2 minute read

REMOVE AND INSTALL DRIVER STATUS MONITOR

from Komatsu HD785-7 Dump Truck Drowsiness Detection System (DDS) Shop Manual SEN06857-04 - PDF DOWNLOAD

Install Driver Status Monitor

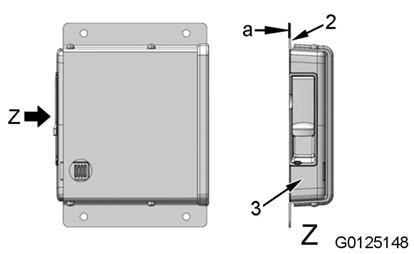

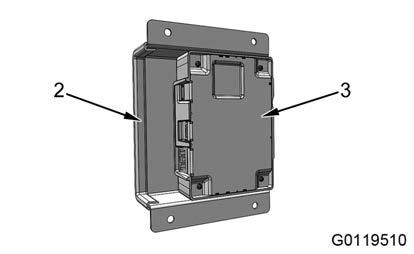

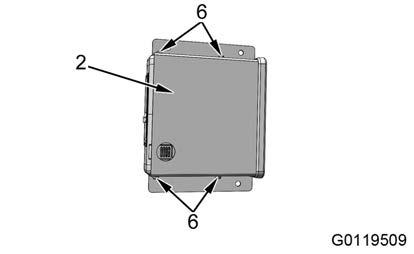

1. Install the driver status monitor (3) to the bracket (2) with the screws (6) (4 pieces).

REMARK

•Install the driver status monitor (3) in the correct direction.

•When you install it, be careful not to let the driver status monitor (3) stay outside the surface (a) of the bracket (2).

Tool: Phillips screwdriver

Screw (6): M4

REMARK

Be sure to put the washer

Tool: Torque wrench (hexagonal)

Hexagonal socket head screw (1): Width across flats 4mm, M6

Hexagonal socket head screw (1): 9.8Nm{1.0kgfm}

Remove And Install Translator Controller

Standard tool list

The listed tools are for reference, and other tools that are not on the list can also be used if the function is the same.

Precautions before and during work k Stop the machine on a level ground, set the parking brake switch to the PARKING (P) position, and stop the engine. k Chock the tires to prevent unexpected movement of the machine. k Set the battery disconnect switch to the OFF position. (For details, see the shop manual for the standard machine, STRUCTURE AND FUNCTION, MAINTENANCE STANDARD, “BATTERY DISCONNECT SWITCH”.) k When you disconnect the wirings and hoses, be careful not to deform or damage them with the clips and clamps. k If the wirings and hoses can be deformed or damaged, remove the clips and clamps before the work.

NOTICE

Check the connector numbers and installation positions before you disconnect the wirings and hoses, and write them down.

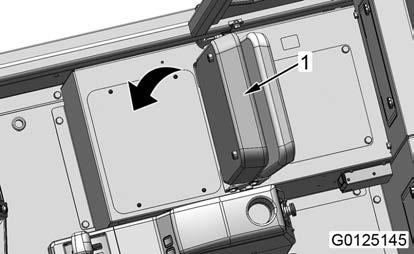

Remove Translator Controller

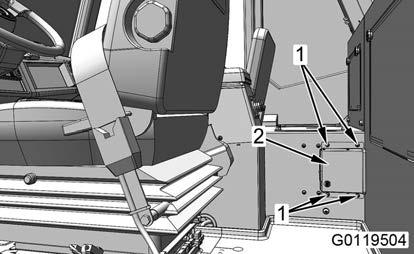

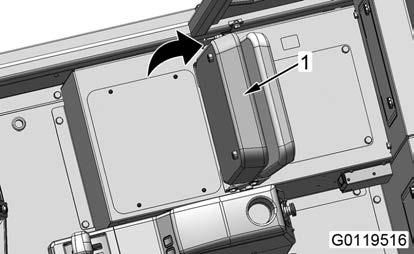

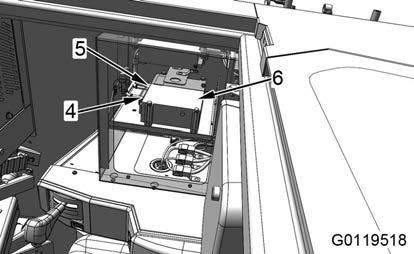

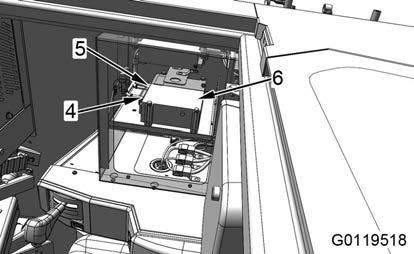

1. Pull up the seat surface of the trainer seat (1).

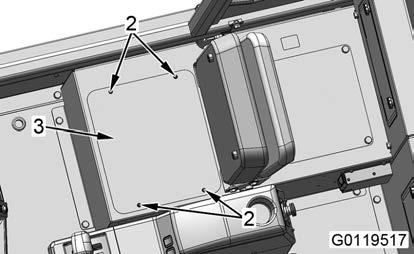

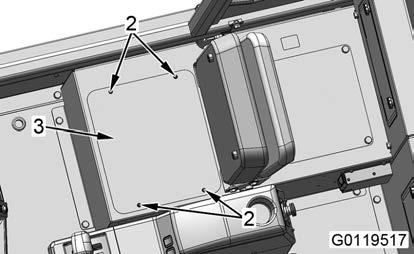

2. Remove the screws (2) (4 pieces), and remove the cover (3).

Tool: Phillips screwdriver

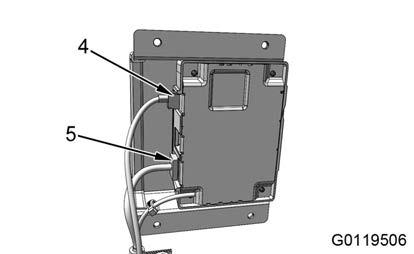

3. Loosen the hexagonal socket head bolt at the center of each connector, and disconnect the connectors TLC2 (4) and TLC3 (5) from the translator controller (6).

Tool: Hexagonal wrench

Hexagonal socket head bolt: Width across flats 4mm, M5

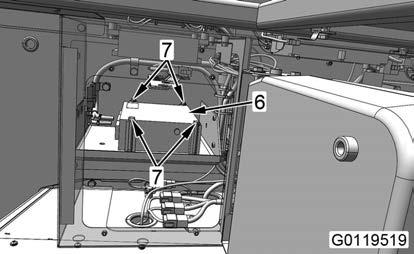

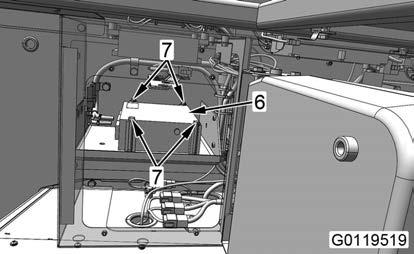

4. Remove the bolts (7) (4 pieces), and remove the translator controller (6).

REMARK

Be careful not to lose the washer

Tool: Ratchet handle

Bolt (7): Width across flats 13mm, M8

Install Translator Controller

1. Install the translator controller (6) with the bolts (7) (4 pieces).

REMARK

Be sure to put the washer.

Tool: Torque wrench (socket)

Bolt (7): Width across flats 13mm, M8

Bolt (7): 27 to 34Nm{2.8 to 3.5kgfm}

2. Connect the connectors TLC2 (4) and TLC3 (5) to the translator controller (6) with the hexagonal socket head bolt at the center of each connector.

Notice

Do not tighten them too much. They can be damaged.

Tool: Hexagonal wrench

Hexagonal socket head bolt: Width across flats 4mm, M5

Install the cover (3) with the screws (2) (4 pieces). Tool: Torque wrench (phillips screwdriver)

Screw (2): 3.44 to 4.41Nm{0.35 to 0.45kgfm}

Remove And Install Drowsiness Detection Camera

Standard tool list

The listed tools are for reference, and other tools that are not on the list can also be used if the function is the same.

Precautions before and during work k Stop the machine on a level ground, set the parking brake switch to the PARKING (P) position, and stop the engine. k Chock the tires to prevent unexpected movement of the machine. k Set the battery disconnect switch to the OFF position. (For details, see the shop manual for the standard machine, STRUCTURE AND FUNCTION, MAINTENANCE STANDARD, “BATTERY DISCONNECT SWITCH”.) k When you disconnect the wirings and hoses, be careful not to deform or damage them with the clips and clamps. k If the wirings and hoses can be deformed or damaged, remove the clips and clamps before the work.

NOTICE

Check the connector numbers and installation positions before you disconnect the wirings and hoses, and write them down.

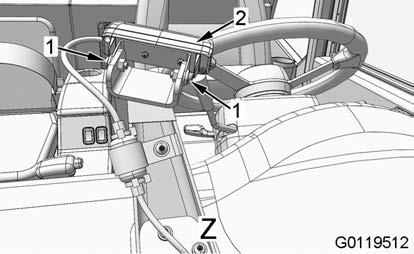

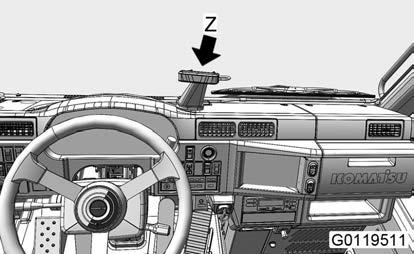

Remove Drowsiness Detection Camera

1. Remove the hexagonal socket head screws (1) (2 pieces), and remove the drowsiness detection camera (2).

REMARK

• The wiring harness is fixed at this time.

• Be careful not to lose the washer.

Tool: Hexagonal wrench

Hexagonal socket head screw (1): Width across flats 4mm, M6