2 minute read

3.6 Lubrication and maintenance operations

Every 50 hours

3.6.14 Cleaning the water separator

Clean the water separator when the machine is parked on a flat and solid surface, the engine and the battery disconnector are off and the gas bottle is closed.

Water separator cleaning procedure:

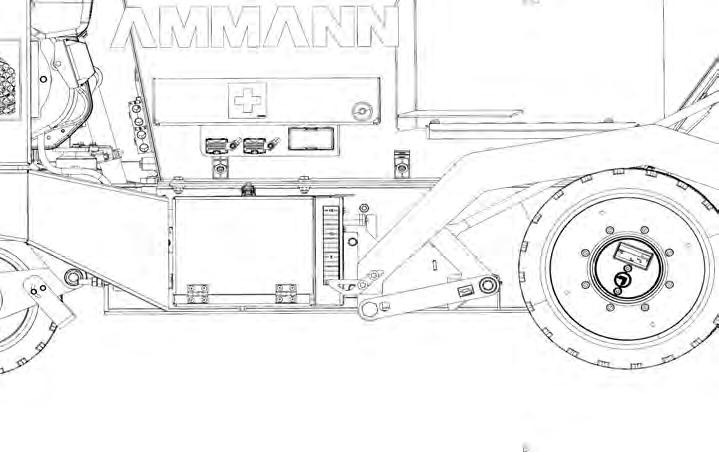

• Open the engine bonnet (1).

• Open the left material hopper side cover (2).

• Place a transparent drain container resistant to engine fuel under the water separator (3).

• Hold the water separator (3) with a spanner by the nut (4).

• Loosen the water separator drain screw (5) with a screwdriver (about 3 – 4 turns) until the liquid starts to flow out.

• Check if there is a dividing line in the drain container between the condensed water (bottom) and engine fuel (top).

• When clean engine fuel flows out, firmly hold the water separator (3) by the nut (4) with a spanner and tighten the water separator drain screw (5).

• Close the left material hopper side cover (2).

• Close the engine bonnet (1).

Caution! When draining the condensate, fuel can come in contact with hot parts of the engine and catch fire. There is a risk of burns from the hot parts of the engine. Clean the water separator when the machine is parked on a flat and solid surface, the engine and the battery disconnector are off and the gas bottle is closed. When cleaning the water separator, do not smoke. There is a risk of fire.

When cleaning the water separator, wear the prescribed protective equipment.

After cleaning the water separator check the tightness. In case of detecting water condensation in the fuel tank, perform the separator cleaning procedure earlier.

Stop the fluid soaking into the ground.

3.6.15 Machine lubrication

Lubricate the machine when it is parked on a flat and solid surface, the engine and the battery disconnector are off and the gas bottle is closed.

Use the prescribed lubricants according to Chapter 3.2.6 for lubricating the machine.

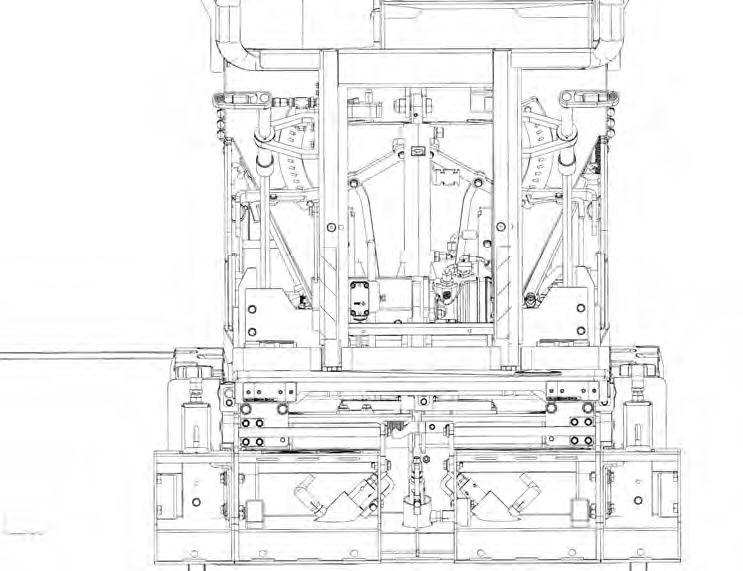

Overview of lubrication points on the machine:

• Mechanism for setting the paving thickness (1).

• Screed lifting mechanism (2).

• Paving width setting mechanism (3).

• Front wheel suspension (4).

• Chains of the conveyor belt and augers (5).

Procedure for lubrication of the paving thickness setting mechanism:

• The procedure is identical for the left and right side of the machine.

• Dismount the protective cover and clean the grease nipple.

• Connect the grease gun to the grease nipple.

• Lubricate the bearing until the lubricant starts to flow out.

• Mount the protective cover on the grease nipple.

Lubricate the machine when it is parked on a flat and solid surface, the engine and the battery disconnector are off and the gas bottle is closed.

When lubricating the machine, use the prescribed protective equipment.

There is a risk of burns from the hot parts of the screed. There is a risk of injury due to the fall of the screed.

Procedure for lubrication of the screed lifting mechanism:

• Dismount the protective cover and clean the grease nipple.

• Connect the grease gun to the grease nipple.

• Lubricate the bearing until the lubricant starts to flow out.

• Mount the protective cover on the grease nipple.

Lubricate the machine when it is parked on a flat and solid surface, the engine and the battery disconnector are off and the gas bottle is closed.

When lubricating the machine, use the prescribed protective equipment.

There is a risk of burns from the hot parts of the screed. There is a risk of injury due to the fall of the screed.