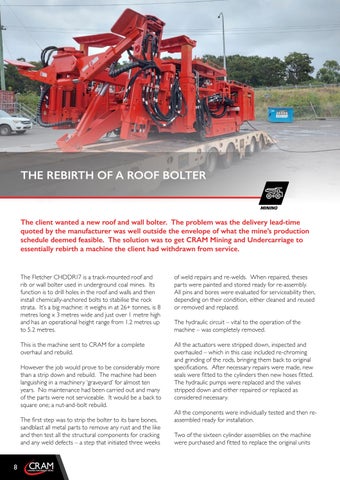

THE REBIRTH OF A ROOF BOLTER

The client wanted a new roof and wall bolter. The problem was the delivery lead-time quoted by the manufacturer was well outside the envelope of what the mine’s production schedule deemed feasible. The solution was to get CRAM Mining and Undercarriage to essentially rebirth a machine the client had withdrawn from service.

The Fletcher CHDDR17 is a track-mounted roof and rib or wall bolter used in underground coal mines. Its function is to drill holes in the roof and walls and then install chemically-anchored bolts to stabilise the rock strata. It’s a big machine: it weighs in at 26+ tonnes, is 8 metres long x 3 metres wide and just over 1 metre high and has an operational height range from 1.2 metres up to 5.2 metres.

of weld repairs and re-welds. When repaired, theses parts were painted and stored ready for re-assembly. All pins and bores were evaluated for serviceability then, depending on their condition, either cleaned and reused or removed and replaced.

This is the machine sent to CRAM for a complete overhaul and rebuild.

All the actuators were stripped down, inspected and overhauled – which in this case included re-chroming and grinding of the rods, bringing them back to original specifications. After necessary repairs were made, new seals were fitted to the cylinders then new hoses fitted. The hydraulic pumps were replaced and the valves stripped down and either repaired or replaced as considered necessary.

However the job would prove to be considerably more than a strip down and rebuild. The machine had been languishing in a machinery ‘graveyard’ for almost ten years. No maintenance had been carried out and many of the parts were not serviceable. It would be a back to square one; a nut-and-bolt rebuild. The first step was to strip the bolter to its bare bones, sandblast all metal parts to remove any rust and the like and then test all the structural components for cracking and any weld defects – a step that initiated three weeks

8

The hydraulic circuit – vital to the operation of the machine – was completely removed.

All the components were individually tested and then reassembled ready for installation. Two of the sixteen cylinder assemblies on the machine were purchased and fitted to replace the original units