1 minute read

Assembly

INSTALL WARNING LIGHTS (Model DH4414)

Note: Model DH44414 only

Refer to 5RP3032326 Light Group Assembly shown in Repa ir Parts List. (Part # 5RPMAN294P)

1. Attach bolting plates to the ends of the rear gang carrier.

2. Attach the lights to the bolting plates so that the red lens faces rearward with the amber to the top visible from both front and rear.

3. Connect the wishbone harness marked left and right to each of the lights.

4. Route the wishbone harness around the frame.

5. Secure the wishbone harness with the clamps provided in the light group assembly.

6. Attach the straight harness to the wishbone harness.

7. Secure the straight harness to the drawbar with a clamp.

8. Store the excess length and the plug in the hose mast.

Specifications

REPAIR PARTS

Specifications

SUGGESTED REPAIR PARTS (DH4414)

Model DH4414I with 32" x 3/8" Disk Blades

ASSEMBLY & OPERATING MANUAL - 5RPMAN294AO

REPAIR PARTS LIST MANUAL- 5RPMAN294P

Specifications

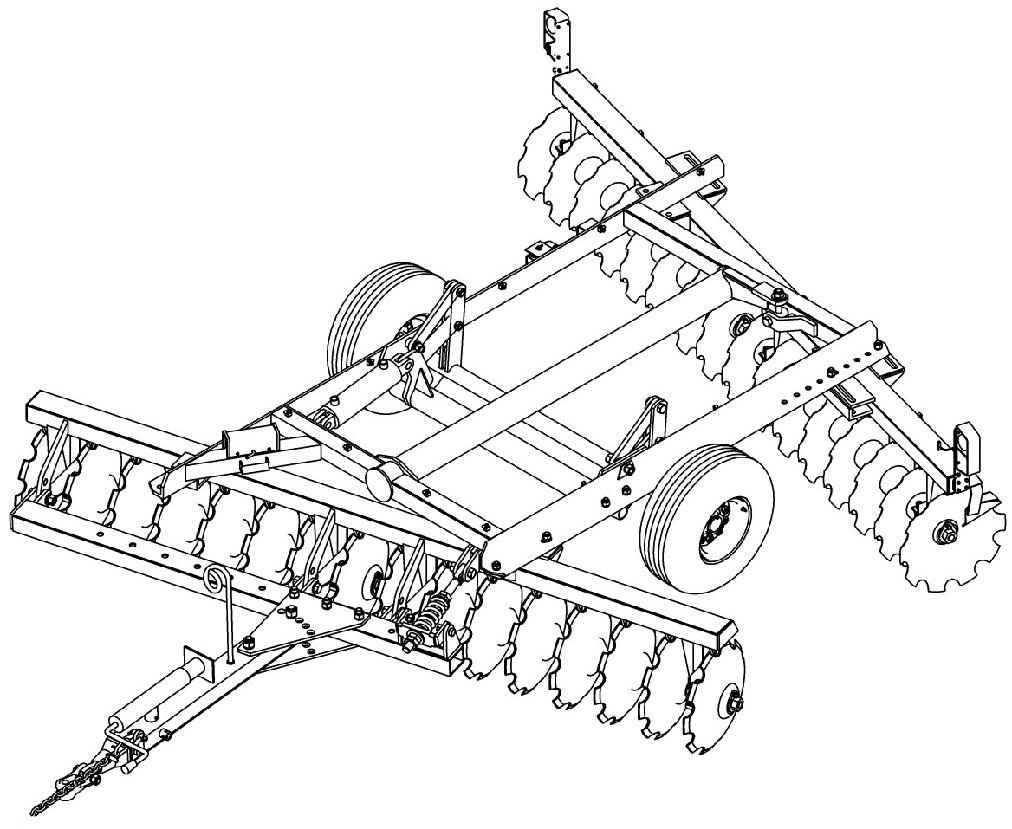

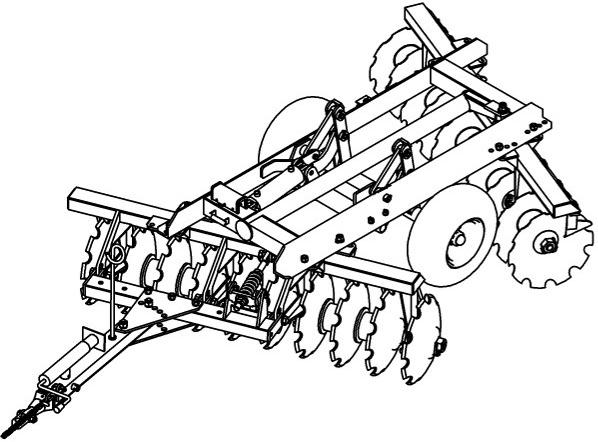

SPECIFICATIONS - CONSTRUCTION OFFSET DISK MODELS DH4411 AND DH4414

FEATURES:

Combines thorough mixing and aerating with easy maneuverability.

High gang carrier design to prevent trash buildup and clogging.

Boxed angle construction for strength and rigidity.

Tapered roller gang bearings - greaseable.

Adjustable disk blade scrapers.

Up to 612 pounds (278 kg) of harrow weight per disk blade.

11” (279mm) – maximum depth of penetration.

Dual purpose transport unit serves for transportability and penetration control.

17 3/4 ” (451 mm) DISK SPACING; 2 1/8” (54 mm) ROUND AXLES. EQUIPPED WITH DUAL TAPERED ROLLER BEAR INGS.

Standard Equipment

32” (813mm) diameter, 3/8” (10mm) thick, cutout (notched) disk blades.

Heat-treated alloy steel axles - 2 1/8” (54mm).

Heavy-duty disk spacer spools.

Adjustable disk blade scrapers.

Dual tapered roller gang bearings - greaseable.

Hydraulic control group includes hydraulic cylinders, hose holder and hoses with fittings and quick couplers to reach rear of t ractor.

New Industrial Tires.

Light Group Assembly, only on Model DH4414.

*Power Take Off Horsepower (PTO-HP) - The amount of horsepower, measured at the PTO respectively, required to move an implement through the soil. Note : HP range provided is an estimate. Power requirements will vary due to key operational conditions such as: soil type, field speed, soil moisture level, penetration depth and others.