5 minute read

6

Rex Chainbelt Inc. warrants products of its manufacture against defects in workmanship and material for a period of six months from date of shipment to customer and in consequence of this warranty, any componant part or parts of such products proving defective within the above specified time will be repaired or replaced F.O.B. factory, providing such parts are returned, transportation prepaid, to the factory and found defective by Rex Chainbelt Inc. This warranty will not apply to any product which shall have been repaired or altered outside of Chainbelt's factory in any way so as, in Chainbelt's judgement, to affect its stability, or reliability, nor which has been subjected to misuse, negligence or accident.

Rex Chainbelt's liability as a manufacturer is limited to the replacement of defective parts, and no allowance will be made for labor performed, delays or expense incident to the replacement of defective parts nor for any consequential damages or injuries.

Rex Chainbelt Inc. assumes no responsibility for engines, electrical equipment or any other equipment and accessories not manufactured by Rex Chainbelt Inc. beyond the warranty of the manufacturer of such equipment or accessories.

Rex Chainbelt Inc. reserves the right to make changes in design from time to time as are deemed desirable without incurring the obligation to furnish them for machines previously sold or shipped.

CHECK FOR SHORTAGE OR DAMAGE

Upon receipt of equipment, a visual inspection should be made. While the equipment is in transit, any delay or damage to it is the responsibility of the carrier, therefore, before unloading from car or truck, a check for shortages or damages should be made. In the event of either, a representative of the carrier must make a full description of the shortage or damage on the freight bill. Any claims for shortages or damages must be made by you to the transportation company. All machines carry a machine Serial Number. The machine Serial Number Plate is located on the left side of the steering wheel mount. Always supply the machine Serial Number when referring to machine or ordering repair parts. Order repair parts through your Rex Distributor being specific on shipping instructions.

OPERATION

Before starting — a complete lubrication check of the machine should be made in accordance with the lubrication chart; engine oil level, radiator coolant, hydraulic oil, air cleaner, etc. All grease fittings should be lubricated.

A general tightening of all nuts and bolts should be made, inspect fuel lines, hydraulic lines and fittings for tightness to prevent leaks. Tire chart must be checked for minimum and maximum pressure for ply used. Refer to tire chart. Fill fuel tank in accordance with engine manufacturer's specifications shown in engine manual.

Also before starting, the operator should familiarize himself with the proper starting and engine operating procedure as outlined in the engine manual.

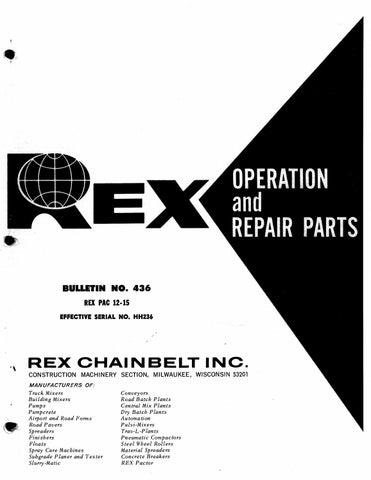

TO START (FIGS. 2 & 2A)

1. Set parking brake. Push brake down to set.

2. Place the 4-speed transmission in neutral.

3. Turn key and start engine. Use throttle-shift control to increase engine speed for warm-up.

4. Place throttle-shift control in neutral.

5. Select and shift to desired gear in 4-speed transmission.

6. Release parking brake.

7. Move throttle-shift control in desired direction.

STEERING

The Rexpac is directionally controlled by means of a standard steering wheel turned in the conventional manner. The steering wheel is connected directly to an ORBITROL rotary servo control. A hydraulic pump, belt driven from the engine provides the oil flow and pressure to the servo control at the steering wheel and is directed to the power steering cylinder at the front by means of two hydraulic lines.

400011 .

REVERSE SHIFT

REVERSE THkOTTLE 11111. NEUTRAL

FORWARD SHIFT

,'31``---.FORWARD THROTTLE

CLUTCH ENGAGEMENT BUTTON ("IN") — ENGAGED ("OUT") — DISENGAGED

4-SPEED TRANSMISSION

FIGURE 2A Ser. No. -HH 236 & Up

matically reverts to a manual steering system. In this condition, the fluid metering sections becomes a rotary band pump and directs fluid to actuate the hydraulic steering cylinder when the steering wheel is manually operated.

It is recommended that in the event of an ORBITROL unit failure, the entire unit be replaced and the old unit be returned to the factory for repairs.

BRAKES

Hydraulic foot operated service brakes and a hand operated mechanical parking brake are provided. The operator's foot brake pedal actuates a master cylinder that in turn operates the wheel cylinder and shoes in the two rear brake assemblies, one on each pair of wheels. The brake shoes are self-adjusting and require no adjusting.

The parking brake is hand operated and is applied when the handle, to the operator's right side, is down in a horizontal position, parallel to the floor. When the handle is in a vertical position, the brake is released. The nob of the handle may be turned to shorten the linkage and insure a tight brake action.

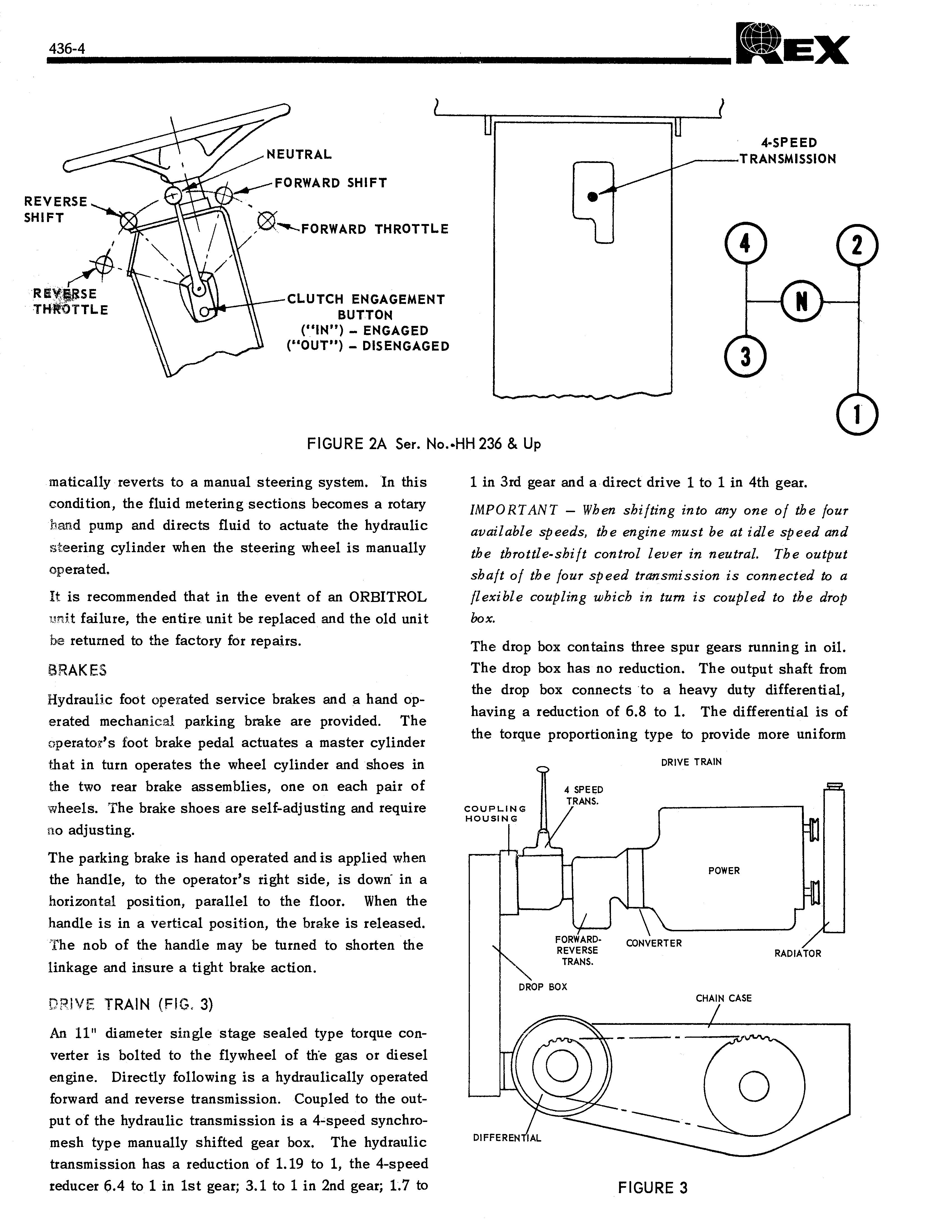

tRIVE TRAIN (FIG. 3)

An 11" diameter single stage sealed type torque converter is bolted to the flywheel of the gas or diesel engine. Directly following is a hydraulically operated forward and reverse transmission. Coupled to the output of the hydraulic transmission is a 4-speed synchromesh type manually shifted gear box. The hydraulic transmission has a reduction of 1.19 to 1, the 4-speed reducer 6.4 to 1 in 1st gear; 3.1 to 1 in 2nd gear; 1.7 to 1 in 3rd gear and a direct drive 1 to 1 in 4th gear.

IMPORTANT — When shifting into any one of the four available speeds, the engine must be at idle speed and the throttle-shift control lever in neutral. The output shaft of the four speed transmission is connected to a flexible coupling which in turn is coupled to the drop box.

The drop box contains three spur gears running in oil. The drop box has no reduction. The output shaft from the drop box connects to a heavy duty differential, having a reduction of 6.8 to 1. The differential is of the torque proportioning type to provide more uniform

DRIVE TRAIN

COUPLING HOUSING

4 SPEED TRANS.

,r-

1

FORWARD- REVERSE TRANS.

DROP BOX POWER

CONVERTER

CHAIN CASE RADIATOR