SILENZIOSO

Technical features

PC.F25T-TW

Technical features

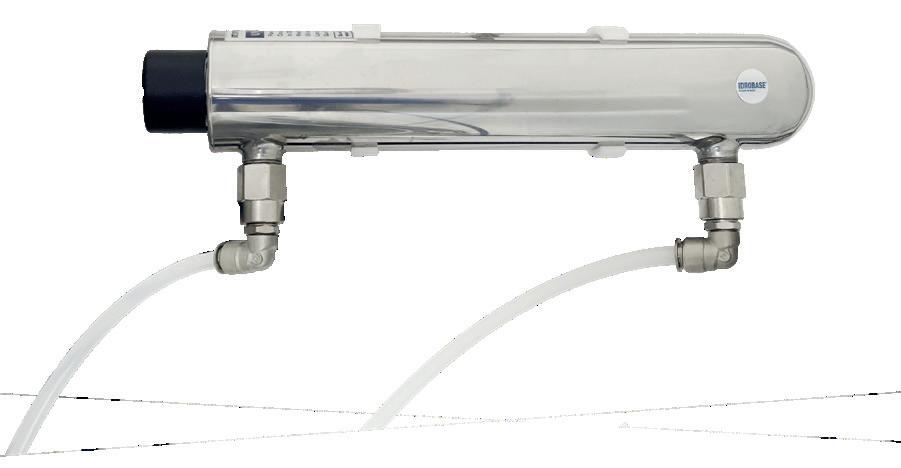

• Water filter with SS cartridge

• Thermal protection fuse

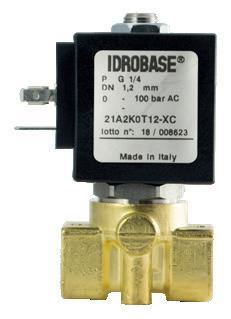

• Solenoid valve inlet water and pressure discharge

Built-in analogue timer: work 1/60"/pause 1/60" **

** The pause time can be changed by the user from seconds to minutes (1'/60')

• Slip-lock inlet ø9,6mm

• Outlet, Slip-Lock ø6,35mm

• Diaphragm pump 25l/h

Accessories page 84 Accessories page 84

Maintenance set page 91

Pump maintenance set 500hours INCLUDED

Technical Data

ZX.5095-D

ZX.5090-D

*The max number of nozzles has been calculated by using a

Accessories page 84

Maintenance set page 91

Pump maintenance set 500hours INCLUDED

Technical Data

ZX.FA1.5

ZX.FA2.0

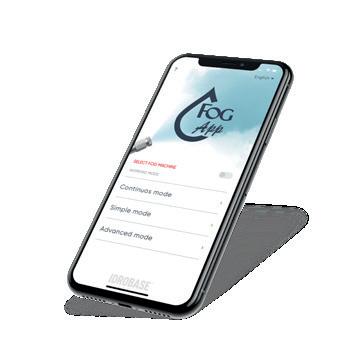

APP 2.0

Fog module 60bar with 30 and 40 nozzles 230V-50/60Hz

Fog App: how to use the fog module with your smartphone

Fog App: what does this fog module do?

Percorso efficienza Innovazione MCE 2018

• Can be activated via smartphone

• Silent

• Compact

• Energy-efficient

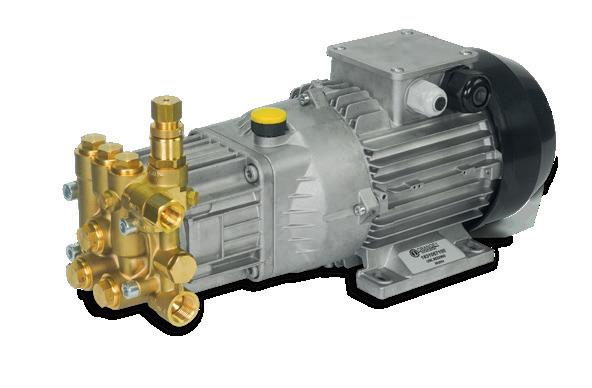

Axial pump with 3 ceramic pistons, head in nickel-plated brass, integrated bypass valve, electric motor 1300Rpm

* The max number of nozzles has been calculated by using a nozzle IT.154C with flow rate 015 (0,047l/min) at 60bar

Technical features

• Frame made of galvanised painted plate

• Electric pump 3 pistons, axial, with brass head

Thermal protection against current surge

• Unloader valve

• L.p. pressure switch due to lack of water

• Solenoid valve l.p. water inlet

Solenoid valve h.p. for pressure discharge

• Slip-lock inlet ø9,6mm

• Outlet, Slip-Lock ø6,35mm

• Instrument panel with 3 touch buttons for:

- machine ON/OFF

(included)

- Manual mode selection or Bluetooth activation for smartphone control

- Alarms reset for Maintenance

• Possibility to manage 3 different modes via the app:

- Nonstop: the Fog module works in continuous mode

- Simple mode: selection of days of the week, selection of max 4 time slots, work/pause time selection with min 3s work time and min 15s pause time

- Advanced mode: selection of the days of the week, selection of max 20 time slots, selection of work/pause times customised for each time slot with min 3s work time and min 15s pause time

Fog module 60bar from 10 to 96 nozzles 230V-50Hz

Nebulizes sterilized water

UV water sterilizer lamp (included)

Water inlet kit complete with pressure stabilizer (included)

• Visible pump for an easy Maintenance

• Pre-set for electronic board

• Essential design

Three-piston axial pump with ceramic pistons, nickel-plated brass head, and integrated by-pass valve. (for

3,6 and 4,8l/min flow rate versions)

Old pump

IDRO9 pump Old pump VS new IDRO9 pump

Axial

pump with 2 pistons

ZX.F60C05

ZX.F60C1

FOG 60 CABRIO-05 60bar 0,5l/min 1415 10 125W 8Kg

FOG 60 CABRIO-1 60bar 1l/min 1420 21 200W 8Kg

Axial pump with 2 ceramic pistons, head in nickel-plated brass, integrated bypass valve.

* The max number of nozzles has been calculated by using a nozzle IT.154C with flow rate 015 (0,047l/min) at 60bar

** 230V/60Hz and 110V/60Hz versions available upon request

Axial pump with 3 pistons IDRO9 pump

ZX.F60C2.2

ZX.F60C3.6

ZX.F60C4.8

FOG 60 CABRIO-2.2 60bar 2,2l/min 710 44 370W 18Kg

FOG 60 CABRIO-3.6 60bar 3,6l/min 710 72 370W 18Kg

FOG 60 CABRIO-4.8 60bar 4,8l/min 950 96 745W 18Kg

Axial motor pump with three ceramic pistons, nickel-plated brass head, integrated by-pass valve

* The max number of nozzles has been calculated by using a nozzle IT.154C with flow rate 015 (0,047l/min) at 60bar

Accessories page 84

Maintenance set page 91

Pump maintenance set 750hours INCLUDED

Technical features

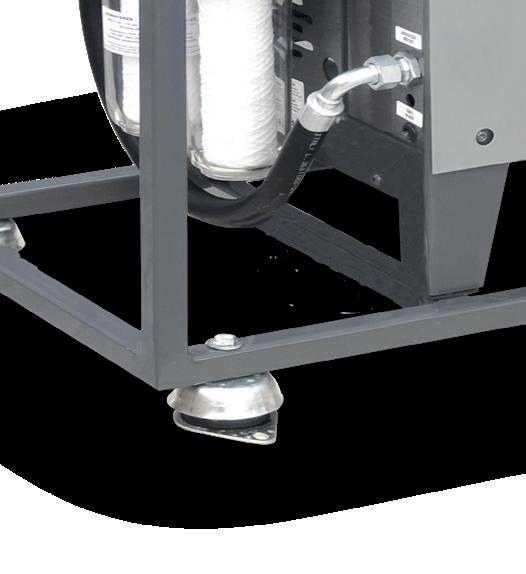

• Frame made up of 4 support feet

L.p. solenoid valve 230V-50Hz, inlet water

• Electric box complete with lighted ON/OFF thermal switch and 3m electric power cable with Schuko plug, pre-set for housing a ZX.0576-60 electronic board (optional)

• L.p. Slip-Lock inlet ø9,6mm

• Outlet Slip-Lock ø6,35mm (for versions 0,5, 1 and 2,2l/min)

• Outlet Slip-Lock ø9,6mm (for versions 3,6 and 4,8l/min)

• Dimensions WxLxH: 500x200x300mm

Fog module 60bar from 10 to 96 nozzles 230V-50Hz

Nebulizes sterilized water

UV water sterilizer lamp (included)

Water inlet kit complete with pressure stabilizer (included)

• Simple and compact

• Pre-set for remote control connection

• Discharge solenoid and pressure switch lack of water

Three-piston axial pump with ceramic pistons, nickel-plated brass head, and integrated by-pass valve.

(for 2,2, 3,6 and 4,8l/min flow rate versions)

Old pump

IDRO9 pump

Old pump VS new IDRO9 pump

Axial pump with 2 pistons

ZX.F60-05

ZX.F60-1

Axial pump with 2 ceramic pistons, head in nickel-plated brass, integrated bypass valve.

* The max number of nozzles has been calculated by using a nozzle IT.154C with flow rate 015 (0,047l/min) at 60bar

** 230V/60Hz and 110V/60Hz versions available upon request

Axial pump with 3 pistons

IDRO9 pump

ZX.F60-2.2

ZX.F60-3.6

ZX.F60-4.8

Axial motor pump with three ceramic pistons, nickel-plated brass head, integrated by-pass valve.

* The max number of nozzles has been calculated by using a nozzle IT.154C with flow rate 015 (0,047l/min) at 60bar

Accessories page 84

Maintenance set page 91

Technical features

• Frame made of painted steel

• L.p. solenoid valve 230V-50Hz, inlet water

• H.p. solenoid valve 230V-50Hz, to discharge the HP line (activates only if connected to a remote control)

L.p. pressure switch due to lack of water

INCLUDED

Pump maintenance set 750hours

• Electrical panel complete with: ON/OFF thermal cutout, electronic board for management of anti-drip system

• Slip-lock inlet ø9,6mm

• Outlet Slip-Lock ø6,35mm (for versions 0,5, 1 and 2,2l/min) Outlet Slip-Lock ø9,6mm (for versions 3,6 and 4,8l/min)

• Dimensions WxLxH: 600x300x300mm

Nebulizes sterilized water

UV water sterilizer lamp (included)

Water inlet kit complete with pressure stabilizer (included)

• Simple and compact

• Electronic control panel with built-in thermostat and humidstat

• Pre-setting for humidity and temperature probes

• System can be activated remotely

Three-piston axial pump with ceramic pistons, nickel-plated brass head, and integrated by-pass valve. (for 2,2, 3,6 and 4,8l/min flow rate versions)

IDRO9 pump

Axial pump with 2 pistons

ZX.FX-05

ZX.FX-1

Axial pump with 2 ceramic pistons, head in nickel-plated brass, integrated bypass valve.

* The max number of nozzles has been calculated by using a nozzle IT.154C with flow rate 015 (0,047l/min) at 70bar

** 230V/60Hz and 110V/60Hz versions available upon request

Axial pump with 3 pistons

IDRO9 pump

ZX.FX-2.2

ZX.FX-3.6

ZX.FX-4.8

Axial motor pump with three ceramic pistons, nickel-plated brass head, integrated by-pass valve

* The max number of nozzles has been calculated by using a nozzle IT.154C with flow rate 015 (0,047l/min) at 60bar

Pump maintenance set 750hours INCLUDED Accessories page 84 Maintenance set page 91

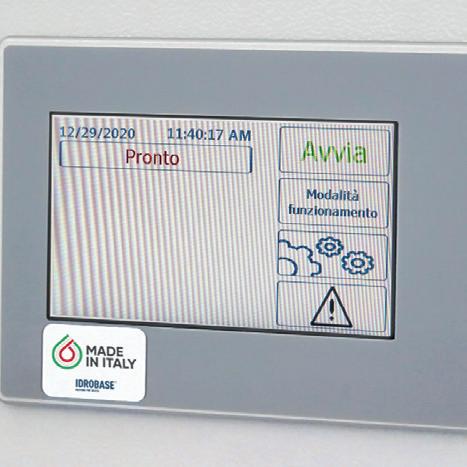

Control panel Fog Extra 2.0

Graphic display

• 5 operating modes

• Temperature setting

Humidity setting

• On/Off timer

Hourly/weekly calendars

• App access via QR Code

• Third language setting

• Maintenance check Integrated Wi-Fi antenna

• Battery-powered clocks

• Aux input Programmable drain time.

• Programmable water shortage time

Possible expansion via ModBUS

Technical features

Frame made of painted steel

• Built-in unloader valve

• L.p. solenoid valve 230V-50Hz, inlet water

H.p. solenoid valve 230V-50Hz, to discharge line pressure

• Electrical panel complete with:ON/OFF thermal cutout, electronic

board for management of anti-drip and timer system

• Slip-lock inlet ø9,6mm

• Outlet Slip-Lock ø6,35mm (for versions 0,5, 1 and 2,2l/min), ø9,6mm (for versions 3,6 and 4,8l/min)

• H.p. switch for no water supply and pipe breaks

• Dimensions WxLxH: 600x300x300mm

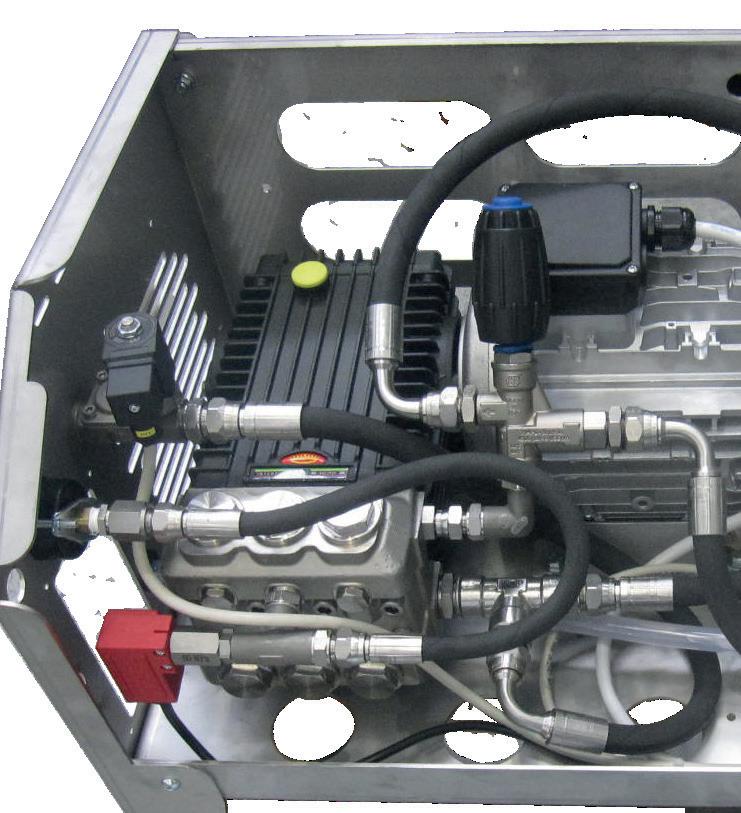

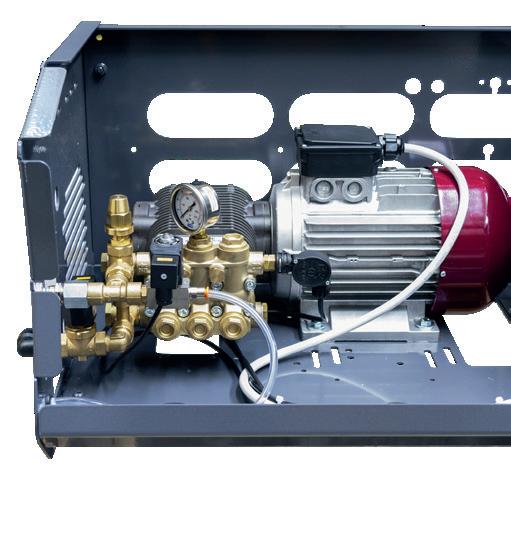

Professional pump unit

• Complete with electric motor

• Crankshaft pump with three ceramic plungers

• Stainless steel pressure gauge

• Electric control panel with thermal switch

• Three-meter power cable

Fog module 70bar from 87 to 280 nozzles 3x400V-50Hz

Pump unit 3x400V-50Hz

ZX.MTPF70-11D

ZX.MTPF70-15D

4 ball-bearing motor-pump unit pre-assembled and tested

* The max number of nozzles has been calculated by using a nozzle IT.204C with flow rate 020 (0,075l/min) at 70bar

Maintenance set page 92

Pump unit 1x230V-50Hz

ZX.MTPF60-2

ZX.MTPF60-4

ZX.MTPF60-6

ZX.MTPF60-8

ZX.MTPF60-11

3 ball-bearing

unit pre-assembled and tested

* The max number of nozzles has been calculated by using a nozzle IT.154C with flow rate 015 (0,047l/min) at 60bar

Pump unit 3x400V-50Hz

ZX.MTPF70-6

ZX.MTPF70-8

ZX.MTPF70-11

ZX.MTPF70-15

ZX.MTPF70-18

ZX.MTPF70-21

3 ball-bearing motor-pump unit pre-assembled and tested

* The max number of nozzles has been calculated by using a nozzle IT.204C with flow rate 020 (0,075l/min) at 70bar

*The calculation uses nozzles with a flow rate factor of 020

Maintenance set page 92

Technical features A

• Electric motor 400V-50Hz 1450Rpm

• Crankshaft pump with three ceramic plungers

Stainless steel pressure gauge

• Electric control panel with thermal switch

3 meter power cable Outlet 3/8 M

Technical features B

• Electric motor 230V-50Hz 1450Rpm

• Crankshaft pump with three ceramic plungers

Stainless steel pressure gauge

• Electric control panel with thermal switch 3 meter power cable Outlet 3/8 M

Technical features C

• Electric motor 3x400V-50Hz 1450Rpm

• Crankshaft pump with three ceramic plungers

Stainless steel pressure gauge

• Electric control panel with thermal switch

3 meter power cable Outlet 3/8 M

Nebulizes sterilized water

UV water sterilizer lamp (included)

Water inlet kit complete with pressure stabilizer (included)

• Essential

Fog module 70bar professional

from 13 to 560 nozzles 3x400V-50Hz

• Visible pump for an easy Maintenance

• Electromechanical management of safety devices

• Possibility of connecting remote control devices

and

Detail of discharge solenoid valve and bypass valve

Control panel with remote outlet for connection of external devices such as humidistat, thermostat, etc.

Detail of head section

pressure gauge

Technical features

ZX.F70AP01

ZX.F70AP02

ZX.F70AP04

ZX.F70AP65

ZX.F70AP08

ZX.F70AP11

ZX.F70AP13

ZX.F70AP15

ZX.F70AP18

ZX.F70AP21

ZX.F70AP26

ZX.F70AP33

ZX.F70AP42

FOG 70 APERTO-1

FOG 70 APERTO-4 70bar

FOG

* The max number of nozzles has been calculated by using a nozzle IT.204C with flow rate 020 (0,075l/min) at 70bar

Accessories page 84

Maintenance set page 92 Pump maintenance set 750hours INCLUDED

Technical features

• Base made of galvanized steel complete with support feet

• Professional pump, crankshaft, with brass head with 3 ceramic plungers

• Electric motor 1450g/min, 3x400V-50Hz, S1

• Unloader valve, in brass

• Pressure gauge with glycerine

L.p. solenoid valve 24V-50Hz, inlet water

• H.p. solenoid valve 24V-50Hz for line pressure discharge

• H.p. switch for no water supply and pipe breaks

• Electric board complete with: ON/OFF thermal cutout switch, remote control switch, fuses, electrical transformer 380/220/24V. Ready to be connected to an external device (thermostat, humidistat and other)

• 3/4” M inlet Outlet, 1/2” M

• Dimensions WxLxH: 380x650x350mm

Hotel - United Arab Emirates

Playground - South Korea

Nebulizes sterilized water

UV water sterilizer lamp (included)

from 13 to 560 nozzles 3x400V-50Hz

Misting system installation

Water inlet kit complete with pressure stabilizer (included)

The 100% stainless steel version is also available

• Sturdy structure made of painted steel

• Compact

• Possibility of installing accessories directly on the module

• Possibility of connecting remote control devices

Idrobase Industrial Pump VS Idrobase Professional Pump

Basico 70bar Fog module, detail of the remote coupling for the connection of external devices such as a thermostat, humidistat or other

Basico 70 is also available in a stainless steel version (casing, pump head, solenoid valve, by-pass)

Technical features

ZX.F70B01

ZX.F70B02

ZX.F70B04

ZX.F70B06

ZX.F70B08

ZX.F70B11

ZX.F70B13

ZX.F70B15

ZX.F70B18

ZX.F70B21

ZX.F70B26

ZX.F70B33

ZX.F70B42

FOG 70 BASICO-1 70bar 1l/min 13 1,5kW 58Kg

FOG 70 BASICO-2 70bar 2l/min 27 1,5kW 58Kg

FOG 70 BASICO-4 70bar 4l/min

FOG

FOG 70 BASICO-13 70bar 13l/min 173 2,2kW 61Kg

FOG 70 BASICO-15 70bar 15l/min 200 2,2kW 61Kg

FOG

FOG 70 BASICO-21 70bar 21l/min 280 3kW 66Kg

FOG 70 BASICO-26 70bar 26l/min 347 4kW 80Kg

FOG 70 BASICO-33 70bar 33l/min 440 6,3kW 98Kg

FOG 70 BASICO-42 70bar 42l/min 560 6,3kW 98Kg

* The max number of nozzles has been calculated by using a nozzle IT.204C with flow rate 020 (0,075l/min) at 70bar

Accessories page 84 Maintenance set page 92 Pump maintenance set 750hours INCLUDED

Technical features

Frame made of painted steel

Professional pump, crankshaft, with brass head with 3 ceramic plungers

Electric motor 1450g/min, 3x400V-50Hz, S1

• Unloader valve, in brass

• Pressure gauge with glycerine in AISI 304 stainless steel

• Solenoid valve l.p. water inlet 24V-50Hz

H.p. solenoid valve 24V-50Hz for line pressure discharge

H.p. switch for no water supply and pipe breaks

Electric board complete with: ON/OFF thermal cutout switch, remote control switch, fuses, electrical transformer 380/220/24V. Ready to be connected to an external device (thermostat, humidistat and other) 3/4” M inlet

• Outlet, 1/2” M

• Dimensions WxLxH: 780x450x500mm

Public park - United Arab Emirates

Private road - United Arab Emirates

Nebulizes sterilized water

UV water sterilizer lamp (included)

Water inlet kit complete with pressure stabilizer (included)

• Highly compact

• Possibility of installing accessories directly on the module

• Electronic control panel with built-in thermostat and humidstat

• Pre-setting for humidity and temperature probes connection

Industrial Pump VS Idrobase Professional Pump

Misting system at Marco Polo Venice airport

Misting system installation

Professional pump with brass head, 1450Rpm, crankshaft, 3 ceramic plungers and brass heads

Control panel with thermostat, humidistat, and weekly programmer. With presetting for ZX.SU20 humidity sensor connections and ZX.ST20 temperature sensors

Idrobase

Technical features Code

ZX.F70X01

ZX.F70X02

ZX.F70X04

ZX.F70X06

ZX.F70X08

ZX.F70X11

ZX.F70X13

ZX.F70X15

ZX.F70X18

ZX.F70X21

ZX.F70X26

ZX.F70X33

ZX.F70X42

FOG 70 EXTRA-1 80bar 1l/min 13 1,5kW 58Kg

FOG 70 EXTRA-2 80bar 2l/min 27 1,5kW 58Kg

FOG 70 EXTRA-4

FOG 70 EXTRA-33 70bar 33l/min 440 6,3kW 98Kg

FOG 70 EXTRA-42 70bar 42l/min 560 6,3kW 98Kg

* The max number of nozzles has been calculated by using a nozzle IT.204C with flow rate 020 (0,075l/min) at 70bar

Accessories page 84 Maintenance set page 93 Pump maintenance set 750hours INCLUDED

Technical features

Frame made of painted steel

Professional pump, crankshaft, with brass head with 3 ceramic plungers

• Electric motor 1450Rpm, 3x400V-50Hz, S1

• Unloader valve, in brass

Pressure gauge with glycerine in AISI 304 stainless steel

Solenoid valve l.p. water inlet 230V-50Hz

H.p. solenoid valve 230V-50Hz to discharge line pressure

H.p. switch for no water supply and pipe breaks

Thermostat and humidistat as standard supplies

• General thermal switch

• 3/4” M inlet

• Outlet, 1/2” M

Control panel with: cyclical ON/OFF timer supplied as standard, weekly programmer with standard time slots, hour counter and Maintenance schedule. Pre-setting for connection of 230V ventilation systems. Possibility of remote management Dimensions WxLxH: 780x450x500mm

Amusement park - South Korea

Venice airport - Italy

Nebulizes sterilized water

UV water sterilizer lamp (included)

Water inlet kit complete with pressure stabilizer (included)

• Ultra compact

from 13 to 560 nozzles 3x400V-50Hz

Misting system at Marco Polo Venice airport

Misting system installation

• Possibility of mounting accessories directly on the machine

• Multi-function control panel with:

• language, date and time setting,

• quick connection to remote control (clean signal)

• touch panel connector with 0.5 meters sheath (ZX.2753)

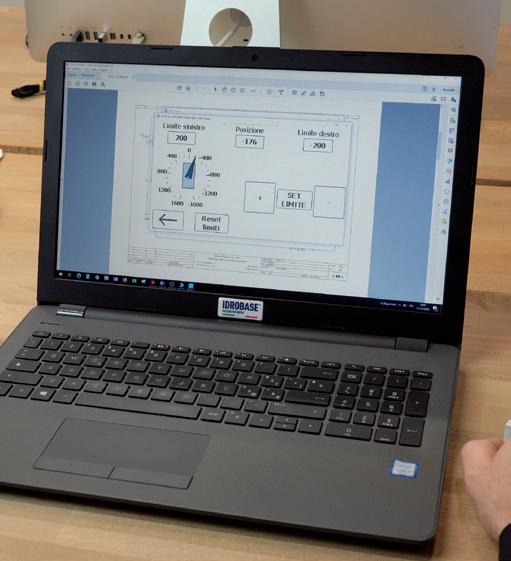

Control panel with PLC and touchscreen to manage the module, available in 7 languages

OPTIONAL Remote control: possibility to interact with the system from a remote terminal

Multifunctional control panel with:

• continuous mode/work pause;

• adjustable setting of pause and work cycles;

• adjustable setting of pause and work cycles;

• unload solenoid valve;

• pipe-breaks / no water supply delay setting;

• work timer counts;

• expiring Maintenance notice; expired Maintenance notice;

• pipe-breaks / no water supply alarm.

Technical features

ZX.F70T01

ZX.F70T02

ZX.F70T04

ZX.F70T06

ZX.F70T08

ZX.F70T11

ZX.F70T13

ZX.F70T15

ZX.F70T18

ZX.F70T21

ZX.F70T26

ZX.F70T33

ZX.F70T42

FOG 70 TOUCH-1 80bar 1l/min 13 1,5kW 58Kg

FOG 70 TOUCH-2 80bar 2l/min

FOG

FOG 70 TOUCH-21 80bar 21l/min 280 3kW 66Kg

FOG 70 TOUCH-26 80bar 26l/min 347 4kW 80Kg

FOG 70 TOUCH-33 70bar 33l/min 440 6,3kW 98Kg

FOG 70 TOUCH-42 70bar 42l/min 560 6,3kW 98Kg

* The max number of nozzles has been calculated by using a nozzle IT.204C with flow rate 020 (0,075l/min) at 70bar

Maintenance set page 93

Pump maintenance set 750hours

Technical features

Frame made of painted steel

Professional pump, crankshaft, with brass head with 3 ceramic plungers

• Electric motor 1450Rpm, 3x400V-50Hz, S1

• Unloader valve, in brass

Pressure gauge with glycerine in AISI 304 stainless steel

Solenoid valve l.p. water inlet 24V-50Hz

H.p. solenoid valve 24V-50Hz to discharge line pressure

H.p. switch for no water supply and pipe breaks

General thermal switch

• 3/4” M inlet

• Outlet, 1/2” M

Control panel with: thermal switch, PLC and touchscreen to manage the module

Dimensions WxLxH: 780x450x500mm

Green area - South Korea

Nebulizes sterilized water

UV water sterilizer lamp (included)

Water inlet kit complete with pressure stabilizer (included)

• System complete with filtering system and mechanical dispenser

• 950Rpm pump unit ideal for working continuously

• Control panel with PLC and touchscreen

• Possibility of remote management

Control panel with PLC and touchscreen to manage the module, available in 7 language

Mechanical proportional dispenser 0,2-2% OPTIONAL Remote control: possibility to interact with the system from a remote terminal

Technical features Code Model

ZX.8211

ZX.8215

* The max number of nozzles has been calculated by using a nozzle IT.204C with flow rate 020 (0,075l/min) at 70bar

Technical features

Frame made of aluminium

Professional pump, crankshaft, with brass head with 3 ceramic plungers

• Electric motor 940Rpm, 3x400V-50Hz, S1

• Unloader valve, in brass

Pressure gauge with glycerine in AISI 304 stainless steel

Solenoid valve l.p. water inlet 24V-50Hz

H.p. solenoid valve 24V-50Hz to discharge line pressure

H.p. switch for no water supply and pipe breaks 3/4” M inlet

• Outlet, 1/2” M

Control panel with: thermal switch, PLC and touchscreen to manage the module

Dimensions WxLxH: 800x560x1000mm

Odor suppression - Algeria

UV water sterilizer lamp (included)

Water inlet kit complete with pressure stabilizer (included)

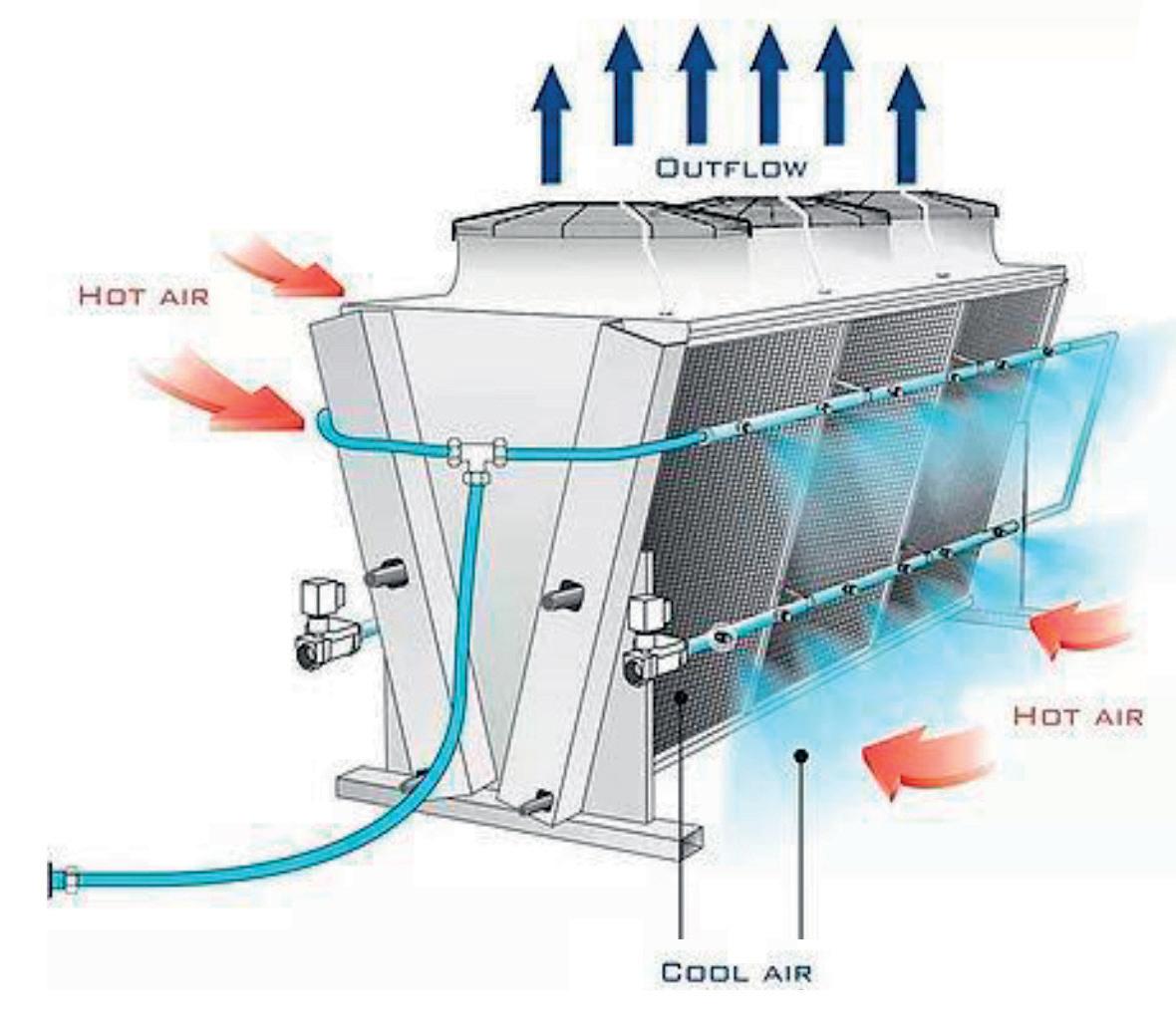

Fog module 70bar industrial 3x400V-50Hz

We show you the Zaryadye Park of Moscow

• Self-supporting structure made of painted steel

• Double pump system for continuous work (H24)

• Control panel with PLC for alternate management of the pumps

• Possibility of remote management

Detail of anti-vibration supports for floor fixing

Idrobase Industrial Pump VS Idrobase Professional Pump

PLC (programmable logic controller) detail

Nebulizes sterilized water

Technical features

ZX.F70H24-8

ZX.F70H24-11

ZX.F70H24-15

* The max number of nozzles has been calculated by using a nozzle IT.204C with flow rate 020 (0,075l/min) at 70bar

** Other flow rates are available upon request

Control panel

Electrical panel with: main ON/OFF switch, remote control switch, fuses. Pump selector for manual/automatic operation. Pre-set to be connected to external devices (e.g.: thermostat, humidistat, etc.)

PLC (programmable logic controller)

ON/OFF general

Technical

features

Frame made of painted steel

Industrial pump with brass head with 3 ceramic plungers

• Electric motor 1450Rpm, 3x400V-50Hz, S1

• Unloader valve, in brass

• Pressure gauge with glycerine in AISI 304 stainless steel

• L.p. solenoid valve inlet water 24V-50/60Hz, brass body

H.p. solenoid valve 24V-50/60Hz for line pressure discharge, brass body

• L.p. pressure switch lack of water

• Dimensions WxLxH: 1100x500x1580mm

Water supply kit

Water supply kit, 10m with screw quick couplings

Professional water inlet kit - 3M

5” water inlet kit complete with pressure stabilizer

10” water inlet kit complete with pressure stabilizer

20” water inlet kit complete with pressure stabilizer

7” water inlet kit complete with pressure stabilizer for hard water

10” water inlet kit complete with pressure stabilizer for hard water

20” water inlet kit complete with pressure stabilizer for hard water

70 Var 3 from 11 to 26 l/min

70 Var 3 from 33 to 42 l/min

Ambiente from 1 l/min

Ambiente from 2 to 4 l/min

Ambiente from 2 to 4 l/min

Description

Sterilizer kit up to 1,1l/min

Sterilizer kit up to 4l/min

Sterilizer kit up to 7,6l/min

Sterilizer kit up to 23l/min

Sterilizer kit up to 45l/min

10” water inlet kit + 0,2-2% dispenser and pressure stabilizer SaniFog Fisso

Manifold 4 outlet kit complete with ball valves

Wi-Fi remote control kit for PLC

Sterilizer

Extra Fog Box from 1 to 26 l/min from 0,5 to 1 l/min from 0,5 to 1 l/min from 2 to 4 l/min from 2 to 4 l/min from 6 l/min from 6 l/min from 33 to 42 l/min from 1 to 26 l/min from 33 to 42 l/min

Humidity probe Fog Extra 20m cable Temperature probe Fog Extra 20m cable Anti-ice kit for FOG 70

ZX.SU20

ZX.ST20

IDROBASE SERIE FS (21L) PUMP MAINTENANCE

Set B - pump maintenance 750 hours consisting of:

750hrs - h.p. industrial pumps maintenance

Set D - pump maintenance 1500 hours consisting of:

1500hrs - h.p. industrial pumps maintenance Compared to the

0,5L

10ml Threadlocker medium

25ml Technical grease

10ml Threadlocker medium

25ml Technical grease

Kit Dolly valves + O-rings Kit Dolly seal packing ø20

Mineral oil for h.p. pumps

Complete seal packing kit Valves + O-Rings kit

Plunger oil seals kit

Ceramic plungers set Plungers fastening kit

0,5L Mineral oil for h.p. pumps

EXAMPLE

FOG 70 EXTRA (ZX.F70X21) MACHINE MAINTENANCE

Set E - machine maintenance 750 hours consisting of:

750hrs - HP industrial fog module maintenance

By-pass valve service kit

Hollow perforated screw with washer

String-wound cartridge, 1micron

String-wound cartridge, 5microns

Set F - machine maintenance 3000 hours consisting of:

3000hrs - HP industrial fog module maintenance Compared to the list price of

Pressure switch (3)

By-pass valve (4)

String-wound cartridge, 1micron (5)

String-wound cartridge, 5microns (6)

Solenoid valve brass, NC, 3/8” FF, 230V, (1)

Solenoid valve brass, NC, 1/4” FF, 230V, (3)

A Set A

Pump manintenance at: 500 hours, 1.500 hours, 2.500 hours, ecc

B Set B

Pump manintenance at: 750 hours, 2.250 hours, 3.750 hours, ecc

C Set C

Pump manintenance at: 1.000 hours, 2.000 hours, 3.000 hours, ecc

D Set D

Pump manintenance at: 1.500 hours, 3.000 hours, 4.500 hours, ecc

E Set E

Machine manintenance at: 750 hours, 1.500 hours, 2.250 hours, 3.750 ore, ecc

F Set F

Machine manintenance at: 3.000 hours, 6.000 hours, 9.000 hours, ecc

ZX. 50D01 ZX. 50D02 ZX. 50IBG19 ZX. 50IBG20 ZX. 50IBG21

ZX.75IP01

ZX.75IBG01

ZX.75IBG02

ZX.75IBG03

ZX.75IBG04 ZX.75IBG05

ZX.75IBG06

ZX.75IBG07

ZX.75IBG08

ZX.75IBG10 ZX.75IBG13

ZX.75IBG24 ZX. 100D01 ZX. 100D02 ZX. 100IBG19 ZX. 100IBG20 ZX. 100IBG21 ZX. 100IBG22

ZX.150IP01

ZX.150IBG01

ZX.150IBG02

ZX.150IBG03

ZX.150IBG04

ZX.150IBG05

ZX.150IBG06

FOG ECO

FOG APP

ZX.5095-D FOG ECO 0.5 DIGITALE •

ZX.5090-D FOG ECO 1 DIGITALE

ZX.FA1.5 FOG APP 1.5

ZX.FA2.0 FOG APP 2.0

ZX.F60C05 FOG 60 CABRIO-05

ZX.F60C1 FOG 60 CABRIO-1

ZX.F60C2.2 FOG 60 CABRIO-2.2

ZX.F60C3.6 FOG 60 CABRIO-3.6

ZX.F60C4.8 FOG 60 CABRIO-4.8

ZX.F60-05 FOG 60-05

ZX.F60-1 FOG 60-1

ZX.F60C2.2 FOG 60-2.2

ZX.F60C3.6 FOG 60-3.6

ZX.F60C4.8 FOG 60-4.8

FOG BOX

ZX.BR60-2UV FOG BOX 60-2

ZX.BR60-4UV FOG BOX 60-4

ZX.BR60-6UV FOG BOX 60-6

ZX.BR70-6 FOG BOX 70-6

ZX.BR70-8 FOG BOX 70-8

ZX.BR70-11 FOG BOX 70-11

ZX.MTPF70-11D

ZX.MTPF70-15D

ZX.MTPF60-2

ZX.MTPF60-4

ZX.MTPF60-6

ZX.MTPF60-8

ZX.MTPF60-11

ZX.MTPF70-6

ZX.MTPF70-11

ZX.MTPF70-18

ZX.MTPF70-21

ZX.F70AP01 FOG 70 APERTO-1

ZX.F70AP02 FOG 70 APERTO-2

ZX.F70AP04 FOG 70 APERTO-4

ZX.F70AP06 FOG 70 APERTO-6,5

ZX.F70AP08 FOG 70 APERTO-8

ZX.F70AP11 FOG 70 APERTO-11

ZX.F70AP13 FOG 70 APERTO-13

ZX.F70AP15 FOG 70 APERTO-15

ZX.F70AP18 FOG 70 APERTO-18

ZX.F70AP21 FOG 70 APERTO-21

ZX.F70AP26 FOG 70 APERTO-26

ZX.F70AP33 FOG 70 APERTO-33

ZX.F70AP42 FOG 70 APERTO-42

ZX.F70B01 FOG 70 BASICO-1

ZX.F70B02 FOG 70 BASICO-2

ZX.F70B04 FOG 70 BASICO-4

ZX.F70B06 FOG 70 BASICO-6,5

ZX.F70B08 FOG 70 BASICO-8

ZX.F70B11 FOG 70 BASICO-11

ZX.F70B13 FOG 70 BASICO-13

ZX. 50D01 ZX. 50D02 ZX. 50IBG19 ZX. 50IBG20 ZX. 50IBG21

ZX.75IP01

ZX.75IBG01 ZX.75IBG02

ZX.75IBG03

ZX.75IBG04 ZX.75IBG05 ZX.75IBG06

ZX.75IBG07

ZX.75IBG08

ZX.75IBG10

ZX.75IBG13

ZX.75IBG24

ZX. 100D01 ZX. 100D02 ZX. 100IBG19 ZX. 100IBG20 ZX. 100IBG21 ZX. 100IBG22 ZX.150IP01

ZX.150IBG01

ZX.150IBG02

ZX.150IBG03

PUMP MAINTENANCE

ZX.F70B15 FOG 70 BASICO-15

ZX.F70B18 FOG 70 BASICO-18

ZX.F70B21 FOG 70 BASICO-21

ZX.F70B26 FOG 70 BASICO-26

ZX.F70B33 FOG 70 BASICO-33

ZX.F70B42 FOG 70 BASICO-42

ZX.F70X01 FOG 70 EXTRA-1

ZX.F70X02 FOG 70 EXTRA-2

ZX.F70X04 FOG 70 EXTRA-4

ZX.F70X06 FOG 70 EXTRA-6,5

ZX.F70X08 FOG 70 EXTRA-8

ZX.F70X11 FOG 70 EXTRA-11

ZX.F70X13 FOG 70 EXTRA-13

ZX.F70X15 FOG 70 EXTRA-15

ZX.F70X18 FOG 70 EXTRA-18

ZX.F70X21 FOG 70 EXTRA-21

ZX.F70X26 FOG 70 EXTRA-26

ZX.F70X33 FOG 70 EXTRA-33

ZX.F70X42 FOG 70 EXTRA-42

ZX.F70T01 FOG 70 TOUCH-1

ZX.F70T02 FOG 70 TOUCH-2

ZX.F70T04 FOG 70 TOUCH-4

ZX.F70T06 FOG 70 TOUCH-6,5

ZX.F70T08 FOG 70 TOUCH-8

ZX.F70T11 FOG 70 TOUCH-11

ZX.F70T13 FOG 70 TOUCH-13

FOG 70 TOUCH-15

ZX.F70T18 FOG 70 TOUCH-18

ZX.F70T21 FOG 70 TOUCH-21

ZX.F70T26 FOG 70 TOUCH-26

ZX.F70T33 FOG 70 TOUCH-33

ZX.F70T42 FOG 70 TOUCH-42

FOG 70 NEUTRA-ODORI

FOG 70 NEUTRA-ODORI

ZX.F70H24-8 FOG 70 H24-8

ZX.F70H24-11 FOG 70 H24-11

ZX.F70H24-15 FOG 70 H24-15

ZX. 50D01 ZX. 50D02 ZX. 50IBG19 ZX. 50IBG20 ZX. 50IBG21 ZX.75IP01 ZX.75IBG01 ZX.75IBG02 ZX.75IBG03 ZX.75IBG04 ZX.75IBG05 ZX.75IBG06 ZX.75IBG07 ZX.75IBG08 ZX.75IBG10 ZX.75IBG13

ZX.75IBG24

ZX. 100D01 ZX. 100D02 ZX. 100IBG19 ZX. 100IBG20 ZX. 100IBG21 ZX. 100IBG22 ZX.150IP01 ZX.150IBG01 ZX.150IBG02 ZX.150IBG03 ZX.150IBG04 ZX.150IBG05 ZX.150IBG06 ZX.150IBG07

A Set A

Pump manintenance at: 500 hours, 1.500 hours, 2.500 hours, ecc

B Set B

Pump manintenance at: 750 hours, 2.250 hours, 3.750 hours, ecc

C Set C

Pump manintenance at: 1.000 hours, 2.000 hours, 3.000 hours, ecc

D Set D

Pump manintenance at: 1.500 hours, 3.000 hours, 4.500 hours, ecc

E Set E

Machine manintenance at: 750 hours, 1.500 hours, 2.250 hours, 3.750 ore, ecc

F Set F

Machine manintenance at: 3.000 hours, 6.000 hours, 9.000 hours, ecc

MACHINE MAINTENANCE

FOG ECO

FOG APP

FOG 60 CABRIO

FOG 60

ZX.5095-D

ZX.5090-D

ZX.FA1.5

ZX.FA2.0

ZX.F60C05

ZX.F60C1

ZX.F60C2.2

ZX.F60C3.6

ZX.F60C4.8

ZX.F60-05

ZX.F60-1

ZX. 50FA ZX. 50F60-A ZX. 50F60-B ZX. 50BR60 ZX. 50MTPF70D ZX. 75F70-A ZX. 75F70-B ZX. 75F70-C ZX. 75F70-D ZX. 75F70-E ZX.75F70-F ZX. 75NO-A ZX. 75NO-B ZX. 300FE ZX. 300FA ZX. 300F60C-A ZX. 300F60C-B ZX. 300F60-A ZX. 300F60-B ZX. 300FL-A ZX. 300FL-B ZX. 300BR60 ZX. 300BR70 ZX. 300MF70D-A ZX. 300MF70D-B ZX. 300MF60 ZX.300MF70-A ZX.300MF70-B ZX.300MF70-C ZX.300F70-A ZX.300F70-B ZX.300F70-C ZX.300F70-D ZX.300F70-E ZX.300F70-F ZX.300F70-G ZX.300F70X-A ZX.300F70X-B ZX.300F70X-C ZX.300F70X-D ZX.300F70X-E ZX.300F70X-F ZX.300F70X-G

ZX.300F70X-H

ZX.300NO-A

MACHINE MAINTENANCE E F

ZX. 50FA ZX. 50F60-A ZX. 50F60-B ZX. 50BR60 ZX. 50MTPF70D ZX. 75F70-A ZX. 75F70-B ZX. 75F70-C ZX. 75F70-D ZX. 75F70-E ZX.75F70-F ZX. 75NO-A ZX. 75NO-B ZX. 300FE ZX. 300FA ZX. 300F60C-A ZX. 300F60C-B ZX. 300F60-A ZX. 300F60-B ZX. 300FL-A ZX. 300FL-B ZX. 300BR60 ZX. 300BR70 ZX. 300MF70D-A ZX. 300MF70D-B ZX. 300MF60 ZX.300MF70-A ZX.300MF70-B ZX.300MF70-C ZX.300F70-A ZX.300F70-B ZX.300F70-C ZX.300F70-D ZX.300F70-E ZX.300F70-F ZX.300F70-G ZX.300F70X-A ZX.300F70X-B ZX.300F70X-C ZX.300F70X-D ZX.300F70X-E ZX.300F70X-F ZX.300F70X-G ZX.300F70X-H

FOG BOX

ZX.BR60-2UV

ZX.BR60-4UV

ZX.BR60-6UV

ZX.BR70-6

ZX.BR70-8

ZX.BR70-11

ZX.MTPF70-11D

ZX.MTPF70-15D

ZX.MTPF60-2

ZX.MTPF60-4

ZX.MTPF60-6

ZX.MTPF60-8

ZX.MTPF60-11

ZX.MTPF70-6

ZX.MTPF70-8

ZX.MTPF70-11

ZX.MTPF70-15

ZX.MTPF70-18

ZX.MTPF70-21

ZX.F70A01

ZX.F70A02

ZX.F70A04

ZX.F70A06

ZX.F70A08

ZX.F70A11

ZX.F70A13

ZX.F70A15

ZX.F70A18

ZX.F70A21

ZX.F70A26

ZX.F70A33

ZX.F70B01

ZX.F70B04

ZX.F70B06

ZX.F70B08

ZX.F70B11

MACHINE MAINTENANCE E

ZX. 50FA ZX. 50F60-A ZX. 50F60-B ZX. 50BR60 ZX. 50MTPF70D ZX. 75F70-A ZX. 75F70-B ZX. 75F70-C ZX. 75F70-D ZX. 75F70-E ZX.75F70-F ZX. 75NO-A ZX. 75NO-B ZX. 300FE ZX. 300FA ZX. 300F60C-A ZX. 300F60C-B ZX. 300F60-A ZX. 300F60-B ZX. 300FL-A ZX. 300FL-B ZX. 300BR60 ZX. 300BR70 ZX. 300MF70D-A ZX. 300MF70D-B ZX. 300MF60 ZX.300MF70-A ZX.300MF70-B ZX.300MF70-C ZX.300F70-A ZX.300F70-B ZX.300F70-C ZX.300F70-D ZX.300F70-E ZX.300F70-F ZX.300F70-G ZX.300F70X-A ZX.300F70X-B ZX.300F70X-C ZX.300F70X-D ZX.300F70X-E ZX.300F70X-F ZX.300F70X-G ZX.300F70X-H ZX.300NO-A

FOG 70 BASICO

ZX.F70B13

ZX.F70B15

ZX.F70B18

ZX.F70B21

ZX.F70B26

ZX.F70B33

ZX.F70B42

ZX.F70X01

ZX.F70X02

ZX.F70X04

ZX.F70X06

ZX.F70X08

70 EXTRA

FOG

ZX.F70X11

ZX.F70X13

ZX.F70X15

FOG 70 TOUCH

ZX.F70X26

ZX.F70X33

ZX.F70X42

ZX.F70T01

ZX.F70T02

ZX.F70T04

ZX.F70T06

ZX.F70T08

ZX.F70T11

ZX.F70T13

ZX.F70T15

ZX.F70T18

ZX.F70T21

ZX.F70T26

ZX.F70T42

Code Description

Complete set of special tools for h.p. pump maintenance Code Description

ZX.2348

ZX.2446

Code Description

Extractor with pliers

Code Description Oil seal maintenance kit

Video special tools

∅18,0/21,5mm

∅25,0/29,5mm 1/2” - 30/210 Nm 3/8” - 5/25 Nm

Code Description

Code Description

CDR.CD38 CDR.CD12

3/8” - 5/6mm 3/8” - 13mm 3/8” - 15mm 3/8” - 17mm

- 19mm

- 21mm

- 22mm

- 24mm

- 27mm

- 30mm

Code Description Sockets for torque wrenche

ZX.1972-5

ZX.2447

ZX.2442

ENGLISH

Copyrights© to this catalogue belong to IDROBASE GROUP® Srl. Reading, reference and dissemination in paper or electronic formats for personal use are permitted. Use for commercial purposes is not permitted, nor is any type of alteration except with the written consent of IDROBASE GROUP® Srl.

This catalogue cancels and supersedes the earlier version.

This catalogue provides general information on the products supplied by IDROBASE GROUP® Srl.

It is intended for retailers, system engineers, designers and more generally, all those who are already adequately familiar with said products, the materials from which they are made, their characteristics, efficiency and operation; it is therefore not intended for consumers who, in order to handle, install or perform any operation with the goods described here, must necessarily contact qualified and skilled personnel.

Also, with regard to skilled personnel, this catalogue should be considered a mere commercial tool, not containing the necessary technical specifications - which may be obtained free of charge from Idrobase, and as such, not suitable for use as a single go-to reference tool for the design, construction or installation of any kind of system.

The illustrations, technical characteristics, functions and other information given here about individual products, systems, installations and the like are based on the current state of the art: however, only the most immediately applicable information can be reproduced here, without any consideration for the global data necessary to design, implement and install any system, which must therefore be carefully assessed by designers, system engineers and installers.

Therefore, for specific indications on all products in the catalogue, please contact our main office, where competent staff are always on hand to answer any additional queries.

All the illustrations reproduced here may be slightly different from actual products and therefore, they should simply be intended as closely representing real items.

We reserve the right to introduce changes in all the products. For this reason, too, it is advisable to directly contact our main office.

In case of doubts regarding interpretation, the original Italian text will prevail.

When a new reprint is published, the present edition will no longer be valid.

Idrobase Group Srl Via dell’Industria, N. 25 35010 Borgoricco (PD) Italia

T: +39 049 9335903 r.a.

www.idrobasegroup.com info@idrobasegroup.com

Recognition of maximum commercial reliability

A day in Idrobase Group