Gesture-Driven Robotic Arm Navigation: Enhancing Safety in High-Risk Environments

Dr.B.Uma Maheswar Gowd1, N.Harjot Kaur Singh2

1M.Tech Research Scholar, 2Assistant Professor Department of Computer Science and Engineering, Sri Guru Granth Sahib World University, Fatehgarh Sahib, Punjab, India

Abstract:

Robot comprise develop into a enter knowledge into different field. Robotic arm are frequently distant proscribed by button before panel with every so often in lot development they are sovereign. Wireless signal gratitude and calculating be a mounting and testing pasture in electronics. These robots fall little in good organization while compare to a Biomimetic automaton proscribed by person gesture. Then, to expand competence since fine as simplicity of organize, signal machinery be apposite. Sensors such as accelerometers be calibrate to the schedule of the consumer which are transmit since mathematical standards. These values are yet over again changed as contribution signal used for the android which is operated accordingly by servo motors. In several industries wireless operation is needed mainly in treacherous or hazard area. In a little of the industry it is essential to knob little job by very high temperature which is not achievable in individual hand over in such bags wireless operation be further competent

Keywords — Biomimetic Robotic Arm, Hand Gestures, Hazardous Environment.

INTRODUCTION

Robotics is the branch of mechanical engineering, electrical engineering and software engineering that deals with the design, construction, operation, application, control systems and information processing of robots. The most fitting and effective solution to these challenges lies in designing the robot with specifications that emulate human actions — a blueprint that ensures both innovation and distinction. Humanoid robots were developed to fully eliminate the need for Deploying machines to operate in hazardous environments marks a

pivotal shift toward safer, technology-driven intervention. However, building a fully functional humanoid robot remains complex and costly. A more practical approach is to engineer specialized humanoid components—each enhanced for specific tasks—offering precision, efficiency, and adaptability without the burden of full replication. Robotic armrest is call as robot manipulator which container executes a choice of function as being arm perform. Several industry uses an android used in support of different function where central piece of several robots is Robotic support before call since machine manipulator

must be proscribed in particular depending winning appliance. These robots areengineered to function in extreme environments, with this project aimed at enabling humans to explore hazardous areas safely while gathering vital target information—eliminatingrisktohumanlife.

EXISTING SYSTEM

A robotic arm is integrated onto a mobile platform, wirelessly navigated via a secondary accelerometer. To control the arm, an accelerometer affixed to the operator's hand interprets gestures and postures, translating human motion into precise robotic movement. A second accelerometer, placed on one leg, tracks leg motionsto controlthe platform’s navigation— ensuring seamless, intuitive human-robot interaction. Unstable communication with robots operating in reactor zones poses safety risks and drives up operational costs. The handling of nuclear waste, in particular, demands extended cooling periods and robust shielding, making reliability and precision in robotic systems absolutely critical. Advanced robotic arms, modeled after the human hand, offer an intuitive solution—allowing precise control through simple hand gestures alone. The support organizers wear the feeler handbag and the automatic support motivation imitates the group of the regulator. Difficult robotic weapons like these protect complete compound and dangerous errands by

relieve. Proposed utility in field’s of construction, hazardouswastedisposal, andmedicalsciences.

PROPOSED SYSTEM

The nuclear plant environment, the robot receives input signals via a ZigBee receiver, responding accordingly based on transmitted data. The system incorporates two distinct controllers—one embedded in the gesturedetecting gloves and the other dedicated to robot operations. Keyadvantagesof thisdesigninclude:

• Seamless and efficient communication enabledbytheInternetofThings(IoT)

• Elimination of health hazards for living beingsthroughremoteinteraction

• Long-range operability, allowing the system to be controlled from distant or securelocationsviaIoTconnectivity

DETAILED EXPLANATION OF COMPONENTS

Accelerometer: ADXL 335 be a minute, slim, small control, total 3-axis accelerometer with gesture accustomed outputs. The accelerometer used in this project features six pins: VCC (power supply), GND (ground), ST (self-test), and three output pins for the X, Y, and Z axes. When the sensor is tilted along any axis, it detects the gravitational force corresponding to the tilt angle. It measures force across all three axes—X, Y, and Z—and outputs values that reflect directional movement or stability. These values are calibrated

to distinguish betweenfour movementtypes and a stationary central position, using error corrections alongeachaxis. Operatingat3.3Vsuppliedbythe Arduino Uno, this setup utilizes only the X and Y axes, The accelerometer is interfaced through analog pins A0 and A1. One of its standout features is its remarkable stability—the output remains consistent and unaffected unless physical movementisdetected.

Accelerometer (ADXL 335)

Arduino: This Arduino automatic armrestcan be proscribed by four Potentiometerfriendly to it, every potentiometer is use to manage both servo. You preserve progress these servos by revolving the pot to select several purpose, by various perform you be able to simply select and shift the article starting single position to one more. We include use short torque servos at this point save for you canister utilize further controlling servos towardselectprofoundentity.

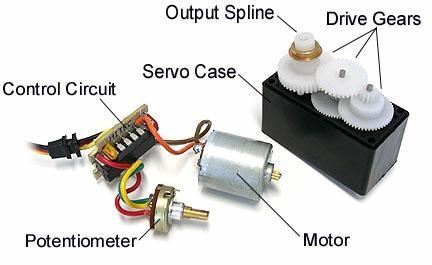

Servo Motor: To enable joint movement and perform tasks, the robotic arm relies on motors. Among the key components facilitating this functionality is the servo motor, known for its precision and control in positioning. A servo speed resolve comprise largely present supports, single is used for constructive power another be for earthwithprevioussingle isfor place situation. The REDcable isassociated to control, Black line is connected to ground and YELLOW wire is coupled toward sign. Go during this lesson of Controlling Servo Motor using Adrianato hear further on it. The motor's impartial location be clear because the place somewhere the servo have the identical quantity of likely revolving in the mutually the clockwise before counter-clockwise track. The PWM send toward the speed determine location of the stream, plus base going on the period of the pulsation send using the organize rope the rotor motivation spin on the road to the desired position. Servo motors are designed to

detect a pulse every 20 milliseconds, with the width of each pulse determining the angle of rotation. Thelonger the pulseduration, thegreater thedegreeofmovement.

ROBOTIC ARM

The robotic arm, a mechanical structure anchored to the receiver unit of the circuit, operates based on control signals generated by the Arduino in response to gesture inputs captured by an accelerometer on the transmitter side. Powered by a DC geared motor at its base, the arm is capable of executing a full 360-degree rotation, enabling flexible and precise movement. The arm consists of two segments—one measuring 20 cm and the other, forming the elbow, extending 30 cm. A load is applied at the arm's end, allowing it to lift objects of varying weights. The corresponding voltage output is fed into the Arduino, which interprets the signal and transmits it wirelessly using the nRF module. The robotic arm, guided by a custom-designed controller, is

capable of grasping, lifting, and relocating objects with respect to their weight and shape, ensuring adaptive and precise handling. The rotation and movement of the robotic arm are precisely governed by gesture inputs captured at the transmitter end, enabling intuitive, real-time controlbasedontheoperator’shandmotions

RESULTS AND DISCUSSION

The functionality of the robotic arm was evaluatedthroughaseriesof variedhandgestures, testing its responsiveness and accuracy in mimicking each movement. The design of the robotic arm is kept simple without the use of any gears or any complex mechanisms. The robotic arm demonstrated precise mimicry of hand gestures and successfully grasped lightweight objects with ease. Its ability to handle intricate and potentially hazardous tasks highlights its effectiveness in demanding scenarios. Subjective evaluations confirmed the system’s reliability as an assistive robotic solution. Gesture commands are transmitted via the wireless ZigBee protocol, ensuring the arm's movements are swift and synchronized with theoperator’shand inrealtime. The system generates serial output values through an Arduino preloaded with custom code, enabling gesture-based control. As a result, the robotic arm mimics human hand movements to grasp and manipulate objects—providing an efficient solution for replacing damaged components withinanuclearreactor.

CONCLUSIONS

The automatic section was finished of small price equipment that was with good grace existing. The representation of the automatic support was constructing and the fund- tonality was hardened. The mechanical division container is illegal over the internet with by Ethernet connectivity plus a camera infavour of diagramresponse. This mode of control not only enhances efficiency but also reduces the physical burden of repetitive tasks while greatly improving operational safety. Usability assessments reveal that the system excels in pick-and-place functions, making it especially beneficial for individuals with physical disabilities and in controlled settings like laboratories. In environments too hazardous for human presence, this technology bridges the gap between the physical and digital worlds—offering intuitive control, increased adaptability, and expanding the scope of roboticapplications across diversefields.

REFERENCES

1. Waldherr, R. Romero, and S. Thrun, “A gesture based interface for human-robot interaction,” in Autonomous Robots, vol. 9, no.2,pp.151-173,Springer, 2000.

2. Kumar Aaditya, Divesh Kumar Pande and Preksha Moondra, “Android Controlled Pick and Place Robotic Arm Vehicle”,

International Research Journal of EngineeringandTechnology,2015.

3. Pradeep and Victer Paul, “Design and Implementation of Gesture Controlled Robotic Arm for Industrial Applications”, International Journal of Advanced Scientific Research and Development, Vol. 3, Issue4,Oct.2016.

4. Pravin Vaishnav and Shalini Tiwari, “Accelerometer Based Hand Gesture Controlled Robot”, International Journal of Science and Research, Vol. 4, Issue 3, March2015.

5. H. S. Yoon, J. Soh, Y. J. Bae and H. S. Yang, “Hand gesture recognition using combined features of location, angle and velocity”, Pattern Recognition, vol. 34, (2001),pp.1491-1501.

6. M. Klingmann, “Accelerometer-Based Gesture Recognition with the iPhone”, Goldsmiths University, MSc in Cognitive Computing, London,September 2009.

7. J. Kela, P. Korpipää, J. Mäntyjärvi, S. Kallio, G. Savino, L. Jozzo, and S. Di Marca, “Accelerometer-based gesture control for a design environment,” Personal and Ubiquitous Computing, Springer, vol. 10, no. 5, pp. 285-299, 2006.

8. Abdul Ishaq T.K, He is from kasargod, Kerala. Currently Pursuing BE in Electronics and Communication, at Bearys

Institute of Technology, mangaluru, larnataka. His research interested in embeddedsystems, ImageProcessuing.

9. Joseph Sebastian, He is from kasargod, Kerala. Currently Pursuing BE in Electronics and Communication, at Bearys Institute of Technology, mangaluru, larnataka. His research interested in embedded systems, Image Processuing. Wirelessnetworks.

10.R. Dillmann, “Teaching and learning of robot tasks via observation of human performance,” in Robotics and Autonomous Systems, vol. 47, no.2-3, pp. 109-116, 2004.

11.R. Raja Prabhu and R. Sreevidya, “Design of Robotic Arm based on Hand Gesture Control System using Wireless Sensor Networks”, International Research Journal of Engineering and Technology, Vol. 4, Issue3, March2017.