STADIUM FORCE

ISSUE 114 | 2022

Columbus Crew fans enjoy bold, fan-centric stadium 10 A STAR IS REBORN Sixth Street Viaduct is a star for L.A. communities 18 NEARING THE FINISH LINE Indiana’s I-69 promises greater safety and mobility 28 FEATURED IN THIS ISSUE

HNTB is an infrastructure solutions firm providing award-winning planning, design, program management and construction management services. hntb.com

@HNTBCorp

facebook.com/HNTBCorp

linkedin.com/company/hntb instagram.com/hntbcorp

HNTB Offices

Albany, NY Allentown, PA Arlington, VA Atlanta, GA Austin, TX Baltimore, MD Bartow, FL Baton Rouge, LA Bellevue, WA Bettendorf, IA Boston, MA Charleston, WV Charlotte, NC Chelmsford, MA Cherry Hill, NJ Chicago, IL Cleveland, OH Columbus, OH Concord, NH Dallas, TX Denver, CO Des Moines, IA Detroit, MI East Lansing, MI El Paso, TX Fort Worth, TX Fort Lauderdale, FL Grand Rapids, MI Harrisburg, PA Hartford, CT Houston, TX Indianapolis, IN Inland Empire, CA Jackson, MI Jacksonville, FL Kansas City, MO King of Prussia, PA Lake Mary, FL Las Vegas, NV Lawrenceville, NJ

Little Rock, AR Los Angeles, CA Los Angeles Airport, CA Louisville, KY Madison, WI Miami, FL Milwaukee, WI Minneapolis, MN Nashville, TN New Orleans, LA New York, NY Newark, NJ Noblesville, IN Oakland, CA Oklahoma City, OK Overland Park, KS Parsippany, NJ Philadelphia, PA Pittsburgh, PA Plano, TX Portland, ME Portland, OR Raleigh, NC Richmond, VA Round Rock, TX Salt Lake City, UT San Antonio, TX San Diego, CA San Francisco, CA San Jose, CA Santa Ana, CA St. Louis, MO Sterling Heights, MI Tallahassee, FL Tampa, FL Virginia Beach, VA Washington, DC Wesley Chapel, FL West Palm Beach, FL

DESIGNER is an HNTB publication and is published by the Corporate Communications and Brand Optimization Department of the HNTB Companies, P.O. Box 412197, Kansas City, MO 6 4141.

Patricia Mosher, senior vice president pmosher@hntb.com

Keri Geffert English, editor kgeffertenglish@hntb.com

To change your address or to be added or removed from the DESIGNER mailing list, send your request to requests@hntb.com or visit h ntb.com/subscribe.

HNTB is an equal opportunity employer M/F/V/D. © 2022 HNTB Companies. All rights reserved. Reproduction in whole or in part without written permission is prohibited.

FEATURING

04Critical Connection

Jacksonville’s new BRT system fulfills promise to deliver seamless mobility solutions

10Stadium Force

HNTB-designed Lower.com Field emerges as a bold, fan-centric stadium that breathes life into the city’s core

Download the HNTB App DESIGNER and the other HNTB publications and resources are available on the HNTB App. Download the free HNTB App from the App Store ® and Google Play.™

18A Star is Reborn

New Sixth Street Viaduct creates a “Ribbon of Light” between downtown and East Los Angeles communities

28Nearing the Finish Line Indiana’s I-69 promises greater safety, mobility and quality of life

36Road to Opportunity Opportunity Corridor poises a previously “forgotten” area in Cleveland for economic development and community connections

42Curbing the Wait

Curbside innovation connects passengers without checked luggage to gates for smooth arrivals and departures in Tampa

52Enhancing Mobility over the Mississippi HNTB’s CEI expertise ensures delivery of the bistate crossing residents envisioned

ON THE COVER Sixth Street Viaduct Los Angeles, California

ON THE COVER Sixth Street Viaduct Los Angeles, California

18 10

Major League Soccer’s Lower.com Field Columbus, Ohio

42Tampa International Airport Tampa, Florida

02 H NTB DESIGNER | Issue 114 HNTB DESIGNER | ssue 114 03

CRITICAL CONNECTION

F OR MORE THAN 10 YEARS, THE JACKSONVILLE

Transportation Authority envisioned a bus rapid transit system that would create seamless, elevated-level mobility solutions for all of its northeast Florida customers. That vision was realized with the September 2021 opening of the Orange Line, the fourth and final line in the agency’s 58-mile First Coast Flyer network.

The $33 million project is part of a $138 million BRT program that began in 2014. The Federal Transit Administration provided $90 million in grant funding, along with the Florida Department of Transportation, which provided a $24 million state match to JTA’s local investment.

The Orange Line links JTA’s system to Clay County, the southernmost county in the Jacksonville region. Growing even before the pandemic, the area has become a top destination for people choosing to relocate over the past two-and-a-half years.

JTA already operated fixed-ride and executive-style alternatives for Clay County commuters. The agency saw the need for an additional option that covered the middle ground, allowing its expanding Clay County customer base to catch busses into Jacksonville on a 10- or 15-minute frequency.

“The Orange Line is critical not only because it represented the completion of JTA’s entire bus rapid transit system, but specifically because of the linkage to Clay County,” said Greer Gillis, JTA senior vice president systems development and capital program.

made good on our promise to the community to solidify the First Coast Flyer system’s dual-county connection.”

“It

ANGLE-DOUBLE-RIGHT The Jacksonville Transportation Authority’s new Orange Line completes its bus rapid transit system, fulfilling a promise to deliver seamless mobility solutions to northeast Florida

Jacksonville

Clay County

04 H NTB DESIGNER | Issue 114 HNTB DESIGNER | ssue 114 05

Leading with technology

Serving as prime consultant, HNTB designed the Orange Line’s infrastructure, including:

• Bus rapid transit stations with premium amenities. The First Coast Flyer Orange Line’s 21 BRT stations are “bus stops on steroids,” said HNTB project manager John Fowler. Beyond the shelters and benches standard at most bus stops, racks provide secure bicycle storage, and smart trash cans offer recycling capabilities. Stations are compliant with Americans with Disabilities Act requirements, and lighting was designed to meet federal safety standards. Interactive totems connected to JTA’s communications system improve travel reliability by allowing riders to track the real-time arrival of the next bus and to view the travel time to each successive stop on the route.

• Transit signal priority. The system reduces transit rider delays by extending green lights when a bus is near the intersection.

• Queue jump lanes. JTA’s BRT lines operate on existing Florida Department of Transportation and City of Jacksonville roadways, rather than on dedicated lanes. To keep busses from getting tangled in the lanes they share with other vehicles, the Orange Line project’s second and final phase will build out dedicated queue jump lanes at the three most-congested intersections on the corridor.

“JTA is a leader nationally for technology and innovation,” Fowler said. “They’re pushing the envelope to improve transit ridership and overall quality of life in Jacksonville.”

The Orange Line project also included a complete rebuild of the traffic signal at State Road 21 (Blanding Boulevard) and Townsend Road, which required significant utility coordination efforts. The area contained electric and fiber optic lines and water, sewer and gas main lines, some buried up to 13 feet deep. With numerous utility owners over a period of months, HNTB coordinated timing and location of utility moves to identify the final traffic signal pole position.

Going beyond design

During project construction, JTA asked HNTB to provide transit signal priority system installation oversight above and beyond its design scope. The firm’s designers stepped in to download and sift through data, troubleshoot and test equipment to ensure proper operation and to work closely in the field with the contractor.

“HNTB’s post-design services were critical,” Gillis said. “When the contractor met with unknown conditions, HNTB was right there with them to make the changes so JTA’s contractor could move forward. Even outside the design services scope, HNTB was committed to working with us as we came across every challenge, helping us solve it so we could ultimately deliver on the project.”

ANGLE-DOUBLE-RIGHT

Jacksonville W Beaver Street Bellair-Meadowbrook Terrace JACKSONVILLE NAVAL AIR STATION OAK HILL WESCONNETT DUCLAY CEDAR HILLS CEDAR HILLS ESTATES LAKESHORE AVONDALE MURRAY HILL FIVE POINTS NORMANDY PAXON PARKST BLA N D I N G BLVD 90 17 17 10 10 95 95 295 “The Orange Line is critical not only because it represented the completion of JTA’s entire bus rapid transit system, but specifically because of the linkage to Clay County. It made good on our promise to the community to solidify the First Coast Flyer system’s dual-county connection.”

GREER GILLIS

JTA SENIOR VICE PRESIDENT

SYSTEMS

DEVELOPMENT

AND

CAPITAL

PROGRAM

JACKSONVILLE, FLORIDA JTA Orange Line

06 H NTB DESIGNER | Issue 114 HNTB DESIGNER | ssue 114 07

Delivering mobility for all Jacksonville is, by area, the largest city in the lower 48 U.S. states. Its population and work centers are spread across a wide geography, challenging JTA to provide effective transit solutions for people with disparate travel origins and destinations.

The Orange Line moves the JTA another step closer to delivering on its mission to provide accessible transportation options and enhanced mobility for all northeast Florida users by serving up enhanced travel time reliability and new opportunities to underserved communities along the route.

“Many of the communities the Orange Line serves are not traditionally those that would receive transportation improvement funding,” Fowler said. “The Federal Transit Administration and state dollars invested in this project are connecting these communities to places of employment, as well as job and educational opportunities that weren’t available without this reliable transportation link. The Orange Line is making an impact that materially improves people’s lives.” n

CONTACT:

KEN MOREFIELD, PE, Regional Business Development Leader (850) 544-2527 n kmorefield@hntb.com

“JTA is a leader nationally for technology and innovation. They’re pushing the envelope to improve transit ridership and overall quality of life in Jacksonville.”

JOHN FOWLER HNTB PROJECT MANAGER

08 H NTB DESIGNER | Issue 114 HNTB DESIGNER | ssue 114 0 9

WHEN COLUMBUS CREW PRESIDENT AND General Manager Tim Bezbatchenko describes the Major League Soccer team’s new Lower.com Field as “intimidating,” he means it as a compliment. The HNTB-designed venue, emboldened with dark colors that are

world, is purposefully imposing and sophisticated.

among stadiums around

The new, HNTB-designed home of the Columbus Crew emerges as a bold, fancentric stadium that breathes life into the city’s core STADIUM

F RCE

unique

the

10 H NTB DESIGNER | Issue 114 HNTB DESIGNER | ssue 114 1 1

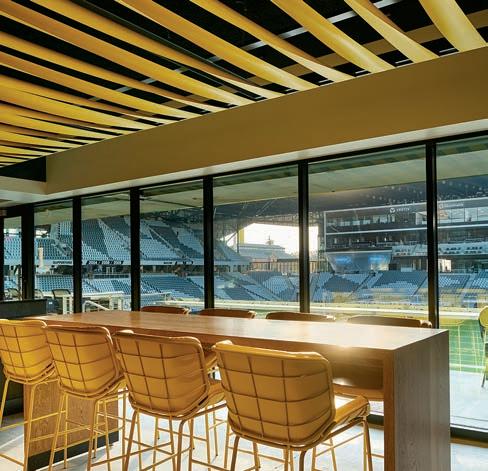

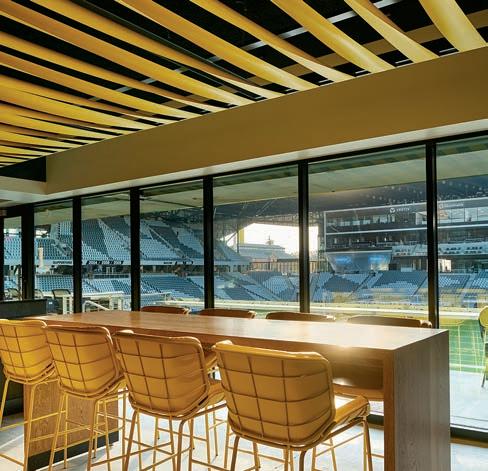

The Columbus, Ohio, facility’s imposing black roof canopy one of the largest in the league caps the aesthetic. Covering every seat in the 20,000-seat stadium, it both provides comfort for fans and delivers the Crew a competitive advantage by reverberating noise back to the field.

“The goal was to create an iconic venue,” said HNTB National Sports Practice Leader Gerardo Prado. “The project team talked about what ‘iconic’ means and decided to create an aesthetic that hasn’t been done before in MLS. There are lots of angles, some perforated, on the exterior façade. The edges look strikingly sharp. The structural system for the canopy is at an angle. Even the canopy lights are arranged in an angular pattern that ties to the Crew’s crest design. These features enforce the brand and showcase movement and speed.”

Tough but sweet

Despite its powerful presence, Lower.com Field invites fans to an intimate experience. The 460,000-square-foot stadium occupies a footprint 150% larger than the team’s previous facility, but places seats 12 feet closer to the pitch at field level and more than 25 feet closer in the upper level. The stadium’s 360-degree main concourse provides unobstructed views of the field to enhance the fan experience and is designed to support 365-day a year activation by supporting non-soccer events.

“Lower.com Field is beautifully practical,” said HNTB Design Director Ryan Gedney. “There are a lot of stadia in the world doing sculptural gymnastics to create physical icons that don’t necessarily function well enough to make the game experience great. The stadium roof, the exterior and the seating all were driven to be honest and practical expressions of the game’s needs, which are to maximize intimacy and energy.”

ANGLE-DOUBLE-RIGHT

STADIUM STATS

Situated on more than 33 acres

20,000 seats, all covered by the stadium’s black roof canopy 460,000 square feet

10 private suites with seats 16 feet from the field and at eye level

360-degree main concourse with two clubs

Second-largest supporters’ section in the MLS 6,200-square-foot plaza where fans enter the stadium 300-capacity sports bar and grill

150% larger than team’s previous facility

“The stadium roof, the exterior and the seating all were driven to be honest and practical expressions of the game’s needs, which are to maximize intimacy and energy.”

RYAN GEDNEY HNTB DESIGN DIRECTOR

COLUMBUS, OHIO Lower.com Field

12 H NTB DESIGNER | Issue 114 HNTB DESIGNER | ssue 114 13

“The stadium is spectacular, and it’s defied all of our expectations. It’s modern… It’s not your traditional stadium that’s being built in so many environments around North America. I think it represents the modern view of the city and its young, aspirational focus. It’s perfect.”

DON GARBER MLS COMMISSIONER

DON GARBER MLS COMMISSIONER

Focus groups and town hall meetings with season ticket holders and Crew Supporters groups allowed HNTB’s design team to hear from the most passionate fans and help inform the design of specialty spaces:

• Lower.com Lounge boasts 10 bunker-style private suites with seats just 16 feet from the field and at eye level to the action on the pitch. Windows in a bar and lounge inside the adjacent club overlook the pitch and an outdoor patio with fireplaces.

• Field Club, the stadium’s largest premiumseating option, lets fans watch players walk from the locker room to the pitch.

• Two main concourse clubs include the refined and classic River Club, with pizza ovens, a large bar and floor-to-ceiling windows that provide both pitch and city views, and the Rail Club, where a festive party vibe celebrates the spirit of the Crew.

• A suite-level club above the concourse, with a bar and lounge and amenities that rival an upscale retail shop, includes a variety of private suites and loge box seats, which provide some of the best views in all of MLS.

Crew Supporters cheer from the Nordecke, a 3,364-seat safe standing seating section and accompanying beer garden situated along the stadium’s north end. It is the second-largest supporters’ section in MLS. With most of the section at a 34-degree angle a nd at 37 degrees at the top players feel like the Nordecke and its boisterous ultra-fans are on top of the field.

ANGLE-DOUBLE-RIGHT

ANGLE-DOUBLE-RIGHT

14 H NTB DESIGNER | Issue 114 HNTB DESIGNER | ssue 114 15

SEEDING A NEIGHBORHOOD

Located in the urban core, Lower.com Field is situated on more than 33 acres adjacent to downtown Columbus and near The Ohio State University. The team’s ownership group recognized that its construction presented an opportunity to build a neighborhood.

“This sports story becomes an economic development story,” said Josh Glessing, vice president of strategy for Haslam Sports Group.

More than seven event spaces, including the Nordecke beer garden, the pub and the extra-wide concourse, are available for non-gameday use. Beyond its purpose as a community connection point, though, Lower.com Field is the anchor for development of Astor Park, a new community being created on 13 acres of the Lower. com Field site. The ambitious effort includes a mix of high-density, multifamily housing, offices, retail, curated art and a new, 2.5-acre riverfront city park. The park, on the east bank of the Olentangy River, will connect Astor Park to the west side of the river via a new pedestrian bridge, giving locals and visitors direct access to the Olentangy Trail and the Central Ohio Greenway network.

“Ancillary development is the norm, representing one of the most fundamental trends in sports,” said Ryan Gedney, HNTB design director. “As sports designers, we have to think about venues at a district level, every time. It changes your mindset in how you think of the stadium being a good neighbor.”

Fan-centric in every detail

Twenty-three years ago, the Columbus Crew was the first MLS club to open a soccer-specific venue. MLS facilities have evolved since then into more complex structures that lean into innovative, sophisticated design that caters to fan experience.

HNTB’s architecture team know that the overall experience is diminished if fans have difficulty getting into the match.

So, the team designed a 360-degree main concourse that allocates 5-square-feet per person, exceeding MLS recommendations. The feeling of spaciousness greets ticketholders on the stadium’s southern community plaza, where up to 70% of fans enter the stadium as they march down Nationwide Boulevard. They enter the stadium through a 6,200-square-foot plaza before reaching the Crew House Pub, a 300-capacity sports bar and grill, and then into the main concourse.

“Having this chance to reimagine the fan experience for one of the original MLS teams was special,” said Gedney. “It was an opportunity for the architecture to draw both from the team’s roots and its future. Once you get beyond the iconic postcard of a stadium image, venues can sometimes start to feel typical. Here, there’s a richness of thinking and detail that will deliver moments of surprise and delight fans.”

Community connector

Besides giving the Columbus Crew a new home, the team’s ownership wanted Lower.com Field to connect to the greater community. The finished stadium is the spark for a new neighborhood, Astor Park, which brings life into an underused area in the urban core. Leveraging Lower.com Field’s plaza and other amenities as key community assets, the Crew’s ownership group and a development partner are creating a dynamic new, pedestrian-friendly neighborhood in downtown Columbus.

“The project turned out much better than we could have possibly imagined,” said Dee Haslam, CEO of Haslam Sports Group, the Crew’s owner. “We worked hard to get the look and feel right. To open a new stadium is a great unifier for the community.” n

CONTACT:

RYAN GEDNEY, HNTB Design Director (816) 527-2652 n rgedney@hntb.com

16 H NTB DESIGNER | Issue 114 HNTB DESIGNER | ssue 114 17

A STAR IS

The new Sixth Street Viaduct creates a “Ribbon of Light” between downtown and East Los Angeles communities REBORN

18 H NTB DESIGNER | Issue 114 HNTB DESIGNER | ssue 114 19

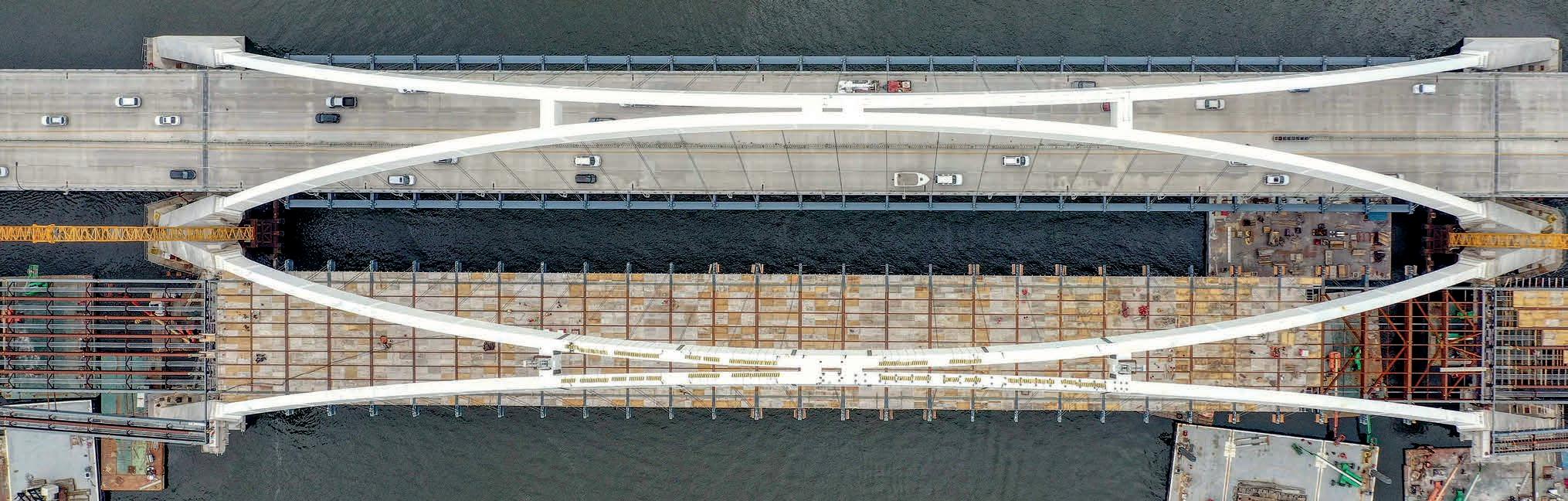

SINCE 1932, THE 3,500-FOOT-LONG Sixth Street Viaduct in Los Angeles had been a beloved landmark and a longtime Hollywood star, appearing in movies, television shows, commercials, music videos and countless personal stories.

Studies showed the bridge needed to be replaced. Unable to be preserved, the longest and most recognizable bridge spanning the Los Angeles River was demolished for safety’s sake in 2016. In its place is a new groundbreaking viaduct infused with innovations that are already leaving a legacy for future infrastructure projects.

Designed for the community

The City of Los Angeles Bureau of Engineering, the Sixth Street Viaduct’s lead delivery agency, recognized the need for extensive public engagement in deciding on a replacement. Working in tandem with neighboring Boyle Heights residents, the Bureau of Engineering launched an international design competition and invited community members to help select the winning design. In 2012, an HNTB-led team with collaboration from Los Angeles architect Michael Maltzan Associates and Danish bridge architect Dissing+Weitling was chosen to design the new structure.

The new Sixth Street Viaduct, opened in July 2022, features 10 lighted pairs of canted, network tied arches that form a “ribbon of light.” It melds structural technology with an aesthetic vision that pays homage to the 1932 bridge, which had two pairs of arches over its L.A. River section.

ANGLE-DOUBLE-RIGHT

ANGLE-DOUBLE-RIGHT

20 H NTB DESIGNER | Issue 114 HNTB DESIGNER | ssue 114 2 1

“Consideration of the community drove the design,” said Michael Jones, HNTB project manager and engineer of record. “We took a holistic approach, turning the whole viaduct into a signature structure, rather than just a crossing over the river, and making it a destination unto its own.”

The reborn bridge is a stellar, one-of-a-kind concrete network tied arch design that has captured the imaginations of Angelenos. Already embraced by the surrounding neighborhood, the new Sixth Street Viaduct rises to the level of icon aesthetically, technically and in the hearts of community members. In a city of stars, it is well on its way to becoming a star in its own right.

Built with pride

A new sense of ownership and awe was created amongst the community during the design and construction. The structure has quickly become a source of pride and a popular gathering place that uplifts the community.

“The city is regaining that pride that says, ‘This one-ofa-kind bridge is ours,’” said Geraldo Iniguez, project executive for Skanska-Stacy and Witbeck, the joint venture leading the construction of the Sixth Street Viaduct. “More than 450 craftsmen from the region participated in constructing this bridge, including one of the highest rates of women employed on any L.A. construction job. The community has embraced the magnitude of this landmark project and has been reenergized by it.”

“Those local workers share in a pride and energy that is palpable in the community,” Jones said. “They know they have helped to build the kind of project that may only happen once in a lifetime.”

The new bridge is even more integral to the area than its predecessor was. It serves vehicles, pedestrians and bicyclists. As a vital community connector, it has brought greater unity and transportation equity to one of the nation’s largest cities by connecting the underserved Boyle Heights community on the east with the downtown Arts District on the west.

Innovation through collaboration

Creating the largest, most complex bridge project in Los Angeles history required an intricate marrying of the architectural vision to the realities of structural engineering. For the first time, the Bureau of Engineering used a Construction Manager/General Contract (CMGC) methodology, enabling HNTB and Skanska-Stacy and Witbeck to work together from the design’s inception. The design team would need to be nimble and collaborative throughout each step to build an icon, allowing the geometry and architectural goals to dictate the project’s structural approach.

“Everyone involved had a project-first mentality that allowed the owners and designers to look at more creative ways to build,” Iniguez said. “We approached very challenging problems with an open mindset that enabled us to work as a team and meet the project’s goals.”

“The collaborative efforts by the City of L.A., Bureau of Engineering, designers, engineers and contractors, with support from Angelenos, has culminated in a ‘bridge to future opportunities’ as we continue to connect our communities together,” said Yung-Nien Wang, HNTB director of structures in California.

Engineering firsts and cultural feats

The Viaduct boasts several seismic innovations that make it virtually undamageable even in a 1,000-year earthquake, establishes a new threshold for seismic safety and expands the utility of urban bridges. The next generation of triple-pendulum friction bearings were specifically developed for this project. If seismic displacements ever exceed displacement demands of a 1,000-year seismic event by a factor of about two, the bearings rapidly stiffen and transform the seismic resistance system into a traditional, non-isolation system. The isolation bearings and non-isolation system together form a “belt and suspender” system that makes bearing failure and/or unseating virtually impossible, signaling a breakthrough in seismic bridge engineering.

ANGLE-DOUBLE-RIGHT

LOS ANGELES, CALIFORNIA Sixth Street Viaduct

22 H NTB DESIGNER | Issue 114 HNTB DESIGNER | ssue 114 2 3

“I expect to see more intricate and unique designs in infrastructure based on what we accomplished with the Sixth Street Viaduct. The project team’s collaborative approach to construction and its technical innovations are already influencing other infrastructure and building projects.”

MICHAEL H. JONES, PE HNTB PROJECT MANAGER AND ENGINEER OF RECORD

24 H NTB DESIGNER | Issue 114 HNTB DESIGNER | ssue 114 25

ADVANCING THE FIELD

The new bridge retains its predecessor’s status as a oneof-a-kind cinematic backdrop. Eighteen Y-shaped bents support the clean aesthetic and flow upward seamlessly into the sculptural arches. At night, programmable LED accent lights illuminate the underside of the arches and Y-bents.

Community members expressed their desire for a multimodal structure, and the design team responded with a viaduct designed to be the heartbeat of daily life. Forty feet wider than its predecessor, the viaduct pulses with vehicle traffic, walkers, joggers and cyclists.

It carries four vehicular lanes, two in each direction, protected bike lanes and pedestrian walkways on each side. It also features five sets of stairs and two bike ramps that connect the viaduct’s bridge deck to the ground below. The east bike ramp is an intriguing fourlevel, 45-foot-tall stadium-like helical ramp, making the viaduct accessible to all.

To serve as a conduit to a planned 12-acre PARC (Park, Arts and River Connectivity Improvements Project) to be constructed below the viaduct, the design incorporated the stairways and bike ramps to give users safe, direct access to future sports fields, a café, restrooms and an amphitheater.

Not content to simply offer a means of transportation, the city has made the bridge an inviting civic event space. Designed with a special loading case for pedestrians, the viaduct can be closed and the bridge deck instantly transformed into a spectacular outdoor venue for citywide parades and celebrations.

Innovation inspiration

Beyond serving as a multimodal destination and Tinseltown star, the Sixth Street Viaduct’s legacy also will be its role in producing new seismic isolation methodology and redefining current engineering thinking.

“We’re beginning to see other projects around the country looking at using technologies introduced on the Sixth Street Bridge,” Iniguez said. “This project has proven you can push out the limits of what’s been done before.”

“I expect to see more intricate and unique designs in infrastructure based on what we accomplished with the Sixth Street Viaduct,” Jones said. “The project team’s collaborative approach to construction and its technical innovations are already influencing other infrastructure and building projects.” n

CONTACT:

MICHAEL H. JONES, PE, HNTB Project Manager and Engineer of Record (714) 460-1649 n mjones@hntb.com

The new multimodal, multipurpose Sixth Street Viaduct surpasses project goals and advances the field of seismic bridge engineering and the engineering profession as a whole with a series of innovations: WORLD FIRSTS First bridge to use triplependulum friction bearing technology, modified to stiffen at a predetermined displacement and developed specifically for the project At 3,500 feet, believed to be the longest, seismically isolated concrete tied arch bridge ever constructed U.S. FIRSTS First application of seismic isolators within the vertical height of the Y-shaped bents First bridge designed with multistrand post-tension couplers, supplied by DSI, part of the CMGC team LOS ANGELES / CALIFORNIA FIRSTS Largest, most complex bridge project in Los Angeles history Caltrans’ first use of grade 80-ksi concrete reinforcement Bureau of Engineering’s first use of a Construction Manager/ General Contract 26 H NTB DESIGNER | Issue 114 HNTB DESIGNER | ssue 114 27

NEARING THE FINISH LINE

HNTB IS ASSISTING THE INDIANA Department of Transportation in realizing a 75-year goal to upgrade State Road 37 to interstate highway standards. The 142-mile corridor’s final 26-mile segment, branded the I-69 Finish Line, connects Martinsville, Indiana, and Indianapolis.

At Martinsville, the highway will be two lanes in each direction until it reaches Indianapolis, where it will range from three to four lanes in each direction.

“Completing the final section of I-69 is Gov. Eric Holcomb’s No. 1 transportation priority,” said Sarah Rubin, INDOT I-69 Finish Line corridor project manager.

Mobility, the traditional way These days, when states think of increasing mobility, they tend to explore transit and high-speed transportation options.

“America isn’t designing and building a lot of new interstates,” said Tim Miller, HNTB’s corridor manager for the project. “The economic impacts and improved mobility will be significant for the region.”

Nation’s newest interstate highway promises greater safety, mobility and quality of life

ANGLE-DOUBLE-RIGHT 28 H NTB DESIGNER | Issue 114 HNTB DESIGNER | ssue 114 29

ESTIMATED

$4.1B

ECONOMIC BENEFITS

26 miles OF NEW INTERSTATE 142 miles CORRIDOR LENGTH

The I-69 project has stretched through five Indiana gubernatorial administrations. But because of the transformative benefits the new interstate promises, Indiana has kept its vision alive, a remarkable achievement in itself.

“I-69 is a generational project that will create economic opportunities, increase safety and reinforce Indiana’s place as the crossroads of America,” Rubin said.

The final 26-miles of new I-69 is estimated to bring approximately $4.1 billion in economic benefits and jobs to the Hoosier State over the next 20 years.

When opened to traffic in 2024, the newest segment will:

• Heighten safety. The project will eliminate at-grade intersections and traffic signals, construct overpasses and underpasses, build local access road connections and consolidate interstate access points. INDOT estimates the cumulative effect of the safety measures will reduce regional crashes by 1,300 per year.

• Increase mobility. The new segment of interstate highway will connect area residents and commerce with industry along the Ohio River, a U.S. naval base, state universities and NCAA events in Indianapolis.

• Enhance quality of life. The interstate will shorten travel time by 11 minutes in the final 26-mile segment between Martinsville and Indianapolis, allowing motorists to invest the time savings in other activities.

A consistent presence

In 2020, HNTB marked its 80th anniversary providing transportation services to Indiana. Part of the firm’s legacy is the I-69 project. In 2003, INDOT awarded HNTB the preliminary design and environmental impact statement for the northern-most 26 miles with Miller as the project manager.

In 2014, HNTB was the project manager for the EIS. And Miller has been involved with the I-69 project from the beginning, including some of the initial planning studies when he was with INDOT in the 1990s. His institutional knowledge of the project and public involvement history has provided a steady hand in assuring the project advances. “During the past eight years, INDOT and I have communicated on a daily basis to assure the project maintains its schedule and we provide the hundreds of stakeholders along the corridor excellent customer service,” said Miller.

“HNTB returned with a historical context of the project who had been in favor of the project and who had been opposed to it,” Rubin said. “Their continuity is part of the reason the public involvement program was a success.”

“Aside from the pause, we have kept the project on schedule for 20 years,” Miller said, “and we intend to see it through.”

The I-69 Finish Line covers a three-county area. Getting all the communities on the same page and ensuring impacts and mitigation were equitable was important for this project’s success. HNTB collaborated with INDOT to create and implement a transparent and aggressive public involvement program that would later be praised by the industry.

ANGLE-DOUBLE-RIGHT

When the entire I-69 interstate highway project is complete, it will run continuously from the Canadian border at Port Sarnia, Michigan, to Texas’ southern tip.

30 H NTB DESIGNER | Issue 114 HNTB DESIGNER | ssue 114 31

“I-69 is a generational project that will create economic opportunities, increase safety and reinforce Indiana’s place as the crossroads of America.”

Kitchen table meetings

Moving into the NEPA process, INDOT and the HNTB team scheduled a series of project updates with community groups and listed the goals to be achieved by the time those meetings were held.

“It was important that we hit those dates. It would help us gain the public’s trust,” Rubin said. “On-time delivery became a conditioned expectation of the public and represented our team’s commitment to delivering this final segment.”

To mitigate the impact of right-of-way acquisition, INDOT and the HNTB team implemented an uncommon and extremely time-intensive grassroots campaign.

“HNTB’s public involvement team offered to meet faceto-face with any stakeholder impacted by the project to explain the plan set and how it would affect them specifically,” Miller said. “We called them ‘kitchen table’ meetings, and they gave stakeholders a greater comfort level.”

There were more than 700 properties to acquire along the 26-mile alignment. To build trust among these critical stakeholders, the HNTB team held more than 400 meetings with property owners, businesses and residents and conducted 15 public information meetings.

“In 2015, we made a public commitment to have the EIS completed and the Record of Decision issued by first quarter 2018, and we were able to do that after hundreds of meetings and thousands of public comments,” Miller said. “At the end, we had a project that was supported by the vast majority of the communities up and down the corridor.”

“HNTB was instrumental in helping us achieve a foundation of trust with the affected communities as we entered the design phase,” Sarah Rubin, INDOT corridor project manager, said.

Other environmental activities included:

• Delineating 200 acres of wetlands and 50,000 linear feet of stream

• Modeling 90,000 linear feet of noise barrier

• Evaluating 560 potential relocations and Section 4(f) resource impacts

• Investigating hazardous materials and petroleumcontaminated wastes at 48 sites

The U.S. Environmental Protection Agency recognized the team’s effort by issuing a Lack of Objections (LO) rating (highest rating) on the DEIS and the Federal Highway Administration issued its approval and a Record of Decision in February 2018.

26 miles of challenges and opportunities The I-69 project is one of the most complex preliminary engineering and environmental studies INDOT has completed. It involved:

• 26 miles of interstate highway

• 36 lane-miles of local access roads

• 39 new bridges

• 35 replaced or rehabbed bridge structures

• 10 new interchanges and access points, including a massive system interchange at I-465/I-69

“The complexity of the new I-465/I-69 interchange design cannot be understated,” Miller said. “It is a multilevel, fully directional interchange that will upgrade the existing, outdated interchange.”

Another challenge? Converting the four-lane, mediandivided state highway with partial access control to an interstate facility with full access control. Using its traffic modeling expertise, HNTB consolidated 92 existing access points to 10 access points and removed 14 traffic signals.

“Nearly the entire alignment needed new drainage infrastructure,” Miller said. “We moved high-tension power lines, relocated a gas line running along much of SR 37, conserved land for a native endangered bat species and other natural environmental features. There wasn’t a discipline we couldn’t address. We have some of the best people in the industry here at HNTB.”

In 2019, INDOT and HNTB accepted the Engineering Excellence Grand Award from the Indiana Chapter of the American Council of Engineering Companies for the I-69 Finish Line’s preliminary design and public involvement process.

In December 2021, Gov. Holcomb, the team and the community celebrated the opening of a new 7-mile section that includes three interchanges, 1.4 miles of noise barrier, the award-winning Grand Valley Boulevard Bridge and two gateway monuments. ANGLE-DOUBLE-RIGHT

SARAH RUBIN

INDIANA DEPARTMENT OF TRANSPORTATION’S I-69 FINISH LINE CORRIDOR PROJECT MANAGER

SARAH RUBIN

INDIANA DEPARTMENT OF TRANSPORTATION’S I-69 FINISH LINE CORRIDOR PROJECT MANAGER

HNTB I-69 Finish Line disciplines • Roads • Bridges • Hydraulic • Traffic and modeling • Planning • Environment • Construction inspection staff 32 H NTB DESIGNER | Issue 114 HNTB DESIGNER | ssue 114 3 3

PREPARING FOR A 5-MILE CLOSURE

To speed construction of a 30-foot-high embankment in Martinsville, Indiana, and ensure the safety of workers and motorists, HNTB helped INDOT prepare for and close 5 miles of SR 37.

“Active traffic presented a safety hazard through the construction zone,” said Jennifer Goins, HNTB’s project manager for construction contracts one and two. “Closing the facility would be safer for everyone involved, and it would consolidate construction of the embankment to two seasons instead of three.”

SR 37 follows the White River. On the other side of the river is State Road 67. When INDOT began contemplating the 5-mile closure of SR 37, SR 67 was the obvious detour. INDOT was confident the four-lane divided SR 67 could handle the additional 35,000 vehicles a day diverted because of the closure.

State Road 39 in Martinsville is an important corridor for the community; the route motorists would use to access SR 67. SR

39 runs through Martinsvillea’s commercial area. The highway was a two-lane facility with an intermittent center turn lane and multiple access points.

To prepare SR 39 for heavier volumes, HNTB designed several improvements to expedite the flow of traffic, including:

• New traffic signals

• Traffic signal timing

• Temporary restriping

• Widening the facility to four lanes in the commercial area

HNTB’s design also improved select Martinsville city streets that will carry an increased load during the closure.

INDOT completed the improvements in time for the year-long shutdown, which took effect Jan. 2, 2021 and operated smoothly.

Section six, now known as I-69 Finish Line, is the final 26-miles and was broken into five construction contracts, totaling more than $1.5 billion.

Innovative contracting method

The 142-mile I-69 corridor project was broken into six sections for environmental, design and construction and started at the southern limits in Evansville and worked its way north. The first three sections consisted of 67 miles and opened to traffic in late 2012. Section 4 opened 27 miles in late 2015, Section 5 opened 21 miles in 2018 and all 26 miles of the northernmost section will open by the end of 2024.

Section six now known as I-69 Finish Line, is the final 26-miles and was broken into five construction contracts, totaling more than $1.5 billion, with HNTB serving in several capacities:

• Communication manager for all five construction contracts

• Lead designer for contracts 1 and 2 that totaled more than $185 million

• Manager of corridor-wide utilities and hydraulics; Subconsultant, providing expertise in communications, utilities and hydraulics for contracts three and four

• Design oversight of 8 miles of added travel lanes on I-465

• Technical procurement advisor and construction inspection lead for the $728 million contract 5 segment, the segment that contains three interchanges in an urbanized area, including a new interchange at I-465 and I-69

“Design-build best value encouraged the contracting community to propose innovative design elements, configurations and safety features that would save money,” Miller said.

HNTB assembled the procurement document and is working with the contractor to ensure all specifications are met.

Amid the pandemic, INDOT set a goal to award contracts four and five by the end of 2020 and met it. Each of the contracts awarded came in at or below the engineer’s estimate. As of April 2021, all Finish Line contracts are under construction and in some cases complete. Contract 1 finished in 2020 Contracts 2 and 3 will be complete in 2022, and contracts four and five in 2024.

“There is a personal commitment on our part and INDOT’s part to make sure the project does not fail, and the schedule does not fail,” Miller said.

“What helps a team thrive are people who have an appreciation for what each team member brings to the table and an appreciation for how the players come together to deliver a successful project,” Rubin said. “A key trait of HNTB is that they are always a team player.” n

CONTACT: TIM MILLER, HNTB Corridor Manager (317) 917-5357 n tnmiller@hntb.com

MARTINSVILLE, INDIANA I-69 Finish Line

34 H NTB DESIGNER | Issue 114 HNTB DESIGNER | ssue 114 35

R AD T0

OPPORTUNITY

The new Opportunity Corridor in Cleveland, Ohio, poises a previously “forgotten” area for economic development and community connections

THE HIGHLY ANTICIPATED, 3.5-MILE Opportunity Corridor in Cleveland, Ohio, fulfills a 20-year goal: to link the I-490/I-77 interchange with University Circle, the square-mile home to Cleveland Clinic, Case Western Reserve University, restaurants, parks and world-renowned museums.

University Circle, Cleveland’s fastest-growing locale, draws millions each year. Until the Opportunity Corridor opened, getting there required visitors to endure constant traffic woes resulting from a lack of direct access.

Beyond improving the area’s transportation system, the Opportunity Corridor is designed to spark economic development in the nearly 1,000 acres between I-490 and University Circle. That area, dubbed the “Forgotten Triangle,” was a neglected, economically depressed zone pockmarked with brownfields.

A new solution to an old problem The Ohio Department of Transportation started looking at creating an “opportunity corridor” in 2000. The idea arose during the I-90 Innerbelt Modernization Study, which focused on improving interstate travel through downtown Cleveland.

During that process, public comments surfaced about the desire for a more direct gateway from the freeways to University Circle. By 2004, ODOT had advanced the Opportunity Corridor as a boulevard project that would both connect the freeway to University Circle and reverse the Forgotten Triangle’s 40-year decline.

ODOT chose HNTB to perform preliminary engineering and National Environmental Policy Act documentation for the corridor.

Traffic signal and securty

Bridge over proposed bouvelard Bridge on proposed boulevard

“Forgotten

OC3 at Buckeye and Woodland Avenue Intersections

Photo courtesy of Ohio Department of Transportation

LEGEND Section 1: E. 105th corridor Section 2: Norman Ave. to E. 93rd St. Section 3: E. 93rd St. to I-490

camera

Triangle”

WOODLAND AVENUE

E. 55TH STREET

QUINCY AVENUE

KINSMANROAD

OC3 at E. 55th Street / Q uadrant Roadway

Photo courtesy of Ohio Department of Transportation

HNTB DESIGNER | ssue 114 3736 H NTB DESIGNER | Issue 114

Eye on environmental justice

Because the area residents are almost exclusively minority and low-income, environmental justice impacts were a key concern.

“HNTB explored numerous preliminary alternatives with the community, learning what was important to them and how they prefer to travel, whether walking, biking, driving or taking the train,” said Matt Wahl, HNTB senior project manager. “We continued to refine the alternatives through extensive public involvement, ensuring the community’s transportation needs were balanced with the goal of improved access from the freeway to University Circle.”

The environmental process also adjusted the Opportunity Corridor’s preferred alignment to mitigate impacts to the neighborhood and to the city’s plans to expand the Woodland Recreation Center, which is adjacent to the roadway.

“We always knew the primary impacts would be to people,” Wahl said. “Our goal was to minimize impacts to the neighborhoods that the roadway would traverse.

The final environmental impact statement ODOT’s first reader-friendly EIS confirmed to the community that residents had been heard and that the recommended project was consistent with their needs and input.”

After ODOT received environmental approval in 2014, the Opportunity Corridor project was split into three construction projects, allowing expedited completion.

The first section utilized traditional design-bid-build, with HNTB as the designer.

The second and third segments employed value-based design-build delivery. That method incentivized diversity and inclusion, which was designated as the primary scoring value in design-build teams’ proposals.

HNTB served as owner’s representative, facilitating development of the design-build procurement documents and providing post-award design-build services, including scope conformance, agency coordination and reviews of numerous submittals.

Mitigating environmental justice impacts

As the home to a high population of minority and low-income residents, the Opportunity Corridor area was rife with potential adverse or disproportionate environmental justice impacts. To mitigate those impacts and support the community engagement efforts, the ODOT/HNTB team:

• Developed an environmental impact statement that communicated technical information clearly and in a visually appealing format. Both the draft and final EIS made it easy for stakeholders to understand project details and the decision-making process.

EARNING PUBLIC TRUST

Gaining public trust meant the community needed to understand how the new urban boulevard would not only support economic development, but also improve access for cars, bicycles and pedestrians between the neighborhoods.

From the start, ODOT engaged residents and local business owners through a steering committee that also included federal, state, regional, county, city and neighborhood representatives. Local stakeholders provided input and advice and helped keep the outreach process public and visible.

The ODOT/HNTB project team held numerous individual and group meetings with residents and businesses to better understand each neighborhood’s strengths, challenges and

opportunities. The project team drew on early input to further develop the project’s alternative routes.

When the design was communicated to the broader community, the project team presented people-focused visuals, including renderings, graphics and a 3D video, to make the project easy to understand. Public meetings at critical decision points sought the community’s comments and questions. This extraordinary level of engagement, which continued throughout construction, ultimately won community support for the project.

• Shared the EIS widely online and in public places, such as local community development corporations, public library branches and recreation centers. Residents’ comments confirmed they understood the information presented in the document.

• Learned through the public engagement process that area residents needed jobs and job training to gain the qualifications necessary to obtain work. In response to this feedback and as an environmental mitigation measure, the project committed $500,000 to Ohio Means Jobs, a collaborative workforce system that helps local employers meet their talent needs while also helping job seekers find success. The funding made on-the-job training opportunities available to residents in the impacted neighborhoods. Two community ambassadors were also brought in to identify and assist those interested in job training. This training has resulted in hundreds of job placements for area residents in construction, health care and social services, manufacturing, administrative, sales, customer service, general labor and more.

Approximately 40,000 additional project-specific on-the-job training hours were set aside for the design and construction of the Opportunity Corridor project. These goals were exceeded for all three sections.

As part of the environmental mitigation efforts, the Ohio Department of Transportation also:

• Implemented a favorable voluntary residential relocation program for people indirectly impacted by the project.

• Committed $500,000 toward expansion of the Woodland Recreation Center adjacent to the corridor.

• Committed funding for construction of enhanced bus shelters where existing bus lines cross the new boulevard.

• Built two pedestrian/bike bridges.

ANGLE-DOUBLE-RIGHT

Looking southwest across Opportunity Corridor over GCRTA and north/south at Quincy Avenue Intersection Photo courtesy of Ohio Department of Transportation

Photo courtesy of City of Cleveland

HNTB DESIGNER | ssue 114 3938 H NTB DESIGNER | Issue 114

“We always knew the primary impacts would be to people. Our goal was to minimize impacts to the neighborhoods that the roadway would traverse. The final environmental impact statement ODOT’s first reader-friendly EIS confirmed to the community that residents had been heard and that the recommended project was consistent with their needs and input.”

MATT WAHL HNTB SENIOR PROJECT MANAGER

MATT WAHL HNTB SENIOR PROJECT MANAGER

Turbocharging diversity

Cleveland’s mayor wanted the Opportunity Corridor’s workforce to reflect the communities where the project was being built. In sections 2 and 3, an innovative design-build funding strategy which used proceeds from Ohio Turnpike and Infrastructure Commission revenue bonds, funding from county and city sources and no federal dollars allowed ODOT to establish unique diversity and inclusion requirements.

These requirements, which ODOT developed and HNTB drafted into the project scope documents, created four subcontractor participation categories on the project: new contractor, small contractor, local contractor and designated state EDGE (Encouraging Diversity, Growth & Equity) program contractor. In the bid packages, ODOT also required design-build teams to name a diversity, inclusion and outreach consultant who understood the affected neighborhoods.

For new, small, local and EDGE companies, ODOT set an overall project goal of 20% of contracting dollars. As the project progressed, the trajectory of diverse subcontractors increased. The Section 1 prime contractor utilized 10 diverse subcontractors; the Section 2 prime contractor used 36 subcontractors; and the Section 3 prime contractor used 86 subcontractors.

Promise fulfilled

The Opportunity Corridor’s final segment opened in November 2021. For residents, it has improved community mobility with enhanced access to the area’s train stations, added sidewalks, an extended multi-use path, new pedestrian pathways over and under railroad tracks and neighborhood aesthetic treatments. Having also fulfilled its promise to link the freeway system to University Circle, Cleveland’s newest boulevard is now poised to attract economic development and restore life to a blighted area.

“Having worked on this project from its inception, Matt Wahl has provided invaluable consistency and perspective throughout the entire project development process,” said David Short, Opportunity Corridor design project manager at ODOT. “The HNTB team has worked seamlessly with a wide range of ODOT personnel, consultants and contractors to deliver this project, which will benefit the community on many levels. I am confident this transformational project would not have been as successful without their involvement.” n

MATT WAHL, HNTB Program Manager (216) 377-5842 n mwahl@hntb.com

CONTACT:

OC3 at E 75th Street

OC1 at Cleveland Clinic

40 H NTB DESIGNER | Issue 114 HNTB DESIGNER | ssue 114 41

CURBING

THE WAIT

Tampa International’s curbside innovation connects passengers without checked luggage to their gates for smooth arrivals and departures

TAMPA INTERNATIONAL AIRPORT (TPA) HAS a track record for being an airport innovator. It opened the world’s first airport people mover in 1971. And now 50 years later, TPA introduced another big innovation: the first express curbsides in the U.S. designed exclusively for passengers who don’t check bags.

The capital project improves customer service, expands airport curbside capacity, increases safety and prepares the airport for future transportation technologies.

“Passenger needs and expectations are changing,” said Joe Lopano, TPA CEO. “This revolutionary project further cements TPA’s place as an industry leader, promoting smart growth that will translate into a positive economic impact for our region.”

ANGLE-DOUBLE-RIGHT

42 H NTB DESIGNER | Issue 114 HNTB DESIGNER | ssue 114 4 3

For the first time, J.D. Power names

TPA #1 large airport in 2022 North

American Airport Satisfaction Study. It shows the airport’s commitment to enhanced passenger experiences and innovations, like the express curbsides, is appreciated by travelers.

HNTB served as architect and engineer-of-record on the progressive design-build team for the Blue and Red Side curbsides, which allow people traveling without checked bags to bypass ticketing and baggage claim areas on their way to and from gates.

“The express curbs solved a lot of problems all at once, and with the way transportation technology is changing, they really position the airport well for far into the future,” said Tom Rossbach, HNTB project director.

A long collaboration

The idea for the express curbsides goes back to 2011, when TPA hired HNTB to develop a Master Plan Update. Data made it clear Tampa International needed more curbside length and lanes to handle current and future peak hour demand.

The airport already had four lanes in areas designated as Red Side (north) and Blue Side (south), on two levels one for drop-offs and the other for pick-ups.

With the airport a nd the Tampa Bay region on a growth trajectory, those lanes were reaching a breaking point. Plans called for adding four additional lanes on each side at each level a total of 16 adjacent to the existing lanes.

“We knew more lanes were needed, but the question was how do we do that without people crossing over the inner lanes,” Rossbach said.

That posed a potential safety issue, and a customer service problem as travelers would have to cross up to eight lanes of traffic to get to ticketing and from baggage claim.

“This also would cause roadway back-ups,” Rossbach said. “When people aren’t crossing the roads, the roads are more efficient.”

ANGLE-DOUBLE-RIGHT

“One of our top goals as an airport is providing our guests with a world-class experience. These express curbs provide that type of experience and make a really strong first impression on travelers.”

JOHN TILIACOS

TAMPA INTERNATIONAL AIRPORT EXECUTIVE VICE PRESIDENT OF OPERATIONS AND CUSTOMER SERVICE

44 H NTB DESIGNER | Issue 114 HNTB DESIGNER | ssue 114 45

46 H NTB DESIGNER | Issue 114 HNTB DESIGNER | ssue 114 47

Project Features

First “Express Curbside” in the U.S.

16 new express pick-up and drop-off lanes

Allows passengers without bags to completely bypass ticketing

New high efficiency Central Utility Plant

New International Terminal APM Station

FOR THE FUTURE

These first-of-their-kind curbs prepare the airport for far into the transportation future, ultimately adding 16 technology-enabled lanes along the curbsides ready for use by automated and connected vehicles, which will put curbsides at a premium in the decades ahead.

Uber and Lyft had already started moving the traffic away from parking facilities and toward the curb. And the autonomous vehicles in the future, whether they are rideshare, rented or privately owned, may never park.

“They’re going to be dropping those passengers off at the curb and leaving,” Rossbach said.

“That reduces parking demand and increases curbside demand.”

That same research on the future of autonomous vehicles prompted HNTB to suggest converting the bottom floor of a parking garage into new office space for the Tampa International Airport police and maintenance team.

“There was no room for a building for those offices anywhere on the airport campus,” said Andres Chacon, HNTB project manager. “We saw an opportunity with the parking garage and presented a solution that solved a number of problems, including repurposing some real estate that was losing its value.”

TAMPA, FLORIDA

TPA Blue Express Curbside

TAMPA, FLORIDA

TPA Blue Express Curbside

48 H NTB DESIGNER | Issue 114 HNTB DESIGNER | ssue 114 49

AIRPORT PASSENGERS DON’T CHECK BAGS

The Master Plan research showed that 48% of passengers at the airport don’t check bags. So the new outer lanes were designed exclusively for those passengers, providing connections via escalator, elevator or stairs in a vertical circulation building to the transfer level of the airport.

“It allows people to get out of cars and go right to the gates or to go right from the gate to the curb,” Rossbach said. “It’s a less time-consuming process once you get to the airport. They completely bypass the crowds at ticket lobbies and baggage claim.”

TPA’s Blue Express curbs opened in November 2021, two months ahead of schedule and in time for the Thanksgiving rush. Eight additional express lanes on the Red Side of the airport are expected to open in early 2025, doubling the airport’s curbside capacity.

“Tampa International prides itself on being an airport innovator,” said Jeff Siddle, TPA’s vice president of planning and development. “We’ve done it in the past with the people mover, and we did it with the express curbs. Looking forward, we will continue to seek new, innovative ways to improve airport efficiency and the overall passenger experience.”

“One of our top goals as an airport is providing guests with a world-class experience,” said John Tiliacos, TPA’s executive vice president of operations and customer service. “These express curbs provide that type of experience and make a really strong first impression on travelers.”

To accommodate growth from 17 million to 34 million passengers annually, the Master Plan Update included an expansion of TPA’s existing terminal. The approach preserved precious land on the relatively small airport campus for future growth.

Exceeding expectations

In addition to the express curbsides, a new central utility plant was part of the second phase of the three-phase Master Plan. The airport needed a new one, and the selected location was tucked along the curve of the Red Side departure drives.

The 10,000-square-foot building features greater efficiency and a striking architectural design.

The curved building follows the curve of the roadway, with huge windows that allow guests exiting the airport to see the maze of brightly colored pipes and mechanical equipment inside. At night, multicolored LED lighting enhances the effect. The reclaimed water used in the plant’s chillers do double duty as an architectural water feature.

But it’s not just a work of art inside and out. The plant also reduces water and energy consumption and provides insights into how energy and water are being used to allow for continuous upgrades in efficiency.

A model for other airports

The concepts unveiled with the Blue Express Curbsides and the Central Utility Plant are attracting the attention of other airports.

“The word is getting out there and the teams at other airports are looking at Tampa International to see what we did there,” Rossbach said. “There are nuances and different conditions at every airport. But the express curb idea can be rolled out at many airports.”

The same is true of the approach to the Central Utility Plant, said Andres Chacon, HNTB project manager. “We showed with this project that a largely mechanical building doesn’t need to be hidden away. It can be beautiful, and something special.” n

CONTACT:

TOM ROSSBACH, HNTB Project Director (813) 402-4154 n trossbach@hntb.com

ANDRES CHACON, HNTB Project Manager (813) 402-4163 n ajchacon@hntb.com

UNLIKELY SHOWPIECE

As architect and engineer-of-record for the Tampa International Airport’s Central Utility Plant, HNTB took an innovative approach to infrastructure that’s typically hidden away: Make it a showpiece.

“The airport just assumed it would be a utilitarian building and now they call it the gem of the central campus,” said Mathew Hallett, HNTB architectural project designer.

The 10,000-square-foot, state-of-the-art plant is home to an upgraded heating and air conditioning system for the airport’s Main Terminal, including a SkyConnect train station.

Tucked into a bend in the airport’s Red (north) Side the curved building mirrors the curve of the roadway.

Windows allow guests exiting the airport’s Red Side drive to see the maze of brightly colored pipes and mechanical equipment inside. At night, multicolored LED lighting enhances the surprising visuals. The reclaimed water used in the cooling towers

does double duty as an architectural water feature.

But it’s not just a work of art inside and out. It’s also designed to:

• Reduce chiller energy consumption by 30 percent

• Save 8 million gallons of potable water each year by using reclaiming water for the cooling towers

• Increase capacity from 3,600 tons to 4,800 tons

• Provide additional redundancy to meet peak demand

“We showed with this project that a largely mechanical building doesn’t need to be hidden away,” said Andres Chacon, HNTB project manager. “It can help you reach your sustainability goals, and better serve your facilities and customers and tenants, but also be beautiful, something special.”

The Central Utility Plant at Tampa International Airport is part of Phase 2 of a three-phase Master Plan developed by HNTB for the airport. Phase 2 also includes demolition of existing buildings, the first-oftheir-kind Express Curbs, an APM station, a pedestrian bridge, airport loading and receiving docks, elevated roadways, and reclaiming a parking garage as office space.

48%

50 H NTB DESIGNER | Issue 114 HNTB DESIGNER | ssue 114 51

ENHANCING MOBILITY Over The Mississippi

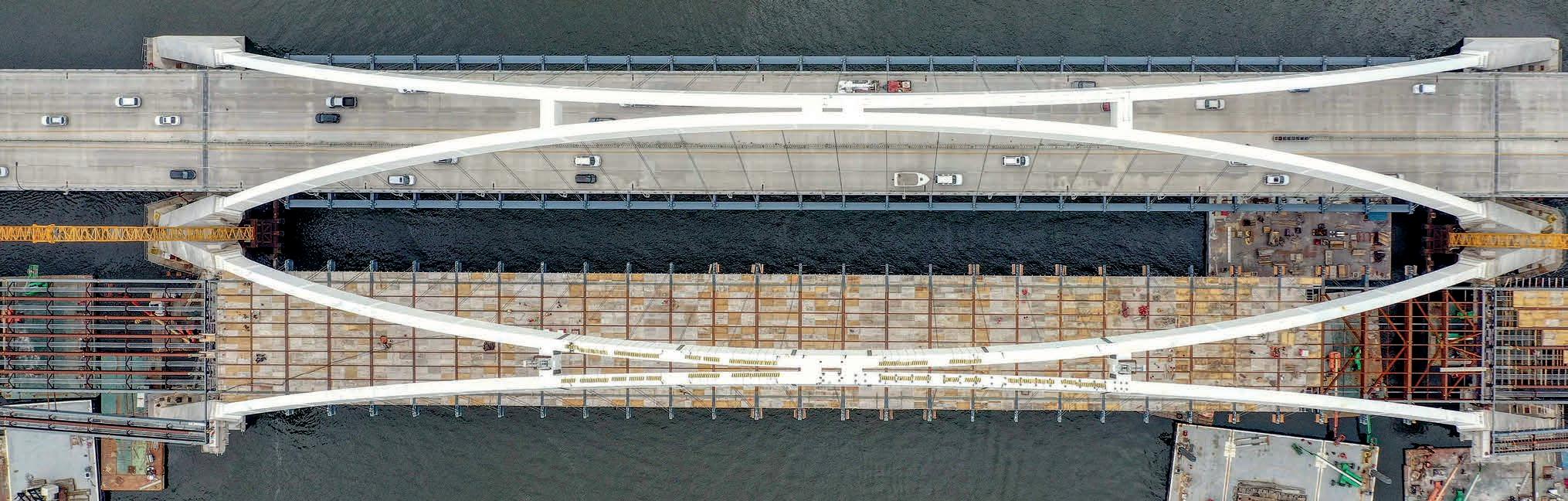

WHEN THE I-74 MISSISSIPPI RIVER

Bridge could no longer adequately serve growing traffic volumes, an improved crossing between Bettendorf, Iowa, and Moline, Illinois, became a regional priority. In planning sessions to replace the twin bridge structures, Quad Cities residents made their preferences clear. They wanted a signature gateway for the region and a true-arch design. Their vision evolved into twin inclined basket-handle true arch bridges providing the essential mobility the communities needed and the structural beauty they wanted.

The new structures were a key component of an ambitious design-bid-build program to improve 5 miles of the I-74 corridor, a major east-west link in the nation’s transportation system. To ensure delivery of the river bridges, lead agency Iowa DOT tapped HNTB’s construction engineering and inspection expertise.

Serving as an extension of Iowa DOT, HNTB provided CEI services for the eastbound and westbound river bridges, Iowa-side viaduct and roadway approaches, as well as local road connections. Services included engineering, inspection, document control, quality assurance and, as the complex project unfolded, much more.

“HNTB provided a full range of expertise and support as needs arose,” said Jim Schnoebelen, Iowa DOT District 6 engineer.

A team approach

HNTB facilitated coordination and collaboration between the DOT, the design team, the contractor and the contractor’s engineer to identify workable solutions to issues with foundations, rebar, thermal control, mass concrete, steel fabrication, geometry and vortexinduced movement due to wind. ANGLE-DOUBLE-RIGHT

HNTB’S CEI EXPERTISE ENSURES DELIVERY OF THE BISTATE CROSSING RESIDENTS ENVISIONED

HNTB DESIGNER | ssue 114 5 352 H NTB DESIGNER | Issue 114

“Strong communication and partnership amongst the project team and Iowa DOT was essential for the successful delivery of the project,” said Bernie Hopfinger, HNTB project manager. “Being in lockstep with each other allowed us to address situations quickly and efficiently to minimize the effect on delivery of the project.”

The team overcame challenges during arch erection, including high water that prevented barge movement in the river, high winds and extremely cold winters. Further, the channel remained open to commercial and recreational boats during construction with brief planned closures.

“The combination of the structure, its location over the Mississippi River and the true-arch design made the project unique,” said Travis Konda, HNTB construction engineering and inspection task lead.

“There weren’t textbook answers for the challenges this project presented. An understanding of the engineering behind the design was necessary to complete the construction.”

And, HNTB did. The firm brought more than 100 years of site experience and bridge engineering best practices to the project.

“We tapped into HNTB’s expertise in drilled shafts, geotechnical engineering, electrical engineering and post-tensioning,” Schnoebelen said.

Expertise in action

HNTB’s extensive history of successful bridge design facilitated understanding the engineering and work to achieve fit-up and closure of the arch ribs standing 245 feet above the river.

“Given the complexity of the arch erection and subsequent tolerances to establish closure, there was a need to develop a technical understanding across the team,” Konda said. “So, we worked with the contractor, designer and Iowa DOT to develop a quality assurance survey plan to ensure the two connected arch segments joined at the apex.”

Tracking the as-built geometry as the arch erection advanced was a joint effort among the contractor, the erection engineer, the designer, Iowa DOT and the field staff.

“Consistent coordination between all parties was key in understanding the current as-built geometry during erection and making adjustments as the work progressed,” Konda said.

Work on the steel portion of the westbound arch began in March 2019 and finished 14 months later in May 2020. Work on the eastbound arch began in July 2020 and was completed 10 months later in May 2021.

As work progressed on the bridges, HNTB’s document controls team worked behind the scenes, ensuring change orders were handled promptly, federal audits went smoothly, the contractor was compensated properly and closeouts were timely and efficient.

When the westbound bridge opened to traffic in November 2020, motorists saw for the first time what they had envisioned for nearly 20 years: a stunning crossing with four lanes, wide shoulders and dramatically reduced congestion. The eastbound bridge opened Dec. 1, 2021. The project included several aesthetic elements such as:

• A 14-foot-wide multiuse path connecting trail systems in Bettendorf and Moline

• Glass oculus embedded in the scenic overlook’s multiuse path

• Dramatic LED lighting

• ADA accommodations

The combined bridges delivered on the overall theme of ‘Reflections,’ making the region’s vision of a signature gateway, improved mobility and greater safety a reality. n

CONTACT:

BERNIE HOPFINGER, HNTB Project Manager (816) 536-8313 n b hopfinger@hntb.com

TRAVIS KONDA, HNTB Construction Engineering and Inspection Task Lead (612) 328-3803 n tkonda@hntb.com

“The combination of the structure, its location over the Mississippi River and the true-arch design made the project unique.”

TRAVIS KONDA HNTB CONSTRUCTION ENGINEERING AND INSPECTION TASK LEAD

BETTENDORF, IOWA MOLINE, ILLINOIS I-74 Mississippi River Bridge

54 H NTB DESIGNER | Issue 114 HNTB DESIGNER | ssue 114 55

The HNTB Companies Infrastructure Solutions

CURBING THE WAIT Curbside innovation connects passengers without checked luggage to their gates for smooth arrivals and departures in Tampa.

The HNTB Companies Infrastructure Solutions

CURBING THE WAIT Curbside innovation connects passengers without checked luggage to their gates for smooth arrivals and departures in Tampa.

More on page 42

ON THE COVER Sixth Street Viaduct Los Angeles, California

ON THE COVER Sixth Street Viaduct Los Angeles, California

DON GARBER MLS COMMISSIONER

DON GARBER MLS COMMISSIONER

ANGLE-DOUBLE-RIGHT

ANGLE-DOUBLE-RIGHT

ANGLE-DOUBLE-RIGHT

ANGLE-DOUBLE-RIGHT

SARAH RUBIN

INDIANA DEPARTMENT OF TRANSPORTATION’S I-69 FINISH LINE CORRIDOR PROJECT MANAGER

SARAH RUBIN

INDIANA DEPARTMENT OF TRANSPORTATION’S I-69 FINISH LINE CORRIDOR PROJECT MANAGER

MATT WAHL HNTB SENIOR PROJECT MANAGER

MATT WAHL HNTB SENIOR PROJECT MANAGER

TAMPA, FLORIDA

TPA Blue Express Curbside

TAMPA, FLORIDA

TPA Blue Express Curbside

The HNTB Companies Infrastructure Solutions

CURBING THE WAIT Curbside innovation connects passengers without checked luggage to their gates for smooth arrivals and departures in Tampa.

The HNTB Companies Infrastructure Solutions

CURBING THE WAIT Curbside innovation connects passengers without checked luggage to their gates for smooth arrivals and departures in Tampa.