4 minute read

Control and operation

stalled), S100-5 or S100-6 (optional). For location of emergency stops, refer to section «Electrical system» in chapter 5 of this manual.

Advertisement

In the two cases:

The main circuit breaker Q2A opens.

Thelowvoltagesystem(heater,airconditioning,batteriescharger,etc.)isdisconnected.

The electric motor is stopped.

If the machine has a 45° access ladder, the ladder is automatically lowered when an emergency stop is operated.

For machines with option «Vessel - excavator data link», if you push an emergency stop:

The machine sends the information «Remote trip to CB» to the vessel.

Caution!

Use this shut off method only in emergencies.

After a shut down via an emergency stop button, you must unlock it before attempting to restart.

Safety controls for hydraulic pumps

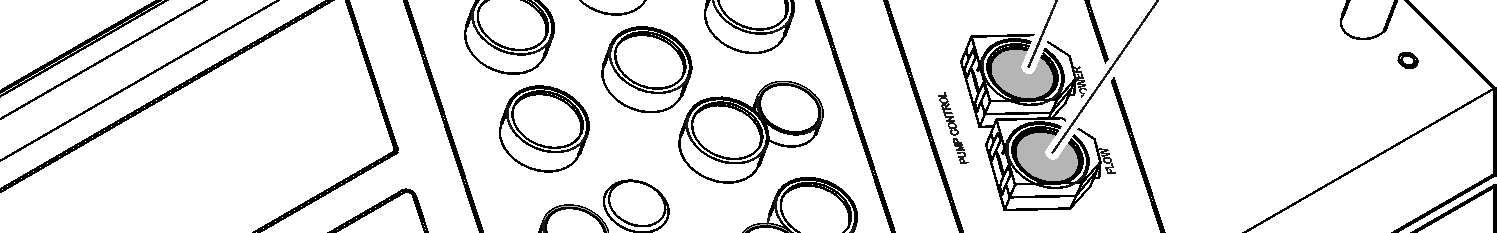

Pumps power safety control

During normal operation of the excavator, the electronic horsepower control continuouslyadjuststhepumpflowtothepressurelevelof theworkingcircuits.Ifatrouble occurs in the circuit of the regulator, the pumps are swivelled back to minimal flow.

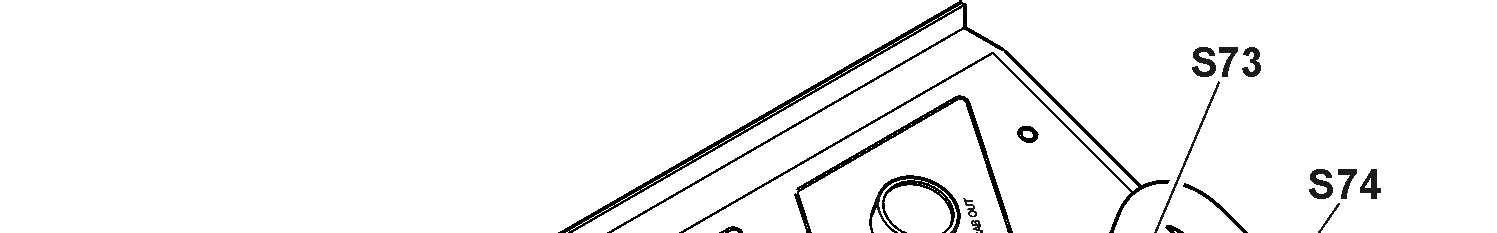

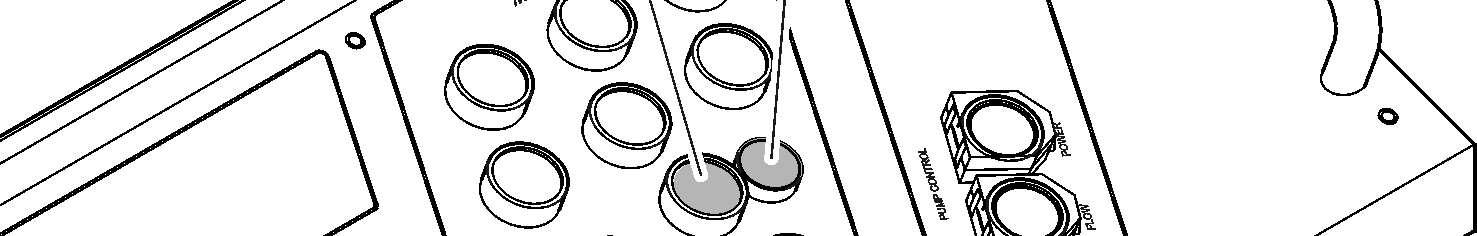

However it remains possible in this case to carry on the working with the machine (with somewhat reduced power) by pushing the button S73

Pumps flow safety control

Duringsafetyoperation,apresetvalue fortheflow ofthehydraulic pumpsisactivated by pushing the button S74

Safety controls for electric system

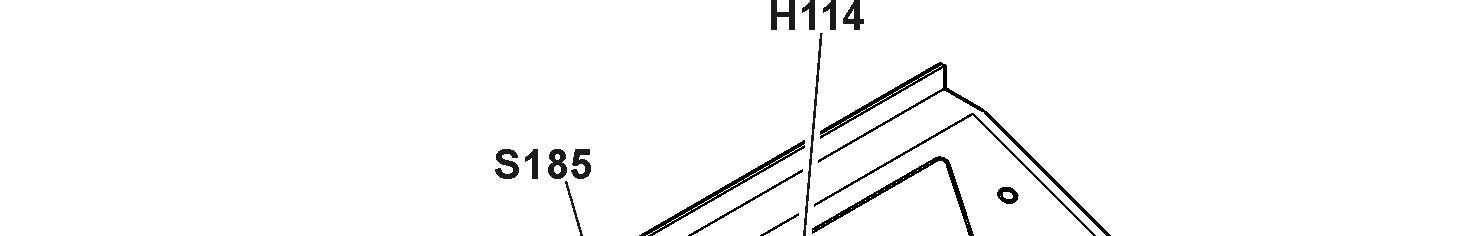

H114 Safety batteries

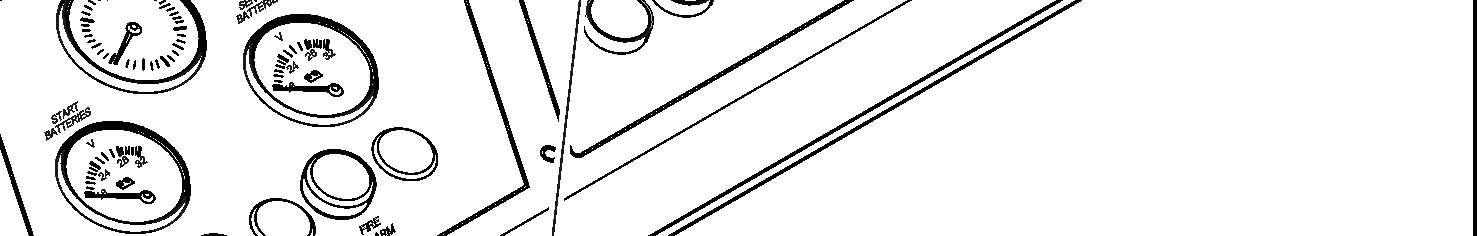

Electric system voltage monitoring

S118 Voltage monitoring relay

S185 Safety 24V

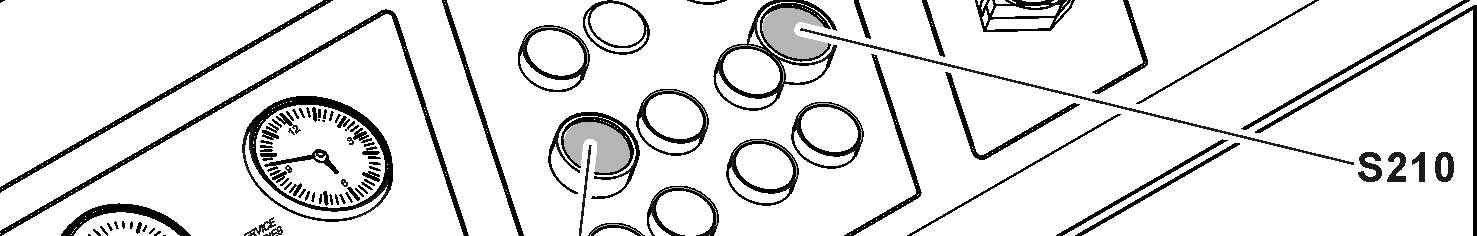

S210 Reset default end sensor S1/S2

The excavator has an overvoltage and undervoltage protection.

If an overvoltage or undervoltage is detected in the electric circuit: The electric motor is stopped. The indicator light in the button S118 comes on.

Push the button S118 to acknowledge the information.

Battery power supply

If the power supply from theelectric plant stops, you can switch to the battery of the copyright © Liebherr-Mining Equipment Colmar SAS 2020

Setting the machine into operation excavator to supply the service system and to lower the attachment if necessary. Push the button S185. Power supply is switch to the battery. The indicator light H114 comes on.

S1 and S2 doors protection

The excavator has protection on high voltage box S1 and low voltage box S2

If the door on S1 or S2 is open: The electric motor is stopped. The indicator light in the button S210 comes on. Push the button S210 to acknowledge the information.

Tow the machine

It is not permitted to tow the machine.

If you must move orrecover a defective or unserviceable machine, contact Liebherr customer service.

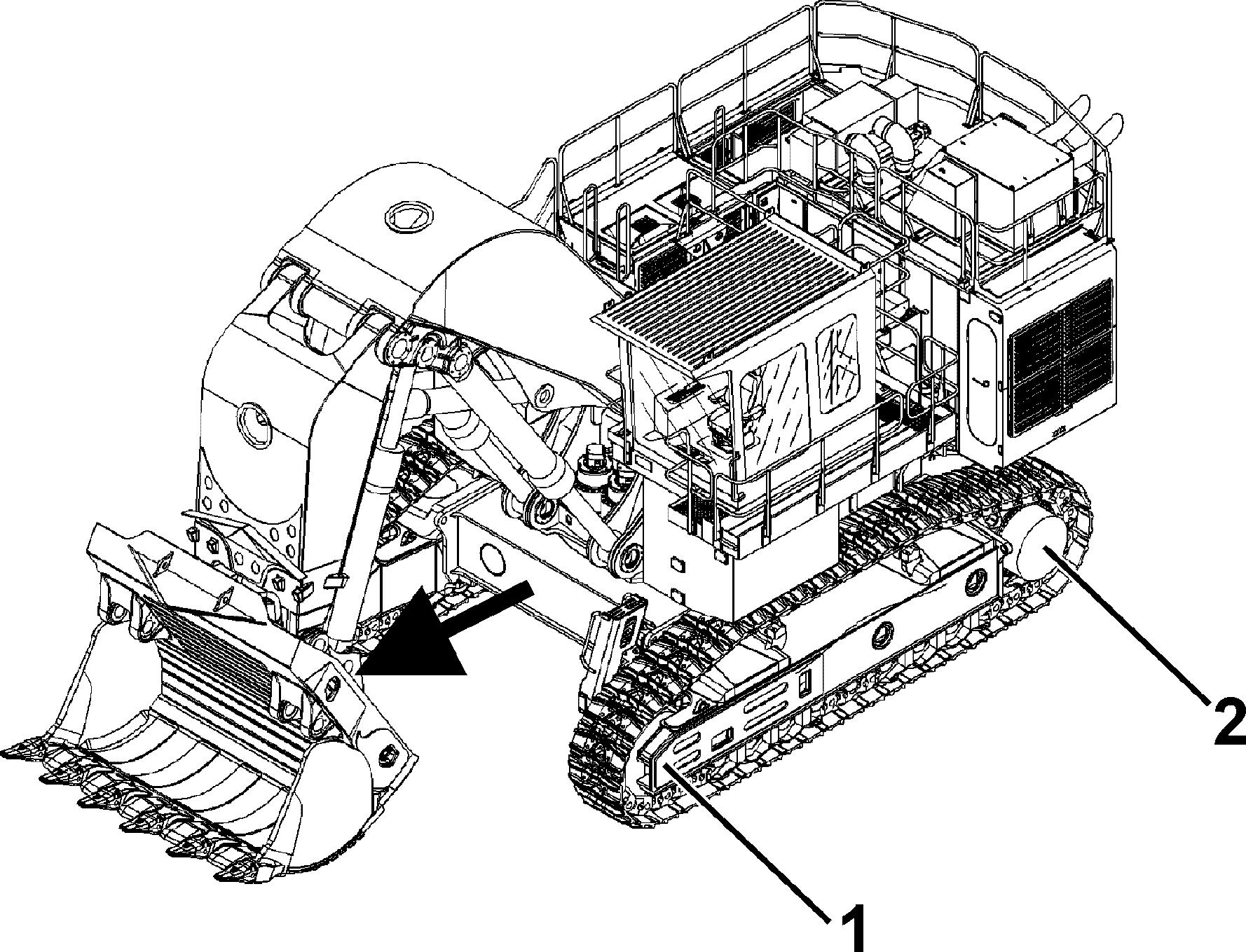

3.3.4Travel movements

Travel straight ahead

2

Caution!

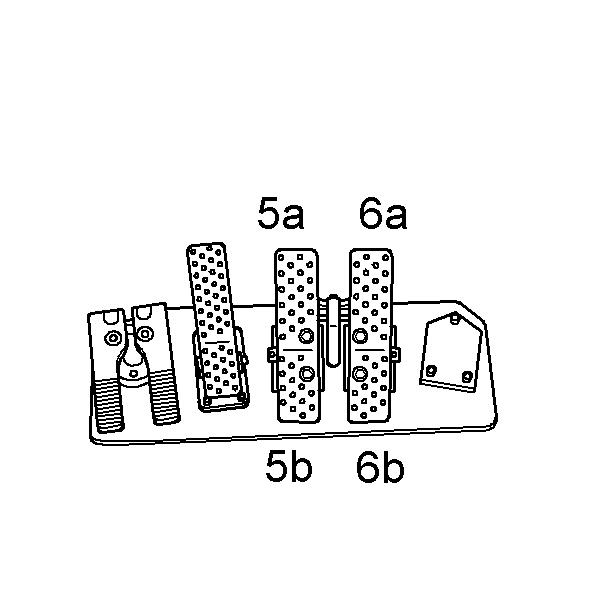

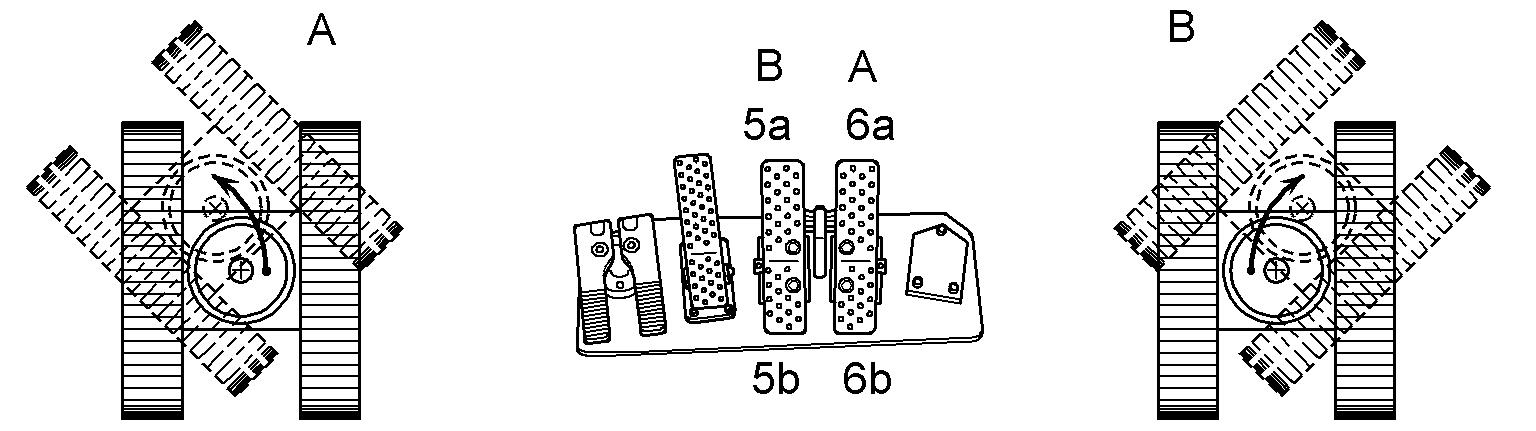

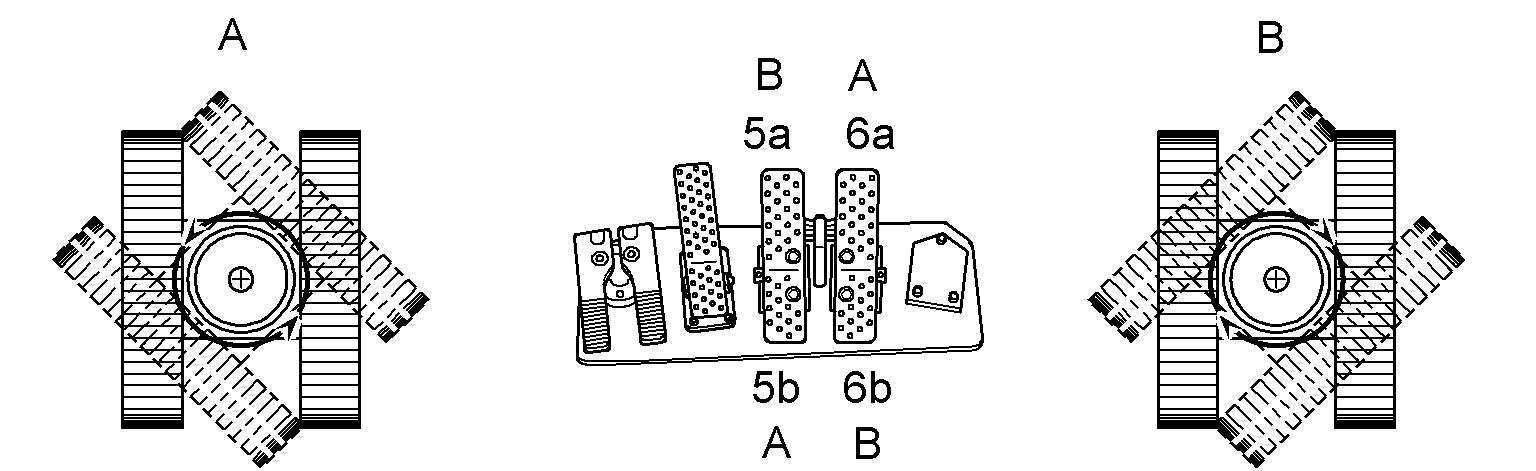

6a for the left travel gear

Pedal for the right travel gear

Whenyoutravelforward,theuppercarriagemustbeturnedtotheundercarriageto have the idler 1 at the front and the sprocket 2 at the rear.

Travel forward copyright © Liebherr-Mining Equipment Colmar SAS 2020

Push the two pedals forward (5a and 6a).

Travel rearward

Caution!

Before you travelrearward, make sure that you can safely go into the area behind you.

Push the two pedals down (5b and 6b).

Turn on the spot

Turn left (A)

Push the leftpedal down (5b) and at the same time pushthe rightpedal forward (6a).

Turn right (B)

Pushthe right pedaldown(6b) andat thesame time pushtheleft pedalforward (5a).

Turn with one track chain

Turn to the left (A)

Push the right pedal forward (6a).

Turn to the right (B)

Push the left pedal forward (5a).

Note!

If possible, do not turn rearward for the preservation of the track components.

Control the speed

TheS21switchcontrolsthetravelspeed.Thetravelmotorscanbeoperatedintwo different positions:

Normal drive (position 1):

Maximum tensile force of the two travel gears at moderate speed.

Fast drive (position 2):

Reduced tensile force of the two travel gears at maximum speed.

Push the S21 switch.

The LED 1 in the switch comes on.

Transfer from normal drive to fast drive is operated.

Whiletravelling,themachinewillautomaticallyswitchfromnormaldrivetofastdrive asthegroundconditionspermit.Afterthetransfertofastdrive,theLED2comeson. If the ground conditions become more difficult again, the system will automatically switch from fast drive to normal drive. Thus, the LED 1 comes on.

Push S21 switch again.

The LED 1 in the switch goes off.

Transfer from normal drive to fast drive is deactivated.

When the S21 switch is switched off, the travel motors stay in position 1

Brake the machine

Stop the machine while travelling

The hydrostatic travelling mechanism of the machine also operates as a service brake.

Release the travel pedals. The pedals go back to the neutral position. The travel gear stops. The machine stops.

When the travel pedals are in the neutral position, the hydrostatic travelling mechanism prevents the machine from rolling off.

Caution!

The machine stops suddenly if you release the travel pedals quickly! Always fasten the safety belt before you start the machine.

Apply and release the travel brake

The travel brake is applied by default when you start the machine. When the travel pedals are in the neutral position, the travel brake is applied automaticallyafterafewseconds.Inthiscase,youcancontinuetomovetheattachment. The travel brake is released when you push the travel pedals.

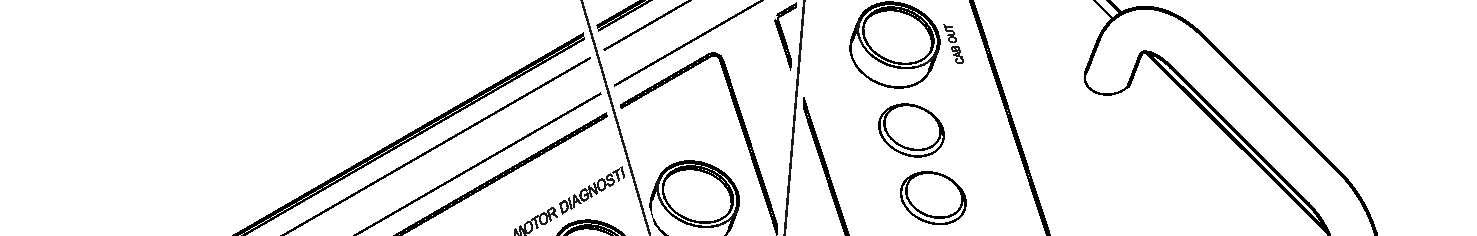

Depending on the machines, you must also use the S354 (SF) button, which is installed on the keyboard.

Push the S354 (SF) button. The LED in the button goes off. The travel brake is released. The undercarriage is unlocked. Push the S354 (SF) button again. The LED in the button comes on. The travel brake is applied. The undercarriage is locked. In this case, the travel brake stays applied when you push the travel pedals. The travel control valves cannot be moved.

The travel brake is applied if the safety lever is up or the access ladder is down or the service trap is down.

Cable reel (optional equipment)

The cable reel winds and unwinds automatically the supply cable.

H140 The cable reel is at the end

H141 The cable reel is near the end

H142 Cable reel failure

Ifthecablereelisneartheend,thewarninglightH141comesonandthebuzzeroperates for 1 second.

Caution!

Risk of damage to the machine.

If the cable reel is at the end, the warning light H140 comes on and the buzzer operates for 1 second.

Do not travel more in direction of the end.

Caution!

Risk of damage to the machine.

If there is a cable reel failure, the warning light H142 comes on and the buzzer operates for 5 seconds.

Stop the machine immediately and tell the maintenance personnel.

1

2 copyright © Liebherr-Mining Equipment Colmar SAS 2020

Caution!

Risk of damage to the machine.

Make sure that theangle A between the undercarriage and the supply cable is never more than 45°.