4 minute read

2.1 M ain safety precautions

2.1.6 Driver's stand and screed operator stand during machine operation

These requirements during operation of the machine are considered binding with regard to the safety of people. Firstly, the machine operator and the screed operators must observe the below-given requirements during machine operation.

Dynapac assumes no responsibility in cases when the machine is operated incorrectly or is used incorrectly in operating modes which may result in an injury or death, damage to the machine or property. During machine operation no objects may be located on the driver's stand.

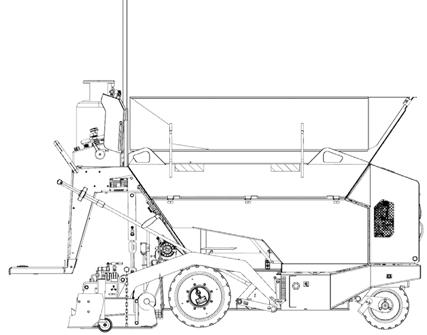

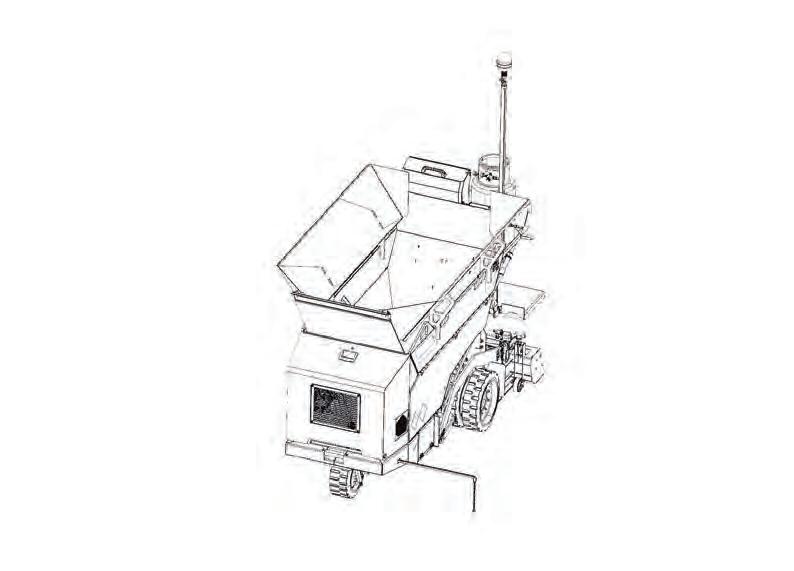

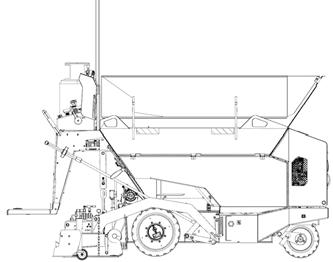

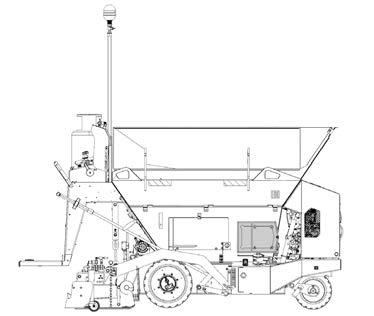

Operation of the machine during paving at a workplace: The driver’s stand during machine travel and paving operation is the machine platform (1). The driver stands on the platform and firmly holds the handle with one or both hands.

2.1.7 Dangerous zone and safe distance

Dangerous zone of the machine:

During the operation of the machine and paving no people may be present and stay in the dangerous zone of the machine. The dangerous zone of the machine (1) may only be entered into for the purpose of maintenance and cleaning of the machine when the conditions below are met:

• when the machine is stationary and secured against spontaneous start-up,

• the entry is only permitted to professionally qualified, instructed and trained personnel authorised to operate and maintain the machine.

During the operation of the machine and paving no people may be present and stay in the dangerous zone of the machine.

The machine user as well as the machine operator must ensure adherence to the prohibition to enter the dangerous zone of the machine during its operation.

These requirements during operation of the machine are considered binding with regard to the safety of people.

Dynapac assumes no responsibility in cases when the machine is operated incorrectly or is used incorrectly in operating modes which may result in an injury or death, damage to the machine or property.

2.1 M ain safety precautions

Safe distance between a public road, the place of paving and the construction site:

The safe distance between a public road, the place of paving and the construction site must be marked with a visible barrier against unauthorised access of other people to the place of paving and construction site.

The safe distance between a public road, the place of paving and the construction site is determined by the machine user on the basis of respective national regulations.

Observe the safe distance between a public road, the place of paving and the construction site.

Safe distance of workers at the place of paving: All workers present at the place of paving, moving near the machine, but not directly operating the machine, must observe the minimum safe distance of 5 metres from the machine.

The machine user as well as the machine operator must ensure adherence to the aforementioned safe distance of 5 m from the machine with regard to safety of workers at the place of paving.

2.1 M ain safety precautions

2.1.8 Machine operation at unclear working areas

The machine operator may not operate the machine if he does not have a sufficient overview of the workplace and potential obstacles are not clearly visible. In such cases, a different efficient form of connection between the appointed worker and the machine operator must be ensured.

Before putting the machine into operation the machine operator must be informed by the machine user about potential obstacles, e.g. distribution lines of gas, potable water, pipelines, sewerage, electrical and telephone lines, both aerial and ground ones. These routes must be properly set out and marked by respective authorities according to national regulations before starting the operation of the machine.

To ensure connection between the appointed worker and the machine operator, we recommend using hand signals.

2.1.9 Manual signals

The machine operator may not operate the machine if he does not have a sufficient overview of the workplace and potential obstacles are not clearly visible. In such cases, a different efficient form of connection between the appointed worker and the machine operator must be ensured. To ensure connection between the appointed worker and the machine operator, we recommend using hand signals.

Hand signals for the machine operator may only be given by persons who:

• are trained for these purposes,

• have proven participation in such training,

• can furnish a certificate of such activity to the user.

When using hand signals, the following principles must be adhered to:

• signals between the appointed worker and the machine operator, given by hand, can only be used in cases when environmental conditions enable visual contact,

• the machine operator must be trained in the used signals before putting the machine into operation,

• during the operation of the machine only a limited number of signals must be used to avoid any misunderstanding between the appointed worker and the machine operator.

EXAMPLES OF HAND SIGNALS:

2.1 M ain safety precautions

Watch out, danger

Machine travel

Drive slowly forward – towards me

Drive slowly backward – away from me

Machine travel – to the right

Machine travel – to the left

Machine travel for a short distance

2.1

Ain Safety Precautions

Get perfectly familiar with the machine operation and maintenance according to the Operating Manual!

Liquid gas is easily flammable. Overheated parts may cause a fire.

Maintain the safe distance from very hot parts. Before performing work, wait until the parts cool down.

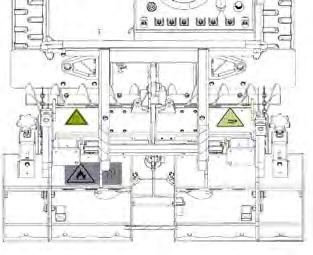

There is a danger of injury and accident by squeezing during screed movement.

Never come close to the screed when it moves. Keep the prescribed and safe distance from the screed of the machine.

Maintain the safe distance from very hot parts. Before performing work, wait until the parts cool down. Wear protective gloves.

Do not touch hot parts of the machine unless you make sure that they have cooled down sufficiently.

Dangerous noise level! Use hearing protection.

Indication of the paving thickness.

Only use these points to lift the machine.

Tie-down the machine for transport at these points only.

It serves for disconnecting the electrical wiring of the machine.

Mounting place for a manual fire extinguisher. Always have a manual fire extinguisher ready on the driver's stand. Perform maintenance of the manual fire extinguisher in prescribed intervals. Immediately replace any damaged or depleted manual fire extinguisher.

Identification of the place for depositing the first-aid kit. The machine must be equipped with the first-aid kit according to the national regulations for first aid measures.

Lubrication points on the machine equipped with a grease nipple.

To lift the machine, use binding means of sufficient loading capacity.

Exhaust gases and their components, operating fluids, batteries and other machine accessories contain chemicals known in the state of California to be substances which may cause cancer, congenial defects and other reproduction problems.

When handling these substances, abide by relevant safety precautions.

Further information see www: www.p65warnings.ca.gov

Always start and operate the engine in a well-ventilated area.

If in an enclosed area, vent the exhaust to the outside. Do not modify or tamper with the exhaust system. Do not idle the engine except as necessary.