| contents | news | events | advertisers | website | e-newsletter |

Mass customisation via metal AM

Forging a process for mass customisation via metal Additive Manufacturing Metal Additive Manufacturing technologies offer the potential for true mass customisation, but in order to leverage this opportunity, new, complex workflows and business models have to be implemented. In this article, Siemens Digital Industries Software's Ashley Eckhoff considers the challenges when addressing the topic, from the addition of further complexity, to an already challenging Additive Manufacturing workflow, to traceability and regulation. By adapting the AM process to meet these needs, companies can reap the benefits of new markets uniquely suited to this technology.

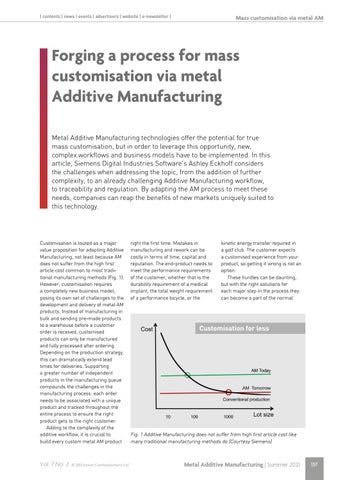

Customisation is touted as a major value proposition for adopting Additive Manufacturing, not least because AM does not suffer from the high first article cost common to most traditional manufacturing methods (Fig. 1). However, customisation requires a completely new business model, posing its own set of challenges to the development and delivery of metal AM products. Instead of manufacturing in bulk and sending pre-made products to a warehouse before a customer order is received, customised products can only be manufactured and fully processed after ordering. Depending on the production strategy, this can dramatically extend lead times for deliveries. Supporting a greater number of independent products in the manufacturing queue compounds the challenges in the manufacturing process: each order needs to be associated with a unique product and tracked throughout the entire process to ensure the right product gets to the right customer. Adding to the complexity of the additive workflow, it is crucial to build every custom metal AM product

Vol. 7 No. 2 © 2021 Inovar Communications Ltd

right the first time. Mistakes in manufacturing and rework can be costly in terms of time, capital and reputation. The end-product needs to meet the performance requirements of the customer, whether that is the durability requirement of a medical implant, the total weight requirement of a performance bicycle, or the

kinetic energy transfer required in a golf club. The customer expects a customised experience from your product, so getting it wrong is not an option. These hurdles can be daunting, but with the right solutions for each major step in the process they can become a part of the normal

Customisation for less

Fig. 1 Additive Manufacturing does not suffer from high first article cost like many traditional manufacturing methods do (Courtesy Siemens)

Metal Additive Manufacturing | Summer 2021

137