1 minute read

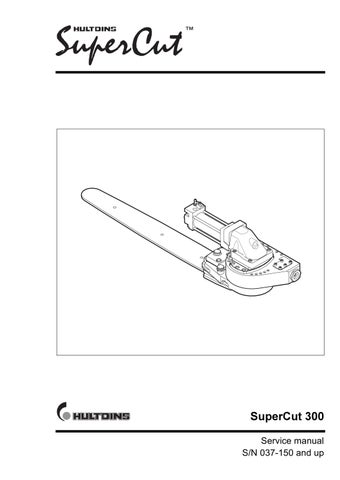

SuperCut 300

The is made up of one Saw Housing (1) which contains a 4-point bearing with a gear drive (8), a feed out cylinder (5) with integrated rack and proportional chain oil pump (6). The hydraulic cylinder (5) is equipped with hydraulic dampening for “Soft Stop” to eliminate shock loads. The piston stops the hydraulic flow by passing the inlet hole in the contact flange (7). The is supplied with a Hultdins F12-40 saw motor (4). The is equipped with a patented automatic chain tension system , made up of a Tensioning device (2) on which the bar holder (3) is attached. Optional accessories such as cut-control device and colour marking kits are easy to install. The saw bar can return either by air or hydraulics. Feed out cylinder (5) and Bar holder (3) are not on the same level, which eliminates problems with snow packing or other debris. The saw bar feed out angle (9) is 90°.The tension device(2) can easily be rotated in 7.83° steps for various “saw bar starting” angles to accommodate specific attachment design requirements. The is designed for 3/4” pitch High Speed chains and can be supplied with rim sprockets of 8 or 9 tooth count and corresponding saw bars.

Fig. 12Design SuperCut 300 Saw Housing Tensioning device Bar holder Saw motor Cylinder with rack Lubrication oil pump Contact flange Gear drive with bearing