2 minute read

Emission Control System (ECS)

Diesel Oxidation Catalyst (DOC)

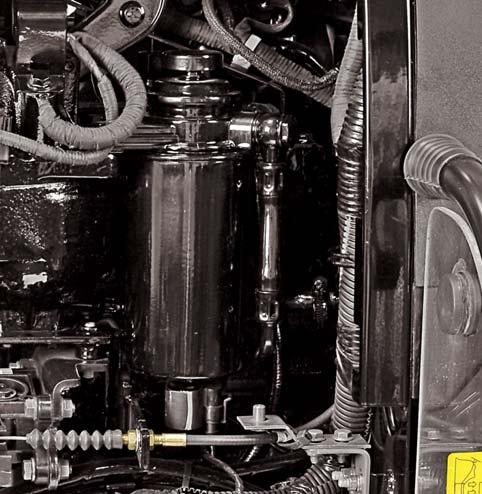

A Diesel Oxidation Catalyst (DOC) is an emission control device which uses a chemical process in order to break down pollutants from diesel engines in the exhaust stream, turning them into less harmful components. It is a part of the exhaust system which is fitted before the exhaust muffler.

Under-Hood Muffler (UHM)

An Under-Hood Muffler (UHM) is an emission control device which reduces exhaust noise by absorption. It is a part of the exhaust system which can be found fitted next to the DOC.

NOTE:

Avoid long duration idling than the recommended idling time.

Avoid frequent cold starts.

Periodic inspection and tightening of mounting hardware is typically appropriate.

The DOC may be damaged by excessive fuel or oil consumption or a poorly maintained engine. Always use recommended fuel and lubricating oil for your engine.

Exhaust system involves high temperature. Wait until the engine cools down to carry out any maintenance work in the exhaust system or nearby area.

Never operate the tractor without the DOC and UHM.

Never operate the tractor with improperly fitted or physically damaged DOC and UHM

Never let the water into the exhaust system which may damage the exhaust system.

Service your vehicle periodically as recommended.

Clean Diesel Fuel

Diesel Fuel should be poured so that no sediment can enter the tractor fuel tank whilst it is being filled. Fuel storage facilities should allow for the periodic removal of sediment from the bottom of the storage tank.

The Diesel fuel filters will remove any sediment still present in the fuel and ensure that the fuel reaching the injection pump and injectors is free of impurities. The fuel filter should be serviced regularly to ensure maximum engine reliability.

It is recommended to use diesel fuel specified to ASTM D-975 D2 S15, EN 590 (ULSD- 15 PPM S LEVELS)

Bleeding the Fuel Filter

The presence of air in the fuel can cause fuel stoppages. The air should be completely bled so that the machine operates satisfactorily. Loosen the banjo bolt (B) on FIP side of filter. Operate hand primer (A) on fuel filter till you get the flow of fuel free of air from the banjo. Re-tighten the banjo bolt (B).

Bleeding the Fuel Injection Pump

Loosen the High-Pressure pipes at the nozzle end. Operate the hand primer (A) on fuel filter till you get a streamline flow of fuel from the High-Pressure pipes. Retighten the High-Pressure pipes and start the engine. Observe till the engine runs smoothly and then shut-off till further use.

Fuel Tank and Fuel Pipes

Fill the tank each time the tractor finishes the days work. This prevents condensation inside the fuel tank. Check regularly to ensure all fuel pipe unions are tight and in good order. Ensure that vent hole provided on fuel tank cap is not choked. Water or dirt settled in the bottom of fuel tank should be drained daily, before starting the engine by loosening the drain cock till clean diesel flows.