1 minute read

3.6 Lubrication and maintenance operations

3.6.3 Hydraulic oil check in the hydraulic tank

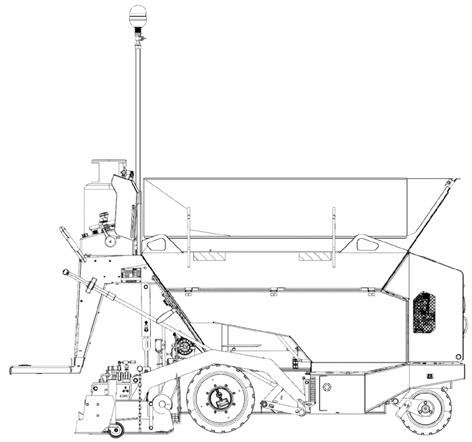

Before checking the level of hydraulic oil, lower the screed all the way down and aim the front wheel straight so that hydraulic oil can flow back into the hydraulic oil tank.

Ensure that the machine is standing on a level and firm surface. Start the engine.

Lower the screed to the lower position using the switch (19) on the main dashboard. Turn off the engine.

Oil level check procedure:

• Check the oil level on the oil gauge (2).

• The hydraulic oil level must be between the MIN and MAX marks.

Hydraulic oil refilling procedure:

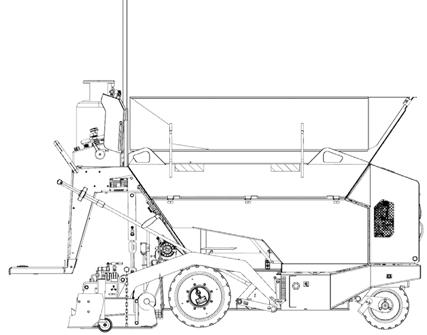

• Open the right material hopper side cover (1).

• Take off the ventilation filter (3) from the filler neck.

• Refill the necessary hydraulic oil quantity according to Chapter 3.2.3.

• Mount the ventilation filter (3) back in place.

• After refilling the oil check the oil quantity in the hydraulic tank on the oil gauge (2).

• Close the right material hopper side cover (1).

Wear suitable protective goggles, protective clothing and footwear.

Thoroughly wash areas on the body that have been in contact with hydraulic oil. Do not inhale hydraulic oil vapours.

The oil level must always be visible in the oil gauge! Refill with the specified hydraulic oil according to Chapter 3.2.3.

In case of large oil losses, find out the cause of leakage of the hydraulic system (leakage of screwed hose connections, hydraulic generators, hydraulic motors etc.) and remedy the defects. Caution! The hydraulic oil level must always be between the MIN and MAX marks on the oil gauge.

Stop the oil soaking into the ground.

3.6.4 Driver's stand cleaning

Clean the driver’s stand always on the machine which is parked on a flat and solid surface, with the machine engine and battery disconnecter off.

Keep the driver's stand continuously clean, dry and without snow and ice during the winter.

Cleaning procedure:

• Make sure there are no objects deposited on the driver's stand (1).

• Remove potential residues of materials from the driver's stand (1) using a scraper.

Caution! There is a risk of injury during cleaning. Remove dirt from the driver's stand only with the engine and battery disconnecter off.

Use the prescribed protective equipment during cleaning.

During machine operation no objects may be located on the driver's stand.