Tungsten heavy alloys

| contents | news | advertisers | events | website | e-newsletter |

Tungsten heavy alloys: An exploration of how key property combinations enable better mechanical performance Applications for PM tungsten heavy alloys span from components for wristwatches and nuclear fusion plasma systems to parts for X-ray systems and eccentric vibrators. Given the huge range of applications, it stands to reason that an equally large variety of compositions, processing cycles and microstructures are used to deliver target combinations of density, strength, hardness, stiffness and conductivity in PM tungsten alloy parts. In this article, Prof Randall German reviews the relationships between key material properties used to achieve these combinations.

Tungsten heavy alloys were first produced nearly a century ago. The early high-density compositions provided radiation protection in a machinable tungsten-based material. From that start arose an array of applications combining tungsten’s density and stiffness with the formability afforded by transition metal (iron, copper, nickel, cobalt) alloy matrix. Applications for tungsten heavy alloys are highly diverse; as well as those applications listed in the introduction to this article, the materials’ thermal-electrical properties match the needs for semiconductor heat sinks, electrodischarge machining tools, and plasma containment structures. Still other uses arise in electrical arc erosion resistance and die casting tools and, for the past half century, a significant use has been in penetrators, munitions, projectiles, and perforation tools that require high density and high strength.

© 2021 Inovar Communications Ltd

Accordingly, a large variety of compositions, processing cycles, and microstructures are used to deliver target combinations of density, strength, hardness, stiffness, and conductivity. Some of the key property combinations are introduced in this article.

What are tungsten heavy alloys? It is common to abbreviate tungsten heavy alloys as WHA – where W is the chemical symbol for tungsten. With respect to properties, there is considerable sensitivity to the processing

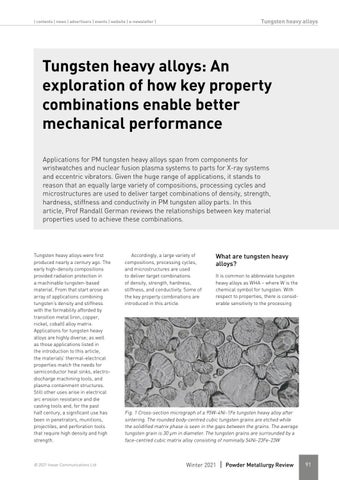

Fig. 1 Cross-section micrograph of a 95W-4Ni-1Fe tungsten heavy alloy after sintering. The rounded body-centred cubic tungsten grains are etched while the solidified matrix phase is seen in the gaps between the grains. The average tungsten grain is 30 μm in diameter. The tungsten grains are surrounded by a face-centred cubic matrix alloy consisting of nominally 54Ni-23Fe-23W

Winter 2021

Powder Metallurgy Review

91