8 minute read

LOADING OPERATlON

LOADING OPERAT10N

SAFE LOADING OPERAT10N

BEFORE LOAD]NG

DIGGING GROUNDDIGGING(DIGGINGON

ALEVELSURFACE)

DUMPING

LEVELING

BULLDOZING

SNOW REMOVAL

HOISTING THE LOADER ADJUST]NG BUCKETAUTO-

LEVELER

ThisManualusesthefoIIowJngSafetyalertsymboIs.

When you seethose symboIsin thetext,fol10Wthe Safetymessagetoavoidpersonalln]uryOrdeath.

Failure to fo”ow thein$truCtionsin the message Willcausea$eriou$aCCidentordeath.

▲wARNING

Failure to f0110W the instructions in the message might cau$e a$erious accident or death.

A cAUT10N

Failure to fo=ow theinstructionsin the message may cause personalln]ury Or damage to the 10ade「.

SAFE LOADlNG OPERATlON

You should understand the capabilities and COnStruCtion of the wheel10ader to operateit Safely.

AwARN[NG

The operator mustfasten his seat beItifthe Wheel10aderi$equipped with a ROPS(RoIL- Over-Protective-Structure)canopyora ROPS Cab;Otherwise,if the10ader turns over,the OPeratOr might be thrown out and,in the WOrSt Ca$e,the operator can be cru$hed by the10ader causlng $eVerelnJury Or eVen death.

Al10f theloader’s functions can be relatively easllycontroLledwiththe10adhand[ing]ever,but theloader can be very dangerousif you fai]to usepropercaution.Youshouldbearin mindthat the bucketorattachmentis heavyand hard and thattheywillsometimes hinderyourviewofthe areainfrontofyou.Beforestartinganoperation, make sure thereis no one neartheworkarea.

The wheeIloaderis a versatile pleCe Of equLPment.This does not mean thatit can be used forJuSt any tyPe Of work.Basica]ly,itis des]gned to scoop up10ads with the bucket, transport theloads,and dump theminto a hopperorontoadumptruck.

Do not try to modify the ROPS canopy or ROPS cab without pr[Or Permission from the manufacturer.Useonlythe ROPScanopyor ROPS cab approved by us.暮f theloader turned over,be sure to rep[ace the ROPS canopy or ROPS cab with a new one before Puttingthe10aderin$erViceagain・

The marking thatareprohibitedordangerous.

On the pictures means actions

In terms of performance,yOu Should know the bucket capacity of the Loader and the size, Weight,and materia10f the10ad you w川 be handling,ln addition,yOu absolute]y must check to seeif the soi10rWOrking surface of the work area is firm enough and strong enough to OPerate the10ader safely.The10aderis not Suitable forwork on soft soi],SuCh as muddy or Sandyground.ln softsoi=tis unabLetoachieve Sufficienttractionforsafeoperation.

The pictures have been drawn based on our medium-SizedwheelLoaders.

Thewheelloaderhasanarticulatedframedesign Which allows the front and rear frames to swivel around the center,Pln for steerlng.ln some POSitions,the10aderissufficientJyunstablethatit may easily turn over if you try to maneuver too heavya10ad.BeforetrylngtOOPeratethebucket Oran attaChment,make sure the frames arein a relatively straight alignment to each other・ Failure to observe this require-ment Canlead to ma[functions and seriousaccidentsinvoIvlng the 10ader.

Protecttheplanet!!

Operatethe10aderwhi[ekeepIngln mindthatyou shou[dbekindto theenvironment.Thispracticewillleadto10WeramOuntSOfexhaust andoperatingnoise・1twj”alsobewelcomedbybothfeIIowworkers andthe residentsaroundthe worksite.

Wearecommittedtoprotectingtheplanet.

ThenumbersnexttothesafetyruJesdonotindicatethepriorityoftherule’simportanceorthedegreeofriskassociatedwiththesituation・

1.Know the rated capacity of the bucket or attachment and never exceedit.Before Startingwork,Checktheweightandcenterof gravityoftheloadyouaregolngtOhandle.

2.Checkthespecificgravityofthe10ad.Takeit intoaccountbeforetrylngtOmOVeit.

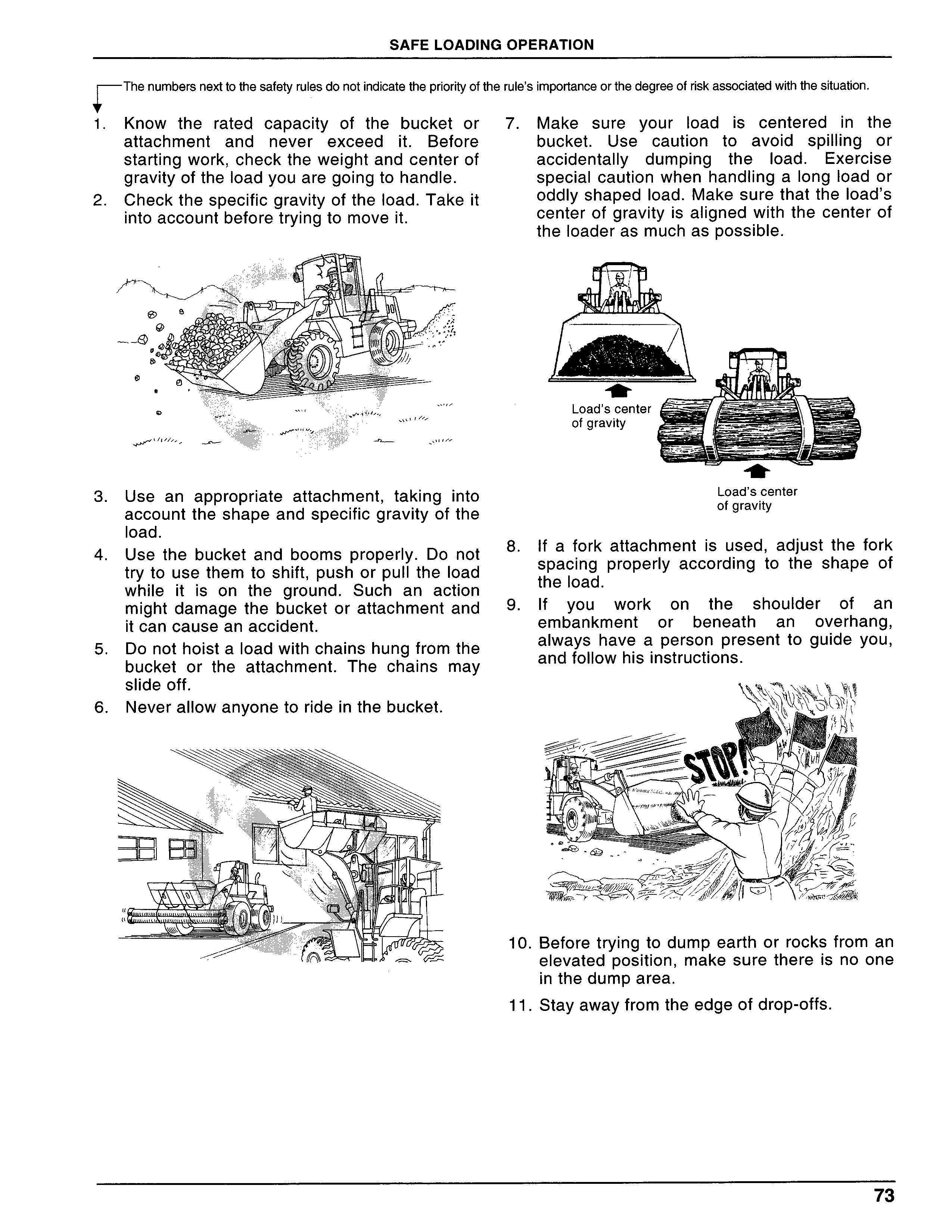

7.Make sure your[oadis centeredin the bucket.Use caution to avoid spi”ing or accidentally dumplng theload・Exercise SPeCialcautionwhen handlinga10ng10ador Oddlyshapedload・Makesurethatthe10ad’s CenterOfgravityisalignedwiththecenterof the]oaderasmuchaspossible.

3.Use an appropriate attachment,takinginto accounttheshapeandspecificgravityofthe load.

4.Use the bucket and booms properly.Do not tryto usethemtoshift,PuShorpu‖the10ad Whileitis on the ground.Such an action might damage the bucket orattachment and it can cause an accident.

5.Donothoistaloadwithchainshungfromthe bucket or the attachment.The chains may Slide o廿

6.Neveral10WanyOnetOrideinthebucket.

8.1f a fork attachmentis used,adjust the fork SPaClng PrOPerly according to the shape of the Load.

9・lf you work on the shouLder of an embankment or beneath an overhang, always have a person presentto guide you, andfoILow hisinstructions.

10.BeforetryJngtOdumpearthorrocksfroman elevated position,make surethereis noone inthedumparea.

11.Stayawayfromtheedgeofdrop-Offs・

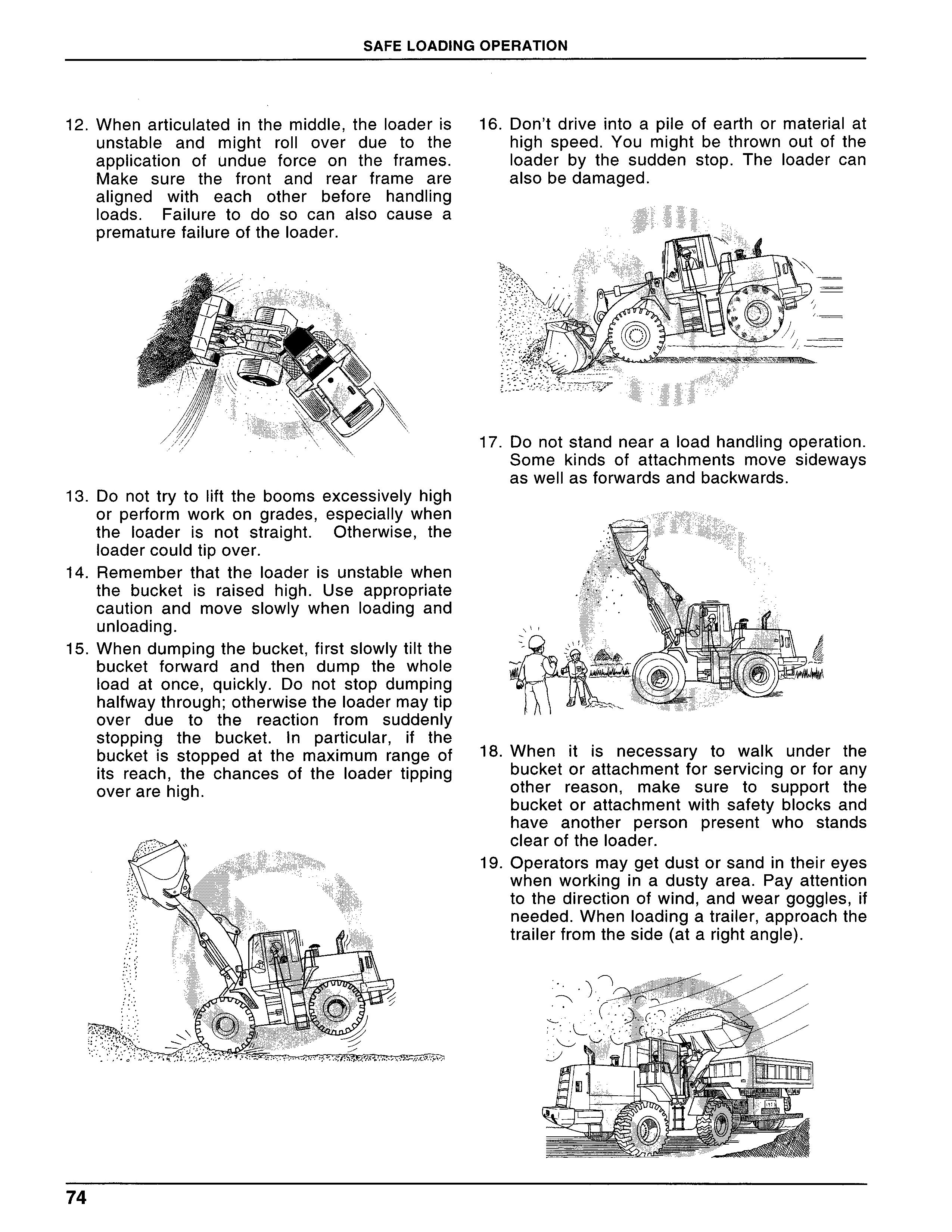

12.When articulatedin the middle,theIoaderis unstable and might roIlover due to the appIication of undue force on the frames・ Make sure the front and rear frame are aligned with each other before handling Loads. Failure to do so can also cause a Prematurefailureoftheloader.

16.Don’t driveinto a pile ofearth ormaterialat high speed.You might be thrown out ofthe 10ader by the sudden stop.The10ader can alsobedamaged.

17.Do notstand nearaload handlingoperation. Some kinds of attachments move sideways as weIIas forwards and backwards.

13.Do nottrytolift the booms excessively high Or Perform work on grades,eSPeCially when the10aderis not straight.0therwise,the loadercouldtipover.

14.Remember that the10aderis unstable when the bucketis raised high.Use appropriate Caution and move s10Wly when10ading and un10ading.

15.WhendumpLngthebucket,firsts10Wlytiltthe bucket forward and then dump the whole load at once,quickLy.Do not stop dumplng halfwaythrough;Otherwisethe10adermaytip OVer due to the reaction from suddenIy StOPPLng the bucket.In particular,if the bucketis stopped at the maximum range of its reach,the chances of the10ader tipplng OVerarehigh.

18.Whenitis necessary to walk under the bucketorattachmentforserviclng Orforany Other reason,make sure to support the bucket or attachment with safety blocks and have another person present who stands Clearof the10ader.

19.0perators maygetdustorsandintheireyes When workingln a dusty area.Pay attention tothe direction ofwind,andweargoggles,if needed.When10adingatrailer,aPPrOaChthe trailerfromtheside(atarightangLe).

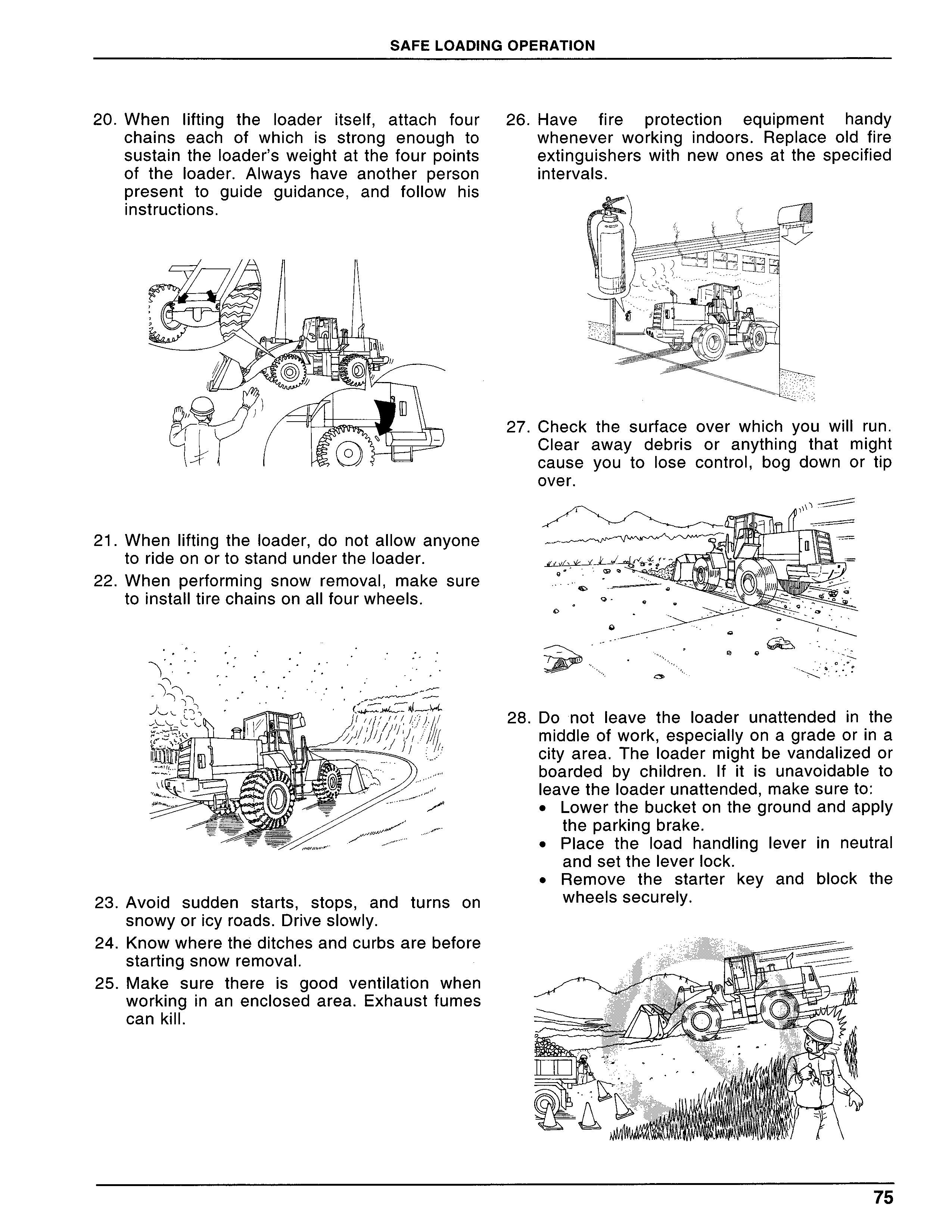

20・Whenlifting the10aderitself,attaCh four Chains each of whichis strong enough to SuStain the[oader’sweightatthefourpoints Of theloader.AIways have another person PreSent tO guide guidance,and fol10W his instructions.

26.Have fire protection equlPment handy Whenever workingindoors.Replace old fire extinguishers with newonesatthe specified intervals.

21.Whenlifting the10ader,do notal10W anyOne to ride on orto stand undertheloader.

22.When performlng SnOW remOVal,make sure toinstalltire chains on a”fourwheels.

27.Check the surface over which you w=run・ CIear away debris or anything that might CauSe yOu tO[ose control,bog down or tip OVer.

23.Avoid sudden starts,StOPS,and turns on SnOWyOr[CyrOads.Drives10Wly.

24.Knowwherethe ditches and curbs are before Startingsnowremoval.

25.Make sure thereis good ventilation when WOrkingln an enC10Sed area.Exhaustfumes Can ki]l.

28.Do notleave theloader unattendedin the middLeofwork,eSPeCiallyonagradeorjn a Cityarea.The10adermightbevandalizedor boarded by children.1fitis unavoidable to leavetheloaderunattended,makesureto: ・Lowerthebucketonthegroundandapply theparkingbrake.

・Place the10ad handlingleverin neutraJ and setthe[everlock.

・Remove the starter key and block the Wheelssecurely.

29.Do not change the specifications or add an additionaLcounterweightormodifythebucket Withoutthemanufacturer’spnorpermission.

30.Do not try to make any modification that affects the performance or strength of the loader.

31.When10adingtheloaderontoatraiLer,make Sure tO:

・Applythetrailer’sparkingbrakeandb]ock its wheels.

・Use ramps of sufficient strength and Width.

● Use nonskid ramps.WheninstaLllng ramps(if they are not permanently attached to the trailer),engage them SeCurelyon the rearofthetrailerand put SuPPOrtSunderthemiddleofthem.

・Usuallybackthe]oaderupthe ramps,but the direction ofloading may change the COndition ofthe trailer.

・When golng uP a ramP,make sure the CenterS Of the rear wheeLs are aLigned With the centers of the ramps.Drive up Slowly.

・Never try to turn the $teering wheeL When halfway up a ramp.If theIoader js not aligned properly with the ramp, drive back down to the ground and StartOVeragaln.

・lfyou havedifficultyseelngifthetiresare allgned on the ramp correctly,have SOmeOne else guide you.Follow their instructions.

32.Another attachment with hydraulic tubing may be installed and it is operated by man[Pu[ating an additional10ad handling lever(forattachment).Donotconfusejtwith the otherlevers.

33.1f a fork attachmentisinstalLed,uSe Caution not to drop the10ads from the pallet by COntrO”ingtheangleoftheforksproperly.

Before Loading

a WARNlNG

U$e Onlythe bucket or attachmentapproved byusfor10adhandlingoperations.

Do not jncrease the bucketcapacity oradd an additionalcounterwejght to the10ader

Without the manufacturer’s pnor permi$- Sion.Failure to do so may cause personal lnJuryOranaCCident.

THESPECIFICGRAVITYOFLOADS (Weight/m3perunitvolume)

The[oaderisdeslgnedto handlea heapedload

On the bucket safe[y,if the materialis sand or earth.However,iron oriron ore,Clayey materiaL COntainlngJots of water,Or feces have a far greater specific gravity than the sand or earth does,and thus they can exceed the rated CaPaCity of the bucket despjte their apparent Smallvolume.When handling such a material, use caution not to exceed the rated capacity of the bucket and10ader.When theload you are golngtO handle hasaIargespecificgravity,itis advised that you exchange the bucket for one With a smaller capacity;When the Load has a Smallerspecificgravity,yOuShouldexchangethe bucketwithonewitha]argercapacity・

For $afe work and operation,eXerCise extreme caution$O that the rated capacity of the bucket and10aderis not exceeded.This leads to reduced maintenance and economi・ Caloperation.

Someexamplesoftheoperationsthe10adercan Performw=beillustratedonpagesthatfo”ow:

Dlgging

a CAUTloN

Makesurethe10adiscenteredwhenfillingthe bucket.Nevertrytoliftunevenload,

“Diggrng”referstooperationsinwhichthe10ader PutS the bucketinto a pile ofsand orthelike to 川=t.

Note:You can performload handJing operation more efficientIy by using the DSS and USS properly,refer to“HANDLING LOADERS WITH AUTOMATJC TRANS・ MISS10N.”

SCOOPING a WARNlNG ff your10aderis equlPPed with an optional APS,make sure to turn off the APS switch

When you are golng tO Perform job$Which requ(rethe10ad handling meansorbucketto be placedin the f10at mOde,SuCh as SCOOPIng,1evelingorsnowremovlng.Jfsuch a jobis performed with the APS turned ON, the Load handling means or bucket might dropaccidenta”y.ForhandIingtheAPS,See Page24.

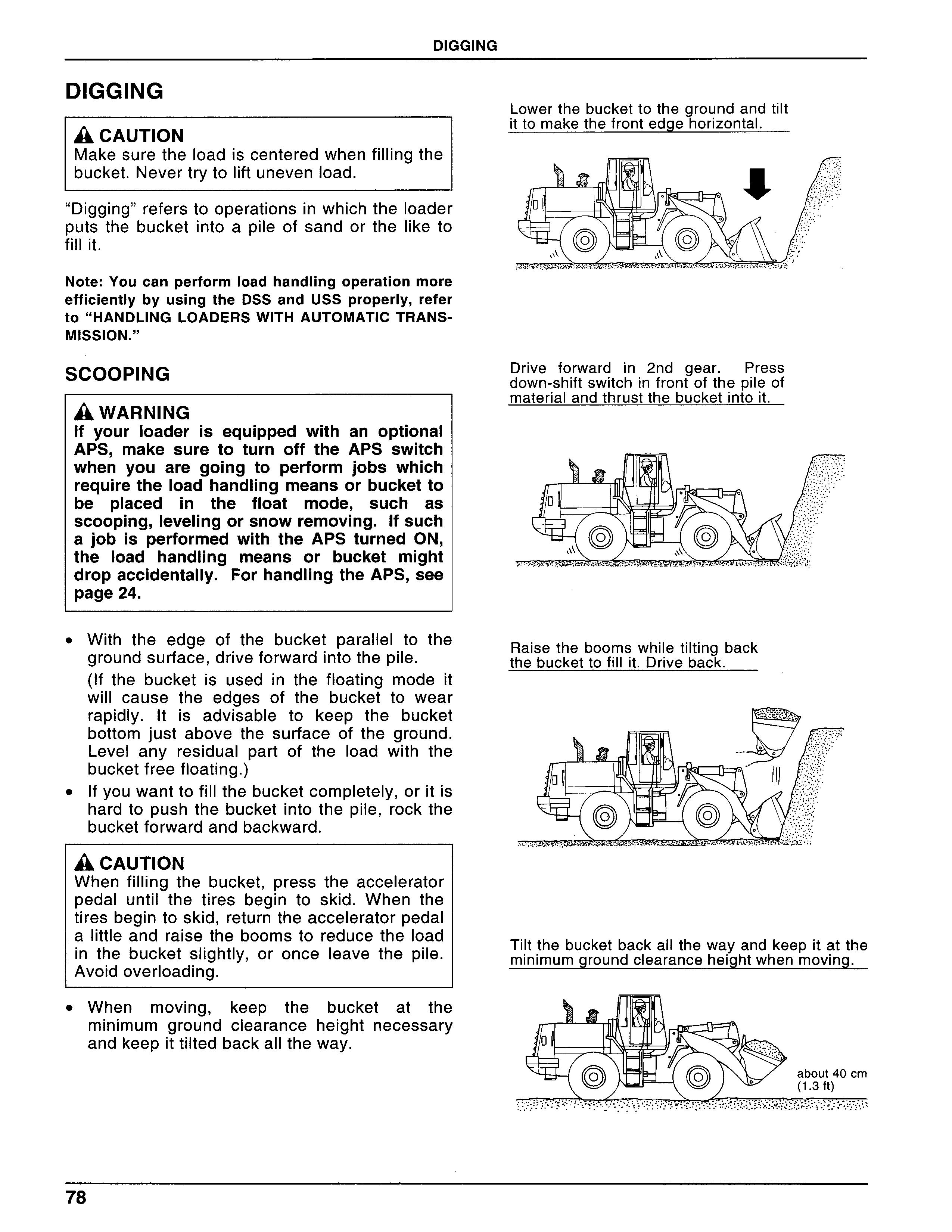

・With the edge of the bucket para‖elto the groundsurface,driveforwardintothepile. (lf the bucketis usedin the floating modeit WiIIcause the edges of the bucket to wear rapidly.1tis advisab[e to keep the bucket bottomJuSt above the surface of the ground. Level any residual part of the load with the bucketfreef[oating.)

・lfyouwanttofillthebucketcompletely,Oritis hard to push the bucketinto the pile,rOCkthe bucket forward and backward.

a CAUTloN

When filling the bucket,PreSS the accelerator

Pedalunti[the tires begln tO Skid.When the tiresbegintoskid,returntheacceleratorpedal alittle and raise the booms to reduce the10ad in the bucket slightJy,Or OnCeleave the piIe. Avoidover10ading.

・When movlng,keep the bucket at the minimum ground clearance height necessary andkeepittiltedbackalltheway.

Lowerthebuckettothegroundandtilt it to make the front ed e horizontal.

Drive forward jn 2nd gear. Press down-ShiftswitchinfrontofthepIleof materiaIand thrustthe bucketintoit.

Raisetheboomswhiletilting back the bucketto fi”it.Drive back.

GROUND DIGGING (Diggingonalevelsurface)

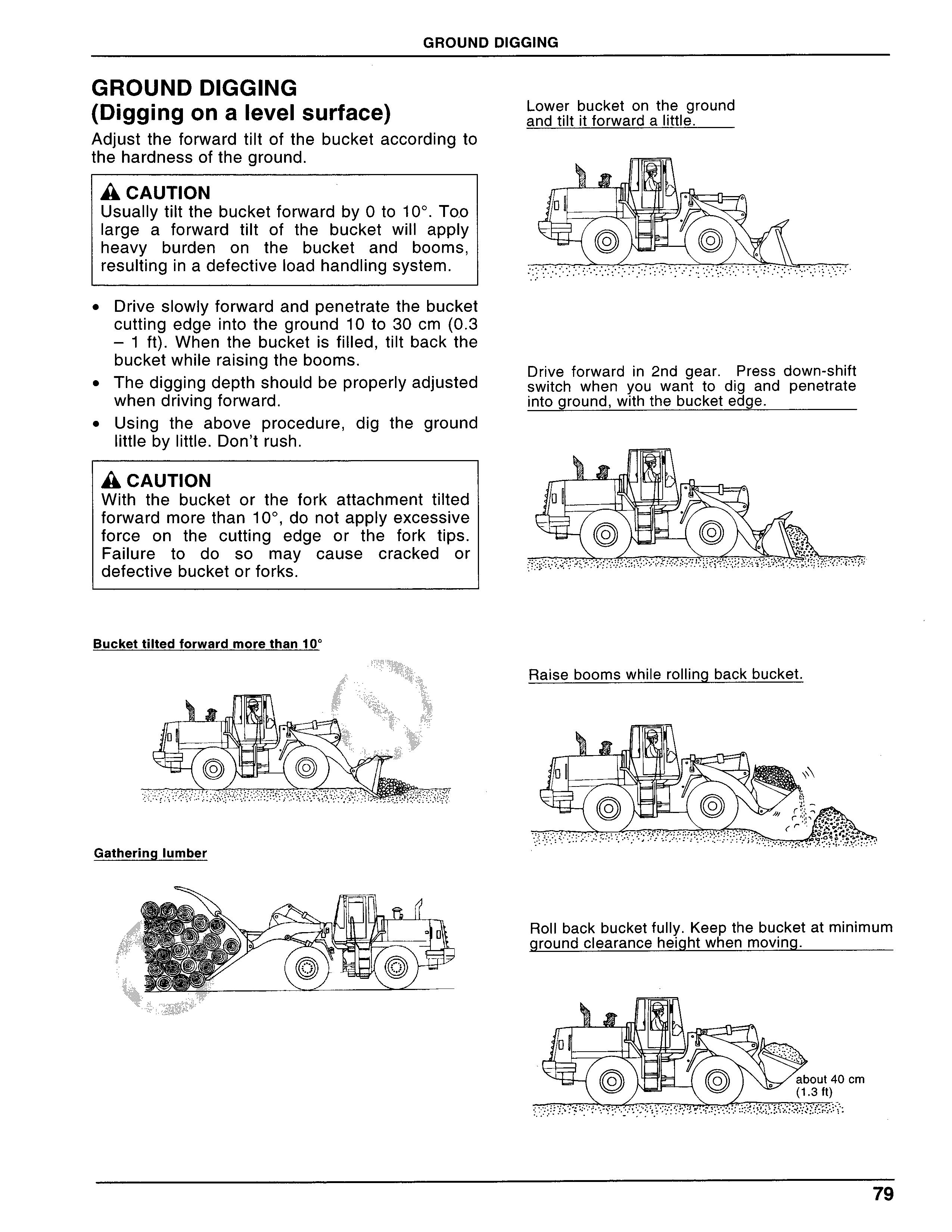

Adjustthe forward tiltofthe bucket accordingto thehardnessoftheground. a CAUTloN

UsuallytiltthebucketforwardbyOtolO0.To,0 large a forward tilt of the bucket wi[lapply heavy burden on the bucket and booms, resultinglnadefective10adhandlingsystem.

・Driveslowlyforwardandpenetratethebucket Cutting edgeintothegroundlOto30cm(0,3 -1ft).When the bucketis fi[Ied,tiltbackthe bucketwhileraislngthebooms.

・ThediggIngdepthshouldbeproperlyadjusted Whendrivlngforward.

・Using the above procedure,dig the ground LittlebylittLe.Don’trush. a CAUTloN

With the bucket or the fork attachment tilted forward morethanlOO,donotapplyexcessive force on the cutting edge or the fork tips. Failure to do so may cause cracked or defective bucket orforks.

Lower bucket on the ground and tiltitforward alittIe.

Drive forwardin2nd gear.Press down-Shift SWitch when you want to dig and penetrate Withthebucketedge. intoground

RoIIbackbucketfulIy.Keepthebucketatminimum

DUMPING a CAUTloN

Clear away any sand or rocks scattered on the groundwhereyouwilIbedrivlngbyuslngthebucket. Thiswillpreventthetiresfrombeingdamaged. a CAUTloN

KeepthebucketIowwhile movlngtOandfromthe 10adinganddumplngareaS.Gos10Wly.Usecareto PreVentthe10adfromfalJingoutofthebucket. a CAUTloN

Do not try to remove clay or muddy earth which has dried on the bucket by banglng the bucket repeatedIyagalnStanyhardsurfaceincludingthe dump truck.Doing so willcause the bucket or attachment to malfunction.Clean the bucket with Waterin such cases.

“Dumplng”refers to operationsin which the10ader isusedtodumpsand,rOCksororeintothebedofa dumptruckorintoahopper. a WARNlNG

●BeforeJifting aIoaded bucket,rOCk the bucketa fewtimesto stabi]izetheIoad.This Wi”help prevent personalinjuryordamage to propertyfrom a”or part ofaIoad fal]ing OutOfthe bucket.

●Proper care should be exerci$ed when approachingadumptruckorhopperwiththe boomsraised high.Drives]owly.Avoidhard braking and $harp turn$;Otherwi$e the 10adermaytipover.

Therearegenerallytwobasic10adcarrylng methods. Select an approprjate methods,COnSidering your WOrkingcondjtions,COSt,andsafetyrequlrementS.

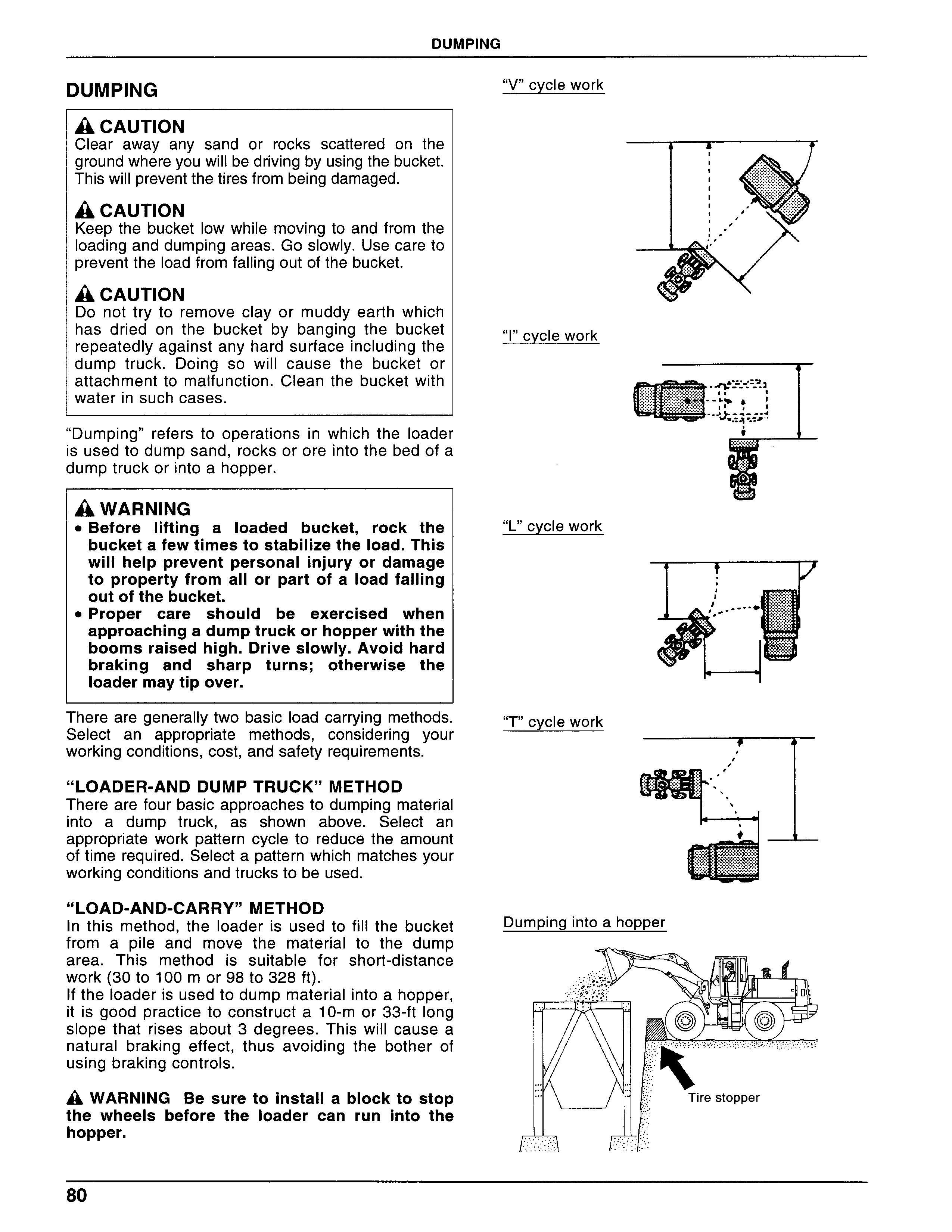

“LOADER・AND DUMP TRUCK”METHOD

Therearefourbasicapproachestodumplngmaterial into a dump truck,aS Shown above.Select an appropriate work pattern cycle to reduce the amount Oftimerequired.Selectapatternwhichmatchesyour WOrkingconditionsandtruckstobeused.

=LOAD-AND-CARRYH METHOD ln this method,the10aderis used to f‖the bucket from a pile and move the material to the dump area.This methodis suitable for short-distance WOrk(30tolOOmor98to328ft). Ifthe10aderisusedtodumpmaterialintoahopper, itis good practicetoconstructalO-m Or33-ft10ng SIope that rises about3degrees.This willcause a naturalbraking effect,thus avoiding the bother of usIngbrakingcontroIs.

▲wARNING the wheeIs before the[oader can runinto the hopper.

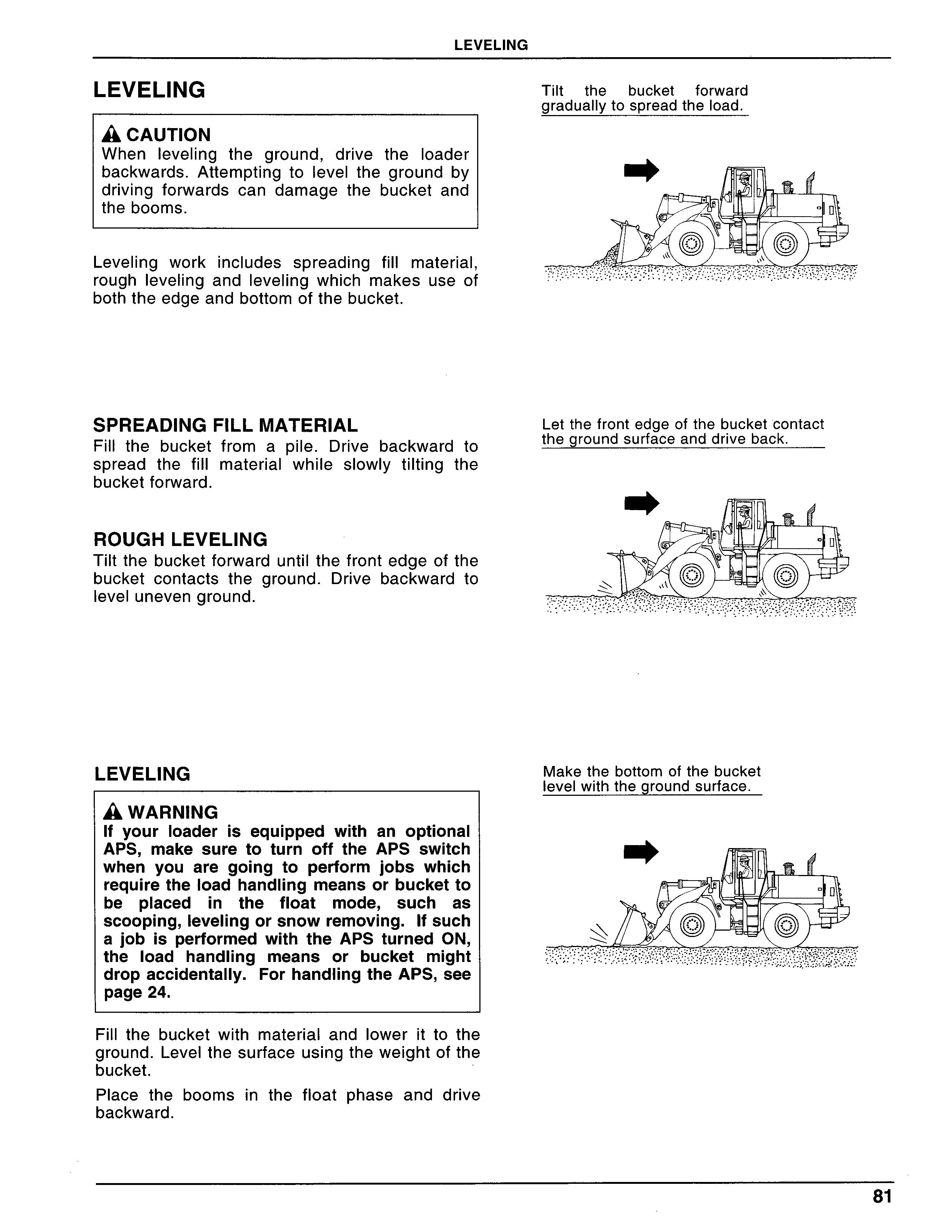

LEVELlNG a CAUTloN

WhenleveLing the ground,drive the10ader backwards,Attempting tolevelthe ground by drivlng forwards can damage the bucket and the booms.

Levellng WOrkincludes spreading fillmaterial, roughleveling andleveling which makes use of boththeedgeandbottomofthebucket.

Tilt the bucket forward gradua”ytospreadtheIoad.

SPREADlNG FlLL MATERlAL

Fillthe bucket from a pIIe.Drive backward to SPread the fi[lmaterialwhile s10Wly tilting the bucket forward.

ROUGH LEVELING

Ti[tthe bucketforward unti]thefrontedgeofthe bucket contacts the ground.Drive backward to levelunevenground.

Letthefrontedgeofthebucketcontact thegroundsurfaceanddriveback.

LEVELING a WARNlNG lf your]oaderi$equlPPed with an optional APS,make sure to turn off the APS switch

When you are golng tO Perform jobs which requlrethe10adhandling meansorbucketto be pLacedin the f10at mOde,SuCh as $COOP]ng,levelingor$nOWremOVing.1f$uCh a jobis performed with the APS turned ON, the load handling means or bucket might dropaccidenta”y.ForhandlingtheAPS,$ee Page24.

FiLlthe bucket with materiaL andlowerit to the ground.Levelthesurfaceuslngtheweightofthe bucket.

Place the booms in the float phase and drive backward.

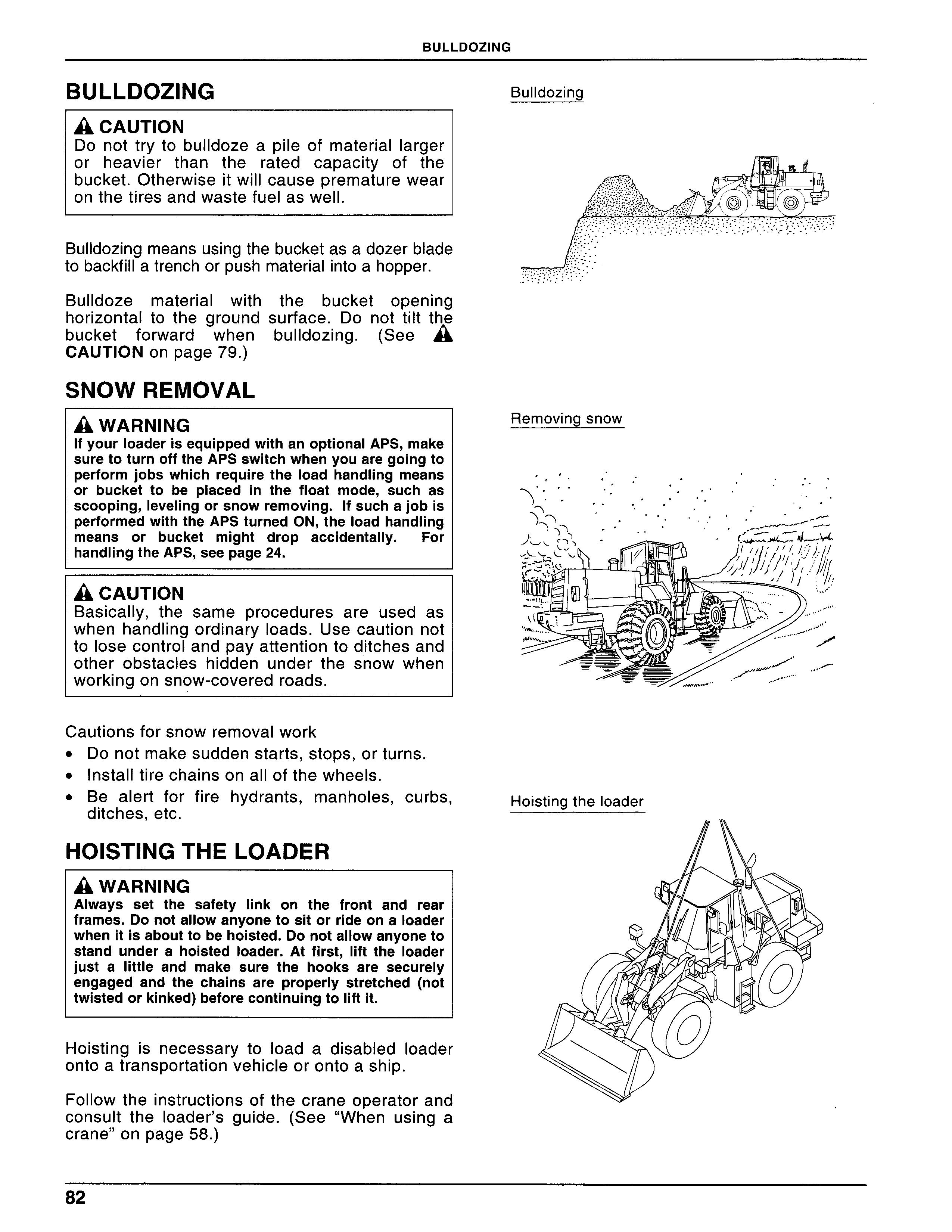

BULLDOZING a CAUTloN

Do not tryto bu”doze a piJe of materiallarger Or heavier than the rated capacity of the bucket.0therwiseitw川causeprematurewear On the tires and waste fuelas well.

BulldozlngmeanSuSlngthebucketasadozerblade tobackfillatrenchorpushmaterialintoahopper.

Bu=doze materialwith the bucket openlng horizontalto the ground surface.Do not tilt the bucket forward when bulldozing.(See A CAUT10Nonpage79.)

SNOW REMOVAL a WARNlNG lfyourloaderisequlPPedwithanoptionalAPS,make SuretOturnOfftheAPSswitchwhenyouaregoingto Perform jobswhich requirethe10ad handling means

Or bucket to be pLacedin the float mode,SuCh a$ SCOOPing,levelingorsnowremovlng.1f$uChajobis PerformedwiththeAPSturnedON,theloadhandling means or bucket might drop accidentally. For handlingtheAPS,SeePage24. a CAUTloN

BasicalLy,the same procedures are used as When handlingordinaryJoads.Usecaution not tolosecontroLandpayattentiontoditchesand other obstac[es hidden under the show when WOrkingonsnow-COVeredroads.

Cautionsforsnow removalwork

・Donotmakesuddenstarts,StOPS,OrturnS.

●Installtirechains on al10fthewheels.

・Be alert for fire hydrants,manholes,Curbs, ditches,etC.

HOIST[NGTHE LOADER

a WARNlNG

AIway$ Set the safetyIink on the front and rear frames.Donotallowanyonetositorrideona10ader

Wheniti$abouttobehoi$ted.Donota”owanyoneto $tand under a hoistedIoader.At fir$t,lift the10ader ju$t aIittIe and make sure the hooks are securely engagedandthechain$arePr?Perly$tretChed(not twistedorkinked)beforecontinulngtOljftit.

HojstinglS neCeSSary tOload a disabled[oader OntOatranSPOrtationvehicleorontoaship.

Fol10Wtheinstructionsofthecraneoperatorand COnSult theloader’s guide.(See“When using a Crane”onpage58.)

Bu”dozing

Removing snow

Hoistingthe10ader

Adjusting Bucket Autoleveler

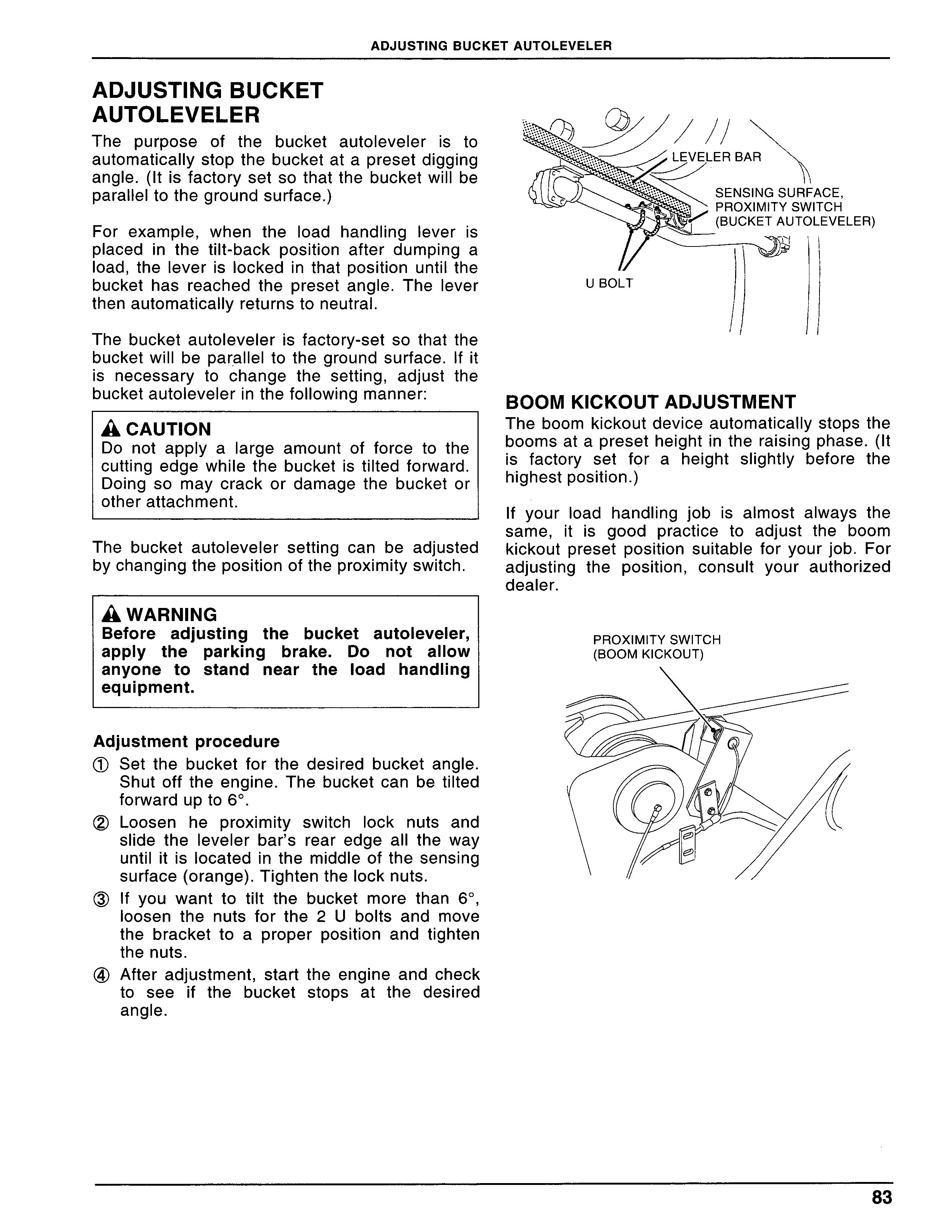

The purpose of the bucket autoleveler is to automaticallystopthebucketatapresetdigglng angle.(ltisfactorysetsothatthe bucketw‖be Para[le[tothegroundsurface,)

For example,When theload handIingleveris Placedin the tilt-back position after dumplng a 10ad,the Leveris10Ckedin that position untiLthe bucket has reached the preset angle.Thelever thenautomaticallyreturnstoneutral. e th圧仙

The bucket autoleveleris factory-Set SO that bucketwillbe para]leLtotheground surface. is necessary to change the setting,adjust bucketautoleveIerinthefo”ow[ngmanner: a CAUTloN

Do not apply a Large amount of force to the Cutting edge while the bucketis tilted forward. Doing so may crack or damage the bucket or Otherattachment,

The bucket autoleveler setting can be adjusted bychanglngthepositionoftheproximityswjtch. a WARNlNG

Before adjusting the bucket autoleveler, apply the parking brake.Do not a]10W anyone to stand near the load handling equlPment.

Adjustment procedure

①Set the bucket for the desired bucket angle. Shut offthe englne.The bucketcan be tilted forwardupto60.

②Loosen he proximity switch10Ck nuts and Slide the Leveler bar’s rear edge allthe way untiIitis10Catedin the middleofthesenslng Surface(Orange).Tightenthelocknuts.

③lf you want to tilt the bucket more than60, loosen the nuts for the 2 U bolts and move the bracket to a proper position and tighten the nuts.

④Afteradjustment,Start the engine and check to seeif the bucket stops at the desired angle.

BOOM KlCKOUT

Adjustment

Theboom kickoutdeviceautomaticallystopsthe boomsatapresetheightintheraisingphase.(lt is factory set for a height slightly before the highestposition.) lf yourload handling jobis almost always the Same,itis good practice to adjust the boom kickout preset position suitable foryourjob・For adjusting the position,COnSuIt your authorized dealer.