2 minute read

2.8 Special conditions to use the machine

2.8.1 Towing the machine

The machine is not fitted with any system that would manually release the parking brake. If the pressure in the brake system is too low, the rear wheels will remain blocked.

We recommend towing the machine only for short distances or to avoid towing completely, if possible.

• Depending on the possibilities, have the machine repaired or maintenance performed on location.

• If possible, use a crane to lift the machine and transport it for maintenance and repairs.

Procedure to tow the machine:

• The towing movement when towing the machine must be smooth. Do not exceed the towing speed by more than 1 km/hour (0.6 mph).

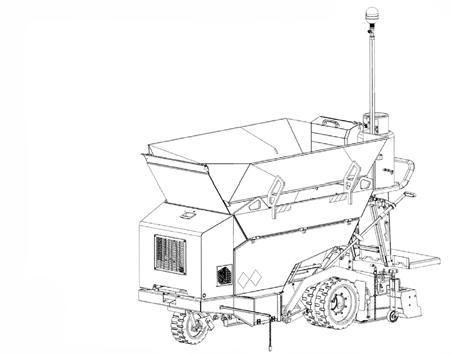

• The towed machine must be attached to the towing lug (1).

• Make sure there are no persons in the dangerous area of the machine.

• Move away from the danger zone of the machine.

• Have the machine towed in compliance with the instructions of the machine owner.

Risk of injury when towing the machine.

For towing, use undamaged tow ropes or tow bars of a sufficient capacity 1.5 × higher than the weight of the towed vehicle. Do not use a chain for the towing.

Ensure that there are no persons in the dangerous area when the machine is towed.

Move away from the danger zone of the machine. The safe distance is at least 5 metres.

The machine may only be towed attached to the towing lug (1), by means of a tow bar (2) or tow rope (2).

No persons are allowed on the machine when the machine is towed!

There is a risk of damage to the machine when the machine is towed.

The rear wheels are blocked and will skid over the surface. The front wheel can turn, but cannot be controlled.

Tow the machine very slowly and smoothly.

Tow the machine only using vehicles with a sufficient tow force considering the weight of the towed machine.

2.8.2 Climatic conditions

Operating the machine at low temperatures

Prepare the machine for operation at low temperatures:

• Replace the engine oil with the oil recommended for the range of ambient temperatures.

• Use hydraulic oil of the corresponding cinematic viscosity.

• Use a winter diesel.

• Check the battery for charging.

Operation at low temperatures:

• The good condition of the battery is a precondition for good starting under low temperatures. The machine can be used at full power only after the operating fluids have been heated to their operating temperatures.

• Every week check all rubber parts, e.g. hoses, V-belts.

• Check all electrical cables and connections for worn and/or damaged insulation.

• Refill the fuel tank at the end of every shift.

Operating the machine at higher temperature and humidity:

• The engine power output decreases with the increasing temperature and air humidity. Considering that both of the factors reducing the engine power are independent on each other, it is possible to describe their impact as follows:

- Every 10 °C (18 °F) of the temperature rise means a power drop by up to 4% (at a constant humidity).

- Every 10 % of the relative humidity rise means a power drop by up to 2% (at a constant temperature).

• At outdoor temperatures when the hydraulic oil temperature is constantly about 90°C (194°F), we recommend you to replace the oil with the oil ISO VG 100 having the cinematic viscosity of 100 mm2/s at 40°C (104°F).

Machine operation at high altitudes

• With the increasing altitude, the engine power output decreases as a result of the lower atmospheric pressure and specific density of the incoming air.

2.8.3 Operation of the machine in dusty environment

While operating in a very dusty environment, shorten cleaning and replacement intervals of air filter cartridges and shorten cleaning intervals of coolers.

The recommended cleaning interval is once a week.