3 minute read

5.5 Removing the operator’s platform

from Caterpillar NSP 10N2R 12N2R 12N2IR 14N2R 14N2IR Lift Trucks Service, Operation & Maintenance Manual

CAUTION

When removing the operator’s platform, note that it weights 35 kg.

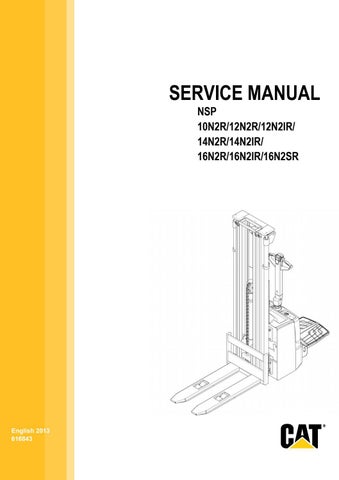

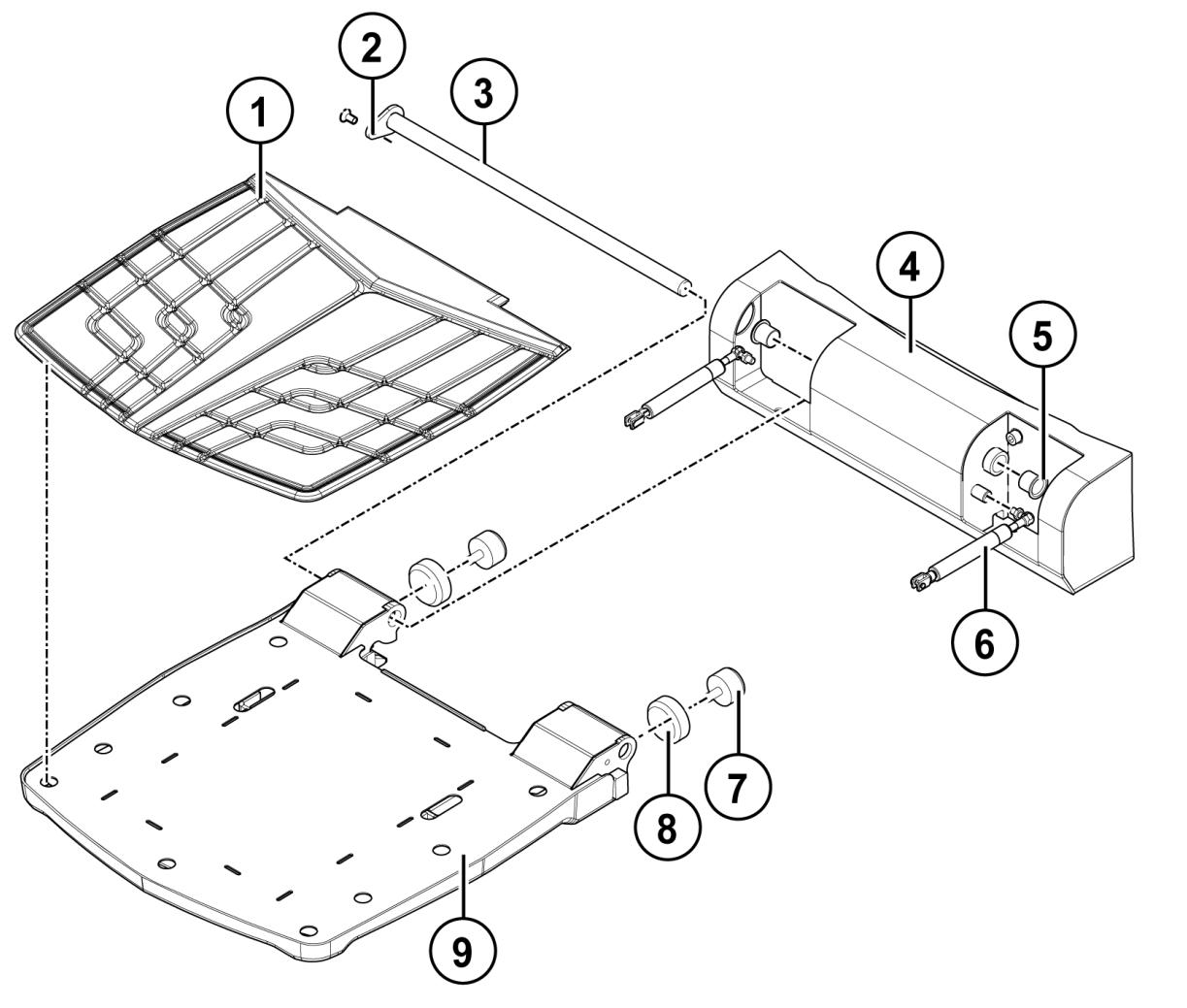

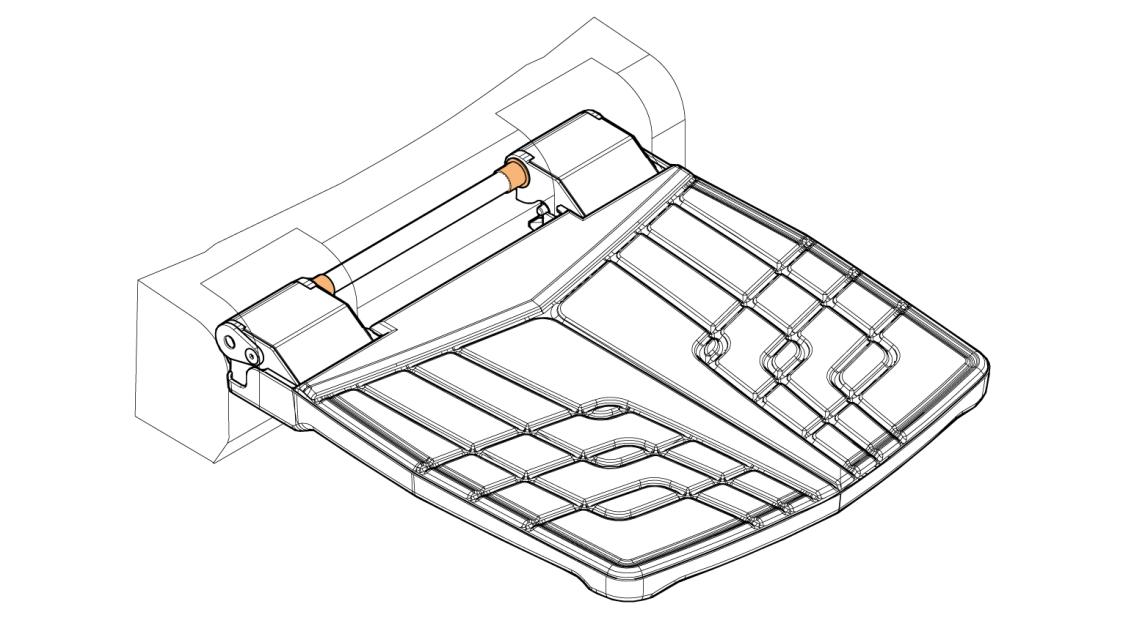

Figure 26. Operator’s platform overview

1. Operator’s platform 2. Rubber absorber

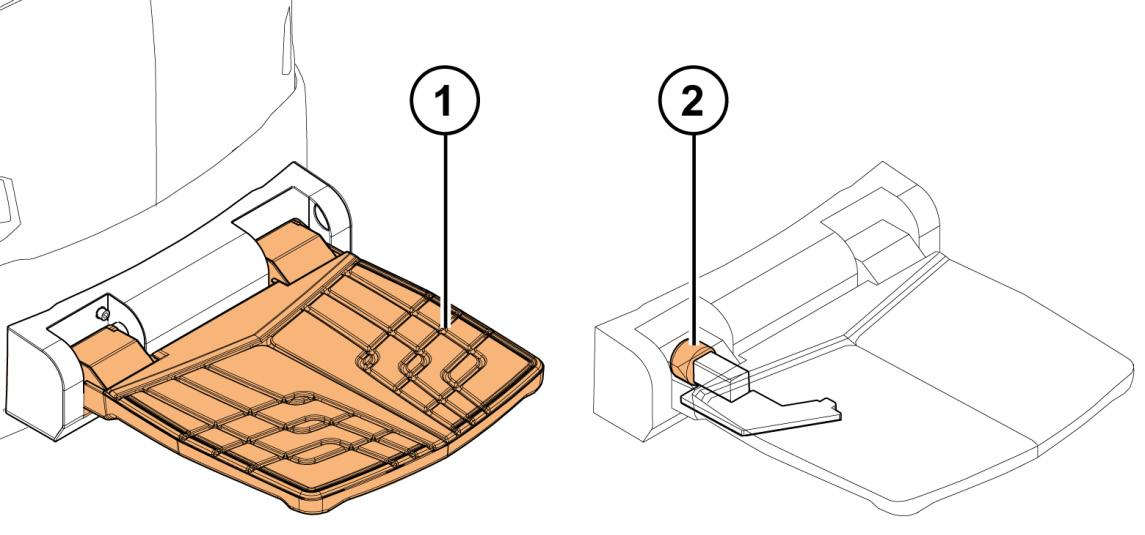

1. Remove the two screws at the base of the operator’s platform.

Copyright© 2013 by MCFE. All rights reserved. Revision: B Document ID: 616843 45 (338)

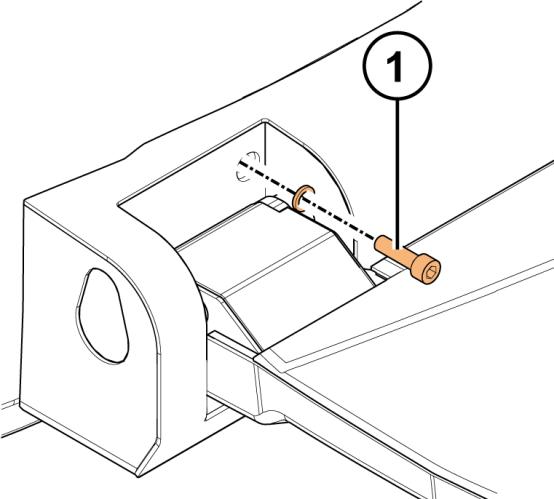

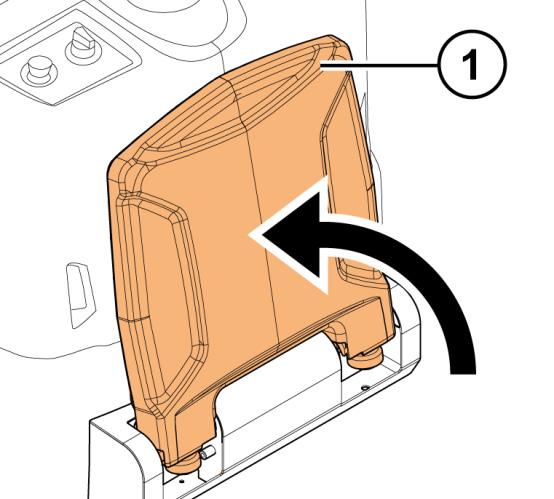

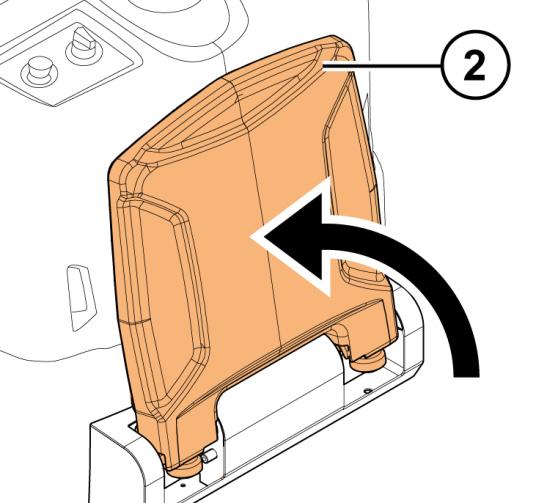

2. Remove the operator’s platform.

NOTE: When installing the operator’s platform, place a support, such as a block or similar, between the operator’s platform and the mounting bracket to prevent the operator’s platform from lifting too much.

Copyright© 2013 by MCFE. All rights reserved. Revision: B Document ID: 616843 46 (338)

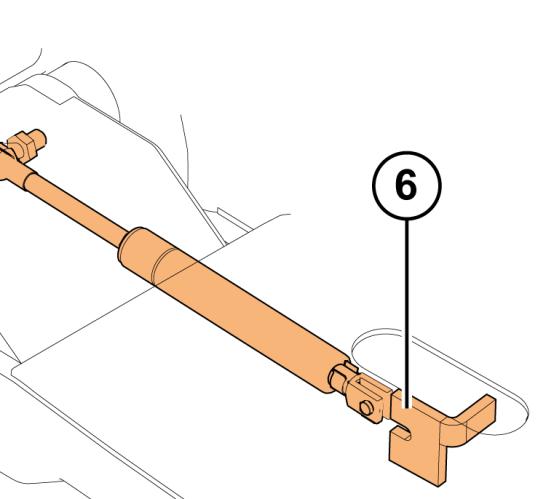

Figure 27. Operator’s platform detailed construction

1. Rubber mat 2. Locking screw 3. Shaft 4. Mounting bracket 5. Slide bearing 6. Gas spring 7. Rubber absorber 8. Support 9. Operator’s platform

Copyright© 2013 by MCFE. All rights reserved. Revision: B Document ID: 616843 47 (338)

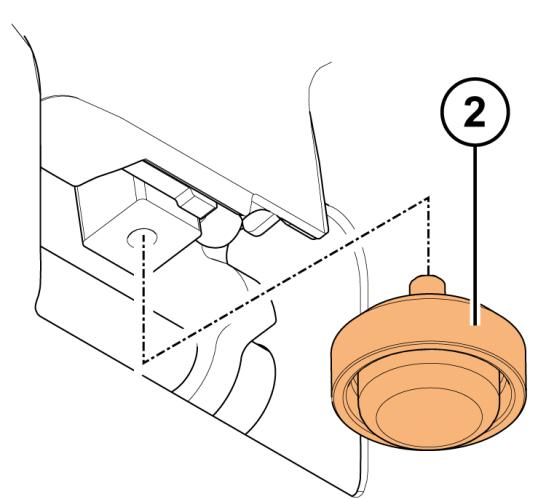

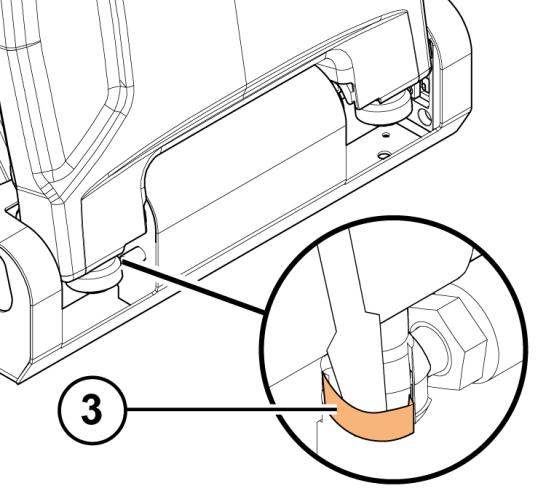

CAUTION

After removing the rubber absorbers, beware of sharp edges.

When installing the rubber absorbers, remember to use locking glue (for example, Loctite 243).

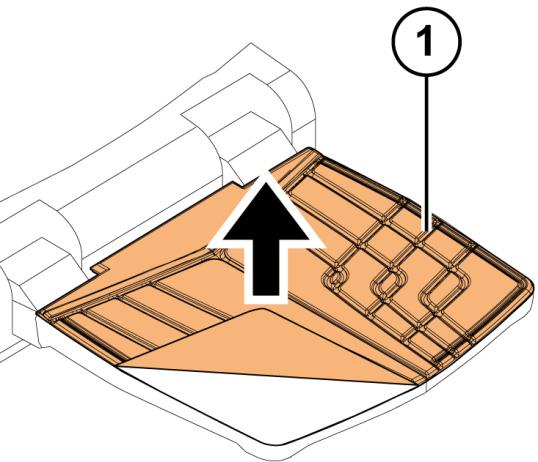

1. Lift the operator’s platform up.

2. Remove the rubber absorbers using a support bar.

Copyright© 2013 by MCFE. All rights reserved. Revision: B Document ID: 616843 48 (338)

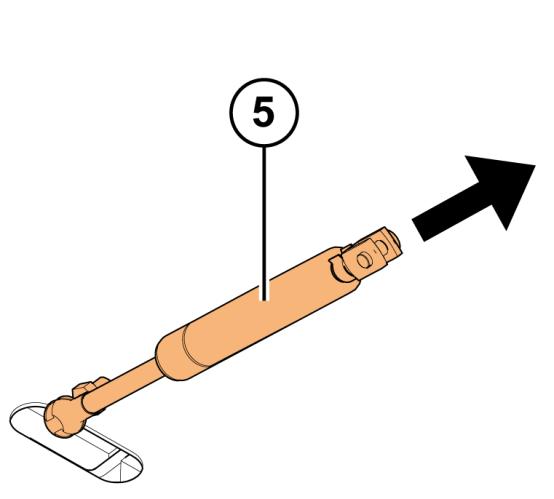

The gas spring of the operator’s platform can be replaced either with the platform in place or with the platform removed completely from the truck frame. Instructions for replacing the operator’s platform gas spring are provided below, but the same instructions can be applied also while working with the platform removed.

1. Remove the rubber mat from the operator’s platform by pulling it from one corner.

2. Lift the operator’s platform up.

3. Open the locking spring using a screwdriver. Also remove the ball joint if needed.

Copyright© 2013 by MCFE. All rights reserved. Revision: B Document ID: 616843 49 (338)

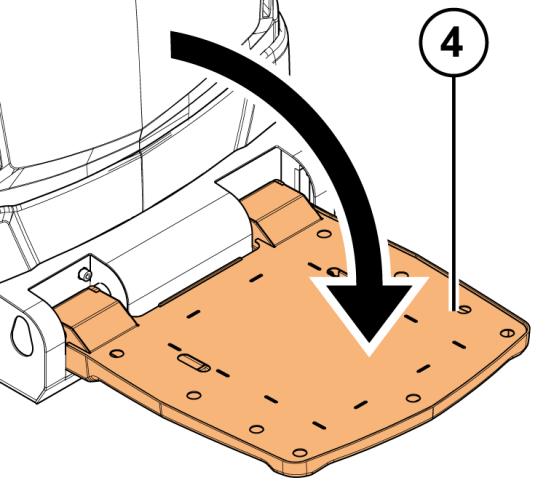

4. Carefully lower the operator’s platform.

5. Pull the gas spring out through the hole in the operator’s platform.

6. Push the new spring into place, making sure that the spring’s head is positioned correctly into the slot inside the operator’s platform.

7. Carefully lift the operator’s platform, making sure that the new spring does not fall out. 8. Tighten the gas spring locking spring and install the ball joint if it was removed earlier. 9. Lower the operator’s platform. 10. Attach the rubber mat to the operator’s platform.

Copyright© 2013 by MCFE. All rights reserved. Revision: B Document ID: 616843 50 (338)

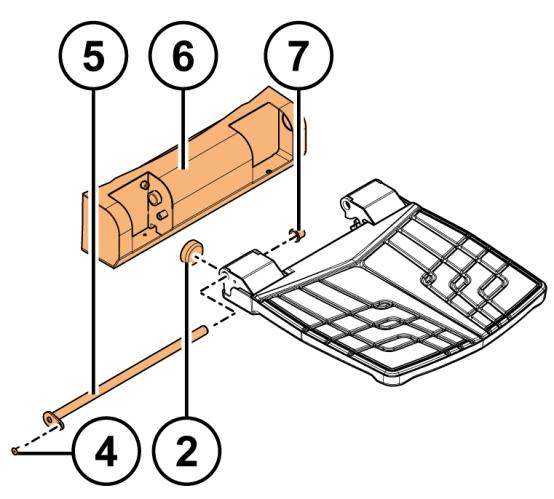

Figure 28. Operator’s platform slide bearing overview

1. Remove the operator’s platform from the truck frame. For instructions, see section 5.5.

2. Remove the support at the base of the operator’s platform. 3. Remove the operator’s platform gas spring. For instructions, see section 5.5.2. 4. Remove the shaft locking screw. 5. Remove the shaft. 6. Remove the mounting bracket. 7. Remove the slide bearing.

Copyright© 2013 by MCFE. All rights reserved. Revision: B Document ID: 616843 51 (338)