicals sector is vital to Europe’s economy, underpinning the manufacture of almost all goods. It provides essential materials and technologies to industries that support the welfare, security and resilience of European economies, including automotive, construction, healthcare, agriculture, clean technologies and defence.

The European Chemicals Industry Action Plan builds on the Competitiveness Compass and Clean Industrial Deal. Following the President’s Strategic Dialogue on 12 May 2025, it is the Commission’s third sector plan after automotive and steel. The simplification package presented today delivers on President von der Leyen’s commitment to simplify EU laws and cut administrative burdens, helping businesses innovate and grow. Presi-

dent von der Leyen announced a sector-specific omnibus in the first Strategic Dialogue on the future of the Chemical Industry in Europe with representatives of the sector, held on 12 May 2025. The Single Market Strategy adopted in May 2025 reiterated that commitment. The Omnibus for the Chemicals Industry is one of a series of Simplification Omnibus packages presented by the Commission under this mandate. The EU chemical industry is the fourth largest manufacturing sector, with 29,000 companies providing 1.2 million direct jobs and supporting 19 million across supply chains.

“Chemicals is the mother of all industries, with over 96% of manufactured goods relying on chemicals”, said Stéphane Séjourné, Executive Vice-President for Prosperity and Industrial Strategy. “This action plan on chemicals is our business plan to secure this critical sector’s future in Europe. It includes all levers to put the sector back on a growth track, from production-support measures to keep our steam-crackers and chemical sites in Europe, to trade defence instruments to protect our chemical businesses from unfair global competition, all the way to securing domestic demand for clean & ‘made in Europe’ chemicals.”

Stéphane Séjourné, Eu Commission Executive Vice-President for Prosperity and Industrial Strategy

Since June Gergely Sved has been the new Chief Executive Officer (CEO) of Ellab, following the departure of Ludvig Enlund. Mr Sved is a highly experienced healthcare and life sciences executive. Most recently he served as Executive Vice President and Group President for the Healthcare and Life Sciences division at Ecolab Inc, a global leader in water, hygiene and infection prevention solutions and services. At Ecolab, he was

responsible for driving an ambitious growth strategy for the Life Science and Purolife, its Cleanroom, API and Bioprocessing businesses. Previously, he led the expansion of Ecolab’s Endoscopy, Surgical and Infection Prevention businesses – including during the Covid pandemic. Prior to Ecolab, Mr Sved spent 23 years with General Electric in various roles, including most recently at GE Healthcare, where for six years he was Vice President and General Manager Europe Services.

Anders Hedegaard, Chair of Ellab, commented: “Ellab is at a very exciting point in time as we

Ampersand Capital Partners, a private equity firm specializing in growth equity investments in the life sciences and healthcare sectors, announced the acquisition of CurTec Group B.V., a Netherlands-based manufacturer of high-performance plastic packaging solutions for pharmaceutical and specialty chemical applications from Bencis Capital Partners in partnership with management. Headquartered in Rijen, CurTec has manufacturing operations

in the Netherlands and the United States and sales offices across Europe, North America and Asia. CurTec designs and manufactures GMP-compliant, UN-certified packaging solutions engineered for the secure storage and transport of active pharmaceutical ingredients (APIs), excipients and other high-value and sensitive biopharma and chemical ingredients used in regulated environments where cleanliness, compliance and durability are critical.

look to accelerate growth and development of the business. Gergely brings a wealth of relevant experience, and we look forward to working with him as we execute our ambitious growth strategy. We are grateful for Ludvig’s contribution to bringing Ellab to where we are today and wish him well in his onwards career”.

“Ellab is a fascinating business that plays a critical role in ensuring integrated compliance solutions, anchored in its customers’ most critical operations” says Gergely Sved. “It has great products and services, and a highly experienced team, and I am looking forward to working together to help Ellab fulfil its tremendous potential”.

“We are thrilled to welcome Ampersand as our new partner as we focus on scaling U.S. operations, advancing product innovation, expanding our footprint and growing into adjacent markets,” said Bart van Berkel, CEO of CurTec. “Their deep expertise in the life sciences supply chain and their US network will help accelerate our global presence while reinforcing our commitment to quality, innovation, and sustainability.”

“CurTec is a premium brand trusted by leading pharmaceutical companies – including those within Ampersand’s portfolio – for its excep-

Last June, Dow Chemical hosted the Together for Sustainability (TfS) General Assembly at its site in Horgen, Switzerland, bringing together representatives from 57 member companies united in its mission to drive sustainability across global supply chains. The meeting marked an important milestone in this collective journey, as they reviewed progress and aligned on next steps within the Accelerate4Impact strategy – the shared roadmap for increasing impact and scaling sustainable business practices across industries.

The Assembly re-elected Jennifer Jewson (LyondellBasell) as TfS President for a second two-year term. Her leadership continues to be instrumental in guiding the strategy and momentum.

The elected TfS Steering Committee (SteerCo) members are: Bertrand Conquéret, Cathy Budd, Götz Lauschke, Thomas Udesen (re-elected); Matthias Dohrn and JC Fuenmayor (newly elected).

All will serve a 2-year mandate to advance the shared sustainability agenda. Through TfS, procurement becomes a force

tional product quality and regulatory standards,” said Hidde Van Kerckhoven, Principal at Ampersand. “We look forward to working closely with Bart and his team to expand capacity, strengthen commercial capabilities, and support long-term growth.”

“We look back on a very successful partnership with CurTec and the team, evolving into a global leader in regulated packaging through innovation, operational and ESG excellence, and a clear focus on pharma,” said Zoran van Gessel, Managing Partner at Bencis.

for good – shaping more transparent, responsible, and resilient supply chains.

EyeC GmbH, a leading global provider of automated artwork and print image inspection systems, has appointed Matthew Wilkins as its new National Sales Manager for the United Kingdom and Ireland.

In this strategic role, Matthew will oversee all sales operations across the UK and Ireland, with a particular focus on expanding EyeC’s presence and footprint in the region. Upon joining EyeC, he will report directly to Dr Ansgar Kaupp, CEO of EyeC GmbH, and Markus Fietkau, Sales Director.

With over 20 years of international experience in sales and marketing management, Matthew brings a wealth of knowledge from various industries, including Financial Ser-

vices, Digital Media, and Healthcare. His most recent positions have been with the 3M PLC Food Safety Division and the 3M Safety and Industrial Business Group, where he played a pivotal role in expanding market share through strategic collaboration and reliable partnerships with key account clients.

Matthew has a proven track record in delivering customer-focused solutions, leveraging deep market insights to develop best practices and optimize manual systems. His experience also includes supporting clients in automation and robotics, helping them modernize and streamline their operational processes.

Regarding his new position, Mat-

thew Wilkins said: “EyeC is a dynamic, innovative, and ambitious company. I am looking forward to working with the team to help achieve our future goals and strengthen our presence in the UK and Ireland.”

Founded in 2002, EyeC GmbH provides fast, accurate, and easy-touse artwork and print inspection systems.

EyeC is the only provider on the market that ensures product quality throughout the entire manufacturing process – from the first artwork file to the finished printed product. Products from EyeC provide users with 100% confidence about the print quality of their products, such as labels, folding boxes, package inserts, or flexible packaging.

The solution for your compliance with international standards

Comprehensive and intuitive instruments for online and portable measurements of TOC, conductivity and ozone.

Global Compliance and International Standards

• Complies with FDA 21 CFR Part 11, EMA Allegato 1 and 11, and international pharmacopoeias (USP, Ph. Eur., ChP, JP).

• Designed according to GMP, GAMP ® , ASTM, ISO, and ISPE to meet the highest expectations of the industry.

Secure Data and Simpli ed Management

• Multi-level user management with electronic signatures.

• Complete history and meta data according to ALCOA+ principles.

• Tamper-proof control for process security.

Swan Analitica Srl ∙ IT-16167 Genova www.swananalitica.it ∙ swan@swananalitica.it

Maziar Mike Doustdar:

“From my decades in leadership roles across Novo Nordisk, I know the extraordinary talent and commitment of our people and the excellence of our science.”

Novo Nordisk announced that Maziar Mike Doustdar has been appointed as president and chief executive officer, effective 7 August 2025. Mike Doustdar succeeds Lars Fruergaard Jørgensen, who will step down as president and chief executive officer on the same date. The company also announced other executive-level changes, effective 7 August. Mike Doustdar, currently Novo Nordisk’s executive vice president of International Operations, has a strong track record of creating value and driving growth. Under his leadership over the past decade, Novo Nordisk’s International Operations have more than doubled sales to approximately DKK 112 billion in 2024. The business includes all of Novo Nordisk’s affiliates outside of the US and employs nearly 20,000 people.

Novo Nordisk Chair, Helge Lund, said: “Mike is an exceptional leader and has the unanimous support of the Board. We are confident that he is

the best person to lead Novo Nordisk through its next growth phase. Mike has consistently demonstrated the ability to drive growth through strong commercial execution and building high-performing teams. This is an important moment for Novo Nordisk. The market is developing rapidly, and the company needs to address recent market challenges with speed and ambition. I believe Novo Nordisk will build on its strengths as a global leader in obesity and diabetes, and Mike has a clear vision of how to unlock the full potential of the opportunities ahead.”

Mike Doustdar has been appointed as the result of a comprehensive process that included external and internal candidates. The Novo Nordisk Foundation fully endorses Novo Nordisk Board’s decision to appoint Maziar Mike Doustdar as president and chief executive officer. Mike Doustdar said: “It’s an enormous privilege to lead this company at a time of

tremendous opportunity and change. I come to this role with a sense of urgency, a laser focus on high performance, and a fierce determination for Novo Nordisk to aim higher than it’s ever done, and to deliver to many more patients the innovation they need. From my decades in leadership roles across Novo Nordisk, I know the extraordinary talent and commitment of our people and the excellence of our science. This has enabled us to achieve great things in the past and will ensure we continue to do so in the future.”

Novo Nordisk Chair, Helge Lund, added: “Under Lars’s leadership, Novo Nordisk has undergone a profound period of growth and now reaches millions more patients with life-changing medicines. On behalf of Novo Nordisk’s Board of Directors and our employees, I want to thank Lars for 34 years of unstinting commitment to the company and wish him all the best in his future endeavours.”

Coesia, a global leader in advanced industrial and packaging solutions, has announced the acquisition of the majority capital of Autoware, an international Manufacturing Software Integrator based in Vicenza, specialized in high-quality software for manufacturing operations management, supply chain operations and process control.

Its portfolio includes Manufacturing Execution Systems (MES), Manufacturing Operations Management (MOM) software, and Supervisory Control and Data Acquisition (SCADA) solutions for leading companies, mostly but not limited to those in the Food & Beverage, Consumer Packaged Goods, and Pharmaceutical sectors.

“This acquisition marks another important steppingstone in Coesia’s digital transformation journey, reinforcing our commitment to leading the Industry 4.0 evolution. By integrating Autoware’s deep digital expertise with Group’s

extensive industry knowledge, we are expanding our ability to deliver seamless, end-to-end solutions that enhance efficiency, foster innovation, and meet the rapidly evolving needs of manufacturers worldwide. This move accelerates our vision of becoming a global leader in smart manufacturing solutions.”, says Alessandro Parimbelli, CEO of Coesia.

“Partnering with Coesia is a significant opportunity to establish a truly global platform and broaden our reach into new geographies and markets. The Group’s extensive customer portfolio across key industries will further accelerate Autoware’s growth in continuity with the existing strategy, while maintaining our commitment to delivering high-quality solutions for digital transformation in manufacturing”, states Luigi De Bernardini, CEO and founder of Autoware.

The pharmaceutical industry is a key asset to scientific and medical progress. The research-based pharma can play a critical role in restoring Europe to growth and ensuring future competitiveness in an advancing global economy.

Thanks to advances in science and technology, the research-based pharmaceutical industry is going through an exciting era in medicines development. Research methods are evolving and we have many promising prospects on the horizon, with ground-breaking cell and gene therapies being increasingly available. The innovative pharmaceutical industry is driven by, and drives, medical progress. It aims to turn fundamental research into innovative treatments that are wide-

ly available and accessible to patients. Already, the industry has contributed to significant improvements in patient well-being. Today’s European citizens can expect to live up to 30 years longer than they did a century ago. Some major steps in biopharmaceutical research, complemented by many smaller steps, have allowed for reductions in mortality, for instance from HIV/AIDS-related causes and several cancers. High blood pressure and cardiovascular diseases can be controlled with antihypertensive and cholester-

ol-lowering medicines; knee or hip replacements prevent patients from immobility; and some cancers can be controlled – or even cured – with the help of new targeted treatments. European citizens can expect not only to live longer, but to live better quality lives. Yet major hurdles remain, including Alzheimer’s, Multiple Sclerosis, many cancers, and rare diseases.

A key asset to the european economy As well as driving medical progress by researching, developing and bringing

new medicines that improve health and quality of life for patients around the world, the research-based pharmaceutical industry is a key asset of the European economy. It is one of Europe’s top performing high-technology sectors. The research-based pharmaceutical industry can play a critical role in restoring Europe to growth and ensuring future competitiveness in an advancing global economy. In 2024 it invested an estimated € 55,000 million in R&D in Europe. It directly employs some 950,000 people and generates about three times more employment indirectly – upstream and downstream – than it does directly (PwC, Economic and societal footprint of the pharmaceutical industry in Europe, November 2024). However, the sector faces real challenges. Besides the additional regulatory hurdles and escalating R&D costs, the sector continues to be hit by the impact of fiscal austerity measures introduced by governments across much of Europe since 2010. There is rapid growth in the market and research environment in emerging economies such as Brazil, China and India, leading to a gradual migration of economic and research activities from Europe to these fast-growing markets. During the period 2019-2024 the Brazilian, Chinese and Indian markets grew by 14.3%, 2.2% and 9.5% respectively compared to an average market growth of 7.9% for the top 5 European Union markets and 9.8% for the US market (source: IQVIA MIDAS, May 2025). In 2024 North America accounted for 54.8% of estimated world pharmaceutical sales compared with 22.7% for Europe. According to IQVIA (MIDAS May 2025), 66.9% of sales of new medicines launched during the period 2019-2023 were on the US market, compared with 15.8% on the Eu-ropean market (top 5 markets). The fragmentation of the EU pharmaceutical market has resulted in a lucrative parallel trade. This benefits nei-

EFPIA (The European Federation of Pharmaceutical Industries and Associations) represents the research-based pharmaceutical industry operating in Europe. Founded in 1978, its members comprise 36 national pharmaceutical industry associations, 40 leading pharmaceutical companies and 13 small and medium sized enterprises undertaking research, development and manufacturing of medicinal products in Europe for human use. EFPIA aims to create an environment that enables its members to innovate, discover, develop and deliver new therapies and vaccines for people across Europe, as well as contribute to the European economy. EFPIA’s vision is for a healthier future for Europe. A future based on prevention, innovation, access to new treatments and better outcomes for patients.

As well as driving medical progress by researching, developing and bringing new medicines that improve health and quality of life for patients around the

As well as driving medical progress by researching, developing and bringing new medicines that improve health and quality of life for patients around the

Through its membership, EFPIA represents the common views of about 1,900 large, medium and small companies including the entire European research-based pharmaceutical sector whose interests also include a significant part of the generics and biosimilars segments. Vaccines Europe (VE) is the specialised vaccine industry group within EFPIA. It represents major innovative research-based global vaccine companies as well as small and medium sized enterprises operating in Europe.

world, the research-based pharmaceutical industry is a key asset of the European economy. It is one of Europe’s top performing high-technology sectors.

world, the research-based pharmaceutical industry is a key asset of the European economy. It is one of Europe’s top performing high-technology sectors.

Values in € million unless otherwise stated

(1) Data relate to EU-27, Norway, Switzerland and United Kingdom since 2005 (EU-15 before 2005); Croatia and Serbia included since 2010; Turkey included since 2011

Values in € million unless otherwise stated

(1) Data relate to EU-27, Norway, Switzerland and United Kingdom since

(2) Data relating to total exports and total imports include EU-27 intra-trade (double counting in some cases)

and Serbia included since

Source: EFPIA member associations (official figures) - (e): EFPIA estimate; Eurostat (EU-27 trade data 2000-2024)

- by the time a medicinal product reaches the market, an average of 12-13 years will have elapsed since the first synthesis of the new active substance;

Note:

Note:

The figures relate to the R&D carried out in each country. Poland, Slovenia, U.K.: 2022 data; Austria, Netherlands: 2021 data; Hungary, Slovakia, Turkey: 2020 data; Norway: 2015 data; Cyprus, Ireland: 2013 data; Croatia: 2011 data Belgium, Croatia, Denmark, France, Greece, Ireland, Italy, Netherlands, Norway (LMI members), Romania, Slovenia, Sweden, Switzerland (Interpharma members), Turkey: estimate

The figures relate to the R&D carried out in each country. Poland, Slovenia, U.K.: 2022 data; Austria, Netherlands: 2021 data; Hungary, Slovakia, Turkey: 2020 data; Norway: 2015 data; Cyprus, Ireland: 2013 data; Croatia: 2011 data Belgium, Croatia, Denmark, France, Greece, Ireland, Italy, Netherlands, Norway (LMI members), Romania, Slovenia, Sweden, Switzerland (Interpharma members), Turkey: estimate

Source: EFPIA member associations (official figures)

EMPLOYMENT IN THE PHARMACEUTICAL INDUSTRY (1995-2024)

EMPLOYMENT IN THE PHARMACEUTICAL INDUSTRY (1995-2024)

Source: EFPIA member associations (official figures)

Note:

Note:

Data includes Iceland (since 2017), Croatia, Lithuania and Turkey (since 2010), Bulgaria, Estonia and Hungary (since 2009), Czech Republic (since 2008), Cyprus (since 2007), Latvia, Romania & Slovakia (since 2005), Malta, Poland and Slovenia (since 2004)

Data includes Iceland (since 2017), Croatia, Lithuania and Turkey (since 2010), Bulgaria, Estonia and Hungary (since 2009), Czech Republic (since 2008), Cyprus (since 2007), Latvia, Romania & Slovakia (since 2005), Malta, Poland and Slovenia (since 2004)

Source: EFPIA member associations (official figures) - (e): EFPIA estimate

Source: EFPIA member associations (official figures) - (e): EFPIA estimate

EMPLOYMENT IN PHARMACEUTICAL R&D (1995-2024)

EMPLOYMENT IN PHARMACEUTICAL R&D (1995-2024)

Note:

The importance of Research and Development

ther social security nor patients but deprives the industry of additional resources to fund R&D and leads to supply dis ruptions on several smaller markets. Par allel trade was estimated to amount to € 6,497 million (value at ex-factory prices) in 2023.

All new medicines introduced into the market are the result of lengthy, costly and risky research and development (R&D) conducted by pharmaceutical companies:

- the cost of researching and developing a new chemical or biological entity is estimated at € 3,130 million ($ 3,296 million in year 2022 dollars) in 2022 applying the methodology used by Joseph A. DiMasi in his 1991, 2003 and 2016 Tuft Center for the Study of Drug Development studies (Wild, C. and Fabian, D. (2024), AIHTA, The Role of Public Contributions to the Development of Health Innovations, HTA-Projektbericht 158). On average, only one to two of every 10,000 substances synthesised in laboratories will successfully pass all stages of development required to become a marketable medicine. In 2023 the pharmaceutical industry invested about € 52,400 million in R&D in Europe. A decade of strong US market dominance led to a significant shift of economic and research activity towards the US during the periods 19952005 and 2015-2020, a trend that has been somewhat slowing down following the Covid pandemic. Additionally, Europe is now facing increasing competition from emerging economies: rapid growth in the market and research environments in countries such as China are contributing to the move of economic and research activities to non-European markets. In 2024 China outpaced both US and Europe as originators of new active substances launched for the first time on the world market. In 2024, out of a total of 81 new molecules, 28 originated from Chinese (including Hong Kong) headquartered companies whilst 25 and 18 originated from US and European headquartered companies respectively. After having lost its crown as the top innovation region in the world in 2000, Europe is now on the third place on the podium as originator of new molecules.

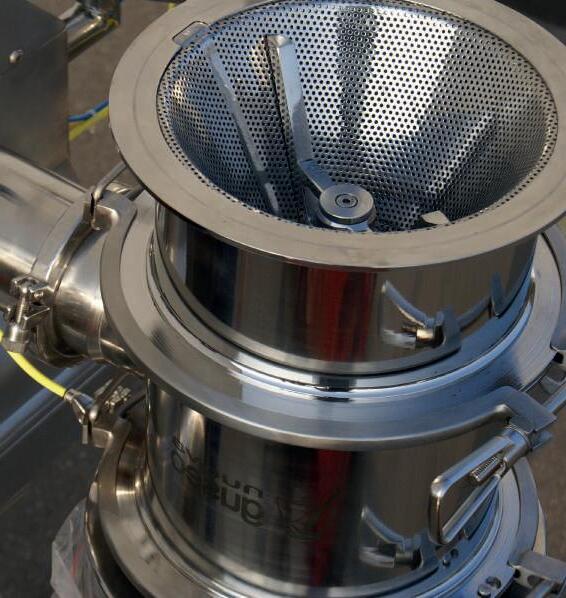

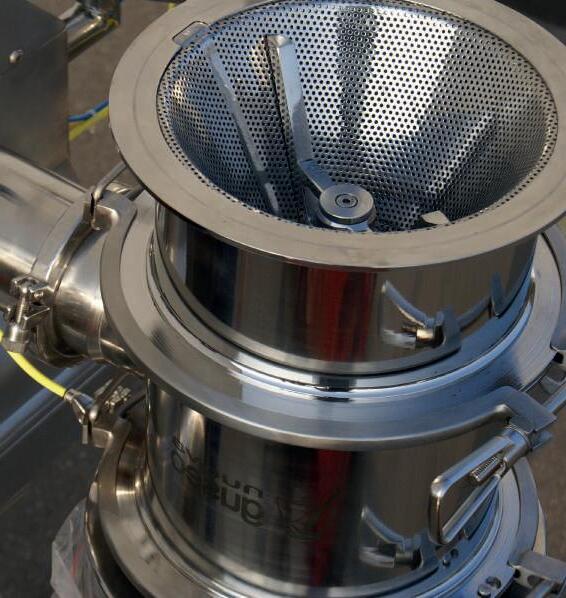

Our passion for screening was conceived at the end of the 1970s.

We have always demonstrated intuition and enthusiasm, thanks to which we have successfully established ourselves in the world of screening.

Our way of working is characterised by a high level of flexibility, which allows us to obtain significant immediate results.

Direct contact with customer issues constantly stimulates our planning

We offer an absolute guarantee of quality, and we have always guaranteed optimum operation of the vibrating screen made ad personam

We are a 100% Made in Italy company; every one of our vibrating screens is entirely made inhouse.

Our vibrating screens are able to cope with very difficult screening and high hourly flow rates, thanks to the special vibrating motors installed, designed to operate continuously 24 hours a day, 365 days a year.

EMILOS srl Via della Costituzione, 6 42025 Cavriago (RE) - Italy Tel. 0522 575010

E-mail: info@emilos.it www.emilos.it

Generics and biosimilars are usually produced by a manufacturer who is not the inventor of the original chemical or biological substance. They can be marketed after expiry of the intellectual property

protection rights of the innovative product. Data might not be strictly comparable across countries due to differences in procurement and reimbursement practices.

SHARE (ESTIMATE - IN %) ACCOUNTED FOR BY GENERICS IN PHARMACEUTICAL MARKET SALES VALUE (AT EX-FACTORY PRICES), 2023

Note:

Bulgaria, Croatia, Czech Republic, Denmark, Estonia, Finland, Hungary, Netherlands, Slovenia, U.K.: share of generics in pharmacy market sales

Austria, Belgium, Cyprus, France, Germany, Greece, Italy, Portugal, Spain: share of generics in reimbursable pharmacy market sales

Ireland, Latvia, Lithuania, Luxembourg, Norway, Poland, Romania, Serbia, Slovakia, Sweden, Switzerland, Turkey: share of generics in total market sales

Lithuania: 2020 data; Cyprus, Iceland, Malta: data not available

France: data relate only to those active substances listed on the official list of medicines

Source: EFPIA member associations

The North American market remained the world’s largest one

The world pharmaceutical (prescription) market was worth an estimated € 1,413,609 million ($ 1,528,535 million) at ex-factory prices in 2024. The North American market (USA & Canada) remained the world’s largest market with a 54.8% share, well ahead of Europe, China and Japan.

Distribution margins, which are generally fixed by governments, and VAT rates differ significantly from country to country in Europe. On average, approximately one third of the retail price of a medicine reverts to distributors (pharmacists and wholesalers) and the State.

Generics and biosimilars

Generics and biosimilars are usually produced by a manufacturer who is not the inventor of the original chemical or biological substance. They can be marketed after expiry of the intellectual property protection rights of the innovative product. Data might not be strictly comparable across countries due to differences in procurement and reimbursement practices.

The added value of medicines in healthcare

Medicines constitute the smallest part of healthcare costs with, on average, 17.4% of total health expenditure in Europe being spent on pharmaceuticals and other medical goods. In costly diseases such as cancer and rheumatoid arthritis, medicines account for less than 20% of the total disease costs. Medicines can also generate additional savings, for example by substantially reducing costs in other areas of healthcare, including hospital stays and long-term care costs.

Source: EFPIA - European Federation of Pharmaceutical Industries and Associations

| Read More

In the pharmaceutical packaging market, AI and patients choiches are becoming increasingly central and decisive, driving the development of smart, personalized, and sustainable solutions.

In 2025 and the years to come, the pharmaceutical packaging sector is bracing for marked changes and opportunities for all. By the end of 2025, the packaging market for the broader healthcare industry is expected to reach US$159 billion, with predictions putting the value at nearly US$400 billion within the next decade. The pharmaceutical packaging industry plays a pivotal role in the larger healthcare market, ensuring product safety, integrity, and efficacy. As the pharmaceutical industry contends with incoming regulations on sustainability and consumer demands for therapeutics including GLP-1 agonists and innovative treatments, pharmaceuti-

cal packaging will be at the forefront of new ideas and products. The Trend Report “2025 Pharmaceutical Packaging Market Prospects” by CPHI explores the biggest trends affecting the pharmaceutical packaging sector, with a particular focus on the therapeutics demanding innovation and creativity in delivery and packaging. Continuing discussions around meeting sustainability objectives and partnership demands are also influencing the sector’s activities in ways that are changing the industry as a whole.

The pharmaceutical industry is seeing an unprecedented moment

in history where consumer-driven demands are shaping the priorities of the pharmaceutical supply chain. Pharmaceutical companies are now looking for packaging solutions for all kinds of innovative drug products to meet consumer demand.

Increasing demand for certain blockbuster therapeutics, sustainability concerns, and drug delivery devices geared towards specific patient populations like geriatric patients and accessible designs are forcing pharmaceutical companies to take their therapeutic packaging considerations into account at the start of their drug development pipelines.

Top therapeutics demand packaging innovation

While sustainability and ESG practices are a continuing factor driving corporate decision making, patient considerations are now also playing a bigger role in dictating the packaging market. Now, a major driver for new forms of packaging is the response to increasing demand in particular therapeutics.

“What we are seeing in the industry today is a focus on bio-therapeutics (biologics and biological products)”, explains Asmita Khanolkar, Senior Director at SMC Ltd. “A lot of these biological products are complex formulations with special storage and delivery requirements. With injectables in mind, delivery is typically via devices and the stability of biologics requires cold chain storage. This requires a different type of packaging strategy, including a patient-centric approach for self-administration ease. This is causing a shift from standard, off-the-shelf available packaging (that may not meet requirements) to a more strategic packaging solution for the biologics pipeline, cold chain management, and transport logistics. Another item to consider is the focus on ‘one size does not fit all’ approach. Unlike the blockbuster drug launches of the past, with targeted therapies and personalised medicines, patient populations tend to be much smaller. The cost-toscale effectiveness and subsequent longterm therapy costs must be balanced with meeting the patient needs. There are a number of new nuances to consider when planning packaging strategies around biologics, personalised medicine, targeted therapies, selfadministration, targeted populations that relatively smaller, and small-batch manufacturing”.

Pharma 5.0 and packaging success

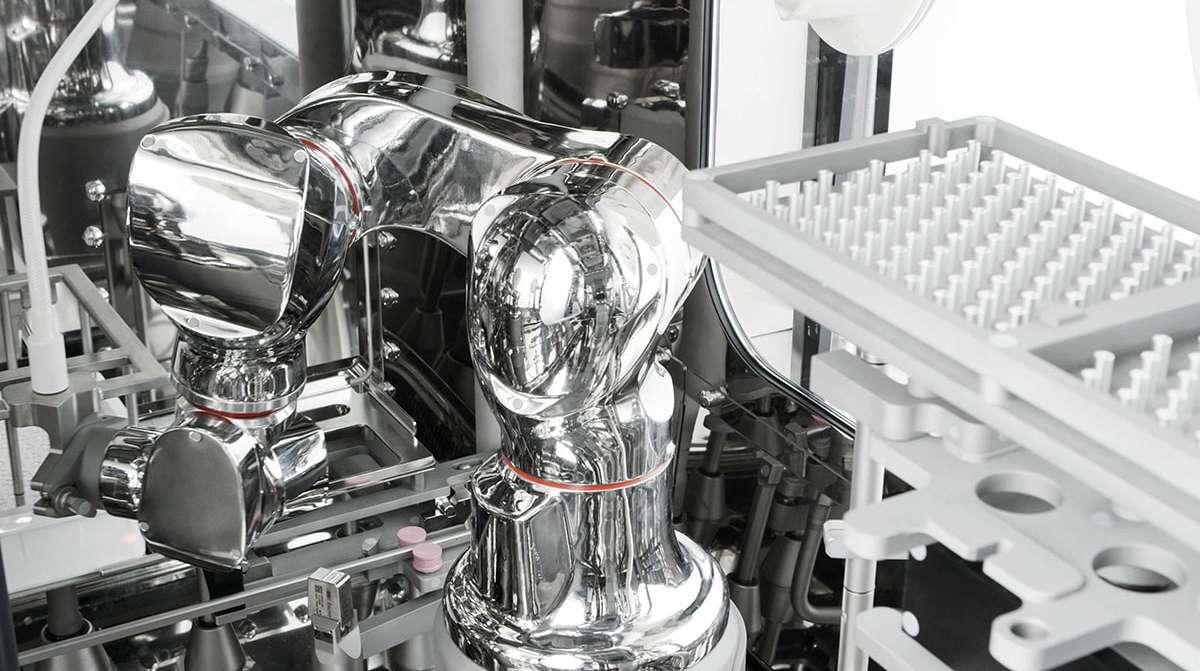

The digitisation of the pharmaceutical supply chain remains a hot topic for all in the industry – and pharmaceutical packaging is no exception. While automation in the pharmaceutical packaging realm is nothing new, the surge in technologies around artificial intelligence and deep machine learning are bringing new awareness to how technology can further innovation in pharma packaging. Importantly, AI-support digital technologies can also help support both patients and companies.

“The pharmaceutical packaging and drug delivery device sectors can leverage digital technologies and AI in several ways to drive innovation and enhance patient support”, adds Lewening. “Smart packaging for enhanced patient adherence; AI-powered supply chain optimization; personalized and patient-centric packaging; advanced drug delivery devices; sustainability and waste reduction”.

Delivering on sustainability initiatives

Sustainability in the pharmaceutical packaging sector continues to be an ongoing discussion. Whether it is implementing the measures promised, recording and reporting to keep each other accountable, or even knowing where to start, it is more important now than ever for pharmaceutical companies and their partners to flesh out their sustaina-

bility strategies for business success. “Some of the biggest challenges faced by the pharmaceutical packaging and drug delivery device companies are around sustainability and regulatory pressures”, states Lengwe Sinkala, a Human Factors and UX Consultant at ClariMed, Inc. “The pharmaceutical industry faces increasing environmental regulations and pressure to reduce single-use plastics and carbon emissions. For example, prefilled syringes, inhalers, and autoinjectors generate medical waste and pose recycling challeng-

The pharmaceutical industry is seeing an unprecedented moment in history where consumerdriven demands are shaping the priorities of the pharmaceutical supply chain

The surge in technologies around artificial intelligence and deep machine learning are bringing new awareness to how technology can further innovation in pharma packaging

es. EU and US sustainability laws demand ecofriendly alternatives, such as France’s ban on certain plastic packaging for medical use”.

Initiatives such as the UK’s Extended Producer Responsibility (EPR) are also being put into place to force organisations responsible for packaging to take accountability for the recyclability and lifecycle of their packaging products. Regulations such as these, while a socially responsible step in the right direction, can also provide difficult challenges for companies affected.

“Stricter global regulations, such as the EU Green Deal, PPWR, and Extended Producer Responsibility laws, are pushing companies toward sustainable materials and reducing plastic waste”, Lewening comments.

“Developing fully recyclable packaging that still meets strict pharma requirements, however, is complex. Compliance with different regulations that frequently updated demand constant adaptation in packaging design and validation, while shortages in plastics,aluminium, and glass due to geopolitical issues or energy crises and impact the cost

of transportation, constrain supply chains, and impact pricing and profitability”.

Regional policies and shifting priorities for packaging

Discussions of pharmaceutical contract organisations in 2025 cannot be had without mentions of the US Biosecure Act, first proposed in December 2023, approved by Senate and House committees throughout 2024, and passed by the House of Representatives in September 2024. While the Act specifically targets pharmaceutical manufacturers based in China, the wider implications for the pharmaceutical supply chain also holds packaging and drug delivery device companies in anticipation.

“When you look at flexible packaging, this used to be a market that was truly global 10-15 years ago”, explains von Kienlin, Consulting Managing Director of L.E.K. Consulting. “You could produce anywhere and ship anywhere. With oil and gas prices through the roof now, it is not so much the case anymore. Companies are now sourcing much closer due to prohibitive costs – this is just one example where the cost of logistics in shipping has prompted a regionalisation of markets”.

“There’s quite a lot of varying regulations for waste management across countries, which creates further fragmentation”, states Edgar Pogna, Director, Life Science L.E.K. Consulting. “While there are some truly innovative packaging solutions that may seem like they have a competitive advantage, they might only work in an environment where waste is managed in a certain way, for example, how sample films are separated from blisters, or dismantling of injection pens. Even within Europe, there are differences in how this is regulated, creating further compli-

Patient-centricity in particular is at the forefront of innovative packaging opportunities

cations in managing logistics and supply chains”.

The future of industry collaborations for pharma packaging success With M&A activity dominating industry news for pharma in 2024, some are anticipating continuing collaborative deals or further amalgamations of some of the biggest players in the industry, including packaging companies. Packaging companies that saw landmark mergers or acquisitions include that between Smurfit Kappa and WestRock and Amcor’s purchase of Berry Global. While not pureplay pharmaceutical packaging companies, the sector can expect such partnerships to continue shaping how packagers are integrated to help the industry achieve innovation, sustainability, and business goals.

Patient-centricity in particular is at the forefront of innovative packaging opportunities, particularly with ageing populations across the globe demanding accessible packaging options for their medications.

AGENTI FILMANTI - DISGREGANTI - LUBRIFICANTI - GLIDANTI

- LEGANTI - DILUENTI - OPACIZZANTI - AMIDI E DERIVATIPOLIALCOLI - ZUCCHERI - DOLCIFICANTI - VISCOSIZZANTICONSERVANTI - CORRETTORI DI PH - ANTIAGGLOMERANTI - PRINCIPI ATTIVI - PLASTICIZZANTI

Gli eccipienti e le materie prime distribuite da Faravelli ti aiutano a raggiungere la formulazione farmaceutica perfetta, proprio quella che stai cercando: funzionale, sicura, efficace, performante. La formula che rende ogni cliente soddisfatto e felice.

“Accompagniamo con competenza globale e sensibilità locale i nostri partner verso scelte innovative, per formulare il futuro con ingredienti e soluzioni affidabili e sostenibili”.

With Powtech Tecnopharm, the Nuremberg exhibition grounds again become the hub where everything revolves around technologies for processing powders, solids and liquids.

From 23 to 25 September 2025, the Nuremberg exhibition grounds will again become the hub where everything revolves around technologies for processing powders, solids and liquids. Visitors can already look forward to their old favourites as well as some new ideas and concepts. Participants will also benefit from the co-location with Fachpack, the European Trade Fair for Packaging, Technology and Processes. Partec, the prestigious international scientific congress, will be held alongside Powtech Technopharm again in 2025.

A new feature this year is that Powtech Technopharm will now occupy Halls 9 to 12 in the northwest grounds of the exhibition centre. This area is readily accessible directly from the underground station or coming from the eastern section of the grounds through the exhibition park, where live demonstrations of explosions will be held again this year. Many visitors are sure to also benefit from a tour of the other exhibition halls, where Fachpack will simultaneously be showcasing current and future packaging solutions. The Powtech Technopharm

ticket also gives visitors access to Fachpack. “The feedback we are getting from all parties is that the entire processing community is already looking forward to the exhibition again. People have gradually got their heads around the new cycle – two consecutive years of Powtech Technopharm every September, followed by a break in the third year – which makes it easier for people to plan,” says Marianny Eisenhofer, Director of Powtech Technopharm, of the status quo around six months ahead of the event. “In terms of international presence, we are also already making good progress. And with the new Processing Alliance, we will be focusing even more strongly in future on building business relationships in international markets.”

The Processing Alliance of NürnbergMesse GmbH is an international network of leading events for the global processing community that aims to address trends in the respective markets worldwide and focus even more specifically on customer benefits.

Spotlight on pharma Extending the brand to Powtech Technopharm lives up to the new

claim “Your Destination for Processing Technology” and puts the spotlight on the pharmaceutical and life sciences industry, especially GxP-compliant manufacturing of liquid, semi-solid and solid pharmaceuticals. The supporting organisation APV (International Association for Pharmaceutical Technology) is honorary sponsor. The Technopharm Forum has been set up specifically to showcase in Stage Talks the various segments of the pharmaceutical industry. At the new “Pharma-in-Focus” pavilion, companies will present specific products and solutions to the high-calibre professional audience with relatively little effort but significant impact.

Supporting programme offers balanced blend of old and new At the September 2025 event, the supporting programme for Powtech Technopharm will include familiar features and new concepts. Alongside the Technopharm Forum, the popular Powtech Forum gives companies another opportunity to present themselves and their innovative solutions to an interested audience. The Call for Papers has already been launched and is available on the website. A proven and familiar feature is the special show by the VDMA – a long-standing partner to Powtech Technopharm – which will also be part of the supporting programme this year. Organised by the VDMA’s

Air Handling Technology and Processing Technology and Equipment associations, it will feature presentations by companies under the banner “Experience the process chain of the bulk solids industry first-hand”. The Networking Pavilion will once again offer established market players and newcomers the opportunity to take part in the trade fair without overstretching their resources. A new addition to the programme is the inaugural meeting of the “Women4Processing” network for women working in the processing industry. The aim is to give women a platform where they can share knowledge and ideas, learn from one another, and provide mutual support. Women working in processing technology will also benefit from dialogue with the participants of “Women4Packaging”, a similar network organised by Fachpack.

Koeln Parma Exhibitions (KPE), a joint venture of Koelnmesse and Fiere di Parma, launches the first edition of Labotec, the new event entirely concerned with technologies, solutions and services for laboratories and analysis, coming up in Parma – Italy on 28 and 29 October 2025 to promote business opportunities, networking and development for research in Italy. Labotec welcomes exhibitors including producers and distributors

of instrumentation for laboratories, contractor laboratories and service suppliers. The event’s highly qualified visitors, including laboratory directors and managers, quality managers, researchers and scientists, will represent all fields of manufacturing industry (food and beverage, pharmaceuticals, chemicals, cosmetics, life sciences and biotechnologies, environment, livestock farming) as well as medical and care facilities, public sector organisations and research institutes and organisations. In line with its primary mission of underlining and restoring the centrality of the complex role of scientific research in Italy, Labotec offers a stage for a series of projects and special areas that will enrich participants’ experience and make the event an ideal hub for exchanging knowledge. These will include LabWorld Arena, organised in collaboration with partner LabWorld. it, hosting conferences and work-

shops focusing on strategic topics of current importance in the field and addressing issues such as competencies and innovative management in the lab, automation and artificial intelligence, advanced analytics, sustainability and green labs, and the trends and potential of investment in research. A special Startup Area will open a window on innovative trends with a true treasure chest of pioneering ideas and projects underway all over Italy, drawing on the experience of visionary startups. Another highly interactive section will be the Demo Area presenting real and virtual demonstrations of cutting-edge technologies. There will be plenty of opportunities for networking and job placement thanks to the Talent Academy project, aimed at establishing initial contact between companies in the field and highly qualified young talents in order to promote their integration into the world of work.

Dechema, which organises the Achema, the leading trade show for the global process industry, launches Achema Middle East in Saudi Arabia together with Messe Frankfurt. Dechema and Messe Frankfurt have reached the necessary agreements and the event will be held for the first time in Riyadh in 2026, and then every three years after that. Achema Middle East is supported by the Ministry of Industry and Mineral Resources of the Kingdom of Saudi Arabia. This is against the backdrop of Saudi Vision 2030, the ambitious government programme for economic and social development. With Achema Middle East, there will be a new industry meeting place for the process industry in the region, bringing together compa-

nies, political decision-makers and experts to showcase and discuss the very latest developments, technologies and innovations. The event organisers are aiming to attract as many as 400 international exhibitors. The trade show will be accompanied by an extensive congress programme.

As Dr Björn Mathes, CEO of Dechema Exhibitions, explains: “With Messe Frankfurt, we have found a strong partner who shares our vision of further expanding Achema internationally, moving into new markets and adding new, future-oriented elements to our programme. Messe Frankfurt brings its vast expertise in the international trade show business and its worldwide network to the table. At the same time, we contribute our

in-depth sector knowledge and technological expertise from the chemical, pharmaceutical and biotechnology industry – not to mention the experience and community that comes from organising Achema for over a hundred successful years. This opens up excellent opportunities for us to firmly establish Achema Middle East and to reach a global audience there.”

Messe Frankfurt CEO Wolfgang Marzin adds: “We are very proud that Dechema has been holding its leading event for the chemical industry at our Frankfurt base for 88 years. This is why we are especially pleased to join forces with Dechema in setting up Achema Middle East and to launch this renowned brand in a whole new region.”

Where safety isn’t optional: tailor-made environments for pharma with guaranteed contamination control

Engineering | Design | Planning | Construction & Commissioning

Equipment & Validation | Turnkey | Utilities | Equipment

Cables & Piping | Support & Maintenance

Catalyst performance optimization requires more than just technical expertise – it demands a perfect fusion of human knowledge, reliable guidance and cutting-edge technology. Clariant’s Applied Catalyst Technology (ACT) team was built around this mantra.

Lorena Oviol, Head of Applied Catalyst Technology at Clariant Catalysts, unveils how to achieve real impact by maximizing plant performance with catalysts. Her revelations about the fusion of human expertise and cutting-edge technology will prove invaluable for anyone seeking to understand how catalyst optimization offers a competitive advantage. In today’s rapidly evolving chemical industry, where operational efficiency and plant reliability are paramount, catalyst performance optimization re-

quires more than just technical expertise – it demands a perfect fusion of human knowledge, reliable guidance, and cutting-edge technology. Clariant’s Applied Catalyst Technology (ACT) team was built around this mantra, offering dependable, expert support that builds lasting partnerships with customers. While advanced digital solutions drive operational excellence, it’s the team’s hands-on guidance and deep understanding of each customer’s specific challenges that truly set ACT apart. The team serves as trusted advisors who

combine their technical expertise with proven methodologies and advanced digital tools, helping prevent costly downtimes and maximize operational value in an increasingly competitive marketplace.

How does the ACT team combine expertise and innovative solutions to improve catalyst performance throughout the lifecycle?

“The ACT team takes pride in delivering value that extends beyond technical support. By integrating decades

of human expertise with sophisticated digital solutions like CLARITY™, we develop a comprehensive understanding of each catalyst’s lifecycle. This holistic approach enables us to create tailored solutions that precisely match our customers’ operational requirements. What distinguishes our methodology is our commitment to comprehensive lifecycle management rather than focusing on isolated performance metrics. Our team of skilled professionals collaborates with advanced models and platforms to continuously monitor, enhance, and optimize catalyst performance. This integrated approach ensures our customers receive comprehensive solutions, rather than just technical troubleshooting.”

Can you elaborate on the importance of global-local expertise synthesis, and how programs like the Clariant Catalyst Institute (CCI) contribute to this fusion?

“The power of our global-local approach lies in its ability to deliver the best of both worlds. We have strategically positioned five regional teams across the globe, ensuring that our customers receive support that’s both world-class and locally relevant. The Clariant Catalyst Institute (CCI) plays a crucial role in this synthesis by equipping and empowering our talented engineers, account managers, and R&D scientists through comprehensive catalyst training. This ongoing development ensures our teams maintain industry excellence standards.

Our local teams understand the specific challenges and requirements of their regions, while our global network ensures that innovations and best practices are shared across all locations. This structure allows us to be responsive to local needs while maintaining consistent, high-quality standards worldwide. Through the CCI’s development programs, we ensure our customers work

with the most qualified catalyst solutions team capable of optimizing performance, efficiency, and sustainability. The CCI’s continuous training and development opportunities keep our teams at the forefront of catalyst technology, enabling us to provide consistent, reliable service.”

How does Clarity exemplify the combination of human expertise and innovative technology for enhancing performance?

“The integration of our digital service portal Clarity with ACT team’s extensive expertise has transformed the way we deliver value to our customers. By incorporating Navigance’s capabilities, we’ve created a unique position in the market to deliver optimized solutions that enhance customer interactions and operational outcomes. In an environment of increasing industrial competition, our combination of advanced tools and data-driven analytics empowers customers to maintain their competitive advantage.

The real-world impact of Clarity is evidenced through customer feedback across various chemical industries. Plant managers and technical officers from global chemical companies have praised the platform’s ability to display catalyst operations in real-time, monitoring critical parameters like pressure drop and hotspot locations.”

In what ways does the ACT team integrate expertise and advanced solutions to contribute to Clariant’s safety goals?

“In the ACT team, we prioritize looking out for each other while implementing comprehensive safety practices in our daily operations. This approach ensures that safety standards are well integrated into our work, driving continuous improvement in how we operate.

Our team regularly shares safety

learnings and best practices, helping to build and reinforce a strong safe ty culture. Through regular safety re views and discussions, we ensure that safety remains a top priority in our daily work. When optimizing catalyst performance, we operate within de fined safety parameters and en courage open communication about safety concerns and im provements.”

This commitment to safety ex tends to how we work with our customers, sharing rel evant safety insights and promoting responsible op erational practices.”

How does ACT set Clariant Catalysts apart by going the extra mile beyond technical service to become a trusted partner?

“What truly sets us apart is our commitment to being more than just a service provider – we aim to be a trusted partner in our customers’ success. This partnership approach is embedded in everything we do, from our global-local presence to our investment in cutting-edge digital solutions like Clarity.

We firmly believe that by working together, we can maximize the promise of our customer’s technology. Our approach combines lifetime coverage of catalyst performance with state-of-theart digital platforms and tools, all supported by our global network of reliable experts.

The future of catalyst technology requires this powerful synthesis of expert service and cutting-edge solutions. At Clariant, we’re committed to continuously evolving this synthesis to generate increasing value for our customers, setting new benchmarks in technical service delivery and customer collaboration.”

Source: https://www.clariant.com/en/ Corporate/Blog

Eli Lilly and Company announced results from the longterm extension (LTE) of the Phase 3 TRAILBLAZER-ALZ 2 study showing that participants treated with Kisunla (donanemab-azbt) demonstrated slowing of decline, a benefit that continued to grow over three years compared to an untreated external cohort from the Alzheimer’s Disease Neuroimaging Initiative (ADNI).

Participants in the study who started treatment later still saw benefit. However, earlier initiation of Kisunla in study participants significantly reduced the risk of progression to the next stage of the disease compared to those who received Kisunla treatment later. These data were shared as a late breaking 2025 Alzheimer’s Association International Conference (AAIC) presentation in Toronto.

“The TRAILBLAZER-ALZ 2 long-term extension reaffirms that Kisunla delivered sustained clinical benefit that continued to increase over three years and a consistent safety profile,” said Mark Mintun, M.D., group vice president, Neuroscience Research & Development, Eli Lilly and Company.

“Participants continued to show meaningful outcomes, re-

FDA has granted 510(k) clearance for Takeda’s devices to simplify HYQVIA administration

Takeda announced that the U.S. Food and Drug Administration (FDA) has granted 510(k) clearance for HyHub™ and HyHub™ Duo, devices for patients 17 years of age and older that allow HYQVIA® [Immune Globulin Infusion (Human), 10% with Recombinant Human Hyaluronidase] to be transferred from vials without using a needle in a home environment or clinical setting. The HYQVIA administration process consists of dual vial units (DVUs) including one vial of immunoglobulin (IG) and one vial of hyaluronidase. HyHub and HyHub Duo, which act as docking stations for these vials, were developed to simplify administration of HYQVIA by reducing the number of steps required to prepare the infusion of two DVUs or more. HYQVIA is a combination of IG and hyaluronidase for facilitated subcutaneous immunoglobulin (SCIg) infusion that is approved for treatment of adults and chil-

dren two years of age and older with primary immunodeficiency (PI) and as maintenance therapy for adults with chronic inflammatory demyelinating polyneuropathy (CIDP) in the United States. Depending on the indication, HYQVIA can be infused up to once monthly (every two, three or four weeks).

“This milestone exemplifies our dedication to advancing innovative solutions that can enhance the treatment administration experience for people who rely on infusions of facilitated immunoglobulin like HYQVIA,” said Kristina Allikmets, senior vice president and head of Research & Development for Takeda’s Plasma-Derived Therapies Business Unit. “We designed HyHub and HyHub Duo, Takeda’s first customized devices for use with a plasma-derived therapy, with input from patients and caregivers, demonstrating our focus on leveraging technology and deep insights to

inforcing the long-term value of early intervention.”

The TRAILBLAZER-ALZ 2 LTE study was a Phase 3, double-blind extension of the original TRAILBLAZER-ALZ 2 trial, evaluating the efficacy and safety of Kisunla in individuals with early symptomatic Alzheimer’s disease. Participants originally treated with Kisunla either continued treatment or were switched to placebo, while those initially on placebo began Kisunla in a blinded manner. An external comparator group from ADNI was used to assess outcomes against a matched, untreated population.

offer a patient-centric ecosystem of support throughout the treatment journey.”

HyHub and HyHub Duo reduce the number of steps required to prepare the IG and hyaluronidase of the HYQVIA infusion by up to half compared to infusing with a pooling bag depending on the device and number of DVUs used.

HyHub and HyHub Duo also reduce the ancillary supplies required to prepare the infusion and a dedicated carrier bag is available for convenience that enables room-to-room mobility.

“For people living with primary immunodeficiency, innovative devices that can help simplify the administration process of their immunoglobulin treatment can be especially meaningful as many require lifelong treatment for their disease,” said Jorey Berry, president and chief executive officer of the Immune Deficiency Foundation.

HyHub and HyHub Duo are intended for use only with HYQVIA and the devices will be available at no additional cost to patients.