1 minute read

Operating the Machine

from Frontier Hinge Wheel Off Set Disk Harrow DH4317 DH4320 Assembly & Operating Instruction Manual(5RPMA

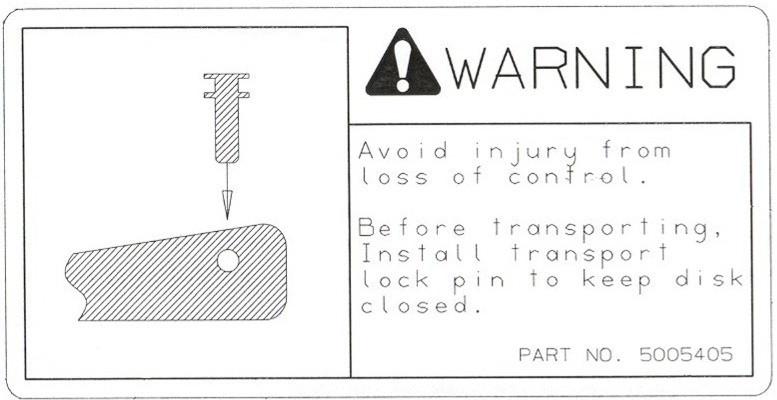

Preparing Harrow For Transport

The harrow operates off of a single hydraulic circuit on the tractor and is equipped with a selector valve, which can be set for either hydraulic ANGLE CONTROL or TRANSPORT CONTROL (hydraulic wheel lift operation). The use of a selector valve prevents the accidental lowering of the wheels when the disk is in angle. Note: If the wheels are lowered when the harrow is in angle, damage can occur.

For proper transporting, the following preparation procedure should be used:

1. With the control lever, close the disk gangs until they are parallel.

2. Remove the transport lock pin from its storage position and place it in the transport position to keep the harrow from opening while being transported.

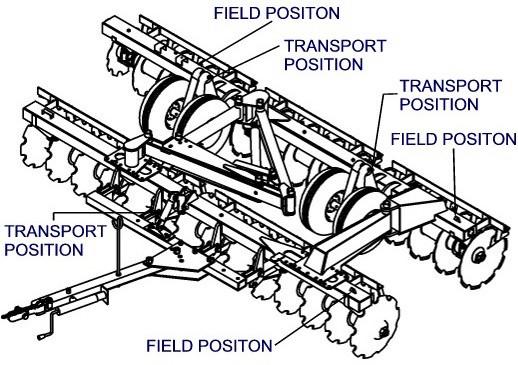

3. Move the selector valve to the TRANSPORT CONTROL position.

4. Using the tractor hydraulic control lever, raise the disk by lowering the wheels until all lift cylinders are fully stroked.

5. Install cylinder rod transport locks on each of the three transport cylinders and pin them securely in place (To TRANSPORT POSITION shown in illustration at right). Important: Install transport locks in the following sequence: front, right rear, then left rear.

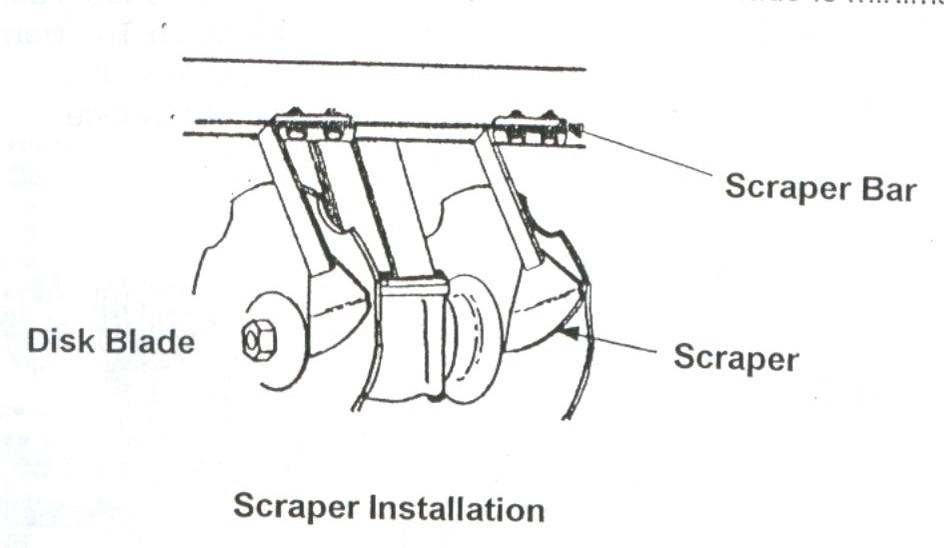

Scraper Adjustment

The point of the scraper should be set as close to the blade as possible without rubbing the heel of the scraper. This is about 1/4" away from the disk blade and should be slightly closer at the point so trash build-up between the scraper and the disk blade is minimal.