3 minute read

6.6.2 Injector – Removal and installation

from MTU 12V4000M23F_ 12V4000M23S_ 16V4000M23F_ 16V4000M23S_ MS150068_01E Diesel Engine Operating Instruc

Preconditions

☑Engine is stopped and starting disabled.

Special tools, Material, Spare parts

Designation / Use Installation/removal jig Milling cutter Torque wrench, 0.5-5 Nm Torque wrench, 10-60 Nm Ratchet adapter Torque wrench, 60-320 Nm Ratchet adapter Assembly paste(Optimoly Paste White T) Assembly compound (Kluthe Hakuform 30-11C/Emulgier) Engine oil O-ring

WARNING Fuels are combustible.

Risk of fire and explosion!

• Avoid open flames, electrical sparks and ignition sources. • Do not smoke. Part No. Qty.

F6789889 F30452739 0015384230 F30452769 F30027340 F30452768 F30027341 40477 X00059351 1 1 1 1 1 1 1 1 1

(→ Spare Parts Catalog)

Preparatory steps

1. Shut off fuel supply to engine. 2. Remove cylinder head cover (→ Page 176).

Removing injector

1. Disconnect connectors on injector.

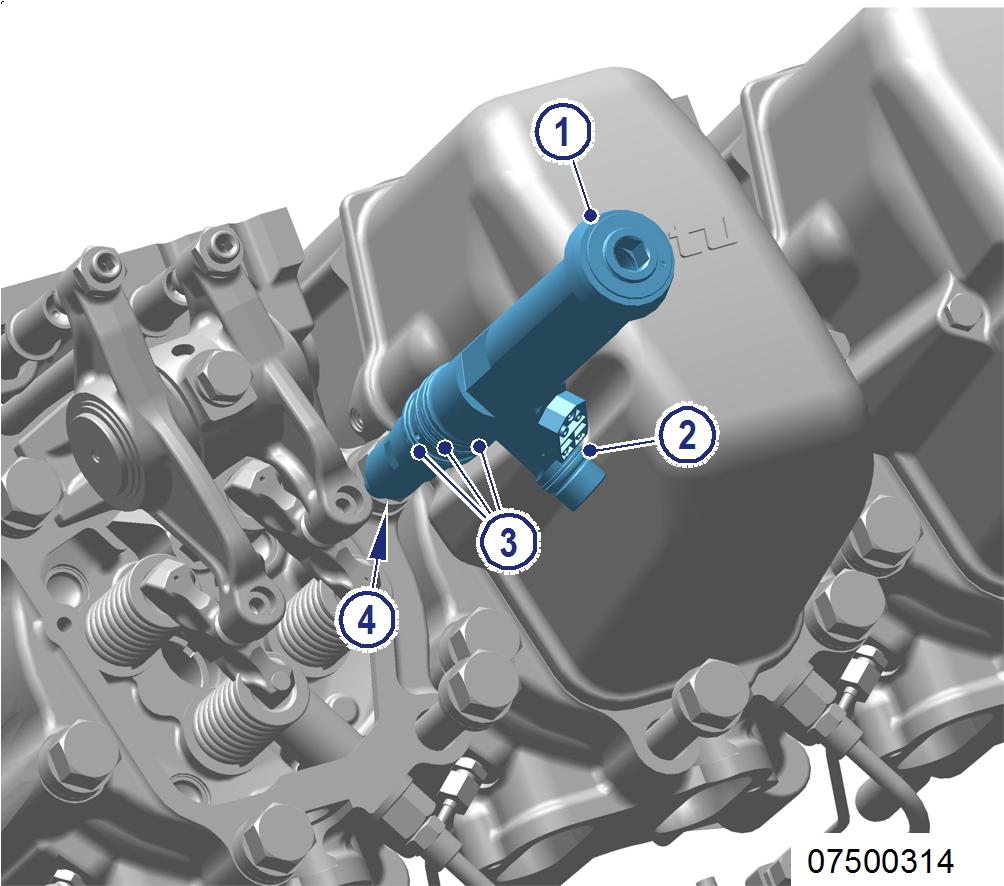

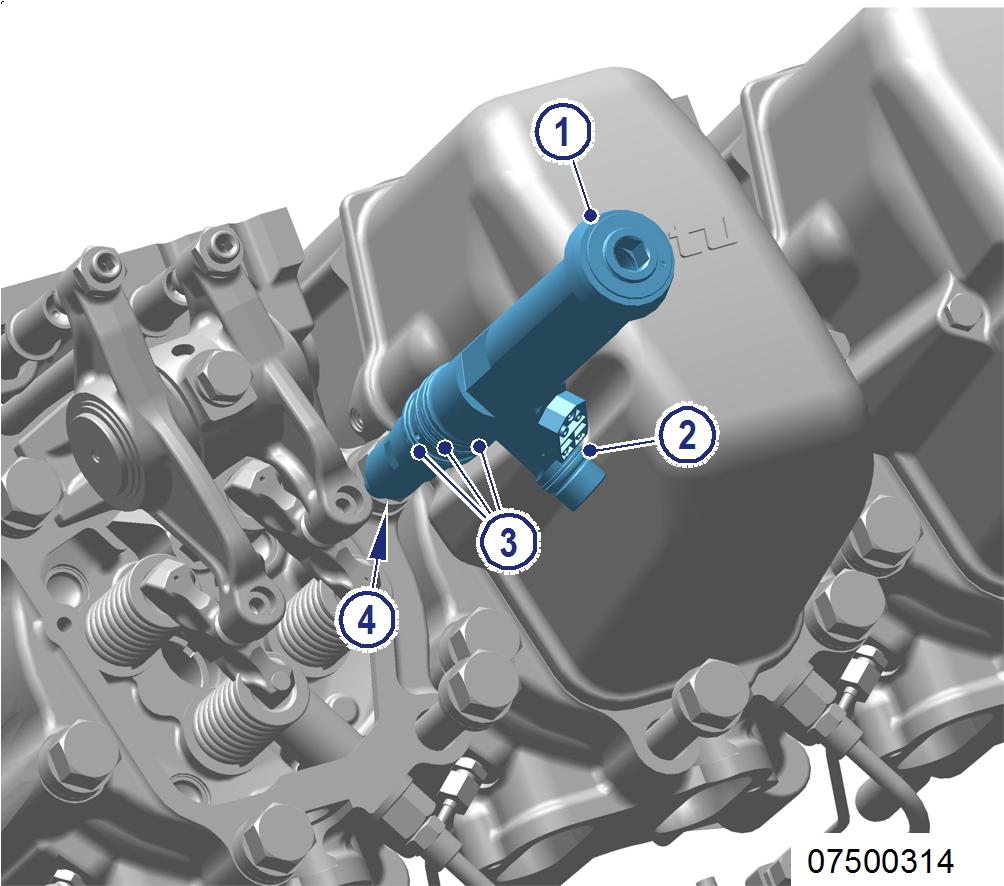

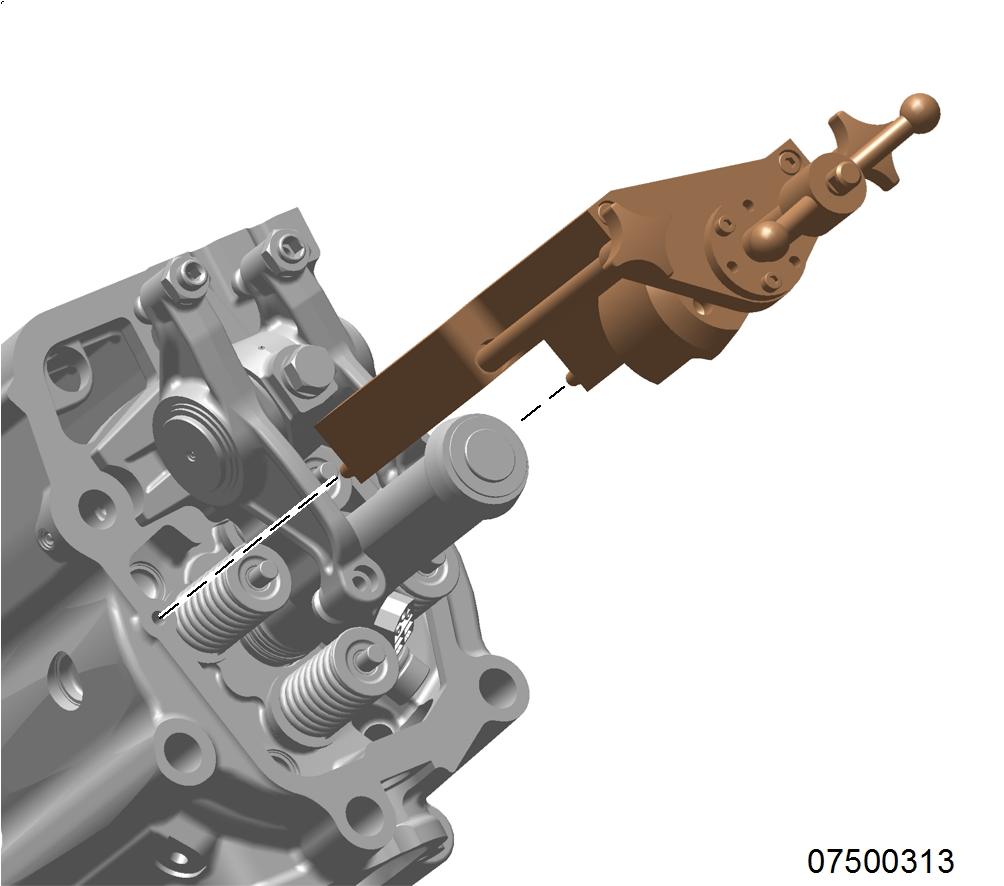

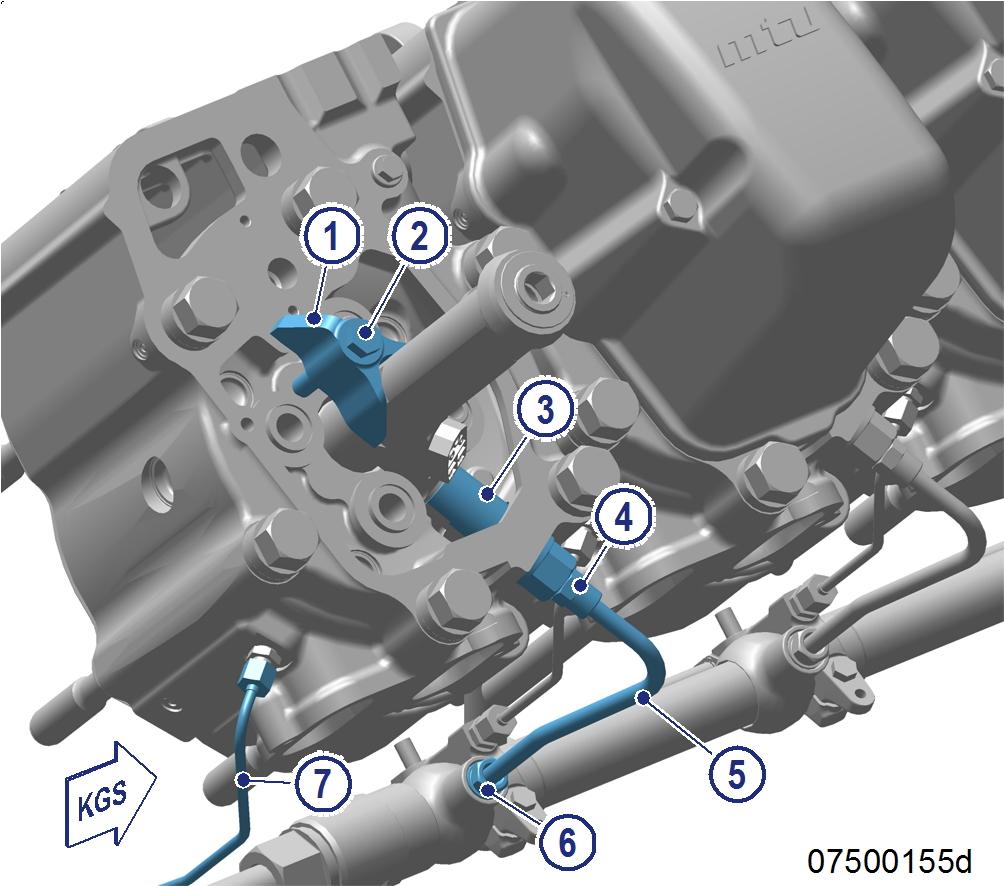

2. Remove HP fuel line 4). Note: While the adapter is removed, the injector is drained. 3. Remove adapter (3). 4. Remove screw (2) and take off hold-down clamp (1).

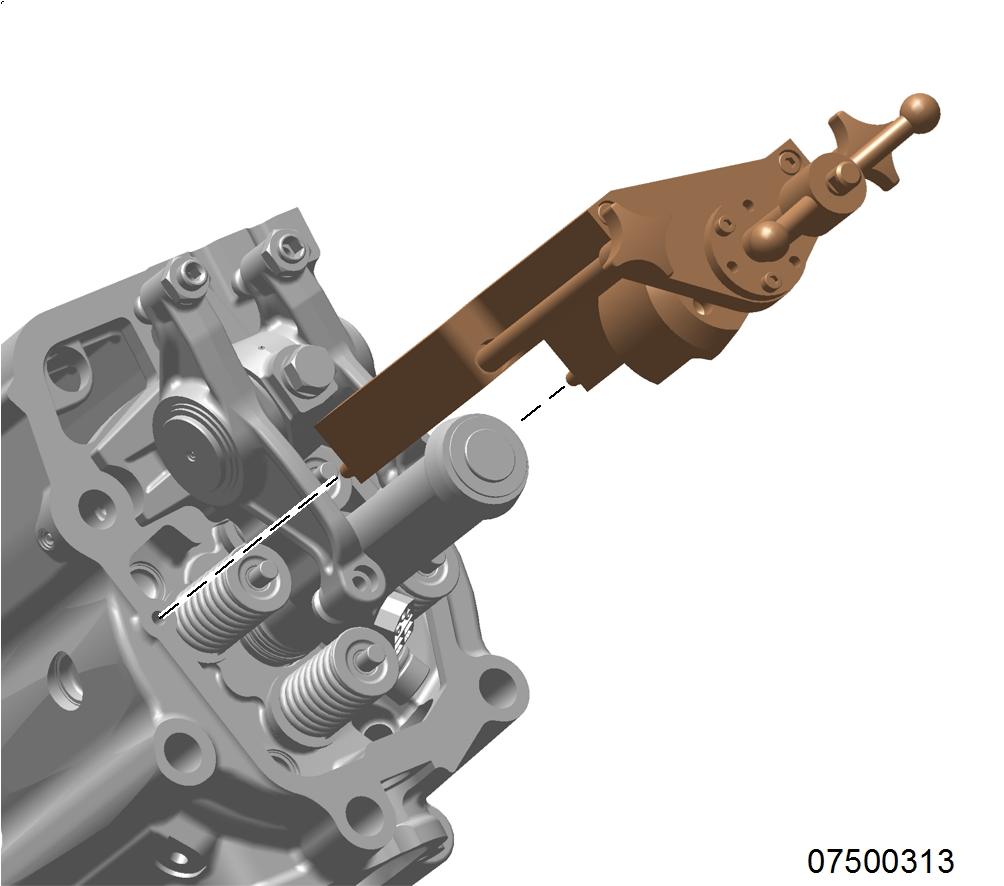

5. Install installation/removal jig on cylinder head. 6. Remove injector with installation/removal jig. 7. Remove installation/removal jig.

8. Remove sealing ring (4) from injector or use a self-made hook to take it out of the cylinder head. 9. Remove O-rings (3), O-ring (2) and damper ring (1) from injector. 10. Clean all mating and sealing surfaces. 11. Cover all connections and bores, or seal with suitable plugs.

Installing injector

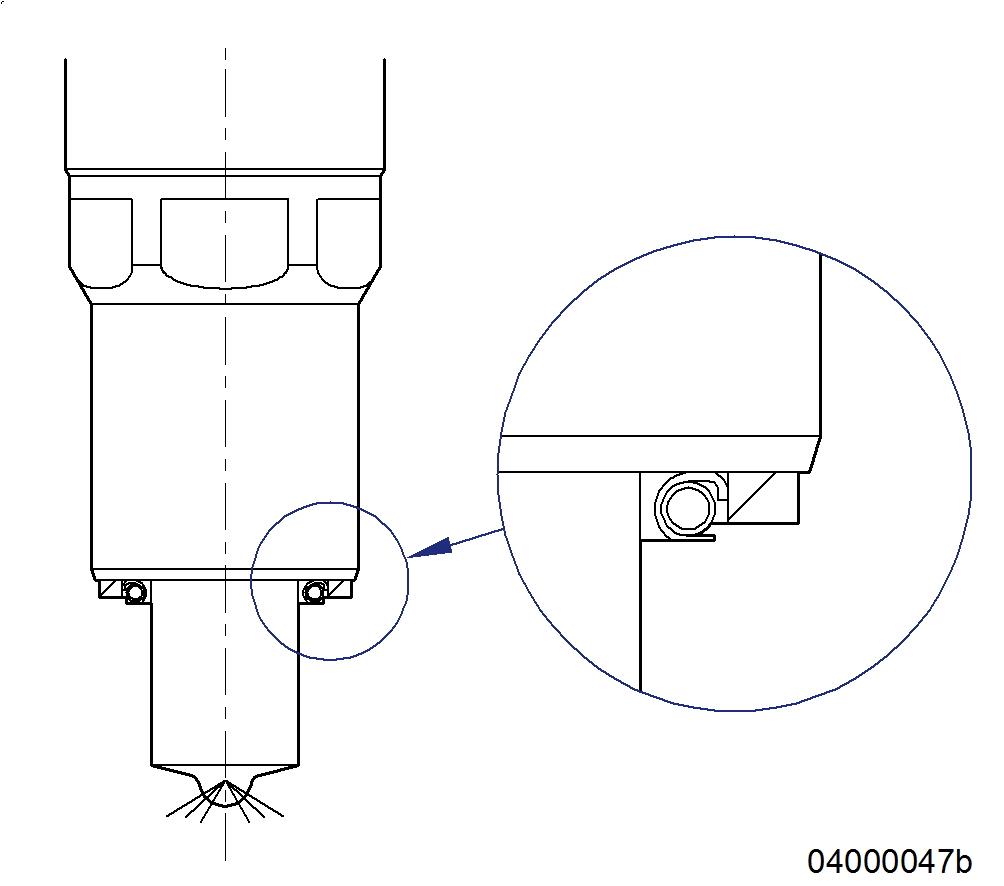

1. Remove plug before installing the injector. (Do not remove the plug from the HP line before installing the adapter). 2. Coat injector with assembly paste at the seat of the nozzle retaining nut. 3. Fit new sealing ring (included in the scope of delivery of the injector) with assembly compound on injector, observe installation position of sealing ring.

4. Fit new O-rings (3) (included in the scope of delivery of the injector), O-ring (2) and damping ring (1) onto the injector and coat with assembly compound (Kluthe Hakuform 30-11C/Emulgier). 5. Remove oil carbon from sealing face on cylinder head and protective sleeve with milling cutter. 6. Insert injector into cylinder head, ensuring that the HP line adapter is correctly aligned.

7. Press in injector with installation/removal jig. 8. Remove installation/removal jig.

9. Coat screw head mating face (2) and thread with engine oil.

10. Fit hold-down clamp (1) in the correct position and use torque wrench to tighten screw (2) to the specified initial tightening torque.

Name

Screw Size Type M12 Preload torque Lubricant

(Engine oil) Value/Standard 5 Nm to 10 Nm

Note: Ensure special cleanness. 11. Coat thread and sealing cone of adapter (3) with engine oil. 12. Install adapter (3) and use torque wrench to tighten to the specified initial tightening torque.

Name

Adapter Size Type Preload torque Lubricant

(Engine oil) Value/Standard 5 Nm to 10 Nm

13. Tighten screw (2) with torque wrench to the specified tightening torque.

Name

Screw Size Type M12 Tightening torque Lubricant Value/Standard 100 Nm + 10 Nm

14. Tighten adapter (3) with torque wrench to the specified tightening torque.

Name

Adapter Size Type Tightening torque Lubricant Value/Standard 100 Nm + 10 Nm

Note: Ensure special cleanness. 15. Coat thread and sealing cone of HP line (5) with engine oil. 16. Mount jacketed HP line (5) and use torque wrench to tighten to the specified torque. Tightening sequence: 1 Adapter (4) 2 Rail (6)

Name

Union nut / thrust screw Size Type Tightening torque Lubricant Value/Standard 40 Nm + 5 Nm

17. Fit connectors on injector. Note: Failure to reset drift compensation (CDC) will void the emissions certification. 18. Reset drift compensation (CDC) with DiaSys® (→ E531920/...). If DiaSys® is not available, contact Service.

Final steps

1. Install cylinder head cover (→ Page 176). 2. Open fuel supply to engine.