1 minute read

2.5 O peration of the machine

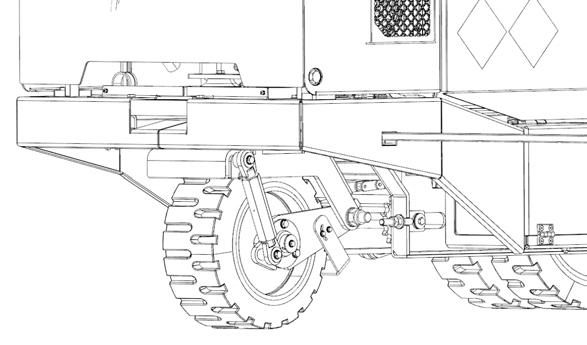

2.5.13 Front wheel

The machine is fitted with a height adjustable front wheel (1). By adjusting this front wheel (1) the levelling of the machine is set as required so that the machine can pave the material in parallel with the subgrade.

The wheel is adjusted due to:

• Increase traction on a soft subgrade.

• Set the correct angle of machine travel in a gap.

• Set the levelling of the machine against the subgrade.

Make adjustments with the engine off.

Procedure of front wheel adjustment:

• Always adjust the front wheel at the place of paving before starting the paving.

Lowering:

• Turn the adjusting screw (2) counter-clockwise to lower the wheel.

Lifting:

• Turn the adjusting screw (2) clockwise to lift the wheel.

Caution! Always before starting the paving of a material check the setting of the machine levelling against the subgrade (e.g. using a spirit level) and if necessary, adjust the wheel.

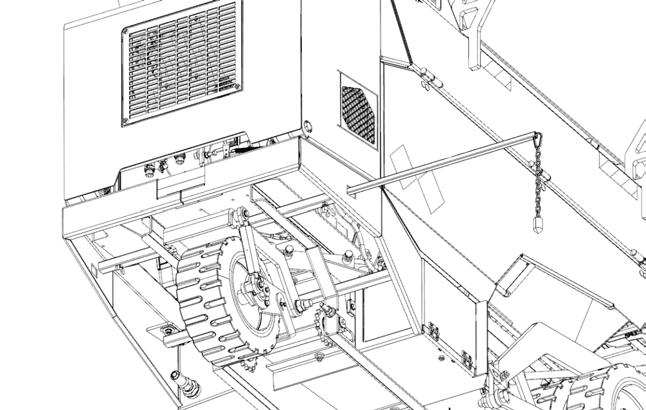

2.5.14 Using and setting the paving direction indicator

The machine is equipped with a paving direction indicator (3).

Use:

• By setting the paving direction indicator (3), the required paving direction is adhered to during the operation of the machine.

• The paving direction indicator (3) can be mounted on the left or right side of the machine.

Setting the paving direction indicator:

• Release the locking screw of the paving direction indicator (1).

• Pull out the paving direction indicator rod (2).

• Mount the paving direction indicator (3).

• Set the paving direction indicator rod (2) so that the paving direction indicator (3) extends beyond the outer outline.

• Tighten the locking screw of the paving direction indicator (1).

• Set the height of the paving direction indicator (3) by opening the snap-hook and adjusting the chain length.

In the transport mode the paving direction indicator rod (2) must be retracted and secured, the paving direction indicator (3) dismounted and deposited on the machine.