4 minute read

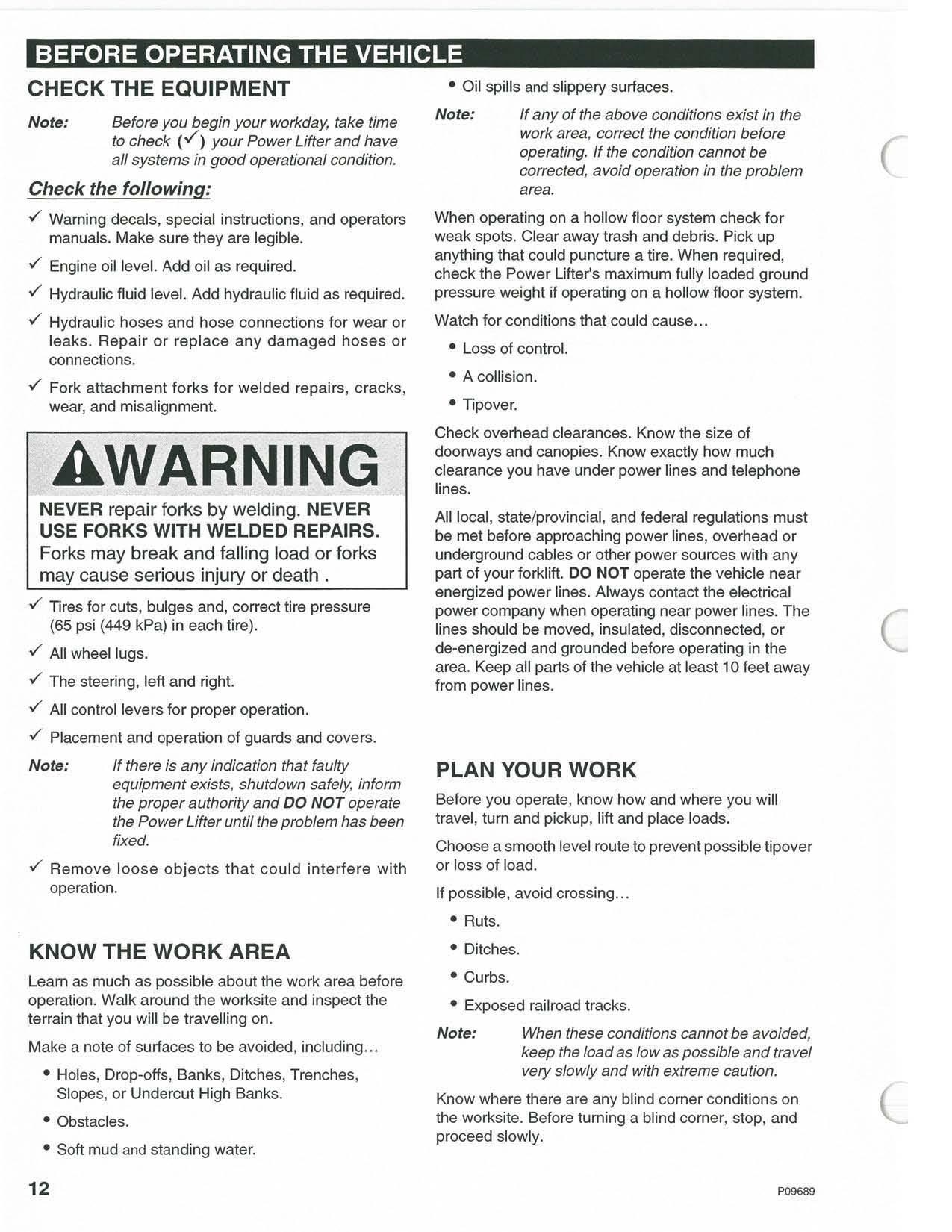

BEFORE OPERATING THE VEHiCLE

Note: Before you begin your workday, take time to check (./) your Power Lifter and have all systems in good operational condition. Check the following:

../ Warning decals, special instructions, and operators manuals. Make sure they are legible. ./' Engine oil level. Add oil as required. ./ Hydraulic fluid level. Add hydraulic fluid as required. ./' Hydraulic hoses and hose connections for wear or leaks. Repair or replace any damaged hoses or connections. ./' Fork attachment forks for welded repairs, cracks, wear, and misalignment.

AWARNING

NEVER repair forks by welding. NEVER USE FORKS WITH WELDED REPAIRS. Forks may break and falling load or forks may cause serious injury or death.

./ Tires for cuts, bulges and, correct tire pressure (65 psi (449 kPa) in each tire), ./' All wheel lugs. ./ The steering, let! and right. ./ All control levers for proper operation . ./ Placement and operation of guards and covers. Note: If there is any indication that faulty equipment exists, shutdown safely, inform the proper authority and DO NOT operate the Power Lifter until the problem has been fixed.

./ Remove loose objects that could interfere with operation.

KNOW THE WORK AREA

Learn as much as possible about the work area before operation. Walk around the worksite and inspect the terrain that you will be travelling on. Make a note of surfaces to be avoided, including ... • Holes, Drop-ofts, Banks, Ditches, Trenches,

Slopes, or Undercut High Banks. • Obstacles.

• Oil spills and slippery surfaces. Note: If any of the above conditions exist in the work area, correct the condition before operating. If the condition cannot be corrected, avoid operation in the problem area .

When operating on a hollow floor system check for weak spots. Clear away trash and debris. Pick up anything that could puncture a tire. When required, check the Power Lifter's maximum fully loaded ground pressure weight if operating on a hollow floor system . Watch for conditions that could cause ...

• Loss of control.

• A collision .

• Tipover. Check overhead clearances. Know the size of doorways and canopies. Know exactly how much clearance you have under power lines and telephone lines.

All local, state/provincial, and federal regulations must be met before approaching power lines, overhead or underground cables or other power sources with any part of your forklift. DO NOT operate the vehicle near energized power lines. Always contact the electrical power company when operating near power lines. The lines should be moved, insulated, disconnected, or de-energized and grounded before operating in the area. Keep all parts of the vehicle at least 10 feet away from power lines .

PLAN YOUR WORK

Before you operate, know how and where you will travel, tum and pickup, lift and place loads. Choose a smooth level route to prevent possible tipover or loss of load .

If possible, avoid crossing ...

• Ruts.

• Ditches.

• Curbs. • Exposed railroad tracks. Note: When these conditions cannot be avoided, keep the load as low as possible and travel vel}' slowly and with extreme caution. Know where there are any blind comer conditions on the worksite. Before turning a blind comer, stop, and proceed slowly.

AL WA VS maintain safe distances between your Power Lifter and other equipment that may be on the worksite. Know the weights of all loads you may be expected to transport before attempting to lift them. Avoid loads of loose material if possible. Check that loads are properly banded or strapped together. Insure that adequate clearance is provided between both rear tail swing and front fork swing of the Power Lifter to avoid injury to personnel or damage to nearby equipment. Important: NEVER turn or park the Power Lifter on a slope or incline as this is a dangerous, potential tipover condition. Know where you will be expected to park your Power Lifter at the end of the work day. Lower the attachment to the ground, turn ignition to OFF, remove the key, and block the wheels. Wear all the protective clothing and personal safety devices issued to you or called for by job conditions. You may need:

• A hard hat.

• Safety shoes. • Safety glasses, goggles, or face shield.

• Heavy gloves. • Hearing protection. • Reflective clothing. • Wet weather gear. • Respirator or filter mask.

Remember ...

• Be alert-know that conditions can change. • Use common sense-show that you are a responsible operator. • Be a defensive operator-prevent accidents before they happen.

SAFE VEHICLE OPERATION

For safe operation of this Power Ufter you must be a qualified and authorized operator. To be qualified, you must understand the written instructions supplied by the manufacturer, have training (including actual operation of this vehicle) and know the safety rules and regulations for the worksite. An operator must not use drugs or alcohol which can affect his alertness and coordination. An operator on prescription or over-the-counter drugs needs medical approval to safely operate these vehicles.

KNOW THE RULES

Most employers have rules governing proper operation and maintenance of equipment. Before you start work at a new location, check with your supervisor or the safety coordinator. Ask about rules you may be expected to obey. Make sure you understand the rules covering traffic at your worksite. Make sure you recognize and understand the meaning of all signs, flags, and markings. Make sure you understand all hand, flag, whistle, siren, or bell signals.