Risk Assessment Documents for Chemicals

Toxicsoftware.co.uk - your online partner in effective chemical management

The complementary website

The website gives you instant access to all the ready-to-use documents, tools, policies, etc. that complement this publication. and enter your access code

No part of this publication may be reproduced or transmitted in any form or by any means or stored in any retrieval system without permission.

Cover: ©iStockphoto.com

First Edition - First Print - E01P1

© 2024 Indicator - FL Memo Ltd.

Every effort has been made by Indicator - FL Memo Limited to ensure that the information given is accurate and not misleading, but Indicator - FL Memo Limited cannot accept responsibility for any loss or liability perceived to have arisen from the use of any such information. Only Acts of Parliament and Statutory Instruments have the force of law and only the courts can authoritatively interpret the law.

UKRADOOE

COSHH/DSEAR assessment record

If you use hazardous or dangerous substances, or create them as by-products of your processes, then you need to undertake a specific type of risk assessment. Our record has been created for that purpose.

How to use the form

Before starting ensure that you have sufficient experience and/or training to complete the assessment properly. As a guide, most people should be able to have a go at assessing low-risk cleaning substances, but complex processes will certainly require expert help.

First of all, make sure that you have the product packaging available and an up-to-date copy of the manufacturer’s safety data sheet. You can usually obtain these online or by phoning the supplier.

Complete the form in sequence, referring to the guidance provided.

Make sure that managers implement the risk control measures identified and get them to sign at the end of the form. They should train employees in the findings of the assessment and ensure that a copy is readily available.

Product:

SDS reference:

SDS date:

Assessor details:

COSHH/DSEAR ASSESSMENT RECORD

Date completed:

Date for review:

Reviewed by:

Signature: Signature:

Activity/details of use:

Hazards:

Indicate “Yes” or “No”:

Hazards:

Indicate “Yes” or “No”:

Further information:

Precautions:

Indicate “Yes” or “No”:

Further information:

Storage and transport: Recycling, disposal:

First aid Eyes Skin Swallowing Inhalation

Details of substance

Details of hazardous/dangerous substances which the product contains:

Workplace exposure limits which apply:

Level, type and duration of potential exposure:

Hazardous properties (include hazard statements (HXXX):

Manufacturers’ limitations of use:

Risk control measures for normal use

Describe any exposure monitoring and health surveillance:

Risk control measures already in place:

New or improved risk control measures required:

Chemical reactions to be avoided:

Maintenance arrangements, e.g. for extraction systems, PPE etc.:

Assessment of risk

With the above risk controls the risk is: High Medium Low

Is the risk adequately controlled? Yes No

Can the substance be substituted for one that is less hazardous? Yes No

Note. A copy of the safety data sheet must be filed with this assessment. Further information on completing COSHH assessments can be found at http://www.hse.gov.uk/coshh/essentials/index.htm

Pictograms © Rivington Designs Ltd

Handling and storage of chemical substances

The handling and storage of chemical substances may present risks to staff which, left unmanaged, could cause accidents and potentially put you on the wrong side of the law.

Managing the risks

To help you identify the hazards associated with handling and storage operations involving chemicals etc. and the appropriate ways of controlling them, use our example Risk Assessment - Handling and Storage of Chemical Substances. It covers the generic hazards associated with this type of activity and suggests control measures to reduce risks to an acceptable level.

Note. This risk assessment only deals with the risks involved with handling and storage of chemical substances. You should prepare a separate assessment for using the substances as required by the Control of Substances Hazardous to Health Regulations 2002 (as amended 2004).

You should ensure that your document only addresses “significant” hazards, i.e. any that could, and more importantly are likely to, cause an accident or injury.

Make your instructions clear

Don’t include activities in your document that simply don’t need to be there. Work to the principle that if there is any chance of your staff being unaware of the safe way of doing something, then you will need to make it clear in your document. Finally, always ensure that any control measures you identify and follow only go so far “as is reasonably practicable”.

Note. The list of potential hazards is not exhaustive. For your risk assessment to be considered suitable and sufficient in the eyes of the law it must accurately reflect the “significant” hazards found in your workplace.

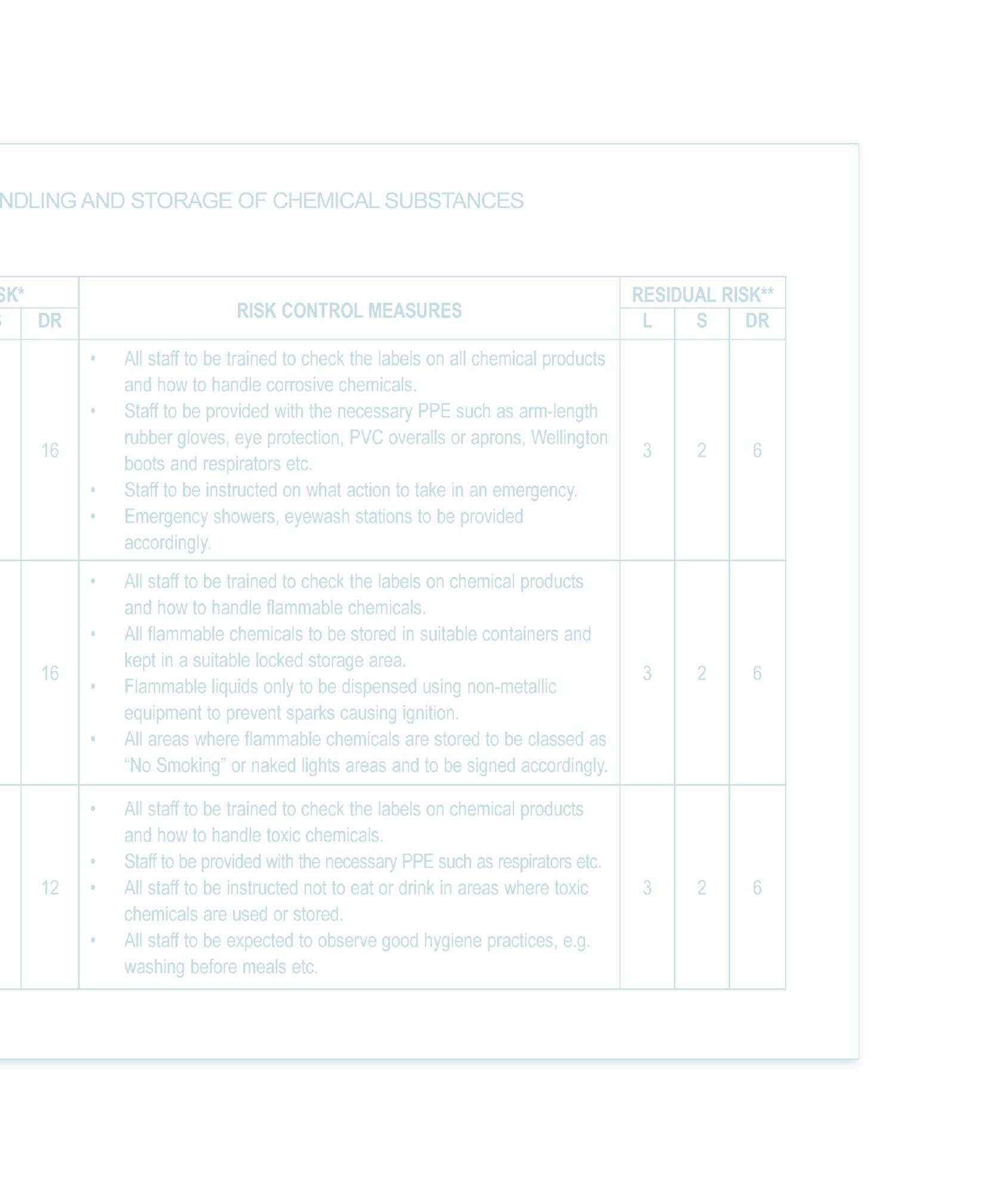

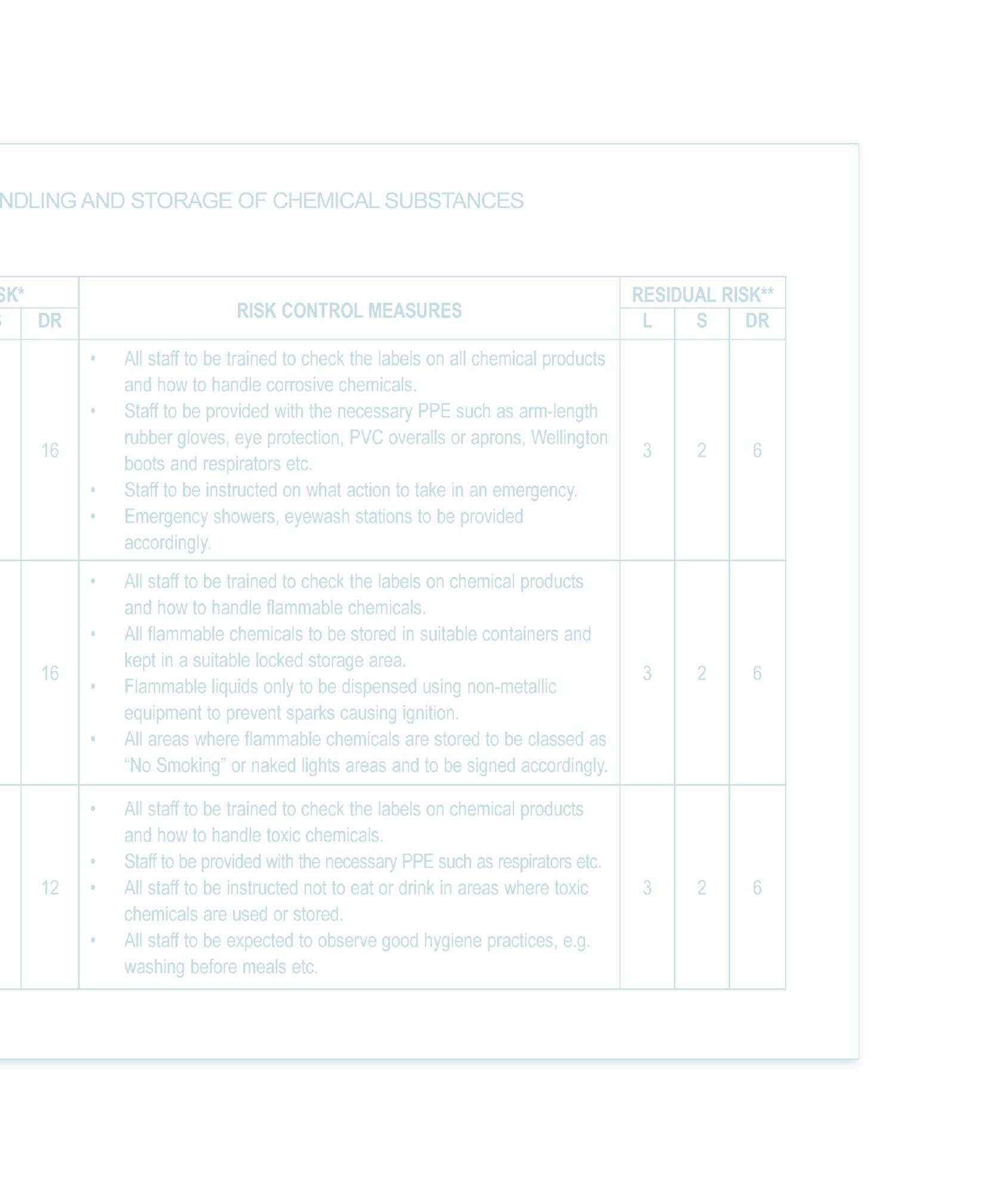

RISK ASSESSMENT - HANDLING AND STORAGE OF CHEMICAL SUBSTANCES

Risk assessment - topic/area covered

Location(s):

Department/staff:

Tasks/activities:

Other information:

Risk assessment sign off

Prepared by: Signature:

Reviewed by: Signature:

Date

Document issue record

Date:

Date:

Acceptability of risk guidance

Guidance. When completing a risk assessment, you should:

High risk: 15-25

Medium risk: 8-12

Low risk: 1-6

Likelihood (L) x Severity (S) = Risk rating (RR).

High-risk activities should cease immediately. Further effective control measures to mitigate risks must be introduced.

Medium risks should only be tolerated for the short term and only whilst further control measures to mitigate the risks are being planned and introduced.

Low risks are largely acceptable. Where it is reasonable to do so, efforts should be made to reduce risks further.

1. Identify the persons at risk and the significant hazards.

2. Calculate an initial RR for the activity.

3. Identify risk control measures that reduce the risks to an acceptable level.

4. Calculate a revised RR - you should consider how much safer the task will be if the control measures are followed. Here, you should consider changing both the likelihood (L) and the severity (S) ratings.

Note. Ideally, you should look to reduce the risks so that the task can be classified as “low risk”.

Personal protective equipment (PPE) assessment

In many instances, you will be able to reduce risks further by asking staff/others to wear/use PPE. You should identify which items are required for the task here:

Additional requirements (list here):

Note. PPE must only be considered as, when other control measures, such as guarding, local exhaust extraction, preventing noise at source, eliminating the need to work at height etc. are not possible. PPE should always be considered as a last resort option. PPE should only be worn when there is reasonable justification for doing so.

Risk assessment

corrosive chemicals without personal protection Staff

Corrosive chemicals coming into contact with the skin or eyes etc. may cause serious chemical burns 4 4 16

• All staff to be trained to check the labels on all chemical products and how to handle corrosive chemicals.

• Staff to be provided with the necessary personal protective equipment (PPE) such as arm-length rubber gloves, eye protection, PVC overalls or aprons, Wellington boots and respirators etc.

• Staff to be instructed on what action to take in an emergency.

• Emergency showers, eyewash stations to be provided accordingly.

• All staff to be trained to check the labels on chemical products and how to handle flammable chemicals.

• All flammable chemicals to be stored in suitable containers and kept in a suitable locked storage area.

2 6 Handling flammable chemicals As above

Handling flammable chemicals near to a source of ignition may lead to fires resulting in serious burns and property damage 4 4 16

Handling toxic

ingestion

• Flammable liquids only to be dispensed using non-metallic equipment to prevent sparks causing ignition.

• All areas where flammable chemicals are stored to be classed as “No Smoking” or naked lights areas and to be signed accordingly

• All staff to be trained to check the labels on chemical products and how to handle toxic chemicals.

• Staff to be provided with the necessary PPE such as respirators etc.

• All staff to be instructed not to eat or drink in areas where toxic chemicals are used or stored.

• All staff to be expected to observe good hygiene practices, e.g. washing before meals etc.

• All staff to be trained in the handling and storing of carcinogenic chemical substances.

• Staff to be instructed on what action to take in an emergency.

• Such chemicals to be stored in a designated area.

• No eating or drinking to be allowed in areas where such substances are stored.

• All staff to be expected to observe good hygiene practices, e.g. washing etc. before meals. 2 3

• Staff to be instructed on the action to take in the event of spillages.

• Spill kits to be provided and be regularly checked.

2 6

Liquid spillages

There are hazards and risks present when dealing with liquid spillages which, left unmanaged, could cause accidents and potentially put you on the wrong side of the law.

Managing the risks

To help you identify the hazards and appropriate ways of controlling them, use our example Risk Assessment - Liquid Spillages document. It covers the generic hazards associated with such work and suggests control measures to reduce risks to an acceptable level.

You should ensure your document only addresses “significant” hazards, i.e. any that could and more importantly are likely to, cause an accident or injury. For example, your risk assessment doesn’t need to cover activities such as the minor spillage of a cup of coffee, or anything similar (although you must have systems in place to deal with such incidents).

Making your instructions clear

There is no point putting activities on the document that simply don’t need to be there. Work to the principle that if there is any chance of your staff being unaware of the safe way of preventing spillages or clearing up such spillages, then you will need to make it clear on your document. Finally, always ensure any control measures you identify and follow only go so far “as is reasonably practicable”.

Note. The list of potential hazards is not exhaustive as you are in the best position to know which products you use that are likely to be hazardous when spilled. For your risk assessment to be considered suitable and sufficient in the eyes of the law it must accurately reflect the “significant” hazards associated with the tasks found in your workplace.

RISK ASSESSMENT - LIQUID SPILLAGES

Risk assessment - topic/area covered

Location(s):

Department/staff:

Tasks/activities:

Other information:

Risk assessment sign off

Prepared by: Signature: Date:

Reviewed by: Signature:

Date for review:

Date:

Acceptability of risk guidance

Guidance. When completing a risk assessment, you should:

High risk: 15-25

Medium risk: 8-12

Low risk: 1-6

Likelihood (L) x Severity (S) = Risk rating (RR).

High-risk activities should cease immediately. Further effective control measures to mitigate risks must be introduced.

Medium risks should only be tolerated for the short term and only whilst further control measures to mitigate the risks are being planned and introduced.

Low risks are largely acceptable. Where it is reasonable to do so, efforts should be made to reduce risks further.

1. Identify the persons at risk and the significant hazards.

2. Calculate an initial RR for the activity.

3. Identify risk control measures that reduce the risks to an acceptable level.

4. Calculate a revised RR - you should consider how much safer the task will be if the control measures are followed. Here, you should consider changing both the likelihood (L) and the severity (S) ratings.

Note. Ideally, you should look to reduce the risks so that the task can be classified as “low risk”.

Personal protective equipment (PPE) assessment

In many instances, you will be able to reduce risks further by asking staff/others to wear/use PPE. You should identify which items are required for the task here:

Additional requirements (list here):

Note. PPE must only be considered as, when other control measures, such as guarding, local exhaust extraction, preventing noise at source, eliminating the need to work at height etc. are not possible. PPE should always be considered as a last resort option. PPE should only be worn when there is reasonable justification for doing so.

carrying or decanting flammable

• Staff to be trained in the methods of decanting liquids.

• All liquids to be carried in suitable containers and not over filled.

• All spillages to be cleaned up immediately or warning signs (barriers, cones etc.) to be placed in the spillage area.

• Staff to be trained in dealing with hazardous liquid spillages.

• COSHH assessments and manufacturers’ safety precautions to be briefed to staff handling hazardous liquids.

• Suitable spill kits to be made available.

• Staff to be trained in dealing with flammable liquid spillages.

• Spillage areas to be kept well ventilated until properly cleaned.

• Suitable spill kits to be made available.

• Company fire precautions to be observed.

• Appropriate PPE to be worn at all times when handling flammable liquids.

• Maintenance personnel to be trained in dealing with oil spillages.

• Oil spillage kits to be readily available.

• Tanks and containers to be bunded to contain leakages.

• Appropriate PPE to be worn at all times.

• All personnel involved in cleaning up blood spillages to be trained in the relevant precautions to be taken.

• Good hygiene practices to be followed.

• Spillages of blood to be treated first with hypochlorite granules prior to cleaning up.

3 2 6

3 1 3

• Appropriate PPE to be worn at all times. 3 2 6

• Staff who work with sewage to wear the appropriate PPE, i.e. rubber gloves and Wellington boots, coveralls and face mask.

• Good hygiene practices to be maintained, e.g. washing of hands and forearms before eating, smoking, etc.

• If operative suffers a cut, then consideration must be given to a hospital visit for a Tetanus injection.

3 1 3

• SDS for chemical compatibility to be consulted and sorbent materials etc. chosen accordingly. In general:

- corrosives: use polypropylene-based absorbents

- strong oxidising solutions: use mineralbased absorbents

- flammables: bear in mind that wicking effect (high surface area of absorbents, and evaporation) may contribute further to formation of flammable atmosphere and therefore to risk of ignition.

• If liquid is unknown, it is highly unlikely to be a strong oxidising solution (would be readily apparent by reaction with floor or ground): test with small quantity of absorbent material; maintain awareness of possible fumes given off, and take appropriate precautions if detected. Remember, packaging of waste arising must also be resistant to spilt liquid.

Preliminary COSHH assessment

If you’re a low to medium-risk business, you may find that a full COSHH assessment is unnecessary. In order to identify if this is the case, consider using our preliminary COSHH assessment form.

Preliminary COSHH assessment

If you use many chemicals, or just wish to avoid unnecessary work, you may choose to identify whether or not a full COSHH assessment is going to be necessary. If so, you could use a Preliminary COSHH Assessment. This allows you to identify whether or not a more in-depth assessment will be necessary. For a typical low to medium-risk business, you may find that this is all that’s necessary in order to keep you legally compliant.

A time-saving device

Our form is set in a simple table format with two columns. The left-hand column lists the questions, whilst the right-hand one contains space for brief answers. There are ten questions in total, which include ones relating to the substance, its hazards, your control measures and whether or not they’re working properly. As a rule of thumb, you will find that a full assessment will be required if your answers reveal that respiratory sensitisers such as glues are used and there are processes which generate dust or fumes.

PRELIMINARY COSHH ASSESSMENT

Preliminary COSHH assessment form

Chemical name:

Assessment questions

Which area/process are these hazardous substances used in?

What is the hazardous substance that’s used?

Try to group items, e.g. many bleaches have the same active ingredient regardless of the trade name.

Are any hazardous substances a by-product of a process, e.g. welding fume?

What is the actual hazard?

This could be corrosive, irritant, etc. Look at the chemical labelling, etc.

Are there other hazards that don’t come under COSHH?

These could be flammable or explosive hazards.

How could exposure occur?

This could be via skin contact, inhalation, etc.

What controls are in place?

E.g. extract ventilation, personal protective equipment, etc.

How well are these controls working?

There may be dust or strong chemical smells even though extract ventilation has been installed.

Can we eliminate/reduce the substance quantity?

Look at using less hazardous substances.

Is there sufficient information relating to the hazardous substances in our workplace?

Answers

Safe use of basic cleaning materials

The misuse of basic cleaning materials can prove harmful, leading to skin conditions as well as other forms of illhealth. Where such materials have warning labels on their packaging, they will require a full assessment under the Control of Substances Hazardous to Health Regulations 2002 (as amended) (COSHH). However, this risk assessment deals with the general precautions to be taken when storing, using and disposing of such materials to prevent harm to members of staff who may come into contact with them.

Managing the risks

To help you to identify the common hazards associated with storing, using and disposing of basic cleaning materials and the appropriate ways of controlling them, use our example Risk Assessment - Safe Use of Basic Cleaning Materials. It covers the generic hazards associated with these types of activities and suggests control measures to reduce such risks to an acceptable level. You should ensure that your document only addresses “significant” hazards, i.e. any that could, and more importantly are likely to, cause an accident or injury.

Make your instructions clear

Don’t include activities in your document that simply don’t need to be there. Work to the principle that if there is any chance of your staff being unaware of the safe way of doing something, then you will need to make it clear in your document. Finally, always ensure that any control measures you identify and follow are decided upon the principle of “so far as is reasonably practicable”.

Note. The list of potential hazards is not exhaustive. However, for your risk assessment to be considered suitable and sufficient in the eyes of the law it must accurately reflect the “significant” hazards found when using basic cleaning materials.

Note. This risk assessment only deals with the general risks associated with basic cleaning materials. Where chemical-based cleaning materials are considered to be hazardous, then a separate assessment conducted under COSHH will be needed.

RISK ASSESSMENT - SAFE USE OF BASIC CLEANING MATERIALS

Risk assessment - topic/area covered

Location(s):

Department/staff:

Tasks/activities:

Other information:

Risk assessment sign off

Prepared by: Signature:

Reviewed by: Signature:

This

Date for review:

Document

issue record

Date:

Date:

Risk matrix

High risk: 15-25

Acceptability of risk guidance

Guidance. When completing a risk assessment, you should:

(L) x Severity (S) = Risk rating (RR).

High-risk activities should cease immediately. Further effective control measures to mitigate risks must be introduced.

Medium risk: 8-12 Medium risks should only be tolerated for the short term and only whilst further control measures to mitigate the risks are being planned and introduced.

Low risk: 1-6

Low risks are largely acceptable. Where it is reasonable to do so, efforts should be made to reduce risks further.

1. Identify the persons at risk and the significant hazards.

2. Calculate an initial RR for the activity.

3. Identify risk control measures that reduce the risks to an acceptable level.

4. Calculate a revised RR - you should consider how much safer the task will be if the control measures are followed. Here, you should consider changing both the likelihood (L) and the severity (S) ratings.

Note. Ideally, you should look to reduce the risks so that the task can be classified as “low risk”.

Personal protective equipment (PPE) assessment

In many instances, you will be able to reduce risks further by asking staff/others to wear/use PPE. You should identify which items are required for the task here:

Additional requirements (list here):

Note. PPE must only be considered as, when other control measures, such as guarding, local exhaust extraction, preventing noise at source, eliminating the need to work at height etc. are not possible. PPE should always be considered as a last resort option. PPE should only be worn when there is reasonable justification for doing so.

• Staff to ensure that harmful cleaning substances are only stored in the containers that they are received in, i.e. approved and suitably marked containers.

• No decanting of cleaning materials into other containers such as drinks bottles etc. to be allowed.

•

• Staff to follow the manufacturer’s instructions for the use of cleaning materials.

• Staff to be provided with all necessary personal protective equipment as specified by the manufacturer.

• Staff who use cleaning products that are corrosive to wear the correct types of hand and eye protection.

• Where cleaning products give off fumes that may affect breathing, staff to ensure that suitable ventilation exists before use.

• Staff to be made aware of cleaning products that may damage the skin and to be provided with suitable gloves etc.

• Where possible alternative products to be sourced that are less hazardous.

• Staff to regularly check their skin for signs of damage such as cracking, flaking or reddening

• Cleaning materials to be purchased in suitable sized containers to prevent the need for decanting.

• All spillages of cleaning materials to be cleaned up immediately by following the supplier’s/manufacturer’s guidelines.

• Used containers to be disposed of in accordance with the manufacturer’s instructions.

Storage and handling of flammable liquids

Storage and handling of flammable liquids can present risks to staff which, left unmanaged, could cause accidents and potentially put you on the wrong side of the law.

Managing the risks

To help you identify the hazards associated with the storage and handling of flammable liquids, e.g. slips, trips and falls, fire risks etc., and the appropriate ways of controlling them, use our example Risk Assessment - Storage and Handling of Flammable Liquids. It covers the generic hazards associated with this type of activity and suggests control measures to reduce risks to an acceptable level.

You should ensure that your document only addresses “significant” hazards, i.e. any that could, and more importantly are likely to, cause an accident or injury.

Make your instructions clear

Don’t include activities in your document that simply don’t need to be there. Work to the principle that if there is any chance of your staff being unaware of the safe way of doing something, then you will need to make it clear in your document. Finally, always ensure that any control measures you identify and follow, only go “so far as is reasonably practicable”.

Note. The list of potential hazards is not exhaustive. However, for your risk assessment to be considered suitable and sufficient in the eyes of the law it must accurately reflect the “significant” hazards found when storing and handling flammable liquids in your workplace.

RISK ASSESSMENT - STORAGE AND HANDLING OF FLAMMABLE LIQUIDS

Risk assessment - topic/area covered

Location(s):

Department/staff:

Tasks/activities:

Other information:

Risk assessment sign off

Prepared by: Signature:

Reviewed by: Signature:

Date for review:

Document issue record

Date:

Date:

Risk matrix

High risk: 15-25

Acceptability of risk guidance

Guidance. When completing a risk assessment, you should:

(L) x Severity (S) = Risk rating (RR).

High-risk activities should cease immediately. Further effective control measures to mitigate risks must be introduced.

Medium risk: 8-12 Medium risks should only be tolerated for the short term and only whilst further control measures to mitigate the risks are being planned and introduced.

Low risk: 1-6

Low risks are largely acceptable. Where it is reasonable to do so, efforts should be made to reduce risks further.

1. Identify the persons at risk and the significant hazards.

2. Calculate an initial RR for the activity.

3. Identify risk control measures that reduce the risks to an acceptable level.

4. Calculate a revised RR - you should consider how much safer the task will be if the control measures are followed. Here, you should consider changing both the likelihood (L) and the severity (S) ratings.

Note. Ideally, you should look to reduce the risks so that the task can be classified as “low risk”.

Personal protective equipment (PPE) assessment

In many instances, you will be able to reduce risks further by asking staff/others to wear/use PPE. You should identify which items are required for the task here:

Additional requirements (list here):

Note. PPE must only be considered as, when other control measures, such as guarding, local exhaust extraction, preventing noise at source, eliminating the need to work at height etc. are not possible. PPE should always be considered as a last resort option. PPE should only be worn when there is reasonable justification for doing so.

• Flammable liquids on site to be assessed to see if they can be substituted for a safer alternative.

• Suppliers’ material safety data sheets to be obtained for all flammable liquids.

• Where substitution is not viable steps to be taken to reduce the amount stored on site. 3 3 9

• Quantities of flammable liquids stored inside building to be kept to a minimum and to be limited to a maximum of 50 litres.

• All containers to be sealed when not in use.

• Internal storage to be in a purpose-built cupboard or a bin, which is of a fire-resistant structure and is designed to take spillages.

• All such cupboards and bins to be suitably marked and kept locked when not in use.

• Cupboards and bins to be placed away from any possible ignition sources.

• Suitable ventilation to be provided.

• Material that is not in use should be returned to the designated storage area. 3 2 6

• Dedicated fire-resistant storage areas to be adequately separated from site boundaries, occupied buildings, process areas, fixed sources of ignition and other dangerous substances.

• Incompatible dangerous substances to be segregated and adequately separated to minimise the risk of interaction.

• Good ventilation to be provided in areas where flammable liquids or gases are stored.

• For liquids stored above ground there to be a means to contain leaks and prevent them spreading to other parts of the premises or off-site.

• Good ventilation to be provided in areas where flammable liquids or gases are stored in order to ensure that any such gases or vapours given off from a spill, leak or release are rapidly dispersed.

• Storage areas to be located in well-ventilated positions, preferably in the open air.

• Where storage areas are located within a building, adequate natural or mechanical ventilation to be provided.

• Where dangerous substances are transported to a storage area, or carried or conveyed from a storage area or between work areas, they are to be carried in closed vessels or conveyed in a totally closed system.

• Process activities such as dispensing or decanting not to be carried out in a storage area where they would create a risk of fire involving the stored materials.

3 3 9

3 2 6

3 2 6

Risk assessment

Storage and disposal of empty containers Staff

Maintenance of storage facilities As above

Failure to remove empty containers or dispose of them properly may lead to fires and explosions 3 5 15

Failure to adequately maintain storage facilities may lead to leaks remaining unidentified resulting in fire or explosion 4 5 20

• Containers that are nominally empty but may still contain residues of dangerous substances are to be removed from the workroom and stored in the same manner as full containers.

• Containers to be labelled or otherwise identifiable so that all who handle them are aware of their contents and hazardous properties.

• Waste streams from different sources, having different compositions not to be mixed together.

• Storage facilities to be maintained in a safe condition.

• Storage facilities to be subject to an appropriate inspection programme to establish that they remain fit for purpose.

2 6

• Inspection programmes to be carried out by a competent person. 3 2 6

Transporting small quantities of chemicals, paints and solvents

Many chemicals, paints and solvents could be hazardous if they come into contact with each other or are spilled during transportation. Failure to manage the risks associated with their transportation may lead to staff being injured or suffering from ill-health.

Managing the risks

To help you to identify the hazards associated with the transportation of small quantities of chemical substances and the appropriate ways of controlling them, use our example Risk Assessment - Transporting Small Quantities of Chemicals, Paints and Solvents. It covers the generic hazards associated with this type of activity and suggests control measures to reduce risks to an acceptable level. You should ensure that your document only addresses “significant” hazards, i.e. any that could, and more importantly are likely to, cause an accident or injury.

Make your instructions clear

Don’t include activities in your document that simply don’t need to be there. Work to the principle that if there is any chance of your staff being unaware of the safe way of doing something, then you will need to make it clear in your document. Finally, always ensure that any control measures you identify and follow are decided upon the principle of “so far as is reasonably practicable”.

Note 1. The list of potential hazards is not exhaustive. However, for your risk assessment to be considered suitable and sufficient in the eyes of the law it must accurately reflect the “significant” hazards found when your staff transport chemical substances.

Note 2. This risk assessment only deals with the generic risks associated with the transportation of small quantities of chemical substances. Your assessment should take into consideration the actual substances your staff are transporting as well as the dangers damage to containers and spillages could cause.

RISK ASSESSMENT - TRANSPORTING SMALL QUANTITIES OF CHEMICALS, PAINTS AND SOLVENTS

Risk assessment - topic/area covered

Location(s):

Department/staff:

Tasks/activities:

Other information:

Risk assessment sign off

Prepared by: Signature:

Reviewed by: Signature:

Date for review:

Date:

Date:

This risk assessment should be reviewed if additional risks not covered in this assessment are identified or if there is any reason to suggest that the control measures are deemed to be insufficient.

Document issue record

Risk matrix

High risk: 15-25

Acceptability of risk guidance

Guidance. When completing a risk assessment, you should:

(L) x Severity (S) = Risk rating (RR).

High-risk activities should cease immediately. Further effective control measures to mitigate risks must be introduced.

Medium risk: 8-12 Medium risks should only be tolerated for the short term and only whilst further control measures to mitigate the risks are being planned and introduced.

Low risk: 1-6

Low risks are largely acceptable. Where it is reasonable to do so, efforts should be made to reduce risks further.

1. Identify the persons at risk and the significant hazards.

2. Calculate an initial RR for the activity.

3. Identify risk control measures that reduce the risks to an acceptable level.

4. Calculate a revised RR - you should consider how much safer the task will be if the control measures are followed. Here, you should consider changing both the likelihood (L) and the severity (S) ratings.

Note. Ideally, you should look to reduce the risks so that the task can be classified as “low risk”.

Personal protective equipment (PPE) assessment

In many instances, you will be able to reduce risks further by asking staff/others to wear/use PPE. You should identify which items are required for the task here:

Additional requirements (list here):

Note. PPE must only be considered as, when other control measures, such as guarding, local exhaust extraction, preventing noise at source, eliminating the need to work at height etc. are not possible. PPE should always be considered as a last resort option. PPE should only be worn when there is reasonable justification for doing so.

• Staff to be supplied with the Safety Data Sheet (SDS) for all substances that they will be transporting.

• Supervisors/Managers to ensure that staff understand the information on the SDS regarding transportation.

• Staff to be made aware of action to be taken in the event of a spillage.

• All chemical substances to be transported in their original containers.

• Original outer packaging, complete with original labels and hazard warnings to be used.

• Caps and stoppers on bottles and lids on tins etc. to be in a secure position.

• Glass bottles to be supported with bubble wrap or a similar packaging material in a robust outer container with a lid fastened closed. The outer container to be labelled indicating the contents and the hazard it presents.

• Spillage kits to be made available for use in an emergency.

• Staff to be trained on the action to be taken in the event of a spillage.

• Staff to be issued with the relevant personal protective equipment for use when handling spillages.

• Vehicles to be kept locked at all times when

• Chemical substances not to be left in vehicles overnight unless they are parked securely.

Toxic - your online partner in effective chemical management www.toxicsoftware.co.uk

Toxic supports you in working safely with chemical products and hazardous substances.

With Toxic, we maintain your legally required substances register and ensure that everyone involved in your business has the right level of knowledge to eliminate or reduce health risks.

Keep an overview of all your dangerous substances with your intuitive custom dashboard, receive alerts and notifications to stay legally safe and up to date and communicate effectively with the latest product labels and instructions.

CONTACT

Call: 01233 653500

Email: toxicsoftware@indicator-flm.co.uk

Visit: www.toxicsoftware.co.uk