2 minute read

INSTALLATION

from Frontier Root Grapple Loader Attachments AV20 Owner’s Operator's Manual(5WS105006) - PDF DOWNLOAD L

DETACHING EQ UIPMENT (GLOBAL CARRIER SERIES LOADERS)

NOTE:If using optional parking stands,completely close grapple clamps.Always place unit on a solid level surface.

NOTE:If unit is not equipped with optional parking stands,open grapple clamp arms completely.

NOTE:Disconnect hydraulic attachments before backing away.

1.Position the attachment with the main frame about vertical.

2.Place the transmission in PARK and shut off engine and remove key.

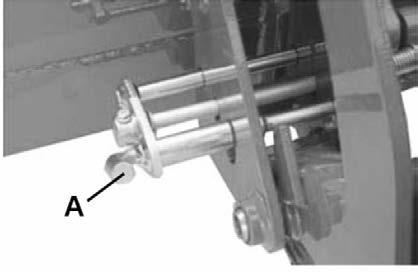

3.Pull and rotate handle to open latch (A).

4A. DETACHING (without Parking Stands)

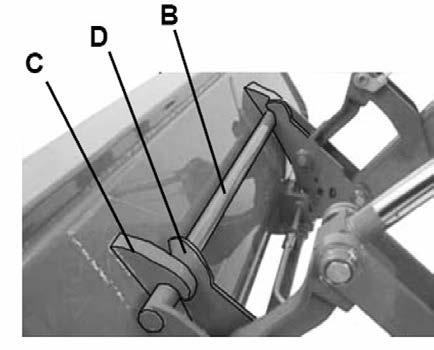

Start tractor and extend bucket tilt cylinders to roll root grapple forward.When tips of grapple clamps and points of main frame are about level with ground, lower loader boom until attachment is on ground.Extend bucket cylinders until loader clears latch plate and bar is free from hooks.

4B. DETACHING (with Parking Stands)

Lower parking stands and pin in position. Start tractor and lower attachment to ground. Slowly extend bucket tilt cylinders until loader clears the latch plate.Lower loader until bar clears the hooks.

5.Drive tractor in reverse until loader is clear of the attachment.

Safety is a primary concern in the design and manufacture of our products.Unfortunately, our efforts to provide safe equipment can be wiped out by an operator’s single careless act.

In addition to the design and configuration of equipment, hazard control and accident prevention are dependent upon the awareness, concern, judgement, and proper training of personnel involved in the operation, transport, maintenance and storage of equipment.

It has been said “The best safety device is an informed, careful operator.”We ask you to be that kind of operator.

Warning

■ Power unit must be equipped with ROPS or ROPS cab and seat belt.Keep seat belt securely fastened.Falling off power unit can result in death from being run over or crushed.Keep foldable ROPS systems in “locked up”position at all times.

Warning

■ Never allow children or untrained persons to operate equipment.

■ Keep bystanders away from equipment.

The operator is responsible for the safe operation of this equipment.The operator must be properly trained.Operators should be familiar with the equipment, the tractor, and all safety practices before starting operation.Read the safety rules and safety decals on pages 3 through page 7.

The Root Grapple is designed to handle logs, brush, loose stumps, limbs, medium size rocks and other hard to handle material.

A hydraulic cylinder(s) operates the grapple clamp arm(s) to grip and hold the material.

The Root Grapple is available in four models.Each model fits specific John Deere Tractor loaders within a horsepower range.(See specifications on page 2.)

One pair of remote hydraulic coupler outlets are required to operate the grapple clamp arm cylinder(s).

OWNER/OPERATOR PRE-OPERATION CHECK LIST

(Owner’s/Operator’s responsibility)

____Review and follow all safety rules and safety decal instructions on pages 3 through page 7.

____Check that equipment is properly and securely attached to tractor.

■ Never allow riders on power unit or attachment.

Warning

■ Rear ballast is required to ensure 25% of gross vehicle weight is transferred to the rear axle. Attachment and load must be included as weight. Adequate rear weights are required to counterbalance maximum loader capacity and safe loader operation.Weight can be added as rear tire liquid,rear wheel weights,rear axle weights and/or three point hitch mounted ballast or implement.Ballasting will vary with tractor and loader attachment.Refer to the Tractor manual for recommended ballasting.

Check that all safety decals are installed and in good condition.Replace if damaged. Check that all hardware is properly installed and secured.

____Do not allow riders.

Make sure tractor ROPS or ROPS CAB and seat belt are in good condition.Keep seat belt securely fastened during operation.