WOLLSDOR - PREMIUM LEATHER FROM AUSTRIA

WOLLSDOR - PREMIUM LEATHER FROM AUSTRIA

LOVATO - A CENTURY OF MARKET LEADERSHIP

LOVATO - A CENTURY OF MARKET LEADERSHIP

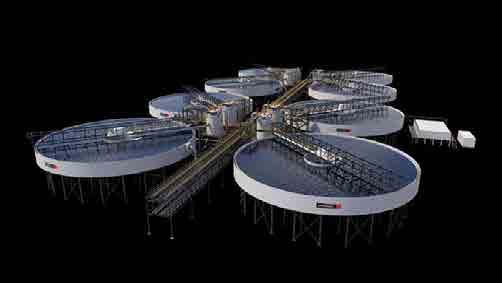

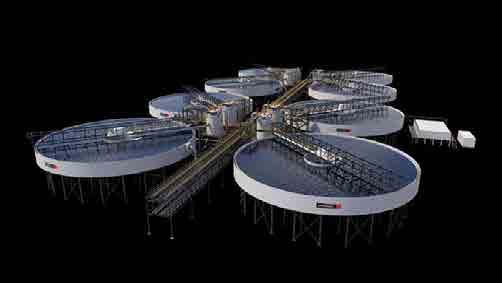

SOLVERA GAWEŁ TECHNOLOGY S.A.

SOLVERA GAWEŁ TECHNOLOGY S.A.

FASTENERS OF THE HIGHEST QUALITY

FASTENERS OF THE HIGHEST QUALITY

THE FUTURE OF NUCLEAR ENERGY IN EUROPE THE FUTURE OF NUCLEAR ENERGY IN EUROPE

VOLUME 33/1 – 2023

The European Energy Crisis: Causes and Impacts

The European energy crisis has been a pressing issue for many years, and it has only become more urgent in recent times. The crisis is rooted in several complex factors, including growing demand for energy, aging infrastructure, and a shift towards renewable energy sources. In this essay, we will explore the causes and effects of the European energy crisis, as well as its long-term impacts on the region.

The European energy crisis has its roots in the continent's aging infrastructure. Much of the energy infrastructure in Europe is decades old, and it is struggling to keep up with the growing demand for energy. This is particularly true in countries like Germany and France, which have large populations and high energy consumption rates. As a result, the energy grid in these countries is under strain, and power outages and blackouts are becoming more common.

Another major factor contributing to the European energy crisis is the shift towards renewable energy sources. While this is a positive development in the long run, it has created significant challenges in the short term. Renewable energy sources like wind and solar are less reliable than traditional sources like coal and natural gas, and they often require significant investments in infrastructure and storage capacity. This has created a mismatch between supply and demand, which has led to energy shortages and higher prices.

The European energy crisis has several immediate effects, including higher energy prices and greater volatility in the energy market. As energy becomes scarcer, prices rise, which can create significant economic challenges for consumers and

businesses. This is particularly true for low-income households, who may struggle to pay their energy bills. At the same time, the energy market has become more volatile, with sudden fluctuations in supply and demand causing prices to spike or drop rapidly. This can create significant uncertainty for energy producers and consumers alike, making it difficult to plan for the future.

created by the energy crisis could lead to increased greenhouse gas emissions. As energy becomes scarcer, countries may turn to more polluting sources of energy, such as coal, to meet their energy needs. This could offset some of the gains made by the shift towards renewable energy sources, and lead to increased air pollution and climate change.

Finally, the European energy crisis could have significant political implications. As energy becomes scarcer, countries may become more protective of their energy supplies, leading to greater tensions and conflicts between nations. This could also lead to greater political instability within individual countries, as citizens become increasingly frustrated with the high cost and unreliability of energy. In the worstcase scenario, the energy crisis could lead to social unrest or even political upheaval.

In the long term, the European energy crisis could have significant impacts on the region's economy, environment, and political stability. One major concern is that higher energy prices could make European businesses less competitive globally, leading to a loss of jobs and economic growth. This could also lead to higher inflation rates, which could further erode consumer purchasing power. In addition, the energy crisis could lead to greater dependence on foreign energy sources, which could create geopolitical tensions and reduce energy security.

Another potential long-term impact of the European energy crisis is on the environment. While the shift towards renewable energy sources is positive in the long run, the short-term challenges

To address the European energy crisis, policymakers will need to take a multi-faceted approach. This could involve investing in new energy infrastructure, such as renewable energy plants and energy storage facilities. It could also involve promoting energy efficiency and conservation measures, such as smart meters and building retrofits. Finally, policymakers may need to consider regulatory changes that encourage greater competition in the energy market and reduce dependence on foreign energy sources.

In conclusion, the European energy crisis is a complex and urgent issue that requires immediate attention from policymakers. The crisis is rooted in several factors, including aging infrastructure, growing demand for energy, and a shift towards renewable energy sources n

Industry Europe 3

To address the European energy crisis, policymakers will need to take a multi-faceted approach. This could involve investing in new energy infrastructure, such as renewable energy plants and energy storage facilities.

4 Industry Europe CONTENTS VOL 33/1 Comment 3 Editorial The European Energy Crisis: Causes and Impacts Focus on Nuclear energy, smart cities/infrastructure 6 The Future of Nuclear Energy in Europe Focus on – Construction & Engineering 8 The importance of health & safety in construction Focus on – energy & Utilities 10 Oil & gas exploration, The shift to lower-risk assets & regions Aerospace & Defence 12 Uplifting performance ASCO 16 Aerospace & Defence news The latest developments in the sector Chemicals & Biochemicals 18 Chemicals & Biochemicals news The latest developments in the sector Construction & Engineering 20 Construction & Engineering news The latest developments in the sector Consumer Goods 22 The smart choice Franke Group 26 A century of market leadership LOVATO 30 Premium leather from Austria Wollsdorf 34 Consumer Goods news The latest developments in the sector Energy & Utilities 36 Energy & Utilities news The latest developments in the sector Healthcare 38 Healthcare news The latest developments in the sector Metals & Mining 40 Metals & Mining news The latest developments in the sector Politics & Economics 42 Politics & Economics news The latest developments in Politics and Economics Technology & Innovation 44 Fasteners of the highest quality Solvera Gaweł Technology S.A. 50 Technology & Innovation news The latest developments in Tech and Innovation Transportation 52 Transportation news The latest developments in the sector Editorial Director Roger Sullivan Profile Writers Romana Moares Dariusz Balcerzyk Emma-Jane Batey Director of Sale & Business Development Katarzyna Pozoga Business Partner, Poland Magdalena Grzempczyńska Art & Design studio@industryeurope.net Editorial Office editor@industryeurope.net Accounts accounts@industryeurope.net Industry Europe 110 Boundary Road, Norwich NR6 5JE, United Kingdom Tel: +44 1133 281 173 Email: studio@industryeurope.net Web: www.industryeurope.com Twitter: www.twitter.com/IndustryEurope LinkedIn: www.linkedin.com/company/industry-europe MAX MEDIA GLOBAL LTD. INDUSTRY EUROPE © Industry Europe 2023 No part of this publication may be reproduced in any form for any purpose, other than short sections for the purpose of review, without prior consent of the publisher.

THE FUTURE OF NUCLEAR ENERGY IN EUROPE

Nuclear energy has been a significant contributor to the energy mix of many European countries. However, with the increasing concerns about climate change and the need to transition to clean energy sources, there is a growing debate about the future of nuclear energy in Europe. This article explores the current state of nuclear energy in Europe and examines the prospects for its future.

Europe is home to many nuclear power plants that generate a significant amount of electricity. According to the World Nuclear Association, there are currently 106 nuclear reactors in operation in Europe, which together provide around a

quarter of the region's electricity. France, which has the most nuclear reactors in Europe, generates around 70% of its electricity from nuclear power.

However, the future of nuclear energy in Europe is uncertain. Many countries

have decided to phase out nuclear power plants due to concerns about safety, waste disposal, and the high cost of maintaining aging plants. Germany, for example, decided to phase out its nuclear power plants by 2022, following the Fukushima

FOCUS ON – NUCLEAR ENERGY, SMART CITIES/INFRASTRUCTURE

6 Industry Europe

nuclear disaster in Japan in 2011. Switzerland has also decided to phase out its nuclear power plants by 2035.

Prospects for the Future of Nuclear Energy in Europe

Despite the challenges facing nuclear energy, there are some reasons to be optimistic about its future in Europe. Here are some of the factors that could shape the future of nuclear energy in the region:

1) Climate Change: As the threat of climate change becomes more urgent, many countries are looking for ways to reduce their carbon emissions. Nuclear energy is a low-carbon energy source that can help countries meet their climate goals. As a result, some countries that had previously decided to phase out their nuclear power plants are reconsidering their decisions. For example, the Swedish government recently decided to reverse its decision to phase out nuclear power, citing the need to reduce carbon emissions.

2) Innovation: Nuclear energy technology is advancing, and new designs are being

developed that address some of the concerns about safety and waste disposal. For example, small modular reactors (SMRs) are being developed that are smaller and more flexible than traditional nuclear power plants. SMRs could be used to provide power to remote communities or to replace aging coal-fired power plants. Other innovations, such as molten salt reactors, could provide a safer and more efficient way to generate nuclear power.

3) Energy Security: Europe is heavily reliant on imported fossil fuels to meet its energy needs. Nuclear energy can help reduce this dependence by providing a reliable source of domestic energy. This is particularly important for countries that are vulnerable to energy supply disruptions, such as those that rely heavily on natural gas from Russia.

4) Public Perception: The public's perception of nuclear energy is changing. While nuclear energy has long been associated with safety concerns and the risk of nuclear accidents, there is growing recognition of the role it can play in reducing carbon emissions. A recent survey by the European

Commission found that 54% of Europeans support the use of nuclear energy, up from 49% in 2018.

5) Policy Support: Finally, the future of nuclear energy in Europe will depend on the policy decisions of governments. Governments can provide support for nuclear energy through funding research and development, providing incentives for investment in new nuclear technologies, and setting clear regulatory frameworks for the operation of nuclear power plants.

Conclusion

The future of nuclear energy in Europe is uncertain, but there are reasons to be optimistic about its prospects. As countries grapple with the urgent need to reduce carbon emissions and transition to clean energy sources, nuclear energy could play a significant role. However, this will depend on innovation, public perception, and policy support. As new technologies are developed and the public's perception of nuclear energy evolves, the role of nuclear energy in Europe's energy mix could change significantly in the coming years. n

Industry Europe 7

THE IMPORTANCE OF HEALTH & SAFETY IN CONSTRUCTION

THE IMPORTANCE OF HEALTH & SAFETY IN CONSTRUCTION

Construction is an inherently dangerous profession. Construction workers are exposed to different risks daily - from minor scrapes to severe injuries. Thus, people working in construction should observe proper health and safety practices. In addition, local governments have imposed many regulations to minimise danger in construction.

FOCUS ON – CONSTRUCTION & ENGINEERING

In this article, let's take a closer look at the importance of health and safety in construction.

Helps Keep Employees Safe

The construction sector is one of the most dangerous of all occupations. According to the HSE Statistics, there's an average of 37 deaths per year in construction over the past five years. Most accidents on the construction site are due to trips, slips, and falls. Some were injured while lifting, handling, and falling from a height on site. This figure emphasises the importance of safety in construction.

Given the ever-changing environment in construction, workers often need to work at a height, operate large machinery, handle heavy loads, and work with dangerous materials. By implementing proper health and safety measures and ensuring that workers are aware of these measures, employers can significantly reduce the risks involved in working in these conditions.

The construction industry is responsible for a third of fatal injuries happening in the workplace and 10% of other major workrelated injuries. Injuries and death usually occur due to workers falling from a height, getting struck by moving objects or being crushed by machinery.

Construction workers are also at risk for work-related illnesses, such as carpal tunnel syndrome, vibration white finger, and occupational deafness. These conditions are often due to vibrating tools, inhaling dust and dangerous chemicals, and exposure to loud noises for long periods. Although we cannot totally prevent accidents, they can be minimised if we ensure proper health and safety measures on all construction sites.

Helps Keep Others Safe

The construction managers are not only responsible for protecting their workforce. They must also ensure the safety and well-being of the people passing the construction site and those that live nearby. If they will not enforce health and safety measures on the construction site, dangers could occur, which will not only put the safety of the construction workers at risk but that of the public as well. Construction dangers can affect passers-by in the same way as they affect the workers, which is why proper measures should be put in place and followed by everyone.

One way construction managers can ensure public safety on construction sites

is by managing access to the site. You should clearly define site boundaries and install suitable fencing. Installing a fence can prevent the public from entering the site and keep construction materials from escaping. Some of the main hazards for passers-by are falling objects, scaffolding, and storing materials. Ensure that the materials from your site will not fall outside the site boundary. You can install netting or attach toeboards on scaffolds. Workers must always look at the surroundings when assembling and dismantling scaffolds to ensure no people are nearby. Avoid stacking or storing materials outside the construction site to prevent the likelihood of someone tripping.

Make sure all materials are kept within the parameter of the construction site, if possible, in secure compounds. When handling hazardous chemicals, make sure that you keep this away from the site parameter. In the same way, keep a close eye on the amount of dust leaving your site and landing in other areas.

Can Affect the Profitability of the Business

If construction managers fail to address the issue of health and safety by not implementing proper health and safety measures, the business can stand the risk of losing revenue. Aside from affecting business profitability, many other issues can result if construction companies will not prioritise health and safety.

A construction business could waste significant working hours and productivity if they don't implement health and safety measures, eventually affecting business profitability. If health and safety measures are not adhered to, workers could get sick. As a result, the time they will spend at work will further be reduced, and so as productivity.

Businesses can also face legal consequences if they fail to implement and maintain proper health and safety measures,

which could cost them a lot of money. Furthermore, businesses will have to pay hefty penalties for failure to abide by the health and safety regulations. More severe cases could lead to the closure of the business. And if an employee or passers-by got injured, they could be sued, which could further cost the company lot of money.

Some construction companies may also have their accreditations and memberships from industry bodies confiscated for failure to follow the law on health and safety.

How To Keep Up with Health and Safety

Keeping up with health and safety is essential no matter how big or small your construction business is. If you have employees working on construction sites, you should implement proper health and safety and educate your workers about it. Thankfully, there are plenty of construction relevant health and safety courses online. With online training, you don't have to let your workers undergo actual training onsite since they can take it wherever and whenever they want to. Since it's convenient for them, they no longer have any reason not to attend the training.

One of the main reasons health and safety training is necessary is because the law requires it. The health and safety at Work Act, introduced in 1974, is a piece of legislation requiring employers to take reasonable and practical steps to ensure the health and safety of their employees at work.

Not adhering to the health and safety law can lead to severe consequences. The UK government has a zero-tolerance approach against companies that don't abide by the law. The hefty penalties could affect the company's financial security, resulting in bankruptcy and closure. Aside from the financial burden, breaking the health and safety law could result in a criminal prosecution that can affect the company's reputation. n

Industry Europe 9

OIL & GAS EXPLORATION

SHRINKS,

COMPANIES SHIFT

TO

LOWER-RISK ASSETS & REGIONS

OIL & GAS EXPLORATION SHRINKS, COMPANIES SHIFT TO LOWER-RISK ASSETS & REGIONS

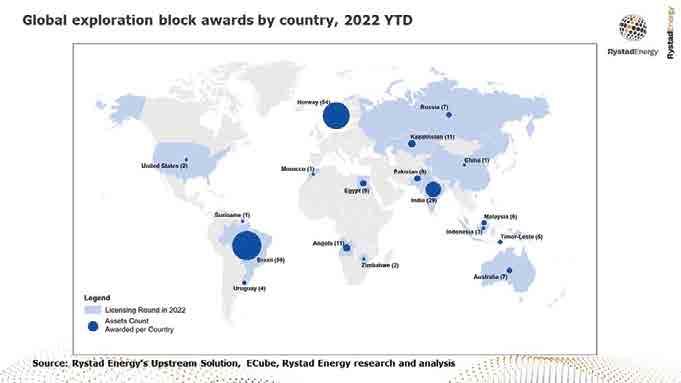

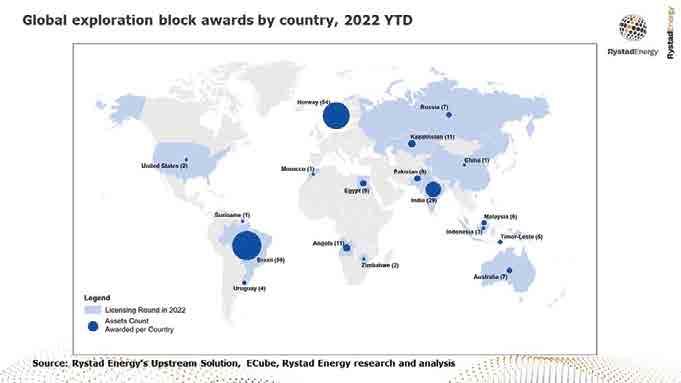

Global oil and gas exploration is set to falter this year as the number of licensed blocks and total acreage fall to near all-time lows as the sector struggles to shake off the effects of the Covid-19 pandemic and the ensuing oil market crash, Rystad Energy research shows.

Only 21 lease rounds were completed globally through August this year, half of the 42 rounds held in the first eight months of 2021. The acreage awarded so far this year has shrunk to a 20-year low of 320,000 square kilometres. Global lease rounds are expected to total 44 this year, 14 less than in 2021 and the lowest level since 2000.

Global spending on exploration has been falling in recent years as oil and gas companies seek to limit risk by focusing on core producing assets and regions with guaranteed output, aiming to streamline their operations and build a more resilient business amid market uncertainty and the threat of a recession.

The political landscape is also contributing to the decrease in license awards, with many governments pausing or halting leases and encouraging companies to wrap up exploration activity within already awarded blocks. This trend is likely to continue as governments are less eager to invest in fossil fuel production and instead look ahead to a net zero future.

“Global exploration activity has been on a downward trend in recent years, even before the Covid-19 pandemic and oil market crash, and that looks set to continue this year and beyond. It is clear that oil and gas companies are unwilling to take on the increased risk

associated with new exploration or exploration in environmentally or politically sensitive areas,” says Aatisha Mahajan, Rystad Energy’s vice president of upstream analysis.

The onshore exploration sector is a significant contributor to the decline in awarded acreage. Total onshore acreage awarded in leasing activity has plummeted from more than 560,000 square kilometres in 2019 to a mere 115,000 square kilometres so far this year. Offshore leased acreage also hit a high point in 2019 before dropping off a cliff in 2020 and has remained relatively flat in the past two years.

Concluded lease rounds have dropped significantly in Russia, the US and Australia this year. These countries have held five lease rounds put together so far this year –three in Russia and one each in the US and Australia – down from 17 rounds in the first eight months of 2021 (eight in Russia, five in the US and four in Australia). The drop in the US is primarily driven by the cancellation of Lease Sales 259 and 261 in the Gulf of Mexico and Cook Inlet in Alaska.

Asian licensing has bucked the trend with increased activity and blocks awarded

10 Industry Europe FOCUS ON – ENERGY & UTILITIES

in Malaysia, Indonesia, India and Pakistan. The global decline in licensing rounds has directly affected the awarded acreage, which has hit an all-time low for the January to August period of about 320,000 square kilometres.

The decline in leasing activity has resulted in a considerable drop in Russian acreage awards, falling 90% from a year ago to 9,000 square kilometres, while licensed acreage in Africa shrank 70% to just 46,000 square kilometres spread across Angola, Egypt, Morocco and Zimbabwe, the only African countries to award new exploration acreage to date in 2022. On the other hand, new acreage awarded in Asia between January and August nearly quadrupled from the

same period last year, while South American awarded acreage surged by 140%.

Drilling into the awards

Brazil is the largest contributor in terms of blocks awarded so far this year, with 59 auctioned during its Third Permanent Offer Round. European majors Shell and TotalEnergies took all eight offshore blocks on offer – six and two, respectively. The remaining 51 onshore blocks in the Tucano, Espirito Santo, Potiguar, Reconcavo and Sergipe Alagoas basins went to regional players

3R Petroleum (six blocks), NTF (two), Petro Victory Energy (19), Origem Energia (18), Imetame Energia (three), Petroborn Oleo (two) and CE Engenharia (one).

Other sizeable block awards after Brazil were Norway with 54 new licenses in its APA 2021 round, India with 29 blocks in its OLAP Rounds 6 & 7, and Kazakhstan’s fourth oil and gas auction round, in which 11 blocks were awarded. There was also some sporadic activity in Africa between January and August, with Egypt providing rights to explore in nine blocks and Angola granting two blocks. South America also saw an offshore licensing round in Uruguay, where three exploration blocks were awarded – blocks OFF-2 and OFF-7 to Shell and Block OFF-6 to US independent APA. Challenger Energy signed a 30-year license for OFF-1 through direct negotiation with the government. n

Industry Europe 11

UPLIFTING PERFORMANCE

ASCO, a supplier of the design and manufacture of high-lift structures, complex mechanical assemblies and major functional components, is thriving as a member of Montana Aerospace, a world leader in the extrusion of high-strength aerospace alloys.

Belgium-headquartered ASCO was founded by Emile Boas Senior and operated as a family-owned business for decades, building worldwide recognition and know-how as an industry benchmark for the design, development, manufacture, treatment, and assembly of complex high-lift mechanisms and critical structural (sub-)assemblies, such as large and complex fuselage and wing and landing-gear components, made of lightweight materials.

Historically, ASCO has worked exclusively on commercial aircraft programmes, becoming the preferred partner for the design and manufacture of enhanced ‘Lift and Landing’ solutions for most of the world’s commercial aircraft fleets. More recently, ASCO has also become a primary supplier within several modern military aircraft programmes for primary critical structures.

ASCO has worked hard to diversify its customer base within the international aerospace industry, through its ability to offer engineering solutions in a competitive landscape. Today, its products are incorporated in most of the world’s aircraft, including commercial jets, regional and larger business aircraft, with the customer base including Airbus, Boeing, Bombardier, Embraer, Cessna, Lockheed Martin and others.

The company makes it clear that the continuous development of innovative products and services has not only helped its cus-

tomers meet their objectives but has the added benefit of helping ASCO produce a leaner organization and use more environmentally friendly manufacturing techniques whilst securing long-term financial strength to the benefit of all stakeholders.

Under new management

Last year, the company reached a significant milestone – in April 2022, ASCO announced that its acquisition by Switzerland-based Montana Aerospace, a manufacturer and supplier of structural parts and assemblies, had been completed.

As declared by Montana Aerospace, the combination of ASCO’s and Montana Aerospace’s competences will accelerate growth and reinforce the group’s standing as a strong industrial company wellequipped to meet the customer needs of tomorrow.

Under the new owner, ASCO is set to look for new opportunities to develop high technology solutions for new aircraft platforms, boosting its research programmes to include the development of new concepts using innovative materials and processes.

This focus will be fully supported by the company’ new Chief Executive Officer. Six months ago, the company’s former CEO and owner, Christian Boas, grandson of the company founder, stepped down from his role. His position was assumed by Olaf Lawrenz, an

AEROSPACE & DEFENCE

international manager with over 30 years of experience in the aerospace industry, working for Airbus & Premium AEROTEC, who is set to keep ASCO’s path to success on a steep upward trajectory.

Multi-year contract

Olaf Lawrenz stated that he will focus on a fast and smooth integration of ASCO into the Montana Aerospace Group and on preparing for the ramp-up within different programmes.

ASCO will also benefit from Montana Aerospace having achieved another successful year in 2022. Despite the challenges of rising costs and uncertainties in the supply chain, the group has managed to exceed its own expectations. Especially in the fourth quarter of 2022, net sales developed very positively compared to the previous quarters.

At the end of last year, Montana Aerospace scored a significant success by winning another new contract with Airbus for the production of extruded aluminium profiles. The multi-year contract with Europe’s largest aircraft manufacturer will start in 2023.

Montana Aerospace will supply Airbus with structural components for the fuselage and wings of the Airbus A320 to A350 with component lengths of up to 18 meters to be manufactured in the company’s large-format aluminium presses.

With this order from Airbus, Montana Aerospace’s third large-size, heavy press – built and commissioned in just 18 months and the first of its kind in Europe – will start series production in Romania. This new technology deployed in its Romanian plant will enable Montana Aerospace to support its European customers in their local4local procurement strategy.

Promising future

In addition to the expansion and development of the extrusion business in Europe, Montana Aerospace has also invested heavily in the development of its one-stop-shop strategy, expanding its service and product portfolio in the area of complex, critical components. The company is currently in the final stage of its extensive investment programme worth over 600 million Euros.

14 Industry Europe

Kai Arndt, Co-CEO of Montana Aerospace AG , commented on the recent achievements: “Market share gains from the recent acquisitions of ASCO and São Marco, the second largest magneto-wire manufacturer in Brazil, completed in 2022, as well as the recovery and trend reversal in the industry, will continue to drive our growth.”

“Montana Aerospace has invested heavily in expanding competencies and capacities in recent years. With the new order from Airbus, we feel confirmed in our strategy of expanding the extrusion business in Europe, in order to serve our customers locally and to support them in the implementation of their ambitious increase in construction rates.”

“Looking to the future, we are confident that we can continue our dynamic growth strategy as we always focus on delivering the highest quality to our customers and reliably stepping in where other suppliers struggle, “ he concluded. n

AEROSPACE & DEFENCE

New developments in the Aerospace & Defence

displays

The order value amounts to SEK 69 million with deliveries in 2023-2025. MilDef's agreement with a partner in the defense industry concerns the development and delivery of products for tactical communication and enhanced cyber defense. The collaboration involves development work and delivery of a large volume of hardware units. The modernization of the current defense system concerns replacing older technology with MilDef's products, as part of the system's

capability increase. Each system is equipped with several 19/2 computers, switches, panel PCs and ruggedized laptops.

“MilDef and many other defense companies are stepping up their cooperation. This collaboration combines two Swedish defense companies that are specialists in their respective fields. MilDef is trusted to contribute with our cutting-edge expertise; to deliver future-proof IT systems that strengthen the protection of our society," says Björn Karlsson, CEO MilDef Group.

New partnership will take tourists to the stratosphere by balloon

French space startup Stratoflight and global tech and engineering company Expleo have announced a partnership for the development of a new zero-carbon footprint spacecraft that will take passengers to near space.

Stratoflight is a new sustainable mode of transport that will allow passengers to reach the stratosphere - 35km above ground level - in a unique capsule complete with an “external” viewing platform.

For its ascent, the spacecraft uses tried-and-tested zero-pressure balloon technology, filled with green hydrogen, like that used for many years by space agencies such as CNES and NASA for scientific flights. To ensure a zero-carbon footprint, hydrogen will be produced locally at the take-off site via renewable energy, including solar and wind.

The vehicle, which measures 8m in length, 4m in width and 3m in height, can accommodate up to six people, including two pilots.

Reservations for passengers will open in early 2023, with the first flight scheduled for 2025.

Expleo is designing the flight capsule for Stratoflight, which includes an extra-vehicular viewing platform, or “balcony”. Passengers wearing a pressurised suit will be able to step out into space to view the Earth from the stratosphere, at an altitude where the planet’s curvature will be visible and a horizon spanning from Barcelona to Amsterdam is visible, approximately 1239km.

Engineers at Expleo’s innovation laboratory had to consider numerous parameters to ensure a safe and immersive experience for passengers in a capsule with large glass areas in its structure, including structural sizing, interior and exterior panels, design of onboard electronics, safety, and aerodynamics.

The cockpit, made of bio-sourced, recycled or recyclable materials, will be able to fly at speeds of up to 140 km/h for the return to land, thanks to its aerodynamic shape with both straight and curved lines. Descent to land is made under a piloted paraglider.

The programme is being developed with several European partners, including Swing for the parachutes and Spartan Space for the pressure suit.

Arnaud Longobardi, airline pilot and co-founder of Stratoflight, said: "Stratoflight provides passengers with multiple exceptional experiences: the ascent to space that feels like a hot-air balloon flight, stepping out onto the viewing balcony, moving into space like an astronaut, and the landing, similar to free flight in a paraglider; all this in a capsule similar to a spacecraft. For me, this mission is not only the realisation of my dreams as a pilot but also a technological innovation respectful of the planet.”

"Making space accessible to all, while respecting the environment, is at the heart of what we believe in at Expleo. Our teams of space engineers have designed this capsule with this dual objective in mind. And we intend to go further. We are currently investigating the possibility of making the capsule out of new green composite materials based on bamboo, which would further reduce its carbon footprint. We are proud of our work with Stratoflight and of our contribution to this innovation," said Frédérique Rebout, Head of Space, Expleo.

Stratoflight will also offer, each year, several flights to people involved in the areas of preservation of Earth, science and space, in the world of education, and in the charity sector. For more information, visit: www.stratoflight.fr

16 Industry Europe NEWS

In connection with the delivery of replacement technology and modernization of a Swedish defense system, MilDef has been entrusted to deliver rugged computers, switches and

MilDef rugged computer 19 inch 2

The Expleo-designed capsule includes an extravehicular viewing platform that allows passengers to step out into space

From Sicily to Mars: Drone & rover tests pave way to the red planet

US-based

drone company Skypersonic, which in 2021 entered into a five-year contract with NASA to provide drone and rover hardware, software and support to the space agency's simulated Mars mission, has successfully completed testing on Mount Etna, an active volcano in Sicily where the landscape is similar to Martian geology.

Skypersonic says that the 15-day test demonstrates how its Skycopter drone can be piloted virtually anywhere, from virtually anywhere.

Using Skypersonic’s Long Range Real-Time Remote Piloting System, the drone and rover on Mount Etna were controlled by personnel in Houston, Texas, in real-time.

While most drones cannot be piloted without connecting to the GPS network, Skycopter uses technology that is able to control and track the drone in locations – such as Mars – where GPS is not available.

"This was a gruelling test that we passed with flying colours. We look forward to the ultimate test – on Earth, at least – when our technology will be used during NASA’s upcoming yearlong simulated Mars mission. We are confident of also passing this test," said Skypersonic CEO

Giuseppe Santangelo

Giuseppe Santangelo

working in a 1,700-square-foot module on Earth, called Mars Dune Alpha,

will carry out a series of missions – including remotely guided exploration and collection of specimens from rugged terrain elsewhere on Earth, up to thousands of miles away."

The test results on the volcano included sample collections made by the rover - an essential capability for robotic exploration of Mars.

The project was a collaboration between Skypersonic, the University of Turin and Etna Park.

Snew project that aims to identify appli cations for its origami-inspired manufacturing technology in outer space.

The startup, which has become known for pushing the boundaries of design and innovation, is working with Sweden’s International Space Asset Acceleration Company (ISAAC) to discover how Stilfold’s “origami” manufacturing tech can be used for transporting and constructing materials in space.

A new organisation, ISAAC was founded by entrepreneur Mattias Hansson and backed by the European Space Agency and Sweden’s first astronaut Christer Fuglesang, and aims to strengthen innovation using knowledge and discoveries from outer space.

network of resources and specialist expertise to support them as they develop their technology for space. Over the next twelve months Stilfold will explore how their technology could be used for interior design solutions, transporters and food assembly in outer space, as well as how they can leverage existing space technologies to develop the perfect metamaterial for use with the Stilfold technology, both on Earth and in space.

Stilfold’s pioneering technology, dubbed “industrial origami”, involves the use of robotic arms to fold sheets of steel over curves to form intricate and lightweight new shapes. It is particularly well-suited to the limitations of space, as it enables the construction of strong and complex structures

stamping or welding. This has the potential to make it easier for astronauts to transport, preserve and construct resources.

Stilfold is currently being used by daughter company Stilride to build a sustainable steel e-motorcycle - but the potential applications for the technology are huge.

“We are constantly looking for new ways to innovate and push the boundaries of our technology, and exploring the possibilities of taking the concept into space feels extra exciting. In our quest to find materials and solutions that have a minimal environmental impact, it is also incredibly exciting to be able to leverage the research and innovation that has taken place and is taking place around space travel to explore new potential applications for Stilfold,” said Jonas Nyvang, CEO and co-founder at Stilfold.

Christer Fuglesang, astronaut and senior advisor to ISAAC added: “The results of the extremely advanced work that goes into getting us into space is knowledge and technology that can also be used to create better conditions for us humans on our beautiful blue planet."

Cecilia Hertz, co-founder of ISAAC, said: “Space travel places very high demands on the material being transported. Any solutions that can help us streamline and improve this are of great interest to the industry as a whole.”

For more information, visit: www.stilfold.com

Industry Europe 17 NEWS INDUSTRYNEWS

AEROSPACE & DEFENCE

Stilfold will take “industrial origami” tech into orbit

The Skycopter. Credit: Skypersonic

New developments in the Chemicals & Biochemicals

BRUGGOLEN®

TP-H2217 belongs to a new class of electrically neutral thermostabilisers from Brüggemann. Specially developed for reinforced and unreinforced aliphatic polyamides with metal- and halogen-free flame retardancy requirements, it ideally meets the needs of electrical and electronic applications, including those of e-mobility. Despite its high efficiency it neither has a corrosive effect on metallic components such as overmoulded sensors, nor does it influence the electrical properties of the polymer it is protecting in any significant way.

New metal- and halogen-free stabilisers from Brüggemann are designed to meet the increased requirements coming from the electrical and electronics industry and especially e-mobility. © Brüggemann.

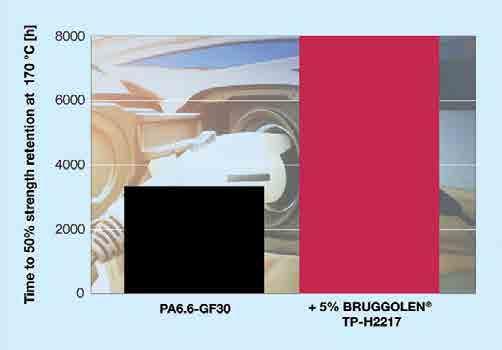

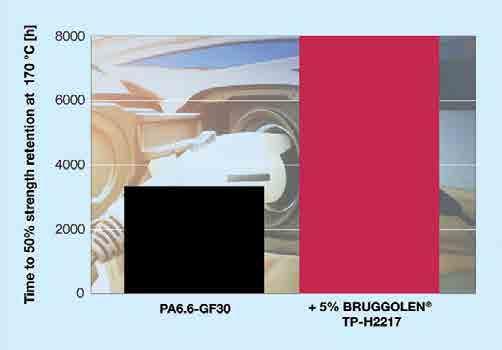

The high efficiency of long-term stabilisation is demonstrated by the example of a PA6.6-GF30. After 8,000 h of heat storage at 170°C, the tensile strength values are still over 50%.

A key requirement of any additives used in e-mobility applications is that the flame retardancy properties of those applications are not harmed. BRUGGOLEN® TP-H2217 is neutral in this respect as is Brüggemann’s new flow enhancer, BRUGGOLEN® TP-P2201, which is used to process glass-fibre reinforced polyamides into thin-walled and complex components with long flow paths.

Dr Kristina Frädrich, Product Manager at Brüggemann, comments: "With BRUGGOLEN® TP-H2217, compounders can for the first time produce polyamide materials that combine a UL94 V-0 classification, electrical neutrality as well as permanent heat resistance at elevated temperatures, and are thus specially tailored to the increased requirements of e-mobility. With this combination, which neither phenol- nor amine-based grades can offer, Brüggemann raises the bar for thermo-stabilisers by a considerable margin."

BRUGGOLEN® TP-H2217 is available as an easy-to-process masterbatch in granular form, with a level of 3% proving sufficient for many applications in laboratory trials.

Sulzer Chemtech’s crystallization technology helps drive DSI’s growth

Song Ho Kim, President of DSI, says: “We are extremely happy with the collaboration established with Sulzer Chemtech. Their solution for crystallizing naphthalene is a leader in the market, so when looking at advancing our offering, we were confident we should invest in this technology. The flexibility of our operations will also be improved, helping us address different market needs while optimizing operational expenses and profitability. We look forward to installing the unit and beginning our first-grade naphthalene operations shortly.”

can be used that can be used for applications with stringent quality requirements.

DSI’s facility in Serang processes naphthalene from coal tar to deliver the valuable chemicals. To this end, the plant has been producing naphthalene related products.

In order to increase the purity level of its raw materials and end products as well as serving the broader downstream sector, the company

sors worldwide, enabling them to deliver high quality aromatics.

Prior to the delivery of the purification unit, Sulzer Chemtech completed extensive feasibility and pilot testing ahead of its basic engineering package. This helped ensure DSI to produce different concentrations, including levels of up to 99.9 wt% at an overall production capacity of 7’000 metric tons per annum.

Etienne Rigaut, Head of Crystallization at Sulzer Chemtech, adds: “For decades, we have been supporting the most challenging separation processes with state-of-the-art crystallization equipment. Thanks to our extensive expertise, combined with testing and engineering capabilities, we have been able to deliver a customized unit that will help DSI enhance its competitiveness in the marketplace. We strive to support our customers and the entire sector with cutting-edge technologies.”

Visit: www.sulzer.com

18 Industry Europe NEWS

New copper and halogen-free long-term heat stabilisers tailored for applications in E&E and e-mobility

Precise gas mixtures even at high flow

For applications needing high flow rates of gas mixtures, such as steel production or the chemical industry, WITT offers the MG 2000ME ERC+ electronic gas mixer. Precisely and reliably, the device generates high-quality gas mixtures of two technical gases, even when the flow rate is fluctuating.

Inside the new top model from the market leader is an electronically operated proportional valve that achieves a maximum mixed gas output of up to 2,180 Nm3/h. The system is controlled either remotely via Ethernet or analog output, or directly on the unit via an intuitive touchscreen. The seamless mixture adjustment is thus particularly precise, and stored mixture specifications can be easily reproduced. When operated remotely, the user can control and see the system status at any time and from anywhere in the world.

The system keeps the mixture and outlet pressure stable, even when the flowrate is changing. In this way, the user obtains a precise mixture over the entire output range, even with cycling flowrates.

Certainly the correct gas mixture

With its numerous features, the WITT gas mixer ensures a particularly high level of process reliability. Pressure fluctuations in the gas supply are compensated by a constant pressure control and have no influence on the mixture quality. Optional pressure and temperature transmitters monitor the gas supply. Excessively low inlet pressures or temperatures generate an alarm and shut down the system. The setting of the mixing valve is maintained even when the mixer is switched off. This means that after a restart, the required mixture is generated again immediately.

For even greater certainty, the mixer can be optionally equipped with an integrated gas analyser for monitoring and documenting the gas mixture.

High quality, flexibility and economy

Like all WITT gas mixers, the MG 2000-ME ERC+ offers the user major benefits : It reliably generates precise and absolutely homogeneous gas mixtures of the highest quality. In addition, it offers the highest possible flexibility with regard to mixing ratio, gas quantity and place of use. By using comparatively inexpensive standard technical gases, the on-site generation of mixtures with the low-maintenance WITT unit is particularly economical.

Depending on the requirements, WITT gas mixers are available in various designs for almost all technical gases and different performance ranges.

Visit: www.wittgas.com

Beyond Ionomers: Regulation Drives Demand for New Fuel Cell Membranes, Finds IDTechEx Research

Membrane materials are of fundamental importance for fuel cells. So significant, in fact, that they typically give their name to the fuel cell, as is the case for Proton Exchange Membrane (PEM) fuel cells, with IDTechEx forecasting the market for ion-exchange membranes in PEM fuel cells to be worth over US$1.1 billion by 2033. Typically, the material of choice for PEMs is an ionically conducting polymer known as an ionomer. These ionomers are one of a family of perfluoroalkyl substances (PFAS), and concerns are mounting regarding PFAS, with alternative materials beginning to emerge.

The new IDTechEx report, "Materials for PEM Fuel Cells 2023-2033", gives a detailed technical overview of membranes and other key components for PEM fuel cells, an analysis of the major players, and also includes granular 10-year market forecasts for key fuel cell components and materials in terms of both units and volume. IDTechEx has also extensively covered the electric vehicle industry and forecasts demand for fuel cell electric vehicles (FCEVs) in "Fuel Cell Electric Vehicles 2022-2042".

The PEM enables the functionality of the fuel cell by transporting protons from one side of the cell to the other while keeping the different fuels separated. In the report, IDTechEx provides extensive benchmarking of the market leader against competing ionomer materials for three of the most critical parameters for PEMs; electrical resistance, ion exchange capacity (IEC), and membrane thickness. Despite transporting protons, it is imperative that the membrane has high electrical resistance to avoid short-circuiting the cell, while the combination of high IEC and thin membrane increases the fuel cell performance by enabling rapid proton transport. Promising alternatives exist, with performance exceeding the market leader in the three previously mentioned categories; however, the latter remains dominant due mainly to its position as the first mover in the market. Although dominant, ionomers are a PFAS-containing material and are subject to many of the concerns relating to PFASs. PFASs are considered "forever chemicals" due to the strength of the fluorine-carbon bond, with several health risks associated with accumulation in the human body, such as liver damage,

kidney cancer, and reduced response to vaccines. PFASs are transferred to the water cycle during their manufacturing stages, use in industrial processes and end-of-life treatment, leading to inevitable exposure for organisms. Bioaccumulation occurs in the tissue of organisms, such as fish in polluted waters, and this is then transferred up the food chain, including to humans.

On the back of these current and proposed restrictions, many companies are moving to reduce their reliance on PFASs. An interesting case study is the American company 3M. Having produced PFASs since 1947, 3M announced in December 2022 that it will cease the manufacturing of, and work to discontinue the use of, PFASs by 2025. 3M cited regulatory restrictions, consumers becoming "increasingly interested in alternatives" and operational difficulties as primary reasons for exiting the PFAS market.

So, what does this mean for fuel cells? Ultimately IDTechEx expects to see the beginning of a transition away from PFAS membranes to alternatives (including hydrocarbons) within the next three to five years. Prototype developmental projects are underway with various OEMs and novel materials gaining traction, predominantly at an academic level, such as metal-organic frameworks (MOFs), although these materials are still at an early stage with little commercial uptake. Historically, hydrocarbons have not seen success as membrane materials due to their tendency to disintegrate in the harsh chemical environments within the fuel cell. However, recent advances at companies such as Ionomr Innovations have seen the development of hydrocarbon ion-exchange membranes capable of fulfilling the requirements for PEM fuel cells without the health and environmental concerns associated with PFAS chemistry.

For more details on the materials demand, trends, and emerging novel alternatives to the incumbents for PEM fuel cells, please see the IDTechEx market report "Materials for PEM Fuel Cells 2023-2033". For more information on IDTechEx's other reports and market intelligence offerings, please visit www.IDTechEx.com.

Industry Europe 19 NEWS

INDUSTRYNEWS

CHEMICALS & BIOCHEMICALS

New developments in the Construction & Engineering

Ferrovial to build €245m port terminal in Gdańsk, Poland

Through its Polish construction subsidiary Budimex and in consortium with Dredging International, Ferrovial will begin work on the new terminal at DCT Gdańsk starting in September this year.

The contract for the new terminal, known as T3, will see the construction of a deepwater pier, drainage works and the building of a 700-metre-long mooring front that will be able to accommodate the largest container ships currently in service.

marine life and habitats in the area influenced by the construction.

“Once complete, the terminal will be the most advanced of its kind in the Baltic Sea and will reflect our commitment to sustainable investing and operating, with reduced CO2 emissions both from the construction, and the equipment we will deploy for future operations.”

Theconstruction of a new container terminal at the Port of Gdańsk in Poland is to go ahead later this year, after port operator DCT Gdansk chose a consortium led by Spanish infrastructure company Ferrovial to carry out the €245 million project.

T3 will span 360,000m2 with a depth of 17 meters, making it one of the largest container terminal hubs in Europe.

Charles Baker, CEO of DCT Gdańsk, said, “During construction, we will take all precautionary measures to protect the environment,

According to port operator DCT Gdansk, which saw its highest amount of container throughput earlier this year, the completion of T3 will increase the port of Gdansk’s capacity by 1.7 million containers a year, up to a total 4.5 million.

The project will take three years to complete, with the final works currently expected to be completed by the first half of 2025.

Sustainable homes: Why eco-friendly homes are top of house buyers' lists

Sustainability remains a buzzword. Being greener and sustainable and becoming eco-friendly are topics that remain popular. In today's world, more people want to be sustainable and live a greener lifestyle. The UK's green economy is continuing to rise. It is now reported to be four times larger than the manufacturing sector. This rise is not likely to slow down anytime soon. The calls for measures to be put in place to help reduce carbon emissions and lower our carbon footprint is becoming increasingly urgent.

It is not just how companies can lower their carbon footprint or what the government can do to help with the fight against climate change. Sustainable homes have become a popular choice for many homeowners and potential buyers. Homeowners are prepared to invest in renovation work to help their homes be more sustainable. As a result, potential buyers want to purchase a property with many sustainable elements and eco-friendly aspects.

Withstand The Elements

The drastic weather the UK has experienced in the past few months and years is a glimpse of the impact of climate change. The recordbreaking high temperatures and storms causing floods have led many people to want to update their homes to ensure they can withstand these extreme elements. Of course, many want to ensure any changes to their home are made with sustainable materials or appliances.

For example, if you want to create a shaded area at the back of your house where you can sit outside but hidden from the sun, you might want to add corrugated roofing. You can look into corrugated roofing from ClearAmber Shop and see how durable the polycarbonate sheets are. Corrugated roofing is ideal for those wanting to have a social area in their back garden but wants it to have shelter to allow privacy and some shade during those warm summer days. With corrugated roofing, the materials it is made from can help to withstand the harsher elements that the UK has been experiencing. In the morning following a stormy night, it is likely that your shaded social area will still be standing.

Likely Have Lower Bills

A common advantage of a sustainable home is that they feature many energy-saving appliances. If any renovation work has been done to the property, they might have aimed to make it as sustainable as possible. Energy-saving appliances can help more than just the environment. Many people invest in energy-saving appliances as they can help to lower their monthly energy bills.

In today's current climate, when prices are rising, finding ways to save is becoming a top priority for many. If having sustainable features in their home can help, many people will be happy to invest. It might take time before a difference in how much is saved, but the amount will likely be noticeable after an extended period.

Worthwhile Investment

It is often said that investing in sustainable appliances is worthwhile. Of course, it can take time before it is noticeable. However, once the cost of bills begins to decrease, you begin to see the difference a sustainable home can make. The cost of living is rising, and numerous factors contribute to this. Energy bills are just one of the many monthly costs that are slowly increasing. Traditional homes are less sustainable, and the energy costs for these properties can be steep. Living in a sustainable home can help to combat this issue. It is one of the reasons why so many wish to live in a sustainable home.

The Bottom Line

As mentioned, the reasons for wanting a sustainable home continue to grow along with the increased pressure to make changes to help tackle climate change increases. Investing in a sustainable home offers a quality home that will save money and help create a brighter future. Sustainable homes are becoming more common as property developers see the increasing demand for sustainable properties. It is likely to be a trend for many years to come.

20 Industry Europe

NEWS

Unknown Unknowns: WASP's 3D printing exhibition opens in Milan

by Steven Gislam

Oneof the most important international events devoted to design and architecture, the 23rd Triennale Milano International Exhibition opened earlier this month, celebrating 100 years since its foundation and featuring a unique exhibition by 3D printing company WASP.

Triennale's thematic exhibition Unknown Unknowns examines a range of themes including:

• Gravity - “The greatest designer”, an artisan that tirelessly shakes the universe in which we live;

• Maps - Systems with which trajectories and routes are determined;

• New challenges facing architecture - The sector is opening itself up to brand new prospects such as extraterrestrial living and, ultimately, the mysteries linked to deep space.

With the ongoing themes of sustainability and reusability as a backdrop, Unknown Unknowns was designed by Space Caviar and produced by WASP. Created wholly using 3D printing with large printers on an architectural scale and with only organic materials, largely waste from the food industry. For the first time, the exhibition pieces were

completely produced inside the museum itself, with 32 different pieces being printed in only 10 days.

Taking inspiration from the potter wasp, which builds its home using materials found on the spot, the company has been developing new, viable construction processes and techniques based on the principles of the circular economy to create 3D printed houses quickly and sustainably using biodegradable, recyclable and locally-sourced natural materials.

For this project WASP used the architectural 3D printer Crane WASP. It is a modular collaborative 3D printing system composed of a main printer unit that can be assembled in different configurations depending on the printing area and therefore on the dimensions of the architectural structure to be calculated in 3D.

For the needs of this specific setup, WASP transported and assembled Crane WASP within the museum and mixed the material near the printer on the first floor of the Triennale.

The company says that Unknown Unknowns is a "brilliant example of how WASP technology is declinable and multidisciplinary".

The thematic exhibition, Unknown Unknowns, is curated by Ersilia Vaudo, an astrophysicist and Chief Diversity Officer at the European Space Agency, and will be on display at the Triennale Milan until 11 December 2022.

Caverion & ABB partner to advance smart carbon-neutral buildings

Finnish sustainable building company Caverion has partnered with Swiss-based tech giant ABB to accelerate the development of energyefficient and sustainable buildings.

The two companies cite the collaboration's aim is to bring advanced, smart solutions for achieving carbon-neutral buildings and reaching their sustainability targets.

ABB’s technology will be brought together with Caverion’s sustainable solutions and system integration capabilities and will expand both companies' presence in Northern Europe.

The results of the partnership could be utilised in new buildings and modernisations to make them more automated, intelligent and sustainable in line with evolving customer demands. Optimal conditions in smart buildings increase also the end-user well-being and satisfaction.

“The agreement with Caverion demonstrates ABB’s ongoing commitment to enabling a carbon neutral society through the power of collaboration. Our joint capabilities will enable customers in the Nordics and beyond to benefit even faster from the latest in innovative smart building technology according to their individual sustainability requirements,” said Uwe Laudenklos, Marketing & Sales Leader for Europe, Canada, and Francophone Africa (ECAF), ABB Electrification’s Smart Buildings division.

"We at Caverion want to create sustainable impact for every customer with the solutions we design and deliver. We are excited to expand our collaboration with ABB as we share common goals toward a sustainable, carbon-neutral society. Together, we will provide our customers with stateof-the-art solutions for energy efficient and sustainable buildings," added Kari Sundbäck, Head of Services, Solutions, Digital and Sustainability of Caverion Group.

ABB's Mission to Zero programme will form a major part of the collaboration. The programme is intended to be a scalable blueprint for smart building solutions combined with onsite renewable energy generation and storage. The key components of the Mission to Zero vision are to accelerate carbon neutrality and energy self-sufficiency through the use of metering & energy management solutions linked to electrification, distributed energy resources technologies and enhanced by renewable energy procurements.

Visit: https://global.abb/group/en

Industry Europe 21

NEWS

NEWS CONSTRUCTION & ENGINEERING

INDUSTRY

THE SMART CHOICE

With its three divisions, the Franke Group, a leading global supplier of products and services for domestic kitchens, foodservice systems and the convenience store sector, is staying ahead of trends.

With over 60 companies, the Franke Group is at home on five continents. Headquartered in Aarburg, Switzerland, Franke Group employs approximately 10,500 staff across Europe, South and North America, Africa, Australia and Asia.

Franke Home Solutions was born in 2021 as a new division of the Franke Group, aiming to expand the presence of the company in the kitchens sector. The new name Franke Home Solutions is intended to be synonymous with food preparation (sinks and taps) and cooking (hoods, hobs and ovens), while it is also intended to reflect the desire to exploit the division’s expertise to increase its presence in the kitchens sector.

Drawing on the Group’s solid tradition. the Swiss kitchen and foodservice equipment manufacturer is standing strong in the volatile market environment, with a sound financial performance and new, innovative products that have been designed to reflect the latest trends supporting sustainability and energy savings.

Positive performance

The company reported that overall it has weathered the ongoing supply chain bottlenecks and rising inflation well. The Group was

22 Industry Europe

CONSUMER GOODS

not only able to supply customers as planned, but also to pass on price increases, thus partly compensating for higher raw material, component and transport costs.

The Franke Foodservice Systems and Franke Coffee Systems divisions were cited as positive contributors, while revenues for Franke Home Solutions fell. This was a contrast to 2021, when the latter had the largest sales growth within the company, at 41.1%.

The results highlight a shift in consumer demand for at-home coffee equipment following a sharp rise in the market during the pandemic when out-of-home coffee shops were repeatedly shuttered. The Group warned that a ‘fragile’ geopolitical and economic situation is expected to continue to further disrupt supply chain operations and lead to higher prices.

Awarded solutions

Despite the challenges, Franke continues to be committed to innovations. For over 110 years, Franke designers have prided them-

selves on their craftsmanship when developing high-quality Swissmade products. Timeless yet contemporary design has remained at the forefront of innovation at Franke, a promise that has been recognised globally with over 120 awards.

Several of Franke Home Solutions’ products collected (again) the Best Red Dot awards in 2022, including the innovative Active Twist Tap, specially designed to link the tap and sink with a dial that, when turned, operates the waste outlet, enabling the water to drain away easily, safely and hygienically. It received this prestigious award for its unique functionality and equally striking aesthetics, which feature a matte black finish.

Red Dot Winners 2022 also included All-In, the flexible, modular food preparation system designed to bring more flow to the kitchen - Maris Fragranite bowls made from Fragranite, which lasts a lifetime, and treated with Sanitized, which contains silver ions that prevent germs, mould and bad odours.

Franke’s Smart Suspended Hood was also awarded – the hood hangs from three wires, lending it clean lines and an elegant shape, and it comes in three chic finishes. It uses a plug-in carbon filter that is easy to change, making it simple to use and maintain. It also has a Class A energy efficiency rating and an impressively low noise level.

Most recently, the company has collected yet another ward – its Mythos Masterpiece Collection has won the 2023 Kitchen Innovation Award, recognising innovation and attention to detail in all its products.

Transformed for a better living

To stay in line with market trends and to reflect the forward-looking company mentality, in September 2022 Franke Group started to roll out a new brand identity across all platforms, complete with the promise: ‘Franke transforms change into opportunities for better living’.

While reminiscent of the brand’s previous look, the updated Franke logo is in a bold ‘Vibrant Red’ tone, an evolution of the current brand colour, which the company says is for greater precision and adaptability.

“The new branding is more than just an updated look for the Franke Group – we relish change and see it as an opportunity to innovate and to keep improving. That’s why we have refined our brand positioning and why we are open to change,” said Patrik Wohlhauser, CEO of the Franke Group.

In concluding, he affirms that the company is boldly push the boundaries and drive forward innovations, so that Franke is always one step ahead. “Day in, day out, we strive to present the best pos sible ideas and solutions to respond to our customers’ ever-chang ing needs. Our new design is a clear expression of this ambition.”

Industry Europe 25

A CENTURY OF MARKET LEADERSHIP

With a history of over 100 years, a catalogue of more than 20,000 products and operations in over 100 countries worldwide, LOVATO Electric is standing strong in a volatile market.

26 Industry Europe

Established in Bergamo, Italy, in 1922, LOVATO Electric is a private company run by the same family for 4 generations. For over a century, the company has been designing and manufacturing low-voltage electrical components for industrial applications.

The product range includes motor protection circuit breakers, contactors, push-buttons, switch disconnectors, limit switches, digital multimeters, energy meters, soft starters, AC motor drives, automatic power factor controllers and engine, generator controllers and more.

“For four generations, our mission has been to create innovative and reliable products to satisfy the client’s requirements, and it continues to be so today,” said company CEO Massimiliano Cacciavillani, explaining that the company’s mission has always been to provide competitive products and services in industrial automation and energy management.

Responsible operation

Being close to its customers has been part of that mission. LOVATO opened its first factory outside Italy in 1979 and international expansion has continued until the present day. The company’s 15 international subsidiaries and a network of over 90 importers ensure the availability of LOVATO Electric products in more than 100 countries across all continents.

It is not only product excellent that is the focus of LOVATO’s management. The company is committed to the maintenance of social, environmental and management standards of the highest order. Its policies and measures are aimed at achieving the “Sustainable Development Objectives” set out in United Nations Agenda 2030. Within these objectives, a whole range of initiatives have been launched to support the staff and their development.

Industry Europe 27

CONSUMER GOODS

As part of the company’s efforts to safeguard and protect the environment, LOVATO Electric has adopted advanced eco-efficient solutions, technologies and equipment, including photovoltaic systems, high-efficiency plastic moulding presses with hybrid or electric power for a lower environmental impact, as well as in-house recycling of reject die castings and sorted waste management.

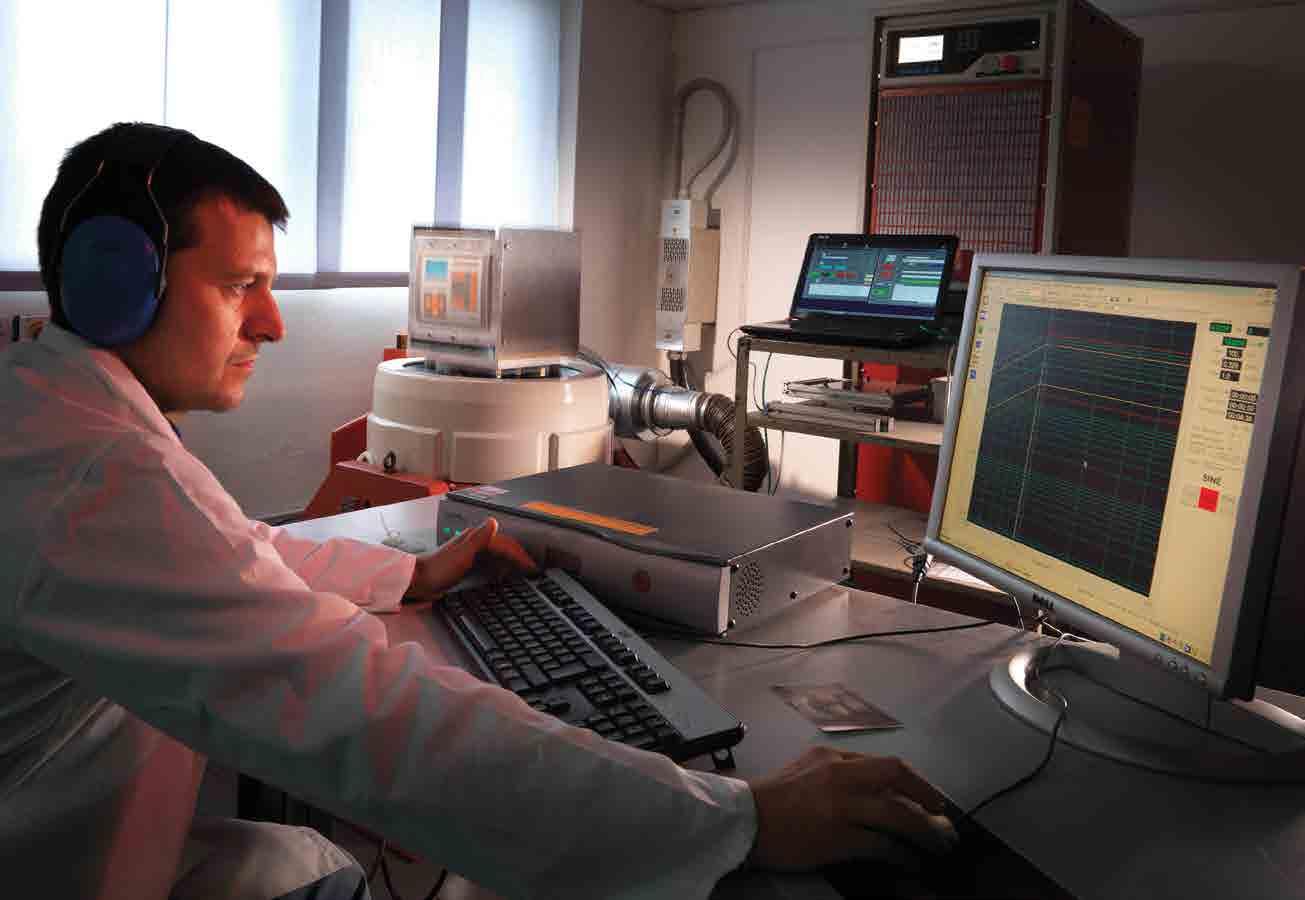

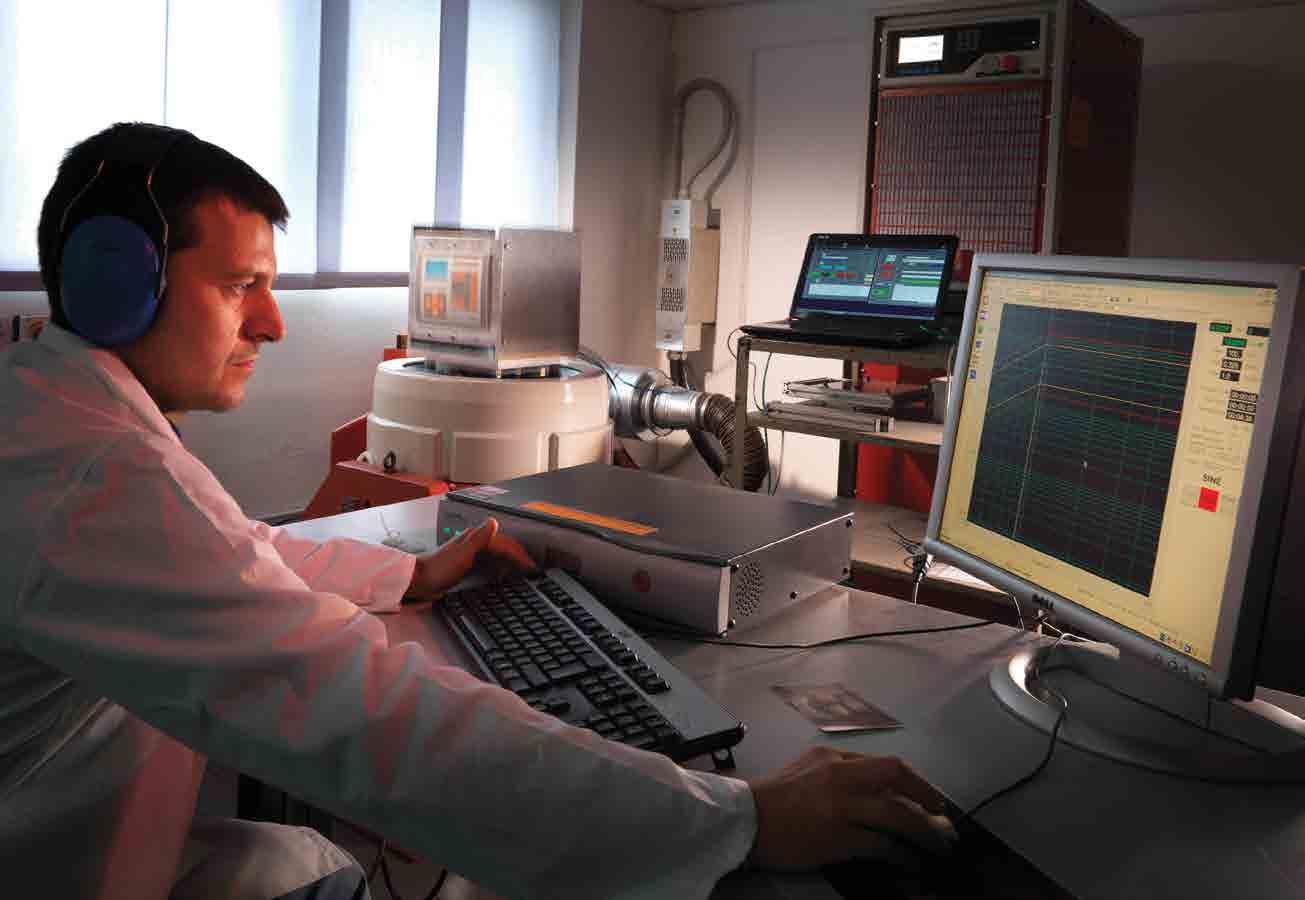

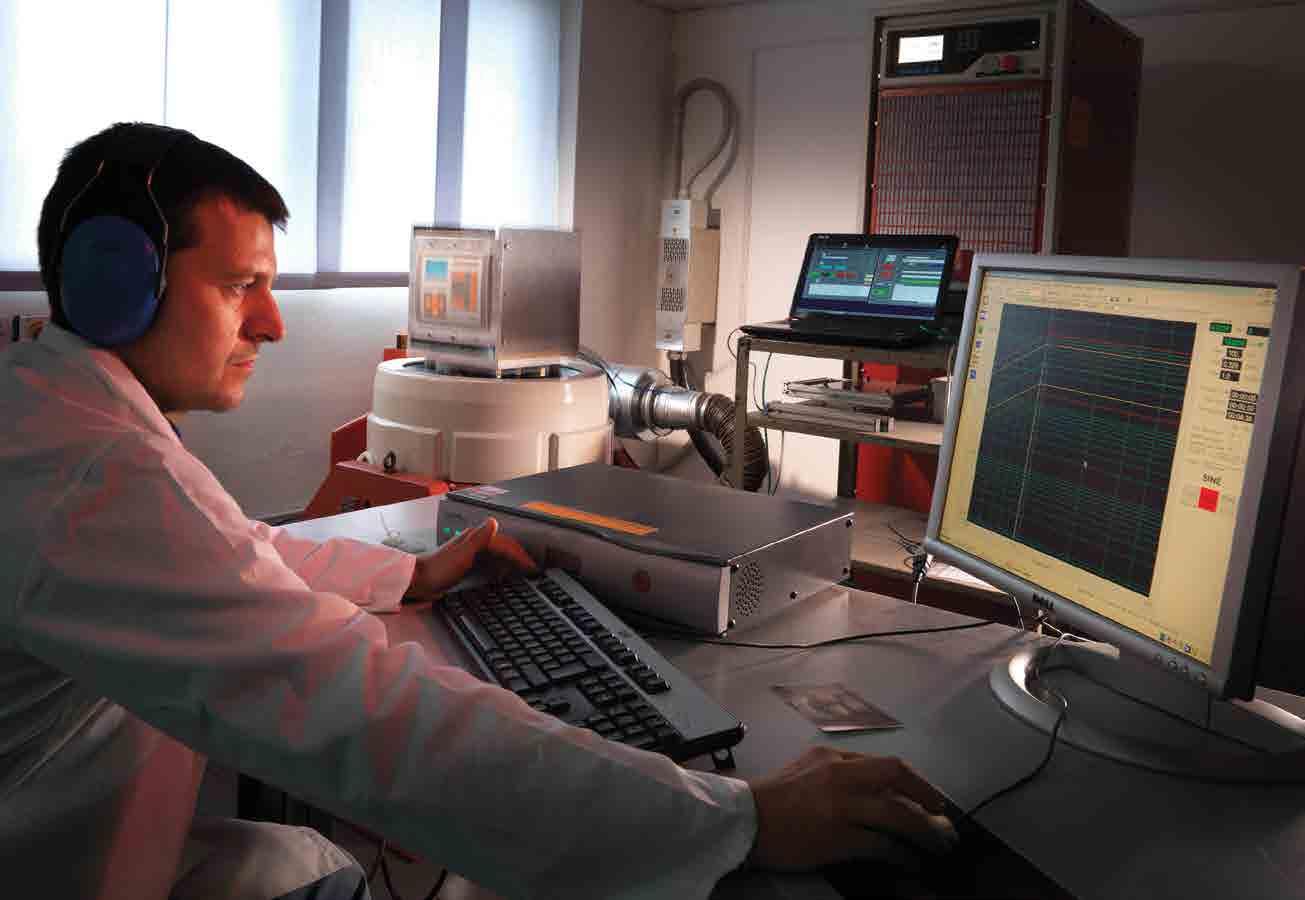

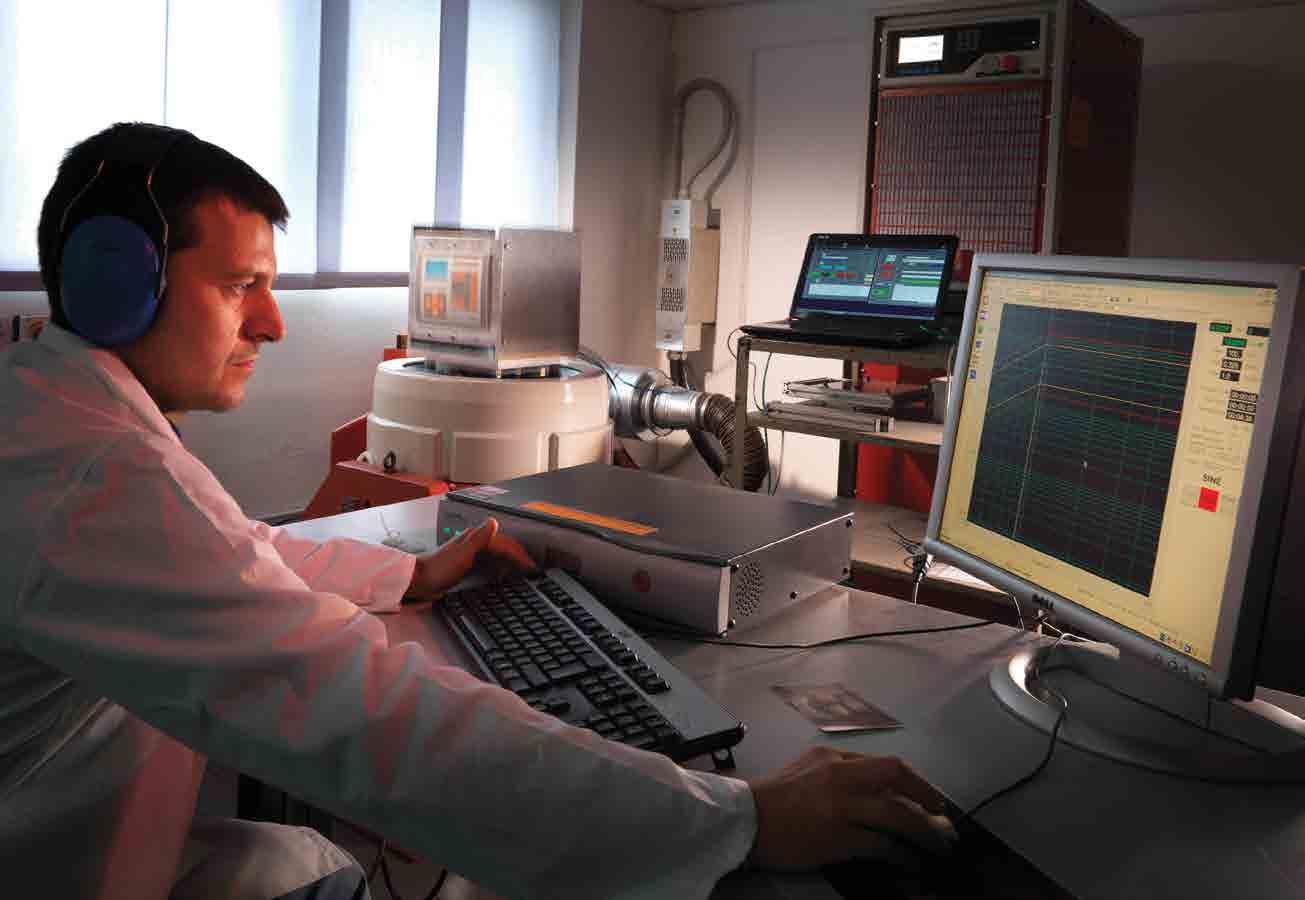

Driven by innovation

A focus on continuously innovating the product range is one of the factors that have pushed the company’s growth and expansion. LOVATO’s R&D laboratory, specialised in R&D testing, was born of the need to expand the company’s testing capabilities for the development of new high-performance products, ensuring the highest standards of safety and reliability while reducing time to market.

Recent innovations include, for example, the updated range of contactors with a new construction size. The new contactors are

rated 160A, 195A and 230A three-phase for motor control applications, and 250A, 275A and 350A in the AC-1 category. They are available in both 3- and 4-pole versions.

Also recently, the company has presented a new generation of power analysers with a widescreen LCD colour display that ensures clear, legible reading of the main analysis parameters, all while maintaining the classic drilling template (92x92mm). The result is perfect compatibility with standard front panel solutions. The measurements are displayed as waveform graphics, polar diagrams and harmonic spectra up to the 63rd order, thus offering everything needed to analyse the condition of the system.

Customers will also appreciate the ADXN series soft starters that are simple, compact and functional. The soft starters are ideal for applications which demand a simple, compact and easy-to-configure solution for gradually starting and stopping motors. Their versatility makes them adaptable to a variety of applications, including

28 Industry Europe

pump, fan, conveyor and compressor control, and they are available with current ratings from 6A to 45A.

Looking into the future

The focus on supplying best-in-class products has been one of the factors that have promoted the company to its leading position, a lasting success reflected in an important milestone achieved last year – in 2022, the company celebrated the first 100 years of its history. The celebrations officially started on September 10th with an event for all employees: a day dedicated to the company’s past, present and future.

The “Follow the Orange” event was staged in the prestigious location of the Donizetti Theatre in Bergamo: a journey through the milestones of these first 100 years of the company, narrated by Gianpiero and Massimo Cacciavillani, respectively President and CEO.

A journey that began in the early 1900s and that, over the years, has connected employees and stakeholders all over the world. Representatives from more than 100 countries around the world gathered for this unique event with a rich and varied programme in which corporate moments were followed by fun and convivial experiences, under the banner of Made in Italy.

“It was in the 1970s when we began to understand the importance of opening up to foreign markets and crossing national borders,” says Gianpiero Cacciavillani, President of the company.

“To see our company grow steadily and play a major role in the international industrial automation scene is a source of great pride,” he noted, affirming that LOVATO Electric will always look to the future, innovations and new challenges, but with a strong attachment to its territory. n

CONSUMER GOODS

Industry Europe 29

PREMIUM LEATHER FROM AUSTRIA

Wollsdorf, headquartered in the Austrian state of Styria, has become a recognised producer of leather products, shipped to customers around the world. Founded in 1937, the Austrian manufacturer draws on decades of experience and extensive know-how. Today the company produces high-quality, highly durable leather furnishings using both high-tech manufacturing processes and traditional craftsmanship.

Its diverse product range provides a high degree of flexibility and allows the company to individually address individual customers’

needs. Wollsdorf’s all-in-one solutions range from whole leather hides, leather cut parts, lamination and perforation serviced to ready-stitched and certified dress covers.

The automotive sector is the strongest market – here Wollsdorf’s products can be found on the steering wheel, car seats, dashboard, gear stick and more. The company also has a strong position in other sectors, including furnishings and aviation: Wollsdorf offers perhaps the lightest bovine aviation leather in the world, used on more than 195,000 seats worldwide.

30 Industry Europe

No matter whether for the automotive, shipping or aviation industries or for the home – premium surface materials have become indispensable. Wollsdorf, a specialist in the production of premium leather and innovative plant-based and synthetic leather alternatives, provides a solution for any application.

In addition to its corporate headquarters with its fully integrated leather tannery in Austria, Wollsdorf also operates production and sales sites in other countries, employing some 1,500 people across its locations. Wollsdorf premium leather goods are produced in China, Croatia and Mexico and the company offers a direct line of contact to customers in the United States and Uruguay.

Tradition meets innovation

The art of leather-making requires comprehensive expertise and up to 160 manufacturing steps in order to turn a perishable rawhide into a resilient leather product. Combining its long-standing experience with highly advanced manufacturing processes and traditional craftsmanship, Wollsdorf creates expertly processed products with a long lifespan that look and feel great and are available in a wide variety of colours.

These leather products can be fully customised. Numerous options are available: leather thicknesses from 0.6-3.0 mm, leather with natural grain or embossed leather as well as a broad colour spectrum, and more.

Research and development form the basis for creating premium and sustainable leather products. An innovative spirit, modern testing equipment and an optimally equipped laboratory also allow for the development of alternative manufacturing processes and creative surface materials.

Ahead of trends

Wollsdorf has pioneered a number of technical solutions including cool leather that does not heat up when exposed to direct sunlight, and shrink-optimized leather for instrument panels.

CONSUMER GOODS

Another innovative product for the aviation industry, developed for Lufthansa a few year ago, was Wollsdorf’s Amba Eco FOC leather, which boasts a weight reduction of as much as 40% compared to standard aircraft leather without compromising on properties such as tensile strength.

Wollsdorf can manufacture leather without the use of heavy metals, chrome and glutaraldehyde, and has developed its EVO+ surface protection that sustainably reduces bacteria on leather surfaces by 99.9%. EVO+ is integrated directly in the dyeing system and guarantees the protection of leather over the course of the product’s entire life cycle.

For applications where an alternative material is required, the new synthetic surface WolSynt®, a high-quality synthetic surface

based on PU, is ideally suited. It is vegan and free of PVC as well as solvents and critical plasticizers.

In line with nature

Wollsdorf Austria has been relying exclusively on green power since 2012. Around 80% of the electricity used group-wide is CO2neutral. This gives annual savings of approximately 4,600 tonnes of CO2. Wollsdorf can thereby provide an essential contribution to climate protection and the fight against global warming.

In 1998, Wollsdorf was the world’s first tannery to receive the ISO 14001 environmental certificate, and the company remains focused on the sustainability of new products and solutions, continually optimising its processes at all its locations.

32 Industry Europe

Low-emission leather guarantees that environmental and healthrelated burdens from the tanning process are minimised over the entire life cycle until recycling or disposal.

On the resources side, the company reduces water consumption through process optimisations and recycling. Waste water at Wollsdorf is treated and purified in an elaborate process and reintroduced into the natural water cycle. Waste materials are recycled, thermally utilised, harnessed for energy recovery or upcycled.

Exceeding clients’ expectations

The company claims that it conscientiously insists on species-appropriate animal husbandry and the consistent fulfilment of ecological procurement criteria when selecting its suppliers – only hides from

healthy and uninjured animals can be processed into premium leather and other products.

None of the animals used by Wollsdorf for leather production are butchered for their hides, since the rawhides are a by-product of the meat and milk industry – a perfect example of upcycling whereby otherwise superfluous materials, i.e. the hides of animals, are processed into sustainable and valuable products.

In 2000, Wollsdorf became the first leather producer in the world to be awarded the ISO/TS 16949 quality certificate and was also EN 9100 certified in 2007. The result of these efforts is a range of exclusive leathers that meet and exceed the high expectations of customers all over the world. n

Industry Europe 33 CONSUMER GOODS

New developments in the Consumer Goods

Avantium and Henkel sign offtake agreement on FDCA for adhesives to be used in electronics applications

Henkel and Avantium have been partners

since 2019, when Henkel joined the PEFerence consortium1 . This consortium of partners, coordinated by Avantium, aims to establish an innovative supply chain for FDCA and PEF (polyethylene furanoate). As part of the PEFerence project, Henkel has tested and positively evaluated the feasibility of FDCA for the use of polyurethane adhesives. Now Henkel has decided to proceed and bring those adhesives to the market for the use in electronics applications, such as consumer devices.

For many years, Henkel has been committed to sustainable business practices. As a market leader for adhesives, sealants and functional coatings, Henkel is making an important contribution to climate protection by embracing innovative solutions that facilitate recycling and enable CO2 savings across the

value chain. “Henkel is constantly innovating high-quality and sustainable adhesives to support our customers and ecosystem partners in their implementation of a circular economy. Avantium’s 100% plant-based FDCA enhances our strategy to incorporate renewable carbon into our technology roadmap while offering improved performance in our products. We look forward to continue working with Avantium in the years to come. For us, this is just the start as we see high potential for FDCA in application areas beyond electronics, such as packaging, wood construction or textile lamination”, says Adrian Brandt, Head of Bio-Renewable materials team at Henkel Adhesive Technologies.

Bineke Posthumus, Director Business Development of Avantium Renewable Polymers , comments: “We are very pleased that yet another partner of the PEFerence consortium