2 minute read

2.6 O peration of the screed

2.6.8 Screed gas heating

To heat the screed with gas, liquefied propane-butane (LPG) can only be used.

The maximum gas bottle volume which may be placed on the machine is 10 kg (22 lb).

It is prohibited to use natural gas for screed heating.

The screed heating system is designed for a maximum operating pressure of 1 bar with a total gas consumption of 10 kg/h (22 lb/h).

The recommended operating pressure for screed gas heating is from 0.6 bar to 0.8 bar, the gas consumption of a burner is approx. 200 g/h (0.44 lb/g).

Propane-butane (LPG) is an extremely flammable substance and any leakage causes a high risk of fire or explosion!

Propane-butane (LPG) is heavier than air and may accumulate in lower places – danger of fire or explosion!!

Do not smoke during machine operation. There is a risk of explosion or fire. Liquid gas can easily ignite.

The machine must be equipped with a fire extinguisher. Have the fire extinguisher ready on the driver's stand at a place intended for this purpose.

Caution! Risk of explosion, if the screed gas heating is operated incorrectly, or safety and fire instructions for using and handling gas bottled are not adhered to.

Operate the screed heating system always according to the operating manual delivered with the machine.

Adhere to the national regulations in the country where the machine is operated. Familiarize yourself with these regulations and observe them.

It is prohibited to use natural gas for screed heating.

Operate the machine only with the liquefied propane-butane (LPG). Propane-butane (LPG) is an odourless liquefied gas.

In some countries, in which the machine is operated, gas manufacturers odorize odourless gasses due to safety reasons (by adding aromatic substances), so that a leak can be identified easily.

In such cases pay higher attention to a potential gas leak during operation of the machine, which is manifested by an odour, and close the gas inlet.

In case of gas leakage, in some cases it is impossible to rely on the gas odour as a sign of gas leak from the system.

During the operation of the machine visually check that the gas system is undamaged.

Regularly check the gas system according to the maintenance plan given in this manual, especially hoses, valves and other components.

Always require a material safety data sheet to the delivered gas bottle. Before mounting the gas bottle on the machine, read and check that the gas bottle meets all conditions for putting the machine into operation.

Risk of burns! The screed may reach the temperature of up to 130°C.

Stop the gas leakage.

In case of gas leakage, inform relevant national authorities.

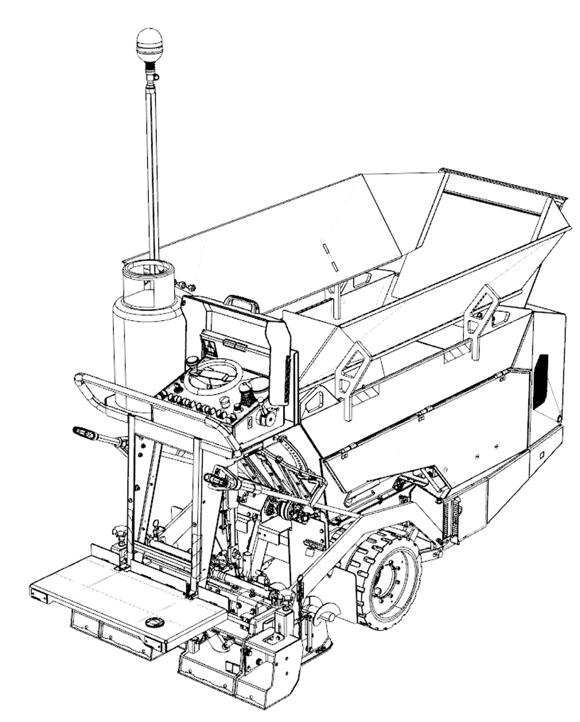

Mounting the gas bottle on the machine:

Before mounting the gas bottle on the machine, check the content of the gas bottle (1) that it contains liquefied propane-butane (LPG).

If the contents of the gas bottle is incorrect or not known, never use the gas bottle (1)!

Before mounting the gas bottle on the machine also check that the gas bottle is undamaged.

Do not use the gas bottle (1) in case of any damage!

Before mounting the gas bottle on the machine, the machine must be equipped with a fire extinguisher at a designated place (35).

Procedure for mounting the gas bottle on the machine:

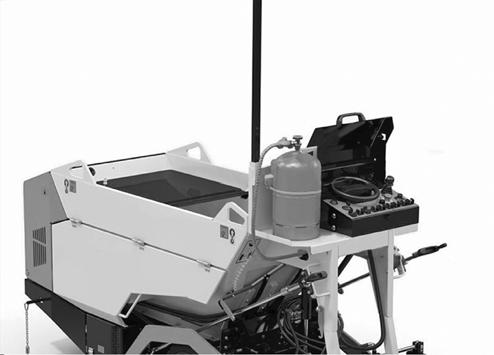

• Place a gas bottle (1) on the platform (4) next to the main dashboard in the vertical position, with the gas bottle shut-off valve facing up.

• Fasten the gas bottle using a fastening strap (3) to the holder (2).

The gas bottle must be placed on the machine vertically with the gas bottle stop valve facing up.

It is prohibited to place and transport the gas bottle on the machine in a different position than specified in this manual.

The maximum gas bottle volume which may be placed on the machine is 10 kg (22 lb).

During machine operation it is prohibited to use damaged gas bottles or gas bottles with an incorrect or unknown contents.

Never operate the machine unless the gas bottle is firmly fastened.

An unfastened gas bottle can fall down and the bottle or gas bottle valve may be damaged.

There is a risk of explosion.

During machine operation check that the gas bottle is correctly fastened.