23 minute read

WET CHEMICAL CLEANUP PROCEDURES.....................................................................................................1

Safety BEFORE WELDING

Special precautions are necessary before undertaking any welding on the machine: 1. Clean up the work area. Remove excess oil or grease, debris, or flammable materials from the vicinity. 2. Keep a fire extinguisher on hand in the work area. 3. Situate the welding ground clamp on the machine such that current will not pass through any bearings—especially the swing bearing. 4. Turn OFF the battery disconnect switch. 5. Remove the battery compartment cover. Refer to

BATTERY COMPARTMENT COVER in SECTION

3. 6. Disconnect the negative battery cable from the negative battery terminal. 7. Disconnect the positive battery cable from the positive battery terminal The following steps protect the sensitive electronics on the machine:

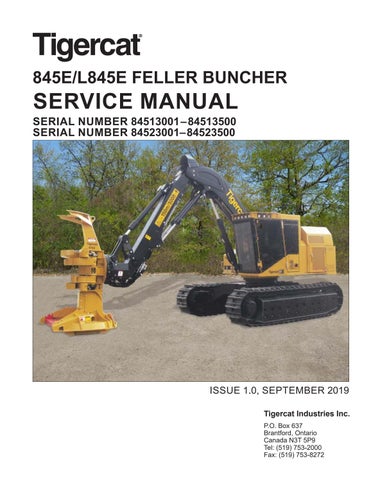

Tigercat 845E/L845E Feller Buncher

801713

Computer Control Module, Pump Compartment

D B A C

801712

Engine ECU (T4f Shown)

A Engine ECU

B FPT Harness Connector

C Engine Harness Connector

D Exhaust Flap Harness Connector 8. Disconnect the three multi-pin wiring harness connectors from the engine electronic control unit (ECU) on the left side of the engine.

801714

Computer Control Module, Hydraulic Tank Rear Wall

A B C

801640

Computer Control Module, Cab Electrical Panel

A Cab Rear Electrical Panel B Harness Connectors C Control Module

Tigercat 845E/L845E Feller Buncher

9. Disconnect the pairs of wiring harness connectors from the computer control modules at the pump compartment, hydraulic tank rear wall, and cab rear electrical panel

B A

A

801640

Cab Bulkhead Plate (From Rear of Cab)

A Ground Cable Plug

B Multi-pin Connectors 10. Disconnect the two multi-pin connectors and the ground cable at the cab bulkhead plate. When welding work is complete: 11. Re-connect all connectors. 12. Connect the positive battery cable to the positive battery terminal. The connection must be tight, clean, and secure. 13. Connect the negative battery cable to the negative terminal. The connection must be tight, clean, and secure. 14. Turn on the battery disconnect switch.

Safety

Safety FLUID INJECTION INJURY

WARNING

Diesel fuel or hydraulic oil under pressure can penetrate the skin and cause serious personal injury, blindness, or death. If any oil is injected into the skin, it must be surgically removed within a few hours by a doctor familiar with treating this type of injury.

Hydraulic oil and diesel fuel systems in forestry equipment operate at very high pressures—often above 200 bar (3000 psi). If a hose fitting becomes loose or a hose ruptures, the leak point will emit a fine, high velocity stream of fluid. Even in systems that operate at pressures as low as 7 bar (100 psi), a fluid stream can penetrate human skin as if it were hypodermic needle. An accidental hypodermic fluid injection may, at first, create only slight stinging sensation. Within a short time, however, the wound will begin to throb painfully, indicating that tissue has already been damaged. If fluid injection penetrates a blood vessel, it can rapidly spread throughout the body's circulatory system. The body is unable to purge this toxin. Time is a critical factor that influences fluid injection injuries. If a fluid injection injury occurs, or is suspected, it is vitally important to seek medical attention immediately. Tissue damage will continue to occur until the injury is treated. Although fluid injection injuries are relatively rare, the resulting injuries have, on occasion, resulted in the amputation of fingers, hands, or entire limbs. The longer the delay in seeking medical attention, the further up the limb the tissue damage will reach. An injury of this nature can have extremely grievous consequences—including death—if not treated promptly and correctly. In the event of a suspected fluid injection injury: • Report the injury to your supervisor immediately. • Seek professional medical attention immediately.

Tigercat 845E/L845E Feller Buncher

Prevention is the best defence against fluid injection injuries. When searching for possible fluid leaks: • Do not use bare hands. Wear thick protective gloves at all times. • Wear safety goggles; a face shield is also recommended. • Keep all body parts well away from the potential leak zone.

• Use the end of a long piece of wood or other long tool to move hoses or other obstacles. • Place the end of a long piece of wood in the suspected path of a fluid stream. Never use a part of your body. • Recognize that the leak source and the fluid stream itself may be nearly invisible. Pooling of fluid may be the clearest evidence of a leak. When performing service work: • Turn off the engine and relieve all diesel fuel or hydraulic oil pressure before disconnecting any lines or otherwise working on the system. • Do not grab hold of any hydraulic or diesel fittings or hoses that are pressurized. • Use the correct hoses and fittings for repairs; they must be rated for the pressures to which they will be subjected. • Do not use hoses or fittings if defects or damage are suspected.

Tigercat 845E/L845E Feller Buncher GREASE INJECTION INJURY–PNEUMATIC GREASE GUNS

Pneumatic grease guns can pump grease at pressures ranging from 17–400 bar (245-5800 psi). Fluids at pressures as low as 7 bar (100 psi) can penetrate human skin.

Seek professional medical attention immediately in the event of a grease injection injury. Provide the attending physician with as much information as possible: the type of grease, the pressure setting of the gun, and related details.

In the event of a grease injection injury, the volume of material injected, the pressure at which it was injected, and the time elapsed between injection and medical treatment will influence the chance of successful recovery. Before using a pneumatic grease gun: • All users must be trained to operate it properly. • All users must be familiar with the hazards involved, and necessary safety precautions. When using a pneumatic grease gun: • Wear protective clothing, such as gloves, safety goggles, and safety helmet. • Inspect the grease gun equipment for damage or wear; replace damaged or worn parts. • Verify that protective shrouds are installed at the grease gun nozzles. • Remove dirt and old grease from grease fittings prior to pumping fresh grease. • Replace any defective or damaged grease fitting on equipment with new fittings. • Replace awkwardly situated fittings with angled or swivel fittings for ease of access.

Safety

Safety LIGHTNING SAFETY AWARENESS

Lighting is a giant electrostatic spark within the atmosphere or between the atmosphere and the ground. It is the product of the complex movement of air and the charging of precipitation particles (ice crystals, hail, and rain) in the atmosphere during thunderstorms. Thunderstorms usually develop early in the day, when the sun warms air near the ground and pockets of heated air rise up into the atmosphere, forming clouds. A developing thunderstorm cloud contains small ice crystals in the upper levels, hail in the middle, and rain or melting hail in the lower levels. Air currents inside the cloud cause these particles to collide and become electrically charged. Particles near the top of the cloud develop positive charges, while those near the bottom of develop negative charges. Meanwhile, precipitation particles nearer to the ground develop positive charges, concentrated around relatively tall objects such as hills, ridges, trees, buildings, vehicles , equipment, and even people. When the difference between the negative electrical charges in the lower part of the cloud and the positive charges nearer to the ground becomes great enough to overcome the resistance of the insulating air in between, an electrical current flows instantly. This is known as cloud-to-ground lightning, or more generally, as a lightning strike. The electrical potential in a lightning strike can reach 100 million volts. Lightning strikes can occur over very large distances: as far as 60 km (37 miles). Lightning travels both in front of and behind a thunderstorm. Strikes may occur before rain has started or after it has stopped. Lightning can, and often does, strike the same point, many times. It may travel as much as 18 m (60 feet) through the soil around the strike point. Thunder always accompanies lightning. When lightning occurs, the air through which it travels is instantaneously heated to a temperature more than 28,000°C (50,000°F). The air expands rapidly due to this heating, then quickly contracts as it cools. The resulting shock wave is audible as thunder.

In many areas of the world, lightning strikes are second only to flooding as the greatest cause of weather-related deaths and injuries. Evidence suggests that nine out of ten lightning strike victims survive their injuries, but a large proportion of survivors suffer permanent disability. The longer term symptoms of a lightning strike injury include memory loss, fatigue, chronic pain, dizziness, sleeping disorders, and the inability to complete several tasks at one time.

Contrary to popular myths, lightning strike injuries occur frequently. Loggers are at high risk because they work outdoors around common strike points such as tall trees and heavy equipment. Loggers can increase their chances of avoiding a lightning strike by following a few simple safety practices. • Designate a crew member to monitor weather forecasts and observe local conditions. The best time to seek shelter is before a storm begins. • Do not start or continue any work that cannot be stopped immediately when a storm approaches. (If thunder is audible, lightening is already within striking range.) • Anticipate a dangerous situation and take action early by moving to a safer location. Do not hesitate.

If there is lightning in the area, the crew is in danger. • Obey the rule: If you see lightning, Flee. If you hear thunder, Clear. • There is no circumstance when it is safe to be outdoors, away from shelter, during a thunderstorm.

Move to shelter as quickly as possible. • Stay under shelter for 30 minutes after the last sight of lightning or the last sound of thunder. The safest location during lightning activity is inside a fully enclosed, substantially constructed building, such as a house, office, school, or shopping centre. Such structures are safest because of the electrical wiring and plumbing that they house. Should lightning strike, the electrical current will travel through the wiring or plumbing into the ground. When such a building is nearby, seek shelter there first. Loggers do not often work close to buildings, so it is necessary to consider alternative forms of shelter. Sheds, weather shelters, hunting blinds, tents, caves, and other partially open or small structures offer no protection against lightning strikes, as they lack the electrically grounded components. Do not seek shelter from lightning strikes inside these structures. Enclosed cars, van, truck, bus, or other vehicles with metal roofs and metal sides are the best alternatives to large structures. The electrical energy of a lightning strike to these vehicles travels to ground through the outer metal surfaces. This is called the skin effect.

Vehicles with fibreglass ,or plastic body shells, convertible top vehicles offer no protection against lightning strikes.

Tigercat 845E/L845E Feller Buncher

Heavy forestry equipment such as a skidders, loaders, feller bunchers, or forwarders with fully enclosed rollover protective structure (ROPS) cabs are relatively safe, since the skin effect applies to them, as it does to an enclosed metal car or van body. Machines with open rollover canopies offer no protection against lightning strikes, as they are open to electrically conductive rainwater. The skin effect does not apply to them. Operators of this type of equipment must abandon their machines and get to a safer location before lightning strikes. Rubber tires on motor vehicles and heavy equipment offer no protection from lightning strikes. It is instructive to consider that lightning has already travelled a great distance through the air immediately before striking a vehicle. By comparison, a few inches of rubber in a tire offers absolutely no additional insulation.

Safety WHAT TO DO IF YOU ARE OUTDOORS AND SEE LIGHTNING OR HEAR THUNDER

GET INSIDE SUITABLE SHELTER

Run to the nearest building, motor vehicle, or fully enclosed ROPS equipment cab immediately. There is no safe place outside.

INSIDE A BUILDING

• Do not watch the storm from open windows or doorways. Many lightning strike victims are hit while standing in doorways or under the porches of otherwise safe structures. Stay in inner rooms. • Stay well away from corded telephones, electrical appliances, lighting fixtures, radio microphones, electrical sockets and plumbing pipes and fixtures.

• Do not step outside of the vehicle or dismount the equipment to move to another shelter. Very dangerous electrical pathways to ground may pass through your body. • Turn off the engine, close all doors, and raise all windows. • Sit squarely in the seat with hands on the lap and feet flat on the floor mat. • Do not touch any metallic objects inside the cab or vehicle compartment. Do not touch door and window handles, control levers, foot pedals, steering wheels, cab interior walls, and or any other inside to outside metal objects. • Do not touch any radio or telephone connected to an outside antenna.

Safety

IF CAUGHT OUTSIDE AWAY FROM SUITABLE SHELTER

• Avoid open areas where you project above the surrounding landscape. • Seek shelter in a low place, such as a ditch, ravine, or valley. Cave entrances are not safe. • Move away from open water such as ponds or streams. • Do not take shelter under any isolated tall trees or small groups of trees. • Seek shelter among the dense, thick growth of the shortest trees. • Avoid small enclosures or shelters. • Do not seek shelter under any motor vehicle or heavy equipment. • Keep clear of any materials that can conduct electricity such as wire fences and gates, metal pipes, poles, rails and tools. Metal objects do not attract lighting more than non-metal objects, but they do conduct dangerous electrical currents. • Stay at least 15m (50 feet) away from metal objects such as a fuel tank, a vehicle or equipment without a cab, a motorcycle, or an all-terrain vehicle. • Stay at least 5m (15 feet) away from other people to prevent a lightening strike from travelling person to person. • Do not lie down on the ground. Touch the ground as little as possible to avoid the chance of ground strikes passing through the body. • Do not use the telephone except for emergencies.

If you hear a crackling sound, feel tingling on the skin, your hair stands on end, or light metal objects nearby begin to vibrate, a lightning strike is probably imminent. • Do not lie down. • Crouch down like a baseball catcher. Hold your head down. Cover your ears to protect them against the noise of the thunder. Keep feet together. The crouch position is a last resort, when it is impossible to reach shelter. Always move toward shelter when thunderstorms approach.

FIRST AID

Perform the following steps if a crew member is struck by lightening. NOTE: The human body does not store electricity. It is not dangerous to touch a lightning strike victim. 1. Call the emergency telephone number immediately. 2. Assess the situation. If the victim is situated in an area where lightning is still active, it may be necessary to move the victim to a safer location before rendering first aid. Do not move victims who are bleeding, or who appear to have broken bones. 3. Lightning often causes a heart attack. Check to see if the victim is breathing and has a heartbeat. 4. If the victim is not breathing. Begin mouth-to-mouth resuscitation. If the victim does not have a pulse, begin cardiopulmonary resuscitation (CPR). Use a portable defibrillator if one is available. 5. Continue first aid until emergency response technicians arrive.

FURTHER INFORMATION ABOUT LIGHTNING

Scientific understanding of lightening continues to evolve. The information in this manual reflects the best available information at the time of printing. To learn more about lightning, refer to the following websites: • National Weather Service Lightning Safety: http://www.lightningsafety.noaa.gov • National Lightning Safety Institute: http://www.lightningsafety.com

When working in a forest environment combustible debris will collect in tight corners of the machine. Left unchecked, this debris may cause a fire; when mixed with fuel, oil, or grease in a hot or confined place, the danger of fire greatly increases. The following fire prevention guidelines should be used to supplement the operator’s fire prevention efforts. In no case should the guidelines be used, or assumed, as replacements for diligent operator efforts at preventing fires. • Maintain a charged fire extinguisher on the machine at all times. Know how to use it. • Remove dust and debris regularly from the air intake doors, cooling system components, and A/C condenser to prevent engine and hydraulic system overheating and to maintain efficient operation.

Refer to CLEANING COOLER PACKAGE in

SECTION 3 . • Remove all forest debris and fine organic material around engine intake and exhaust components (turbocharger, exhaust manifold, exhaust pipes, muffler) at the end of each shift, or more frequently when working in conditions with high volumes of combustible forest debris. Check carefully in small pockets and cavities around the engine enclosure where smouldering debris may gather.

NOTE: Minor debris accumulations near hot components can ignite and smoulder. Smouldering debris may shift and cause fire to spread. • Clean out all accumulated forest debris (twigs, needles, branches, bark, leaves, saw dust, wood chips) and any other combustible materials from inside the machine belly pans, lower machine structures, and engine, hydraulic, and fuel system areas no less frequently than at the completion of each work shift. • Inspect the machine regularly for evidence of diesel fuel or hydraulic system leakage. Check for worn or damaged hydraulic and fuel lines before turning on the engine. • Clean up any grease, diesel fuel, or oil spillage (hydraulic or lubricating) immediately.

Safety

• Steam clean the engine, hydraulic pumps, transmission, brake, fuel and hydraulic oil tank compartments and all machine belly pans at least once each month, or more frequently when working in conditions with high volumes of forest debris • Use only non-flammable solutions for cleaning the machine and components. • Inspect the exhaust system daily for evidence of leakage. Check for worn, cracked, broken, or otherwise damaged pipes or muffler, and missing or damaged bolts or clamps. Make repairs immediately.

Engine exhaust leaks can cause fires. Do not operate the machine until exhaust leaks are repaired.

NOTE: Changes or increases in engine exhaust noise levels often indicate exhaust leaks. Do not ignore these warnings. Shut down the machine immediately and complete repairs. • Park the machine at least 15 m (50 feet) away from other equipment at the end of each shift. • Never leave the machine parked with the boom raised off the ground. Should the hydraulic cylinder hoses burn through in a fire, hydraulic oil will escape and the boom will fall rapidly to the ground. • Turn OFF the battery disconnect switch when parking the machine. • Remain with the machine for at least 45 minutes at the end of operations while the machine cools. • Remove the ignition key, and lock the cab and fuel cap at the end of shift to reduce the risk of vandalism or theft. • Do not smoke in the vicinity of the machine. • Do not smoke during fuelling operations, when the fuel system is open to the atmosphere, or when servicing the batteries. Exercise caution if smoking in the woods. • After transporting a machine by road, open all doors and access panels; remove any debris that may have settled around the engine and exhaust system during the journey. • Before undertaking repair work or welding, clean the surrounding area and place a fire extinguisher within easy reach. • Store rags and other combustible materials safely in a fireproof location. • Do not operate the machine near burning timber. Do not use the machine to push burning timber into a pile. • There is no substitute for fire prevention. Time invested in prevention is repaid through productivity on the job site.

Safety

NOTICE

Equipment fires undermine productive logging, may increase your insurance premiums dramatically, or prevent you from obtaining insurance coverage. Make fire prevention a priority.

HOW TO PREPARE FOR A MACHINE FIRE

• Inspect and maintain all machine systems on a routine basis. • Maintain fire extinguishers in proper working order. Follow the manufacturer’s instructions for inspection and maintenance (on the label of the fire extinguisher and in the user's manual). • Verify that any pressurized water systems on the machine are charged and in working order. Refer to

PRESSURIZED WATER SYSTEM MAINTENANCE as applicable in SECTION 3. • Verify that the correct types of fire extinguishers are available at the work site. Most fires involving mobile forestry equipment will be Class A or B. Dry chemical extinguishers should be rated ABC and pressurized water extinguishers should be rated A. • Class A fires involve ordinary combustibles such as wood, cloth, paper, rubber and many plastics, • Class B fires occur with flammable liquids such as diesel fuel, oil, and grease. • Class C fires apply to energized electrical equipment. • The nozzles on fires extinguishers and pressurized water systems (if applicable) must fit within the fire extinguisher access ports on the machine doors. • Keep the fire detection system in working order as applicable. Refer to FIRE DETECTION SYSTEM in

SECTION 2. • Keep the fire suppression system charged and in working order as applicable. Refer to FIRE

SUPPRESSION SYSTEM in SECTION 2. • Know the recommended fire procedures in your organization's emergency action plan. • Follow all national, state/provincial, and local fire fighting regulations. Regulations will vary from region to region but most will require that: • Workers assigned to fire fighting duties must be physically capable of performing them safely and effectively. • Workers designated to use fire fighting equipment as part of an emergency action plan must receive full and proper training from a qualified instructor.

Tigercat 845E/L845E Feller Buncher

• Whenever portable fire extinguishers are provided for use in the workplace, training must be provided to familiarize workers with the general principles of fire extinguisher use and the hazards involved with fire fighting. • Training must be provided upon initial employment and at least annually thereafter. • Know how to use the fire extinguisher, the pressurized water system (as applicable), and the fire suppression system (as applicable) on your machine. There is no time to read instructions

during a fire emergency. Be prepared to act.

• Keep emergency contact information readily available in case of fire.

IN CASE OF A MACHINE FIRE

If a machine fire occurs: 1. Lower all working attachments to the ground. 2. Turn OFF the engine. 3. Activate the fire suppression system as applicable. 4. Radio or call for help. Report a fire immediately. 5. Turn OFF the battery disconnect switch if it safe to do so. 6. Dismount the cab; take the fire extinguisher and pressurized water system hose (if applicable) with you. 7. Put your personal safety and the safety of other persons first. Approach any fire with extreme caution. All fires are potentially very dangerous and life threatening. Before deciding to fight the fire, be certain that: 1. The fire is small and not rapidly spreading. 2. There is a clear, safe escape route to your back. 3. You have received training in the use of the available fire extinguishing systems and are confident that you can operate them effectively.

If in doubt about your ability to fight the fire, do not attempt to fight it. Stay well back. Wait for help to arrive.

NOTE: Engine coolant, diesel fuel, or hydraulic hoses may fail during a fire. Hot coolant, fuel, or oil could be ignited, or may spray at high velocity from damaged hoses.

Tigercat 845E/L845E Feller Buncher

When fighting a fire: 1. If possible, use a dry chemical fire extinguisher or fire suppression system first. 2. Immediately afterwards use the pressurized water hose supplied with the machine (if applicable) or a pressurized water extinguisher (if available). A fire suppressed by dry chemical may re-ignite from the heat retained by debris or hot machine components in the area. Water cools the area, reducing the chances of re-ignition. 3. Use the fire extinguisher PASS method:

Pull the safety pin at the top of the extinguisher that prevents the discharge lever from being depressed.

Break the plastic seal as the pin is pulled.

Aim the nozzle at the base of the fire. Do not aim the nozzle at the flames. To put out the fire, the fuel must be extinguished, not the flames. Hose nozzles are often clipped to the extinguisher body. Release the hose before taking aim.

Squeeze the discharge lever to release the pressurized extinguishing agent. The handle can be released at any time to stop the discharge.

Sweep from side to side at the base of the fire until the fire is completely out or the fire extinguisher is empty.

822C-190

Typical Fire Extinguisher Access Port

4. Insert the fire extinguisher nozzle into the appropriate access port and discharge the extinguisher. 5. If it is safe to do so, open the access panels in the area of the fire and aim the extinguisher directly at the base of the flames. 6. If it is impossible to reach an access port or to open a panel or door, discharge the extinguisher through mesh screening or any available opening. 7. Monitor the machine after extinguishing a fire in case of re-ignition; remain until help arrives.

Safety

AFTER A MACHINE FIRE

Before returning a machine to operations: 1. Determine the cause of the fire. 2. Complete all necessary repairs. 3. Service and recharge the fire suppression and detection systems as applicable. 4. Report the fire to your dealer and/or Tigercat

Industries Inc. by completing an incident report (Tigercat form 5101). NOTE: Fire detection systems are offered as optional installations on some Tigercat product lines. Please disregard any references made to fire detection systems if not installed on your machine. NOTE: Dry and wet chemical fire suppression systems are offered as optional installations on some Tigercat product lines. Please disregard any references made to fire suppression systems if not installed on your machine.

DRY CHEMICAL CLEANUP PROCEDURES

ABC dry chemical fire extinguishers and fire suppression systems discharge a chemical powder. The powder comprises very fine particles that penetrate and cover all components in the vicinity of the discharge. Areas in contact with dry chemical power must be neutralized and cleaned after a fire. Wear protective clothing, safety goggles, and a fine particle dust mask. 1. De-energize electrical systems prior to any cleanup. 2. In areas that remained cool and dry during the fire, the dry chemical remains in powder form.

Clean these areas immediately to prevent residual powder from coming into contact with water or ambient moisture.

Remove the powder residue by blowing off with air, sweeping, dusting, or vacuuming using a HEPA filter capable of trapping the small dry chemical particles.

Wipe all surfaces with a damp cloth. 3. In areas exposed to moisture during the fire, the dry chemical powder combines with water to form a paste that is mildly acidic. All surfaces covered in dry chemical paste, including electrical contacts, are vulnerable to corrosion.

Neutralize the acidic paste on large surfaces by spraying or washing these areas with a mixture of three parts hot water to one part baking soda. Allow this mixture to stand for several minutes before rinsing with warm water. Wash the area with a mild soap and water solution. Rinse thoroughly with water. Blow-dry to remove all residual water.